International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1PG Student, Department of civil Engineering, Velaga Nageswara Rao (VNR) College of Engineering, (Approved by AICTE and affiliated to JNTUK, Kakinada), G.B.C. Road, Ponnur 522124, GUNTUR, A.P (INDIA)

2Assistant Professor, Department of civil Engineering, Velaga Nageswara Rao (VNR)College of Engineering, (Approved by AICTE and affiliated to JNTUK, Kakinada), G.B.C. Road, Ponnur 522124, GUNTUR, A.P INDIA ***

Abstract - Solid waste management is a big challengeinallaroundtheworld.Graniteslurrygenerated fromgranitestoneprocessingindustryisaprimesourceof solid wasteproducedinRajasthan.Thegeneratedslurryis indiscriminately dumped on vacant lands, river banks or forestareas.Theseslurryparticles being fine enoughare capable of filling pores of the soil, preventing water percolationandmakingthelandfutile.Inthisexperimental study,granitepowder(driedgraniteslurry)wasusedfor the production of 1:4 and 1:6 cement mortar mixes. In order to improve performance parameters of mortars containing granite powder (GP), it was planned to use coarsesand(CS)ofzone IItonegatetheeffectofexcessive fines.Ratioof60:40and70:30ofCS:GPsatisfiedgradation recommended by standards for plaster and masonry mortars.For1:4mortarproportion,theadhesivestrength increased by 21% and 23% for CS30 and CS40 mixes, respectively as compared to control mortar (FS). Drying shrinkage of cement sand granite mortar found to be similarwiththatofcontrolmortarin1:4mixproportionbut dryingshrinkagein1:6proportionexceededintherangeof 20to60%.Onexposureofmortarstoa5%sulphuricacid medium,portlanditeandkatoiteareconvertedintogypsum and ettringite, respectively which reduced adhesion betweenparticlesofmortarsandresultsin22%declinein compressive strength at 28 days exposure period. No significantvariationinperformanceacrossallthemixeswas observedwhenmortarmixesweresubjectedto20cyclesof alternate wetting and drying. Hence, granite powder as partialsubstitute(30 40%)ofsandincementmortarmixes has noadverse effect on mechanical as well as durability propertiesofcementmortar

Key Words: Compressive strength, Workability, Tensile bondstrength,Adhesiontest.

Development of society demands the urbanisation. Urbanisation requires a good infrastructure to achieve economicgrowth.Inordertoachievetheeconomicgrowth a rapid industrialization is required in society. The industrialization promotes the consumption of natural resourcesandgenerateswasteasby product.Suchwastes aredumpedinopenlandswhichcreatealotofpollutionfor

surroundings. The wastealso has disturbedtheability of naturetoself regulationoftemperatureandatmosphere. Forthebettermentofupcominggeneration,anadoptionof sustainabledevelopmentofsocietyshouldtakeplacewhich wouldbalancebothlivingandnon livingbeingonearth.

Agoodnumberofresearchesareavailablewhichhave provedthattheindustrialwasteshavepotentialtobeused ascementandaggregates(bothcoarseandfineaggregate) inconcreteaswellasinmortar.Someofrecommendations aregiveninstandards.IS455:1989recommendedthat65% ordinaryPortlandcement(OPC)canbereplacedbyground granulatedblastfurnaceslag(GGBFS).Recommendations for25%replacementofOPCbyflyashhasbeengivenbyIS 1489:1991.Useofrecycledaggregate,steelslag,ironslag andbottomashasfineandcoarseaggregateinbothplain andreinforcedconcretetosomeextenthasbeenallowedby IS383:2016.

There is a need for comprehensive evaluation of performance of mortar mixes with a wide range of mix proportions with granite powder in place of river sand. Therefore,theobjectivesofthestudyare:

1. To characterize the waste granite powder obtained from granite processingindustries.

2. To evaluate physical and mechanical properties of mortars made with waste granitepowderasapartialsubstituteforfine aggregate.

3. To assess the durability characteristics of mortars made with granite powder when exposedtoadverseenvironment.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

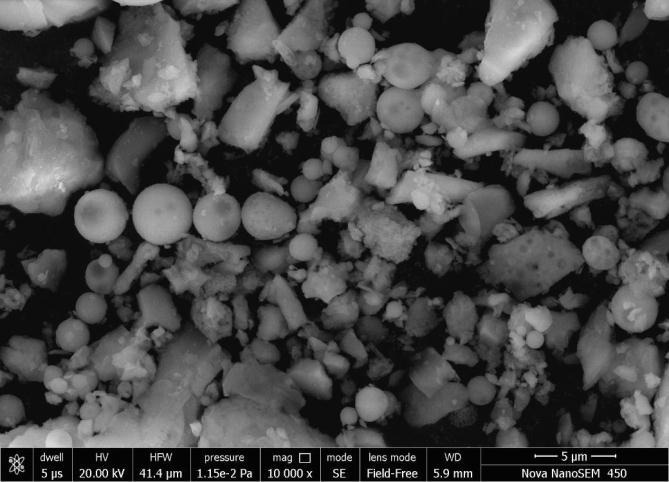

For the experimental program, Portland pozzolana cement (PPC) was utilized conforming to the specifications set by IS 1489 Part 1 (1991). The physical properties are presented in Table 1. The scanningimageofPPCisshowninFigure 1

Table -1:

Property Value

Specific gravity 2.9 Bulk density (kg/m3) 1100

Normal consistency (%) 33

Initial setting time (min) 129

Final setting time (min) 231

Compressive strength after 28th days of curing(MPa) 36

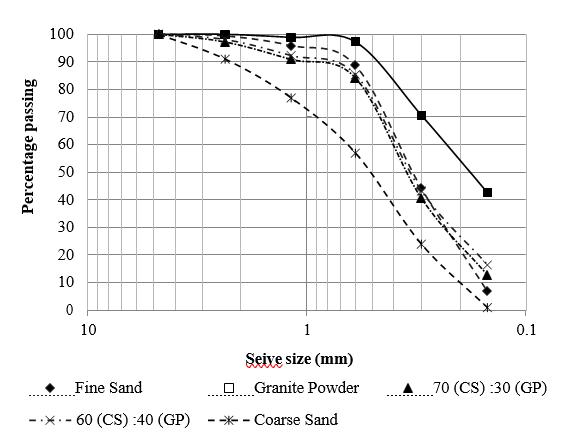

representedinFigure 2,theyweredesignatedascoarse sand(CS)andfinesand(FS).

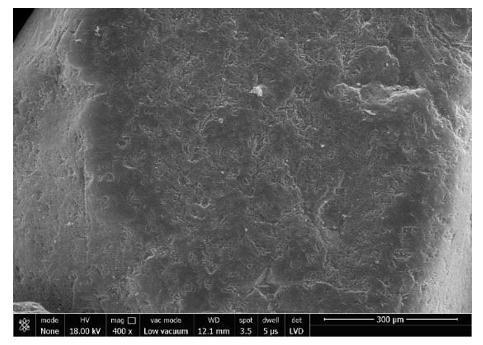

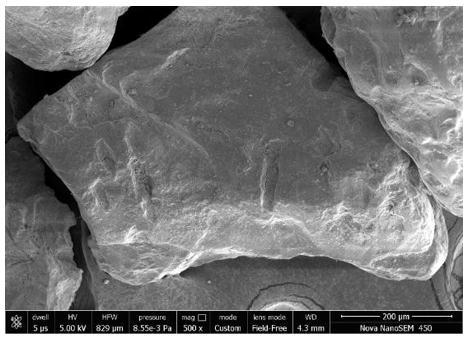

PhysicalpropertiesofbothsandsareenlistedinTable 2.TheSEMimageofbothsandsareshowninFigures 3 and4FromSEMimageitisclearlyobservedthatboth naturalsandshavesmoothandroundedsurface

Table 2: PhysicalpropertiesofCS,FSandGP

Fine aggregate Specific gravity Water absorption (%)

Loose bulk density (kg/m3)

Fineness Modulus

Coarse river sand (CS) 2.68 7.05 1597 2.65 Fine river sand (FS) 2.65 8.83 1545 1.65 Granite powder 2.46 15.29 1368 0.9 (GP)

Fig 1:ScanningImageofPPC

Bothconventional natural river sands were procured locally.Basedontheparticlesizedistributionwhichis

Fig 2:Particlesizedistributionofusedfineaggregate

Fig 3:SEMimageofcoarseriversand(CS)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

In line with the set objectives, river sand was replacedindifferentproportionsbyGPfortheproductionof cement mortars. The experimental study was carried out on mortarswithmixproportionsof1:4and1:6.Twotypesof conventionalnaturalriversandswereusedintwostagesof thisinvestigation.

Inthisstage,FS(zone IV)conformingtoIS2116 (1980)andIS1542(1992)wasusedforthepreparationof controlmortar.ThisfinesandwasreplacedbyGPfrom0%to 100% in steps of 10% by volume. Quantities of materials required to produce one cubic meterof mortar is given in Table 3 Workability, fresh density, compressive strength, waterabsorptionandpermeablevoidswereevaluatedand theirresultswerecomparedwiththoseofcontrolmortar. Table 3: Quantitiesofmaterialstoprepareonecumof mortarmixes

391 100 258 12 83 390 178 13 31 398

Inthisstage,CS(zone II)andGPwerecombinedsuchthat theresultingcompositefineaggregatemixturesatisfiedthe gradationrequirementsstipulatedbyIS2116(1980)andIS 1542 (1992). Based on trials, the required gradation was achievedwhen30%to40%ofCSwasreplacedbyGP.Hence mortarmixesofthesametwoproportionswerepreparedin whichGPconstituted30%and40%offineaggregatevolume. Quantitiesofmaterialsrequiredtoproduceonecubicmeter of mortar is given in Table 4. Initially parameters like workability, fresh density and compressive strength were evaluated.Theseresultswerecomparedwiththoseofcontrol mortarpreparedbyfinesandinPhase I

Table 4: Quantitiesofmaterialstoprepareonem3 of mortarmixesinsecondstage

Mix C ement (kg)

CS FS GP Water (lit) (kg) (kg) (kg)

4FS 273 1534 328

4CS 30 279 1136 416 313

4CS 40 277 964 551 322

6FS 189 1591 337

6CS 30 192 1171 430 323 6CS 40 193 1009 575 327

Thecompressivestrengthtestwasexperimentedon 7 and 28 days water cured mortar cubes as per IS 2250 (1981).Foreachselectedcuringperiod(7and28days)four cubes of size 50 mm were tested using a compressive strength testing machine and the achieved values were recorded. Theload wasapplied ata uniform rateof 2to6 N/mm2 perminuteonthespecimen.Theaverageofthefour values was recorded as the compressive strength at the selectedage.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

temperatureof20o Cfor7days.Thenthesesampleswere takenoutfromthepolythenebagandwerefurtherkeptfor 21days ina roomhavingcontrolledtemperature of20o C andrelativehumidityof65%.Acoreof50mmdiameterwas drilled into the hardened layer of specimens and then the pull heads were attached to the core using a suitable adhesive. A tensile load was applied perpendicular to the testareathroughpullheadstomeasurethestrength.

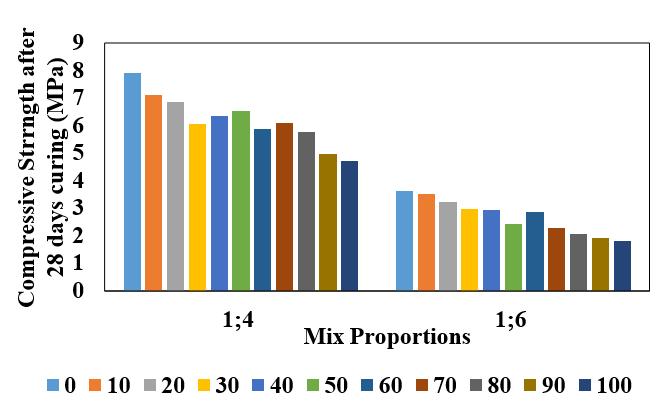

Fig 5:Compressivestrengthofmortar

Thetensilebondstrengthtestwasperformedtodetermine the bond strength ofmasonry in tension by crossed brick coupletsmethod.Thistestfollowedtheguidelinesprovided inASTMC952(2002).Acrossedbrickcoupletspecimenwas preparedusingtwobricksandbondedtogetherusingsquare mortarpastehavingeachsideof92mmand13mmdepth. Theformedspecimenwascompactedusingadrophammer ofweight900g.

Fig 7:Testingofadhesivestrengthofcementmortar

Properties of rich and lean cement mortar trial mixes prepared with air dried granite powder were evaluatedandcomparedwiththoseofreferencemortar. After this a gradationasperBIS1542andBIS2116was attempted by mixing coarse river sand(CS) and granite powder (GP) in order to achieve the required specifications of fine aggregate in mortar. The recommendedproportionwas70:30and60:40forCS:GP mortarmixes.Mechanicalanddurabilitypropertieswere evaluatedformortarmixes1:4and1:6.Theresultsand discussions are presented in detail in subsequent paragraphs.

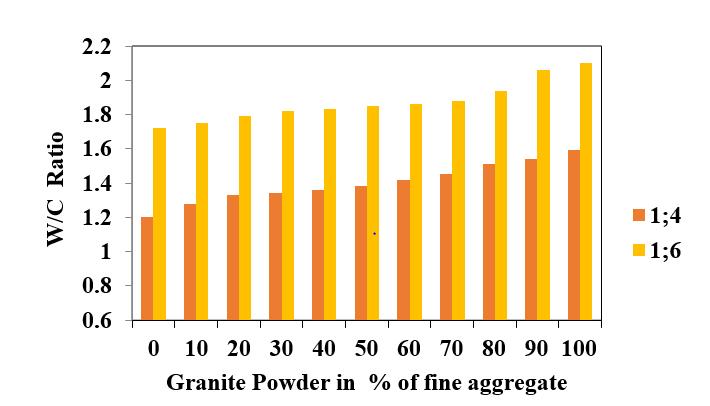

The requirement of water for required flow as per BIS 2250(1981)isshowninFigure 8.

6:Testingofbrickscoupletforbondstrengthtest

Thistestwasconductedtodeterminetheadhesivestrength ofhardenedmortarasplasteronaparticularstratumasper theguidelinesgiveninBSEN1015 12(2000).Alayerof10 mm fresh mortar was applied on the brick and the specimens were kept in air tight polythene bag at a

1. Therequiredflowformix1:4wasachievedat1.2 water cement(w/c)ratioforreference mortar specimenandat1.59formixcontaining100% GP.

2. An appreciable increase in w/c ratio was observedas27%formaximumutilizationofGP in mortar. For other mix 1:6 the increase in waterdemandwas22%.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig 8: Water cementratioofmortars

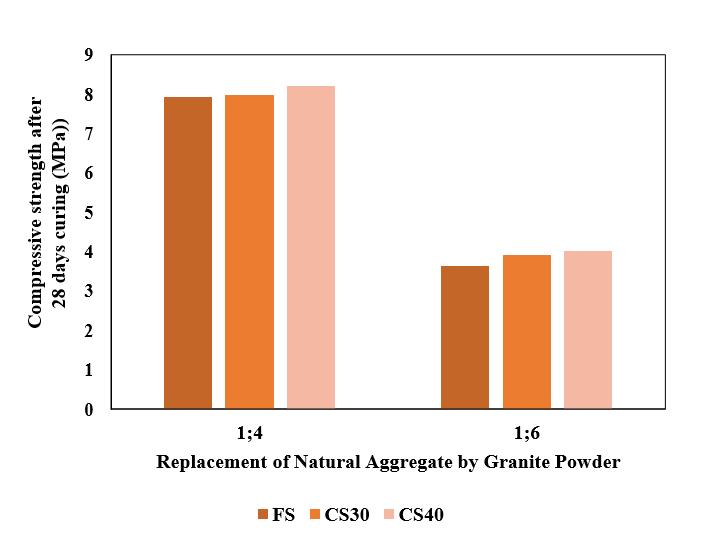

Thisincrementincompressivestrengthmaybeduetothe decrementinw/cratioascomparedtocontrolmortar.The angularshapeofparticlesasseeninSEMimages(ReferFig 10)alsoenhancesbondbetweenaggregatethusresultingin higherstrength.Theobservedcompressivestrengthvalues for CS30 andCS40 mixes were higher than the minimum recommendedvaluesforrespectivemortars3MPaand7.5 MPaasrecommendedbyIS 2250:1981.

Fig-9: Compressivestrengthafter28days

1. Theleastcompressivestrengthafter28daysof curingwas4.7MPaand1.81MPafor1:4and1:6 mix proportion, respectively which is obtained formortarmixespreparedwith100%GP.From theabovetestsonmortarswithFSandGP,itwas observed that performance of mixes with GP declinedascomparedtocontrolmortar.

2. Thereductioninworkability,freshbulkdensity andcompressivestrengthisduetopresenceof excessive finer fraction of granite powder in mortarmixes.

3. Uniform size of GP was unable to fill voids in mortars which are responsible for decline of performance.

4. Therefore,togetthemixwellgradedandatthe sametimeconformingtoBIS:1542andBIS:2116, itwasplannedtousecoarsesandfallinginzone IIinplaceofFS.

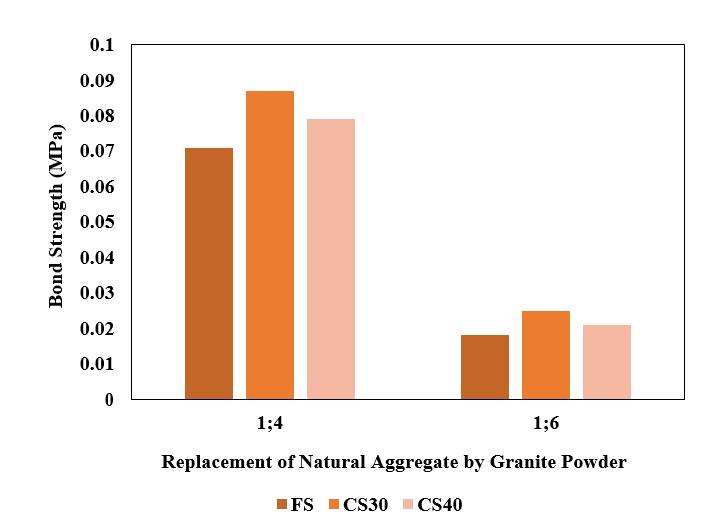

Fig 11: Tensilebondstrengthofmortarmixesat28days

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[1] Abukersh, S.A., Fairfield, C.A., 2011. Recycled aggregateconcreteproducedwithredgranitedust as a partial cement replacement. Constr. Build. Mater. 25, 4088 4094. https://doi:10.1016/j.conbuildmat.2011.04.047

[2] Agarwal, S.K., Gulati, D., 2006. Utilization of industrial wastes and unprocessed micro fillers for making cost effective mortars. Constr. Build. Mater. 20, 999 1004. https://doi.org/10.1016/j.conbuildmat.2005.06.0 09

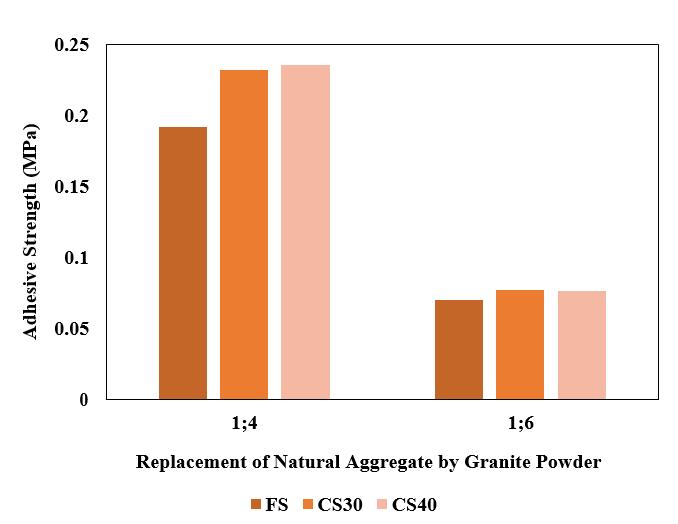

Fig-12: Adhesionofmortarmixesat28days

4.CONCLUSION

1. Water requirement to achieve required flow for mortarswithGPslightlyreducedascomparedto thatofcontrolmortars.

2. Waterabsorptioncapacityandpermeablevoidsof cement mortars with GP were found to be comparabletothoseofcontrolmortar.

3. Themarginalincreaseincompressivestrengthfor cementmortarspreparedwithGP wasobserved due to reduction of water requirement. Angular shapeofparticlesofGPmighthaveenhancedthe bondbetweenaggregates.

4. Themaximumhikeupto27%inUPVvalueswas observedformortarwithGPwhencomparedwith control mortar. It was probably due to better packingofparticlesinmortarmatrix.

5. Dynamicmodulusofelasticityhasalsoimproved formortarswithGPduetolessw/cratio.

6. Tensile bond strength of 1:4 and 1:6 mixes increased by 23% and 39%, respectively. Lesser water requirement in GP mortars has provided betterbondingbetween brick andmortarthatis whybondstrengthforsuchmortarswasincreased by39%.

7. Adhesivestrengthhasincreasedby23%and10% in 1:4 and 1:6 mix proportions, respectively. All mixesof1:4seriesfailedattheinterfacebetween thebrickandmortar,whereascohesivefailurewas observedinmortarmixes1:6.

[3] Akhtar, A., Sarmah, A.K., 2018. Construction and demolition waste generation and properties of recycledaggregateconcrete:Aglobalperspective. J. Clean. Prod. 186, 262 281. https://doi.org/10.1016/j.jclepro.2018.03.085

[4] ASTM C 1148, 2002. Standard Test Method for Measuring the Drying Shrinkage of Masonry Mortar. Annual Book of ASTM Standards (Pennsylvania, USA). https://doi.org/10.1520/C1148 92AR08.2

[5] ASTMC1403,2006.StandardTestMethodforRate ofWaterAbsorptionofMasonryMortars.Annual Book of ASTM Standards (Pennsylvania, USA). https://doi.org/10.1520/C1403 15.2

[6] ASTM C 185, 2002. Standard Test Method for Air Content of Hydraulic Cement Mortar. AnnualBookofASTMStandards(Pennsylvania, USA).https://doi.org/10.1520/C0185 08.2

[7] ASTM C 267, 2001. Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes. Annual Book of ASTM Standards (Pennsylvania, USA).

[8] ASTM C 307, 2003. Standard Test Method for Tensile Strength of Chemical Resistant Mortar, Grouts, and Monolithic Surfacings. ASTM International(Pennsylvania,USA).

[9] ASTM C 348, 2002. Standard Test Method for Flexural Strength of Hydraulic cement Mortars. Annual Book of ASTM Standards (Pennsylvania, USA).

[10]ASTM C 642, 2006. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. Annual Book of ASTM Standards (Pennsylvania, USA). https://doi.org/10.1520/C0642 13.5

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[11] ASTMC666,2003.StandardTestMethod forResistanceofConcretetoRapidFreezingand Thawing, ASTM International. ASTM International (Pennsylvania, USA). https://doi.org/10.1520/C0666

[12]ASTMC952,2002.StandardTestMethodforBond Strength of Mortar to Masonry Units. ASTM International(Pennsylvania,USA).

[13]ASTM C1012/C1012M 15, 2015. Standard test method for length change of hydraulic cement mortars exposed to a sulfate solution, ASTM International, West Conshohocken, PA. https://doi.org/10.1520/C1012

[14]Bacarji, E., Toledo Filho, R.D., Koenders, E.A.B., Figueiredo,E.P.,Lopes,J.L.M.P.,2013.Sustainability perspective of marble and granite residues as concrete fillers. Constr. Build. Mater. 45, 1 10. https://doi.org/10.1016/j.conbuildmat.2013.03.03 2

[15]Behera, M., Bhattacharyya, S.K., Minocha, A.K., Deoliya,R.,Maiti,S.,2014.Recycledaggregatefrom C&Dwaste&itsuseinconcrete Abreakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 68, 501 516. https://doi.org/10.1016/j.conbuildmat.2014.07.00 3

[16] Bilir, T., Gencel, O., Topcu, I.B., 2015. Properties of mortars with fly ash as fine aggregate. Constr. Build. Mater. 93, 782 789. https://doi.org/10.1016/j.conbuildmat.2015.05.0 95

[17] Binici,H.,Shah,T.,Aksogan,O.,Kaplan,H., 2008.Durabilityofconcretemadewithgraniteand marble as recycle aggregates. J. Mater. Process. Technol. 208, 299 308. https://doi.org/10.1016/j.jmatprotec.2007.12.12 0

[18] Bisht,K.,Ramana,P.V.,2017.Evaluationof mechanical and durability properties of crumb rubber concrete. Constr. Build.

[19] Bisht,K.,Ramana,P.V.,2018.Sustainable production of concrete conctaining discarded beverage glass as fine aggregate. Constr. Build. Mater. 177, 116 124. https://doi.org/10.1016/j.conbuildmat.2018.05.1 19

[20] Bogas, J.A., de Brito, J., Ramos, D., 2015. Freeze thawresistanceofconcreteproducedwith fine recycled concrete aggregates. J. Clean. Prod.

1 13. https://doi.org/10.1016/j.jclepro.2015.12.065

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal