International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Enhancement in the Physical Properties of Concrete by Partial Replacement of Cement and Sand by Hypo Sludge and Steel Fiber by adding Superplasticizer

Tiwari1 , Rakesh Sakale2 , Hirendra Pratap Singh31

Civil Engineering, School of Research and Technology Bhopal (M.P.) IndiaAbstract In the worldwide reinforced concrete structure, the major construction typology is the major use of concrete and steel. Apart from this, concrete is the most extensively used material. Greenhouse gas (GHG) emissions are produced during the manufacturing processes of these materials. Reduction of its environmental impact and enhancing the sustainability of partial replacement of cement without altering concrete’s physical and mechanical properties can lead to a reduction in GHG emissions. The disposal of these materials causes serious environmental pollution. Hypo Sludge (HS) is a waste material from the paper industry and is disposed of in large amounts in the form of slurry. Therefore, usage of HS as a partial replacement of cement in concrete manufacturing can help in minimizing the environmental pollution issue. In the present study, based on past research, usage of HS as partial replacement of cement varying up to 40% for concrete manufacturing in combination with the addition of Steel Fiber (SF) up to 4% with superplasticizer of concrete is done, with the objective of finding an acceptable optimum replacement of HS without significant reduction in physical and mechanical properties compared to normal concrete of the same grade. Results were concluded based on lab tests for identification of mechanical properties like compressive strength, split tensile strength, and flexural strength done after 7 days and 28 days of curing. Concrete mix design and experiments were done using relevant Indian Standards. The result indicates the addition of both HS and SF increases the compressive, tensile, and flexural strength of concrete at all curing ages up to a certain point. The best combination of compressive, tensile, and flexural strength of concrete is 20% of HS, 2% steel fiber, and 800 ml of superplasticizer to give the maximum strength and workability and also give an initial and final setting. Compressive strength is measured at 7 and 28 days and found 24.78 kg/cm2 and 43.72 kg/cm2. Split Tensile Strength is 7.66 kg/cm2 and 5.87 kg/cm2 after 7 days and 28 days and Flexural Strength is at 2.94 kg/cm2 and 3.85 kg/cm2. HS and SF mixed concrete reduces 6.51% of the cost with respect to normal concrete strength and up to 7.5% for split tensile and flexural strength.

Keywords Hypo Sludge (HS), Steel Fiber (SF), Compressive Strength, Split Tensile Strength, Flexural Strength,Workability.

IIntroduction

Through the integration of industrial waste into concrete, the environment and energy can be saved. The use of these by products offers environmental advantages like diversion of the material from the waste bodies, reductionoftheenergyusedinprocessingvirginmaterials, usage of virgin materials and a decrease in pollution. For theproductionofordinaryPortlandCement(OPC),weuse earthresourceslikelimestone.Duringthemanufacturingof one tonne of OPC, an equal amount of carbon dioxide is released into the atmosphere, which is harmful to the environment.So,thereisaneedtochooseanalternative.In urbancities,solidwastemanagementisa verychallenging task,whichisacriticalpollutionproblem.Thereasonisthe generation of large quantities of solid waste. Also, at present, the cost of cement is increasing day by day. It is necessary to use industrial waste products in an appropriate manner to reduce environmental problems and costs. Many research organizations are doing massive work on waste materials concerning Paper mill sludge is a majorenvironmentalandeconomicissuefortheboardand paper industry. The material is a by product of the de inkingandre pulpingofpapermills.Thepaperindustryis the primary source of hypo sludge, as it generates a large amount of waste hypo sludge. It is estimated that around 18% of waste (sludge) is generated during the production ofpulp.

Hypo sludge contributes advantageous properties to the concrete while helping to maintain the economy. Therefore, numerous contemporary research works have focused on the application of hypo sludge in cement and concrete production to attain sustainable development. Manyresearchershaveinvestigatedthepossibilityofusing the paper industry waste in concrete production. Disposal cost of paper industries can be reduced by using hypo sludge in concrete and produced the green concrete for construction.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

II Literature Reviews

Manmeet Kaur et al. (2015), this research work is concerned with the experimental investigation of the strengthofconcreteblendedwithhyposludge.Thecement hasbeen replaced byhypo sludgeinthe rangeof 0%, 5%, 10%,15%and20%forM 20mix.Concretemixtureswere produced, tested and compared with the conventional concrete mix in the terms of workability, compressive strength and splitting tensile strength. The tests were carried out after 7, 14 and 28 days. The workability of concrete decreases with the increase in content of hypo sludge the gradual increase was seen in compressive strengthandsplittingtensilestrengthofconcreteblended with0%to10%ofhyposludgecontentforallcuringages. Beyond that there is a significant reduction in strength. The maximum compressive strength and splitting tensile strength were 27.62 N/mm2 and 3.79 N/mm2. Also, the cost analysis indicates that with incorporation of hypo sludgedecreasesthecostofconcrete,butatthesametime strength also decreases. 20% replacement of cement with hyposludgeleadsto18.35%reductionincost

Abdul Ghaffar et al. (2022), main purpose of this research is based on the investigation of the use of steel fibres in structural concrete to enhance the mechanical properties of concrete. The objective of the study was to determine and compare the differences in properties of concrete containing without fibres and concrete with fibres. This investigation was carried out using several tests, compressive test and flexural test. A total of eleven mix batches of concrete containing 0% to 5% with an interval of 0.5% by wt. of cement. ‘Hooked’ steel fibres were tested to determine the enhancement of mechanical properties of concrete. The workability of concrete significantlyreducedasthefibredosagerateincreases

Rajib Kumar Biswas et al. (2021), steel fibers and their aspect ratios are important parameters that have significant influence on the mechanical properties of ultrahigh performance fiber reinforced concrete (UHPFRC).Steelfiberdosagealsosignificantlycontributes to the initial manufacturing cost of UHPFRC. This study presents a comprehensive literature review of the effects of steel fiber percentages and aspect ratios on the setting time,workability,andmechanicalpropertiesofUHPFRC.It was evident that an increase in steel fiber dosage and aspectratio negativelyimpactedworkability, owingtothe interlocking between fibers; compressive strength was positively influenced by the steel fiber dosage and aspect ratio; and a faster loading rate significantly improved the mechanical properties. There were also some shortcomingsinthemeasurementmethodforsettingtime. Lastly, this research highlights current issues for future research

Amit Gupta et al. (2020), he use of Steel Fibre Reinforced composites in infrastructure applications is

becomingmorepopularwiththeintroductionofnewhigh performance materials. Steel Fibre Reinforced composites are introduced to enhance the overall performance of structures,suchascompositebridgedecks,beams,bearing walls, etc. This review from the past experiences presents the results of experimental and analytical studies done on composite material made of Fibre reinforced concrete overlaid on Conventional Reinforcement with Concrete. Results show that the composite structures possess good compressive strength, tensile strength, flexural strength, crackingstrengthandultimatecapacity

Amol Naitam and Dr. Arif Khan (2019), The innovativeuseofhyposludgeinconcreteformulationsasa supplementary cementation’s material was tested as an alternative to traditional concrete. These tests were carried out to evaluate the mechanical properties like compressivestrengthupto28days.Thisresearchworkis concerned with experimental investigation on strength of mortar and optimum percentage of the partial replacement by replacing cement via 4% to 16% of Hypo Sludge.Keepingallthisview,theaimofinvestigationisthe behavior of mortar while adding of waste with different proportions of Hypo sludge in mortar by using tests like compressionstrength

III Methodology

3.1 Properties of OPC

In all my work, 43 grade OPC cement is used and purchased in local market. It was the current packing, a sealedpack,freshandfreefrommoisture.Forbestresults, cement should be stored in moisture less storage. To find outthephysicalpropertiesofcement,thefollowingtestis performed, which is shown in Table 3.1, and the corresponding standard for that parameter as per BIS: 8112 2013isalsolistedinTable1

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

3.2 HypoSludge:-

Hypo sludge was dried in the sun light till the moisture exhaustandafterthatitwasgrinded.Thehyposludgeused inconcretecontains90%particlespassing45 micronsieve. Thechemicalandphysicalpropertiesofhyposludgeandits comparisonwithcement

Table 2:Comparison of theProperties of HypoSludge with Cement

S No Constituents Properties of Cement (%) Properties of Hypo Sludge (%)

handling, placing, compacting and final finishing. The appropriate workability and strength reduced labour cost. Workability test methods have been classified in terms of thetypeofflowproducedduringthetest.

Table 4: Workability of all mixes of Hypo Sludge (HS) and Steel Fiber (SF) with Superplasticizer mix Concrete

S. No. Hypo Sludge in %

Steel Fiber in %

SP in ml/100 kg of cement

Slump Value in mm

1 0% 0% 0ml/100 kg 123.33

2 10% 1% 400ml/100 kg 141.66

3 20% 2% 600ml/100 kg 158.33

4 30% 3% 800ml/100 kg 173.33

1.5 4 0.5 4.5

1 Lime(CaO) 60 67 37 48 2 Silica(SiO2) 17 25 3 12 3 Magnesium (MgO) 0.1 4 0.1 4 4 Aluminum (Al2O3) 3 8 2 7 5 Calcium Sulphate (Ca2SO4)

3.3 Steel Fiber:-

Steelfiberwasfreefrommoistureaswellascorrosion.The steel fiberusedinconcretecontains95%particlespassing 4.75 micronssieveanditsshapeandsizealsosameasfine aggregate.

Table 3:Properties ofSteel Fiber

S No Constituents Properties of Steel Fiber

Remarks

1 Tensile Strength 1600MPa MorethanSufficient forConcrete 2 Compressive Strength 6000MPa MorethanSufficient forConcrete 3 SplitTensile Strength 1000 1300 MPa MorethanSufficient forConcrete 4 Flexural Strength 8.81MPa MorethanSufficient forConcrete 5 MeltingPoint 1000 1300OC MorethanSufficient forConcrete

3 4 Workability of concrete as per IS: 1199 1959

Workabilityisthepropertyoffreshcementconcretemix which shows the ability of ease in working like mixing,

5 40% 4% 1000 ml/100kg 185.00

3.5 BIS Mix Design Method:

The following steps used to design mixed of concrete summarizedbelow:

i) In first step we have to find out target mean strength from the specified characteristics strength on the level of qualitycontrolled.

ii)InsecondstepselectW/Cratio(WaterCementRatio)for targetstrength.

iii)Inthirdstepwiththehelpofslumpconetestdetermine watercontent.

iv)The cement content can be determined from the water/cement ratio determined by slump cone test and watercontentobtainedinstep(ii)and(iii)respectivelyand ischeckedforthewaterrequirements.

v) With the help of characteristics of course and fine aggregatefindoutproportionoffineandcoarseaggregate.

vi)Thetrialmixproportionsaredetermined.

vii) After verifying compressive strength with the trial mixes tested are made to get there the final mix composition.

Mix No.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Table 5:Prepared Mixes for Tests of all Strengths performed onconcrete

W/C Rati o

Sl u m p ( m m )

Hyp o Slud ge in % of Cem ent Wt

Stee l Fibe r in % of San d Wt

SP in ml/10 0 kg of cement

W at er (l / m 3)

Ce me nt Kg/ m3

San d Kg/ m3

Coar se Aggr egat e Kg/ m3

Mix 1 0.45 10 0 0 0 0 19 7 438 686 .31 1082 .71

Mix 2 0.45 10 0 10 1 400 19 7 438 686 .31 1082 .71 Mix 3 0.45 10 0 20 2 600 19 7 438 686 .31 1082 .71

Mix 4 0.45 10 0 30 3 800 19 7 438 686 .31 1082 .71 Mix 5 0.45 10 0 40 4 1000 19 7 438 686 .31 1082 .71

Table 6: Mix proportions of different concretemixes for HypoSludge(HS)

Mix W/C Rati o

HS % HS kg/ m3

Cemen t kg/m3

Fine aggregat es kg/m3

Coarse Aggregat e kg/m3

Wa ter l/m 3

Mix1 0.45 0 0 438.00 686.31 1082.71 197 Mix2 0.45 10 43.80 394.20 686.31 1082.71 197

Mix3 0.45 20 87.60 350.40 686.31 1082.71 197 Mix4 0.45 30 131.40 306.60 686.31 1082.71 197 Mix5 0.45 40 175.20 262.80 686.31 1082.71 197

Table 7: Mix proportions of different concretemixes for Steel Fiber (SF)

Mix W/ C Rat io

SF %

SF kg/m3

Cemen t kg/m3

Fine aggreg ates kg/m3

Coarse Aggreg ate kg/m3

Wat er l/m3

Mix1 0.4 5 0 0 438 686.31 1082.7 1 197

Mix2 0.4 5 1 6.86 438 679.45 1082.7 1 197

Mix3 0.4 5 2 13.73 438 672.58 1082.7 1 197

Mix4 0.4 5 3 20.59 438 665.72 1082.7 1 197

Mix5 0.4 5 4 27.45 438 658.86 1082.7 1 197

Table 8: Mix proportions of different concretemixes for Superplasticizer(SP)

Mi x W/ C Rat io

SP in ml/100 kg of cement

Cemen t kg/m3

Fine aggreg ates kg/m3

Coarse Aggreg ate kg/m3

Wat er l/m 3

Mi x1 0.4 5 0ml/100kg 438 686.31 1082.7 1 197

Mi x2 0.4 5 400ml/100kg 438 686.31 1082.7 1 197

Mi x3 0.4 5 600ml/100kg 438 686.31 1082.7 1 197

Mi x4 0.4 5 800ml/100kg 438 686.31 1082.7 1 197

Mi x5 0.4 5 1000ml/100kg 438 686.31 1082.7 1 197

3.5 Compressive Strength of HS and SF mixed Concrete:

The compressive strength of all the prepared mixes was determined at the ages of 7 and 28 days for the various addition levels of HS and SF with cement concrete. The values ofaveragecompressive strength fordifferent mixes preparedbyadditionofHS(0%,10%,20%,30%and40%) and SF (0%, 1%, 2%, 3% and 4%) at the completion of different curing periods (7 days and 28 days) are given in thevariousTablesbelow

Table 9 Compressive Strength of Hypo Sludge (HS) and Steel Fiber (SF) with Superplasticizer mix Concrete for all Mixes

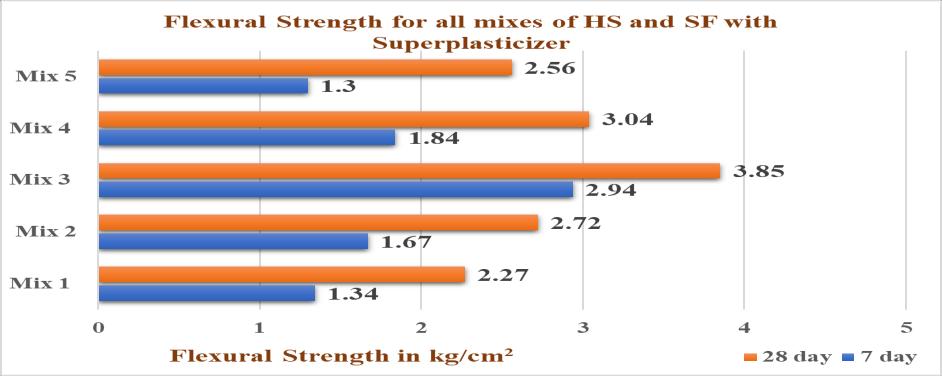

Figure1:CombineCompressivestrengthinkg/cm2for all%ofHSandSFwithSuperplasticizerat7daysand28 days

By these test results we can say that compressive strength of Hypo Sludge and Steel Fiber with Superplasticizer concrete can be increased 43.72 kg/cm2 by adding Hypo Sludge 20% of the weight of the cement content and Steel Fiber 2% of the weight of the sand. It is also clear by these results that more than 20% Hypo Sludge and 2% Steel Fiber start reducing the compressive strengthofconcretethereforewecanalsosaythattheMix 3isthebestsuitablemixforcompressivestrength. Figure 2CubeCasting

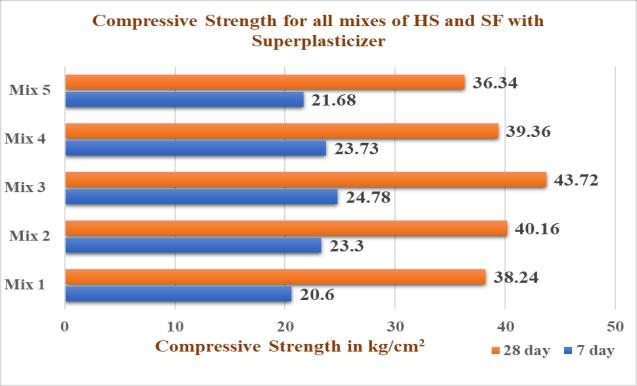

Figure3:Combinesplittensilestrengthinkg/cm2forall %ofHDandSFwithSuperplasticizerat7daysand28 days

By these test results we can say that split tensile strength of Hypo Sludge and Steel Fiber with Superplasticizer concrete can be increased 5.87 kg/cm2 by adding Hypo Sludge 20% of the weight ofthecement content and Steel Fiber2%oftheweightofthesand.Itisalsoclearbythese results that more than 20% Hypo Sludge and 2% Steel Fiber start reducing the split tensile strength of concrete thereforewecanalsosaythattheMix3isthebestsuitable mixforsplittensilestrength.

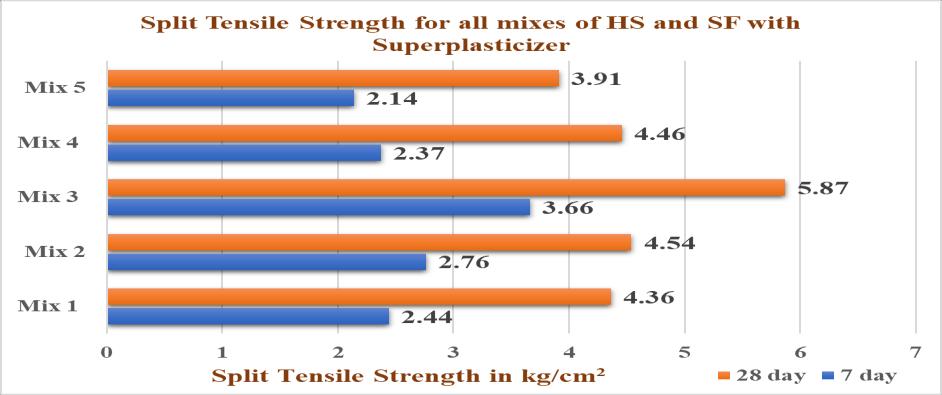

Table 10 Flexural Strength of Hypo Sludge (HS) and Steel Fiber (SF) with Superplasticizer mix Concrete for all Mixes

S. No. Hypo Sludge in %

Steel Fiber in %

Flexural Strength After 7 Days (kg/cm2)

Flexural Strength After 28 Days (kg/cm2)

1 0% 0% 1.34 2.27 2 10% 1% 1.67 2.72 3 20% 2% 2.94 3.85 4 30% 3% 1.84 3.04 5 40% 4% 1.30 2.56

Figure4:Combineflexuralstrengthinkg/cm2forall%of HDandSFwithSuperplasticizerat7daysand28days

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

By these test results we can say that flexural strength of HypoSludgeandSteelFiberwithSuperplasticizerconcrete canbeincreased3.85kg/cm2byaddingHypoSludge20% ofthe weight of the cement content and Steel Fiber 2% of theweightofthesand.Itisalsoclearbytheseresultsthat more than 20% Hypo Sludge and 2% Steel Fiber start reducingtheflexuralstrengthofconcretethereforewecan alsosaythattheMix3isthebestsuitablemixforflexural strength.

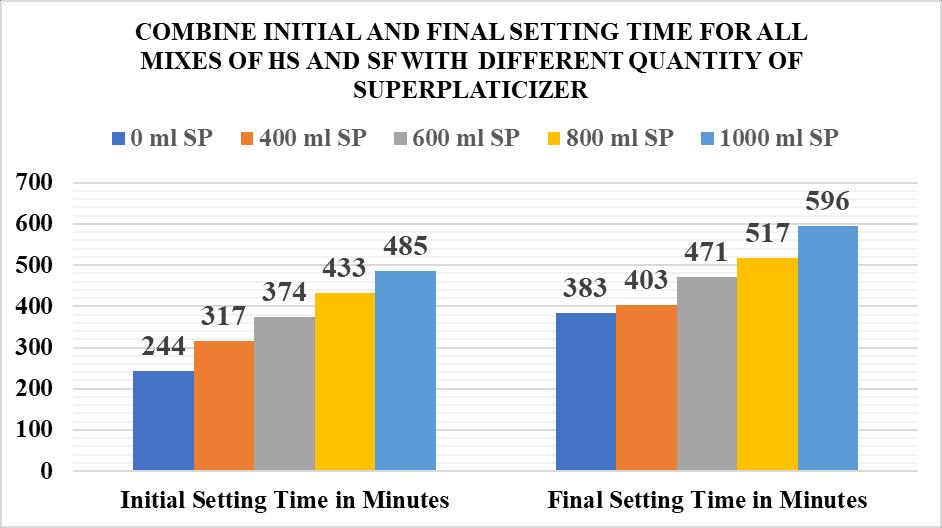

Table-11 Initial and Final Setting for all Mixes of Hypo Sludge (HS) and Steel Fiber (SF) with Different Quantities of Superplasticizer (SP) in Concrete

S. No. HS in %

SF in %

SP in ml/100 kg of cement

Initial Setting Time in Minutes

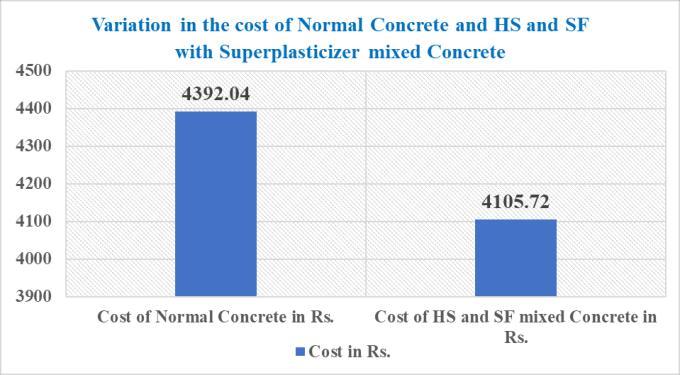

asthepercentageofHSandSFmaterialincreases,thecost goesondecreases.Reductionincostcanbeachievedeasily withoutaffectingstrengthofconcrete

Final Setting Time in Minutes

1 0% 0% 0ml/100 kg 244 383

2 10% 1% 400 ml/100kg 317 403

3 20% 2% 600 ml/100kg 374 471

4 30% 3% 800 ml/100kg 433 517

5 40% 4% 1000 ml/100kg 485 596

Figure6:VariationinthecostofnormalandHSandSF withsuperplasticizermixedconcreteinRs

The cost is low to the normal mix for M 30 grade of concreteanditisincreasewhenincreasesofproportionof Hypo Sludge and Steel Fiber material in the design mix. The difference between normal mix and design mix is 286.32 Rs.Itissavedinpermetercubicofconcrete.

IV Conclusion

[1] Afterthedetail analysisofthetestresults,wecan say that the addition of waste hypo sludge and steelfiberwithSuperplasticizersignificantlyaffect the 7 day and 28 days compressive strength, split tensile strength and flexural strength of the concrete. From the critical difference, it can be clearlyseenthattheadditionofwastehyposludge and steel fiber with superplasticizer in certain amount of the weight of cement and sand increasesthecompressivestrengthaswellassplit tensile strength and flexural strength. Experimental results also show similar trend. Hence, the results of statistical analysis are equivalent to the experimental results. From the experimentalinvestigationthisresearchworkcan beconcludedasfollows:

Figure5:CombineInitialandfinalsettingtimeinminutes atall%ofHSandSFwithdifferentquantitiesof superplasticizerinml

3.4 Cost Estimation

The cost estimation has been done separately for every mix proportion that being used in this work. The rate applied to the all the used materials to estimate cost is fromcurrent2022marketprice.Quantityestimationofall materials which are batched is done as per 1 cubic meter such that total quantity of each material can be calculated separately,andsoonrates ofeachmaterial aspermarket priceareappliedasperkilogram.Rateanalysisshowsthat

[1] HS and SF waste material improves the compressive strength, split tensile strength and flexuralstrengthofconcrete.

[2] The addition of waste HS and SF increases the strength of concrete for all curing ages up to a certain point. After that there is an abrupt reduction in the strength of the HS and SF mixed concrete.Becauseathigherdosage,concreteloses itsabilitytomakeaproperbond.

[3] The gradual increase is seen in the compressive strength of Hypo Sludge and Steel Fiber mixed concreteat7daysand28daysofcuringwith20%

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

addition of HS and 1% addition of SF in the amount of 43.72 kg/cm2, but after that it starts reducing the compressive strength with an increaseofHSand SFadditionandthe mix which givesthemaximumcompressivestrengthisMix3.

[4] ThesplittensilestrengthofHypoSludgeandSteel Fiber mixed concrete is 5.87 kg/cm2 after 7 days and 28 days of curing with 20% HS and 1% SF addition,butitbeginstodecreasewithanincrease in HS and SF addition, and the mix with the highestcompressivestrengthisMix3.

[5] The Flexural strength of Hypo Sludge and Steel Fiber mixed concrete is 3.85 kg/cm2 after 7 days and 28 days of curing with 20% HS and 1% SF addition,butitbeginstodecreasewithanincrease in HS and SF addition, and the mix with the highestflexuralstrengthisMix3.

[6] The workability of Hypo Sludge and Steel Fiber withsuperplasticizermixedconcreteis185cmfor fresh concrete with 40% HS and 4% SF addition andthemixwiththehighestworkabilityisMix5.

[7] The initial and final setting time of Hypo Sludge and Steel Fiber with superplasticizer mixed concreteis485minutesand596minutesforfresh concretewith40%HSand4%SFadditionandthe mixwiththehighestinitialandfinalsettingtimeis Mix5.

[8] The mix which was prepared with the addition of 20% HS and 2% SF with superplasticizer possess the maximum compressive strength, split tensile strengthandflexuralstrengthandfinalmixisMix 3. Therefore, this mix is recommended for maximumstrength.

[9] After estimation of normal concrete (M 30) and the HS and SF with superplasticizer mixed concrete is found that per m3 concrete save 286.32Rs.

V Recommendations

Intheconstructionindustriesthatispurelymanagedwork has good communication and clear guideline on the scope of the work are essential in the construction to avoid undesirable and confusion for the right and the accurate result, we have to prepare assessment report for every activity and every step of work to ensure the proper degreeofcontrol.

[1] For the right and the accurate result, we have to prepare assessment report for every activity and everystepofworktoensuretheproperdegreeof control.

[2] We prepare for result new and accurate machine andupdatedIScodesforformulation.

[3] Allocation of financial and skilled human resourcesforthepurposeofeffectiveandefficient qualitymanagementshouldbeprovided.

[4] There should be training program and quality guidelinestoassuredesiredquality.

VI Scope for the future

[1] Further studies need to be conducted for the test ofdurability,soundness,thermal insulation, crack patternandwaterabsorptionoftheconcrete.

[2] Further studies need to be conducted by using other waste materials (combination of artificial andnaturalmaterial)withcementcouldincreases strengthofconcrete.

[3] IfweincreasetheCaintheHSinconcretethenwe increase huge the strength in compressive strength.

[4] Experiments can be performed to study the behaviorofsoilreinforcedwithHSandSF.

[5] Experiments can be performed to study the behaviorofhighermixofconcretelikeM 40,M 50 andmanymore

References

1. J.V.SolankiandJ.Pitroda“FlexuralStrengthofbeam byPartialReplacementonCementwithFlyAshand Hypo Sludge in Concrete” International Journal of Engineering Science and Innovative Technology (IJESIT),volume.2,no.1,pp.173 179,2013.

2. Zhang Yuannun, Wu Xiaolong, He Guangxian, Shang Qing Jang, Xu Jiangio and Sun Yikai “Mechanical Properties of Steel Reinforced Concrete by Vibratory Mining Technology” Advanced International Certificate of Education (AICE), volume.8,no.10pp.1 11,2018.

3. Manmeet Kaour, Jaspal Singh and Manpreet Haur “Hypo Sludge an Innovative and Sustainable Approch” International Journal of Civil, Structural, Environmental and Infrastructure Engineering Research and Development (IJCSEIERD), volume 6, no.1,pp.1 8,2015.

4. Anmol Naitam and Dr. Arif Khan “Compression Study use of Hyposludge with partial Replacement with Cement in Cement Mortar” International Journal of Engineering Development and Research (IJEDR),volume7,no.1,pp.181 185,2019.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

5. V. Mallikarjuna Reddy and B. Sharada “PerformanceofConcretebyUsingHypoSludgeas a Mineral Admixture” International Conference on Design and Manufacturing Aspects for Sustainable Energy(ICMED),volume7,no.4,pp.04 08,2020

6. P. Akhilesh Kumar, Venu malagavelli and J.S.R. Prasad“VitalityofSteelandpolypropyleneFiberin

High Strength Concrete” International Journal of Innovative Technology and Exploring Engineering (IJITEE),volume8,no.12,pp.4673 4776,2019.

7. Santosh Ahirwarand Dr. Rajeev Chandak “A Study onHypoSludgeasPartiallyReplacementCementin Concrete” International Research Journal of EngineeringandEngineering(IRJET),volume4,no. 5,pp.1240 1242,2018.

8. Dr. P. Velumani, C. Lakshmipriya at el “Feasibility Study on Addition of Hypo Sludge in Concrete” International Journal of Engineering Science and ResearchTechnology(IJESRT),volume7,no.2,pp. 463 467,2018.

9. R. Balamurugan and R. Karthickraja “An Experimental Investigation of Partial Replacement of Cement by Industrial Waste (Hypo Sludge)” International Journal of Engineering Research and Application (IJERA), volume 4, no. 4, pp. 430 435, 2014.

10. Ranjeet Kumar and Dr. Krishna Murari “Influence of Polypropylene Fiber on Recycled Aggregate Concrete” International Journal for Research in Engineering application and Management (IJREA), volume4,no.6,pp.477 492,2018.

11. Anmol Naitam and Dr. Arif Khan “Compression StudyuseofHypoSludgewithpartialReplacement with Cement in Cement Mortar” International Journal of Engineering Development and Research (IJEDR),volume7,no.1,pp.181 185,2019.

12. Vinay Patel and Sanjay Sarawat “Experimental Study of Use of Hypo Sludge in Cement Concrete” International Journal for Scientific Research and Development (IJSRD), volume 6, no. 9, pp. 2321 2331,2018.

13. Abdul Ghaffar, Amit S. Chavan and Dr. R.S. Talwawadi “Steel Fiber Reinforced Concrete” International Journal of Engineering Trends and Technology(IJETT),volume9,no.15,pp.791 797, 2021.

14. Amit Gupta and Rahul Sharma “Investigation on Properties of Steel Fiber Reinforced Concrete” International Journal of Engineering Research and

Technology(IJERT),volume9,no.12,pp.468 471, 2020.

15. Ashish R Prajapati and Shilpesh R Rajpurohit “Formation and Application of Single Crystal Material” International Journal of Science and Research(IJSR),volume17,no.2,pp.52 59,2017.

16. A. M. Shende, A. M. Pande and M. Gulfam Pathan “Experimental Study on Steel Fiber Reinforced ConcreteforM 40Grade”InternationalReferenced JournalofEngineeringandScience(IRJES),volume 1,no.1,pp.43 48,2012.

17. Avinash Joshi, Pradeep Reddy, Punith Kumar and PramodHatker“ExperimentalWorkonSteelFiber Reinforced Concrete” International Journal of Scientific and Engineering Research (IJSER), volume7,no.10,pp.971 981,2016.

18. Rajib Kumar Biswas, Farabi Bin Ahmed, Md. Ehsanul Haque, Afra Anam Provasha, Zahid Hasan, Faria and Debasishsen “Effect of Steel Fiber Percentage and Aspect Ratio on Fresh and Harden Properties of Ultra High Performance Fiber Reinforced Concrete” Molecular Diversity Preservation International (MDPI), volume 2, pp. 501 515,2021.

19. Abhishek Jangid and Arabinda Sharma “Experimental Study on the Properties of Steel Fiber Reinforced Concrete” Indian Journal of Engineering(IJOE),volume17,no.47,pp.151 163, 2020.

20. Manvendra Verma and Nirendra Dev “Effect of SNF Based Superplasticizer on Physical, Mechanical and Thermal Properties of the Geopolymer Concrete” Springer, volume 14, no. 4, pp.965 975,2022.

21. MohammadMuhsenSalam,Md.SalahaldeinAlsady and Megat Jehari Megat Azmi “Influence of Superplasticizer Compatibility on the Setting Time StrengthandStiffeningCharacteristicsofConcrete” Advanced in Applied Science (AAS), volume 1, no. 2,pp.30 36,2016.

22. C. Jilhendra and S. Elavenil “Role of Superplasticizer on GGBS Based Geopolymer Concrete Under Ambient Curing” International Conference on Advances in Material and Manufacturing Engineering (ICAMME), volume 18, pp.148 154,2019.

23. P. Mehta, J. Paulo and Monterio “Concrete Microstructure Properties and Material” Hc Graw

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Hill Professional Edition (HGHPE), pp. 659, 2005 Book.

24. BIS: 8112:2013 “Ordinary Portland Cement 43 GradeSpecification”Code.

25. BIS: 4031:1988 “Method of Physical Tests for HydraulicCement”Code.

26. S. K. Khanna, CEG Justo and A. Veeraragavah “HighwayMaterialandPavementTesting”Book.

27. BIS: 2386:1963 (Part I) “Method of Test for Aggregate for Concrete Partial Size and Shape” Code.

28. BIS: 4031:1988 “Method of Physical Tests for HydraulicCement”Code.

29. BIS:456:2000“PlainandReinforcedConcreteCode ofPractice”Code.

30. BIS: 1199:1959 “Method of Sampling and Analysis ofConcrete”Code.

31. BIS: 10262:2009 “Concrete Mix Proportioning Guidelines”Code.

32. BIS: 5816:1999 “Splitting Tensile Strength of ConcreteMethodofTest”Code.

33. BIS: 516:1959 “Method of Tests for Strength of Concrete”Cod

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008Certified Journal | Page1411