2

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

1

Abstract Global energy demand is rapidly increasing and elevated fossil fuel consumption leads to depletion of ozone layer, global warming etc. In some countries the major sector of energy usage is buildings. Considering the reports from International Energy Agency (IEA), building sector accounts for more than 30 percent of total consumption of energy and is the producer of 30% of the total CO2 emissions. Buildings being energy efficient is of primary concern recently. PCM (Phase Changing Materials) is an efficient solution to the issue. Its capable to reduce temperature variations by changing their state from solid to the liquid when temperature increases via absorbing energy, and can release the absorbed energy, and change from liquid to the solid state when temperature drops and obtain thermal comfort inside the building. Green roof tops are another superior example of a concept for reducing consumption of energy and improving business and residential building comfort levels. Furthermore, because it is obviously known that white colour has the highest solar reflective performance, white or light colour coatings have been frequently placed on the building’s posterior walls or roofs so as to reflect the incident sunlight and thus reduce energyconsumption for interior cooling.

Key Words: Thermal comfort, Phase change material, Heat reflectance, Thermochromic films, Green roofs.

In buildings, majority of energy is utilized to preserve a comfortable ambient environment in terms of comfort on thermal basis (heating or cooling) and the quality of air (ventilation). According to the report by World Bank on power consumption in residential sector, 40% of the energydemandisrequiredtomeettheelectricitydemand for such structures that are built to bring down the amount of energy required for heating and cooling are known as energy efficient buildings. The energy consumption for maintaining thermal comfort can be reduced by the use of Phase Changing Materials. Phase ChangingMaterials(PCM)aresubstanceswhichreleaseor absorbs sufficient energy at phase transition. These materialsstorethermal energyduringthetimeofmelting and in turn liberates thermal energy in the time of freezing.Theyaremainlyemployed for obtainingthermal comfortinsidethebuilding.

***

The phase transitions via produced latent heat is used to store thermal energy in phase change materials (PCMs). sssPCMs can be employed to acquire cooling (below ambient transition temperatures), building thermal swings (below ambient transition temperatures), and short term storage of solar thermal energy. The capacity to store energy in a consolidated form can provide a supply of heat that is quickly accessible when thermal energy comes from a recurring and periodic source, such as radiation from sun. Phase changing materialsthatpossestheabilitytochangestatefromsolid statetoliquidandviceversaareutilisedinconstructionto achieve control over temperature changes. They melt by absorbing heat during daytime and then keeps the room temperature constant until the phase changes. The PCM then turn back to solid state at night. Thus, the phase changecyclerepeats.

Greenrooftopsareanothersuperiorexampleofaconcept for reducing energy consumption and improving the comfort of businessand residential buildings.Green roofs have always been studied as a bioclimatic method for improving building energy efficiency. Green roofs provide undeniable thermal advantages. When opposed to an exposednakedroof,theindoorandrooftemperaturesofa structure with a green roof are much lower. The most important environmental element affecting the green roof's cooling capability is relative humidity. Because Infrared energy makes up almost half of all solar energy, increasing the infrared reflectivity of the outside wall or roof has recently been investigated and used to minimise energyusage.Asitiscommonlyknownthatwhitehasthe highestsolar reflectiveperformance, whiteorlightcolour coatings have been frequently used on the posterior of building walls or roofs till date. However, white or light colours are always susceptible to pollution, and a single hue seldom meets human desire in practical building decorating.Furthermore,noveldeepcolourpigmentswith excellent infrared reflecting properties have been discoveredinrecentyears.

Evidently every field including transportation, buildings and industry, requires energy as a vital component in

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

smooth functioning. All these sectors need massive amountsofenergysoastocarryouttheirtasksleadingto an energy usage of roughly 50%, 25% and 20% respectively. The consumption of energy in the building sector accounts for cooling, ventilation, heating, lighting, etc. Among these splits, the energy consumption for meeting goals of heating, ventilation, and air conditioning (HVAC)isthemostconsiderable.Further,energyusagefor HVAC purpose directly relates to the heat flow between the building and its surrounding, which in turn means that, less heat exchange can result in less HVAC energy usage.Higherthicknessandlowerthermalconductivityof the building materials can help in lowering the heat exchange. Storing energy is an alternate way to lower the heat exchange. Phase change materials (PCMs) are a strong candidate for the purpose as they are well known for its property of thermal energy storage capability from numerous previous studies. If the building envelope incorporates a layer of PCM, taking into consideration its energy storing capability, the effective heat exchange will significantlyreduce.

InastudycarriedoutbyKheradmandetal[3]fluctuations in temperature of façade wall with the addition of PCM was investigated. It was found that the use of PCM devitalizedtemperaturefluctuations,asPCMinhibitedany temperature fluctuations during the phase change. Su et al[4] carried out a comparable study in which layers of microencapsulated PCM having different melting temperature (Tm) were incorporated into drywall to investigate the thermal behavior. It was found that as the thickness of the PCM increased, its efficiency also increased. Considering the conditions supposedly ideal, the temperature was brought down by 6.7◦C. In an experimental study,Chou et al. [5] augmented PCM tothe roofandconcludedthatthegainofheatloweredby52.7% accountingtotheusageofPCM.

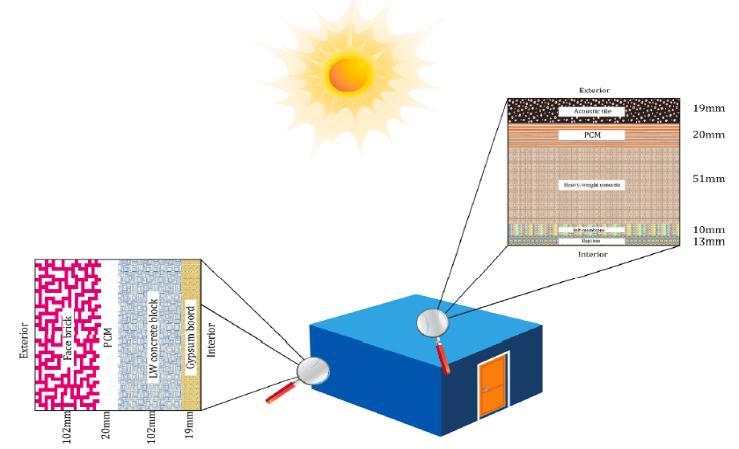

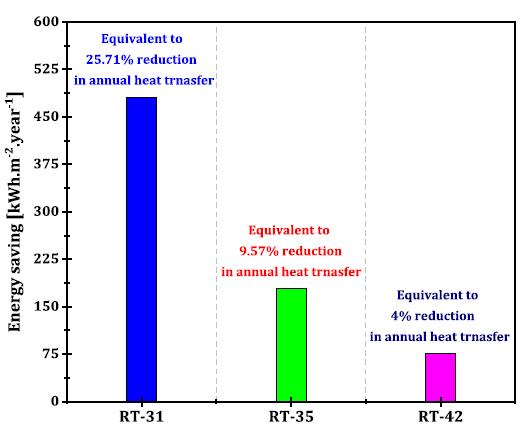

Al Rashed et.al [1] in his study, so asto lower the rate ofheat transfer, incorporated PCM in the sidewalls and rooftop of a buildingin Kuwait City, which has a very hot and humid climate. To examine the relationship among heat gain and melting temperature, PCM variants RT 31, RT 35 and RT 42 (with 20 mm thickness) are investigated. By inducing sol air temperature, the influence of solar radiation on vertical walls and roofs are investigated. Additionally, the annual rate of energy saving and avoidance of CO2 emission are investigated. In this study, the change in heat gain rate of rooms by installing PCM inside the walls and roof are examined.Thewallsofthebuildingareaugmentedwitha PCMlayerof20mmthicknessasshowninFig1.Thebase wallismadeoutoffacebrick(102mmthickness),gypsum board (19mm thickness), lightweight concrete block (102mmthickness)andtheroofismadewithacoustictile (19mm thickness), felt membrane (10mm thickness), heavy weight concrete (51mm thickness) and slag stone (13mmthickness).

As depicted in Fig.1, the building is heated up by the surroundings through the walls along with the roof. Assumption is undertaken that the ambient temperature of the room does not variate over time and stalls at 24 ◦C constantly

Fig.1.Overviewofproposedmethod Al Rashedet.al[1]

The incident rate of sunlight depends upon the geographical direction to where the wall faces and hence the incident solar radiation in different directions is considered. The hourly fluctuations in ambient temperaturealongwithsolarradiationinall geographical directions were acquired using Meteonorm software. SincetheKuwaitCitytemperaturewillbeatitspeakvalue in the month of July the heat gain difference obtained by incorporating PCM in walls and roofs were examined for July. Further, the hourly variations in the temperature for themonthofJulywerealsoexamined.

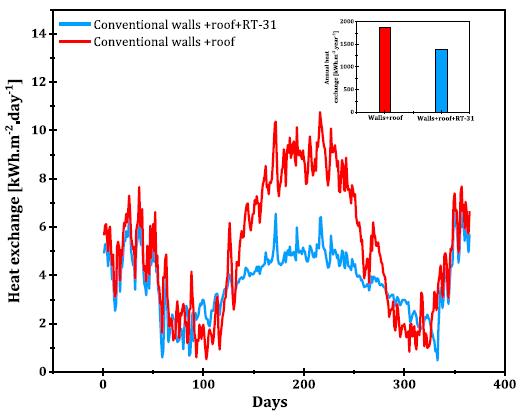

In this study, the reduction effect in the total heatexchangeinsidea building bytheinstallationofPCM inside the walls and roof of the building were analysed. Computations on CO2 saving rates were also carried out. Three kinds of PCMs of standards RT 35 (29 36 ◦C) , RT 31(27 33 ◦C)andRT 42(38 43 ◦C) wereinvolvedinthe investigation regarding the effects of melting temperaturesofthePCMintheeffectivevariationsinheat transfer. The experiments and overall analysis were performedupontwoscenarios.Intheformerscenario,the heat transfer variation due to the effect of usage of PCM wasexaminedforthemonthofJulywhichwasfoundtobe thehottestmonthatthecity.Inthelatterone,PCMswere installed and analysed throughout a whole year so as to evaluate and conclude about the overall effectiveness of augmentingPCMinsidethewalls.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

(a) (b)

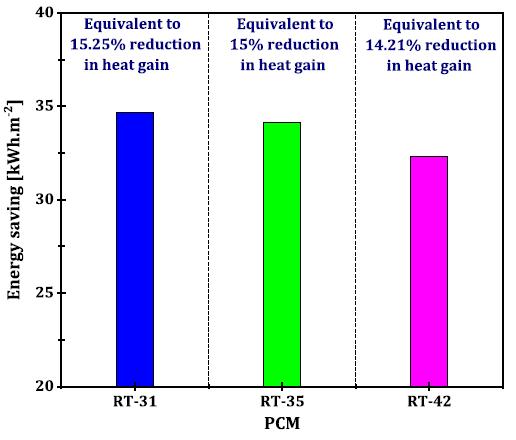

Fig.2.(a)EnergysavingratecomparisonsofdifferentPCM variants.(b)heatgainratecomparison[1]

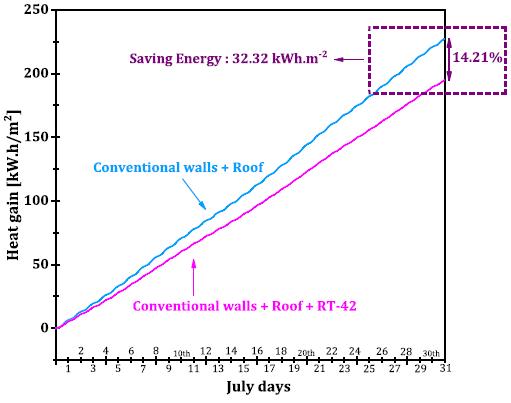

From the results acquired in the month of July, it was concluded that, installing PCM into the roof and walls of the building , reduced the overall rate of heat gain by 15.25%, 15% and 14.21% for RT 31, RT 35 and RT 42 respectively. Fig. 2 (a) shown above confirms that energy saving due to having wall augmented with RT 42 is significantlylesserwhencomparedtotheothervariantsof PCM wall and roof. Fig. 2 (b), shows the overall heat gain forthemonthofJuly.Itwasconcludedthatforthismonth, the heat exchange through the conventional roofs and wallswithoutPCMis227.3kWh/m2,whiletheratefellto 194.98 kWh/m2 when RT 42 variant of PCM was augmentedtotheroofandwalls,whichisapproximatelya 14.21%heatgainreduction.Inaddition,theenergy saving was computed to be 32.32 kWh/m2. Fig 3 shown below reports the annual heat transfer reduction rate. The roof andwallsaugmentedwithPCMvariantsRT 31,RT 35and RT 42 induce an effective reduction of heat exchange at the rate of 25.71%, 9.57%, and 4%, respectively, over the wholeyear.

(a)

(b)

Fig.3.(a)Annualheattransferreductioncomparison(b) Dailyheattransfervariationcomparison[1]

The maximum CO2 saving throughout the year was also calculated to be 198.65 kgCO2/m2.year which was recordedfortheRT 31PCMvariant.

Thermalcomfortdoesnotmerelyconvergetotheaspect ofcoolingtheindoorambienceduringhottemperatures, rather widens its coverage of the concept of heating up the indoor temperature so as to obtain a comfortable temperaturecomparedtotheharshcoldclimateoutside. Inculcation of PCM into building components through multiple applications is an efficient passive way that manyresearchersareconsidering.Ceronetal[6]created a new tile system that uses PCM as a passive thermal conditionerandputtheprototypetothetest.Theycame to the conclusion that the system can balance the ambient temperature in the winter and lower the amount of energy necessary to ensure thermal comfort at night. Zhang et al.[7] created a thermally improved frame wall with the goal of lowering peak air conditioningdemandsinresidentialbuildings.Mouridet

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

al[8] evaluated the effects of PCM inclusion on conventionalwallsinanexperiment,andfoundthatPCM integrated walls can reduce energy consumption by up to20%.

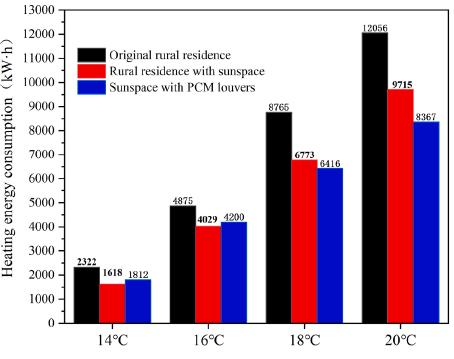

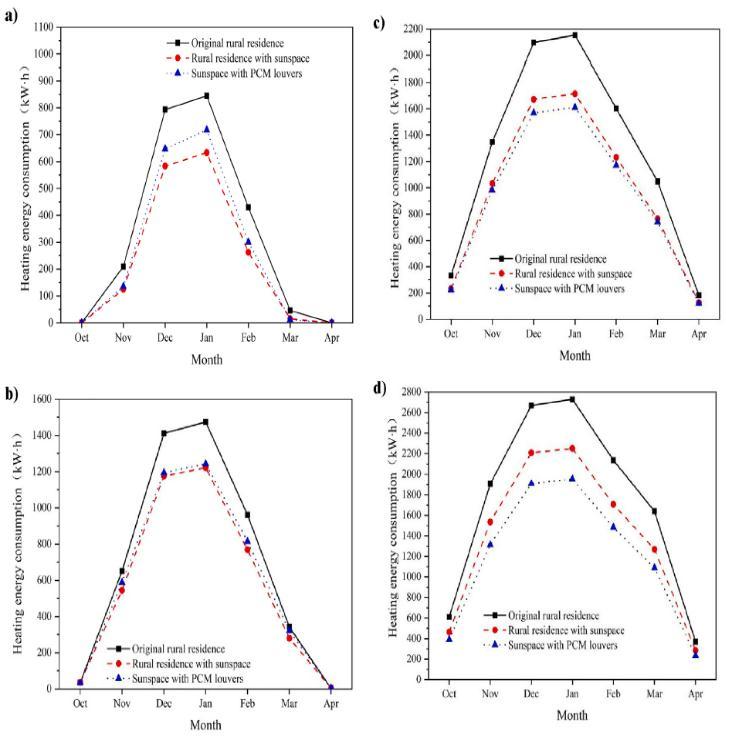

China, as a specific place, is at the pinnacle of urban construction, and this fast growth of urban, village, and town construction has assisted the construction sector and the advancement of building supplies. The need for building heating and cooling has developed, resulting in an elevation in the use of fossil fuels and, as a result, a shoot up in building sourced greenhouse gas emissions, which account for around 40% of total global greenhousegasproductions.Thus,QingLiet.al[2]inhis study, regarding a rural house in China's one of most coldlocation(Heilongjiang),researchersinvestigatedthe effectiveness of a sunspace and alsoa sunspace incorporatingPCMlouvresonusageofenergy.Thetests were conducted out for four various indoor temperatures (14, 16, 18, and 20 °C) during a seven monthperiod,fromOctobertoAprilthefollowingyear.

both sides. The building also gets heat from a variety of sources, including the bodies of the occupants (five people), lighting (three incandescent bulbs with a total powerof190W),andelectricalequipment(kettle,TV,etc. withatotalpowerof190W).

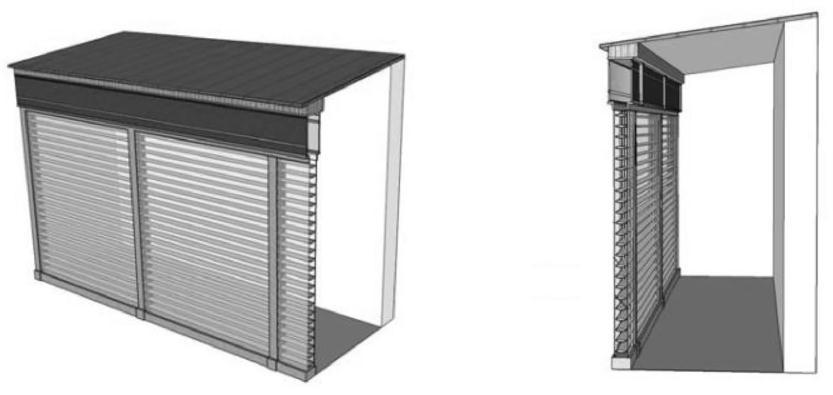

The aluminum alloy enclosure and paraffin wax make up the PCM louvre. The louvre pieces are 100 mm wide and are uniformly distributed within the glass structureatanangleof0°duringthedayand90°atnight. EnergyPlus, which uses the finite difference approach, doestheanalysisforevaluatingtheimpactofPCMlouvres used in the sunspace. A strong tool for assesing building energy which hasbeenusedextensively by researchersis EnergyPlus. The model is verified using experimental work on PCM shutters, taking into account the interior temperature and heat flux measurements collected in the room with PCM shutters on August 4 to check the correctness of the EnergyPlus model simulation. Figure 5 below depicts the test cell composition in PCM shutter study.

(a)

(b)

Fig4:Theschematicviewof (a)frontview(b)lateral viewofthePCMlouvers[2]

Threeinstances,preciselytheoriginalruraldwelling,rural residencewithonlysunspace,andalsosunspacealongside PCM louvres, were developed to illustrate the impact of sunspace and PCM louvre combinations on the rural residence energy saving. Sketchup and the Openstudio plug inwereusedtocreatea basicmodel ofa rural home with sunspace. The rural dwelling with sunspace features a 1.5 meter deep space adjacent to the residence's south façade.Abig(11.4mwideand2.5mheight)glasswindow faces the south. The PCM louvres are inserted into the sunspace's glass envelope, and a simplified model is created to display the front and side views of the studied structure, as seen in Figure 4 (a) and (b) given above respectively.Thephasetransitionfeaturesaparaffin filled shuttle shapedaluminumalloycasing.Thelouvresare1.9 metres long, 0.1 metres wide, and 0.02 metres thick at their thickest point. The louvres are installed in the interlayer of glass layer, with a 150 mm spacing between them and a 25 mm gap between them and the glass on

(b)PlanoftestroomwithPCM

Fig5:TestcellcompositioninPCMshutterstudy[2]

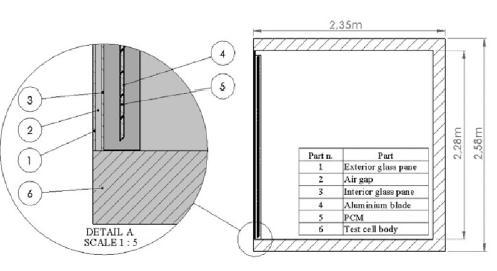

Multiple comparison evaluations were carried out for theenergyconsumptionforheatingofatraditionalrural dwelling in peak level cold region of China, taking into account the installation of a sunspace and extra PCM louvres.Thecomputationsareconductedin thiscontext for three distinct construction types: the original rural dwelling, the rural residence having sunspace, and the

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

rural residencehavingthe PCMlouvres in thesunspace. Throughout the study, 4 distinct interior temperatures (14, 16, 18, and 20°C) are incorporated in the simulations. Furthermore, the simulations are run for a periodofsevenmonths(from18thOctoberto5thApril) in which the weather in the region is classified as cold. Furthermore,the21stofJanuaryischosenasthetypical day for an hourly evaluation as the weather is comparitivelycolderonthisdaythanothersexaminedin the analyses. Summer air conditioning energy use, on the contrary, is not involved in this assessment. The monthly energy usage simulation results for the three examined types of structures are shown in Figure 6 below.

Fig6:Energyconsumptiononmonthlybasisforthe temperaturesa)14◦C,b)16 ◦C,c)18◦C,d)20 ◦C(indoor)[2]

Apart from the month by month study, the overall consumption and savings data during the heating season give a comprehensive picture. Figure 7 (a) given below depicts the overall energy use in relation to interior temperaturesduringthecourseoftheheatingseason.Itis evident that when the desired internal temperature rises from 14 to 20 degrees Celsius, the total energy consumed for the building heating in the estimated cold time rises dramatically. To more accurately assess the impact of sunspace, it should be noted that its inclusion can lower overall energy consumption throughout the time by 704, 846, 1992, and 2341 kWh for internal design temperatures of 14, 16, 18, and 20 degrees Celsius, respectively. The findings clearly show that using the sunspace has a significant influence on reducing heating energyusagethroughouttheyear.

(a) (b)

Fig6(a)Totalconsumptionofenergy.(b)Consumptionof energyonJanuary21(at18oCindoor)[2]

An extension of the study is undertaken for a model day, 21st January, which happens to be the coldest day of consideredperiodregardingtheruraldwelling,inorderto investigatetheimpactsofsunspacealongsidePCMlouvres on energy usage on hourly basis. Despite the fact that the consumption values of the rural dwelling with sunspace andthesunspacewithPCMlouvresarefairlycloseduring the day, the one with PCM louvres consumes somewhat lessenergy,asshowninFigure7(b)above,whichdepicts total energy consumption on January 21. Thus, from this studyitwasconcludedthat,theadditionofasunspacetoa typical rural dwelling in a cold climate considerably decreases energy usage for all of the internal temperatures and months were evaluated. When the building is connected to a sunspace and the inside design temperature is adjusted to 18°C, the monthly along with overall energy savings can be as high as 439 kWh (20.40%)and1992kWh(22.73%),respectively.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Space heating and cooling, which are related with the features of the building enclosure, such as windows, sidewalls, and rooftops, account fora large amount of energy consumption. The roof is responsible for 70% of totalheatgaininastructure.Duetoitshighsensitivityto solar radiation, it accounts for a significant portion of a building's total energy requirements for cooling. A cool roof with increased solar reflectivity and high thermal transmissivityisoneofthe greatestpassivemethodsfor reducing a building's cooling demand. The increased solar reflectance reduces solar radiation absorption, while the high thermal emittance improves the capacity of the roof top to dissipate any absorbed solar energy. When a building needs to be cooled, the roof should be highly reflecting, and when the building needs to be heated, the roof should be extremely absorptive [17] Tilldate,materialstypeshavebeeninvestigatedtoattain this:oneisheterogeneous directional reflectivematerial [18]whichisruledbysun’sangleduringdifferentpoints in time of the year; and thermochromic material [19], which is capable to change itsown colour in response totemperature variation. Furthermore, due to their reactivity being high, nontoxicity, cheap cost, and easy availability, titanium dioxide (TiO2) powders offer enormous promise as perfect and strong photocatalysts fora variety ofcrucial processes.BecauseTiO2 particles do not absorb light in the visible spectrum, they have a white hue. They are also effective UV absorbers that are integratedintopolymercoatingstoincreasetheiroverall life. As a result, photocatalytic, self cleaning, and long lasting coatings incorporating TiO2 particles are predicted[20]

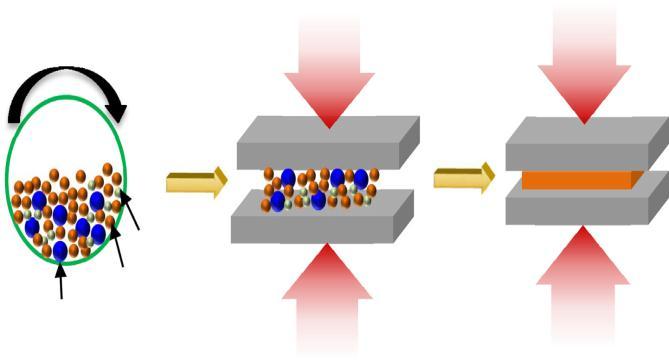

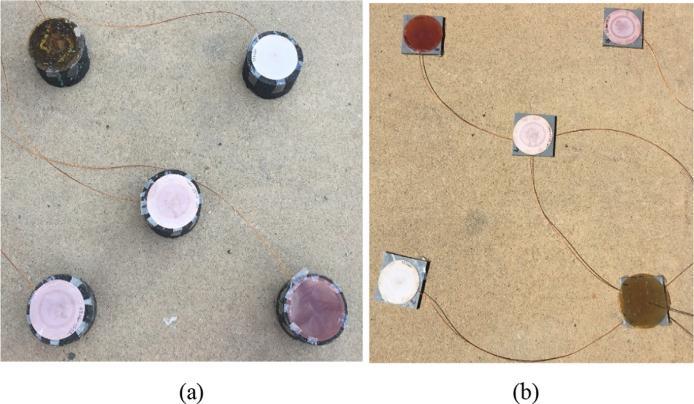

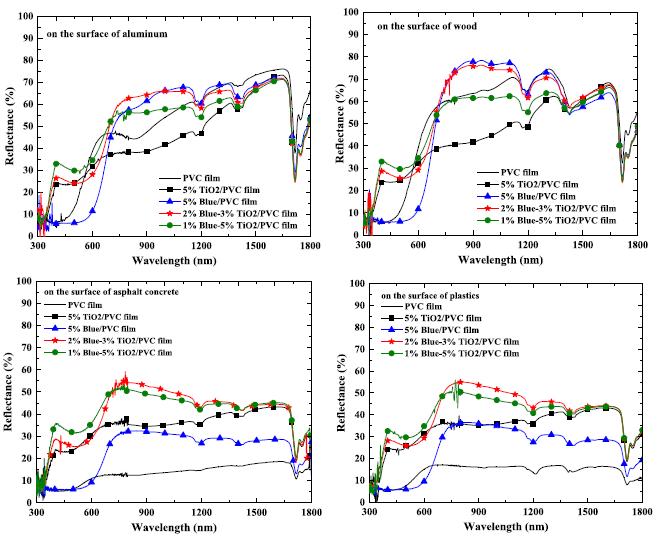

Jianying et.al.[16] in his study, byintegrating thermochromic materials alongsidenano TiO2 particles into a polymer matrix, created,multipurpose films with increased optical characteristics across the solar spectrum and possible self cleaning capability. The techniqueofhot pressingwaschosentomakefilmssince itissimpletoutilizeandcost effectiveforcoveringhuge areas. To develop the unique roofing system, traditional roofing substances (wood, aluminium, asphalt concrete, etc.) were coated with these films. A UV VIS IR spectrophotometer was used to evaluate the optical characteristics of both multipurpose films and the novelroofingsystem.Becauseofitsoutstandingphysical and optical qualities, as well as its resistance to oxidation, polyvinyl chloride (PVC) was chosen as the polymer matrix. In this research, 3 types of thermochromic materials with black, blue, and red hues were used. The temperature at which the changeover occursisroughly31degreesCelsius.ACary6000iUVVis IRspectrophotometerwasusedtoanalysethespectraof reflectance of nano TiO2 and thermochromic powders.

Furthermore, the microstructure of both these components were studied using anelectron microscopeand image analysis was performedto determinetheparticlesizedistribution.

Using a hot pressing process, multipurpose films that itself contain nano TiO2 and thermochromic powders werecreated.IndividualpowderswereputintoPVCfilm at a rate of 5% and 10%. PVC film was doped with mixtures of 0.5 percent blue 3 percent TiO2, 1 percent blue 3 percent TiO2, 2 percent blue 3 percent TiO2, and 4 percent blue 6 percent TiO2 powders. Figure 7illustrated below,depicts a typical multifunctional film manufacturing process through hot pressing. PVC powder was first thoroughly mixed with nano TiO2 and black, blue, and red variants of thermochromic powders for approximately 5 minutes, as being illustrated below. Asthenextstep,theuniformlydispersedmix of powder was kept between two parallel plates after being put betweentwosubstrates.Before loading thesamples,the plateswerewarmedto200oC.

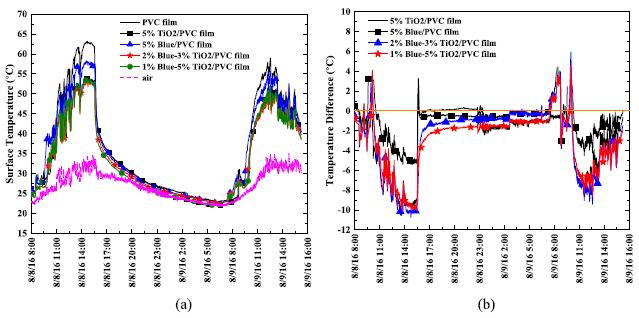

The stack was then warmed for 10 minutes at 200 degrees Celsius before being pressed for 5 minutes at 5 MPa.Afterthat,thefilmwascreatedandallowedtocool to room temperature. After then, the film was peeled awayfromthesubstrates.Thecontrol samplewasmade of pure PVC film without any functional additions. The temperature of roofing sample surfaces that are being coated with various films was monitored to examine both the thermal performance and the comparative cooling impact of the films having multiple add ons. Figure 8 shows how the experiment was set up. Sensors for surface temperature (thermocouples type K) are coupled to a system for data recording in the basic experiment setup. Sensors with a 0.1oC precision were installed in the centre of eachsample's surface. The experiment was carried out in, Cleveland, Ohio, where the samples considered were exposed to direct sun radiation. During the summer days in July and August 2016, the surface temperature of each sample was measured at 1min intervals for a period of 24 hours. Temperaturemeasurementsweretakenandkept every60seconds.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig.8.Experimentalset upfor(a)asphaltconcrete;(b) plastics[16]

When doping 5 percent and 10 percent individual powders, the multipurpose film had SR of 7 18 percent and 11 20 percent, respectively, compared to 7 percent for the control film. Compared to other powders, the addition of blue thermochromic powder and TiO2microparticles, increases the solar reflectance of thefilm by148to211percent.Furthermore,combining both blue thermochromic powder and nano TiO2 particlessignificantlyenhancestheSRvaluesofPVCfilm from7%to24 35%.TheSRvaluesofthefilmswiththe addition of functional particles are raised up to 33 50 percent in the infrared spectrum. 5 percent TiO2/PVC film, 5 percent blue/PVC film, 1 percent blue 5 percent TiO2/PVC film, and 2 percent blue 3 percent TiO2/PVC filmwereusedtocreatenovelroofingsystemsbasedon cost and efficacy. As shown in Fig. 9 below, the reflectance spectra of the system of roofing planned werecomputedovermultiplerangeofwavelengthsfrom 300to1800nmusingspectrophotometryandwerethen compared to each other. The new roofing solutions are morereflectiveintheinfraredrangethantheyareinthe UV and visible ranges, as can be observedfrom the figure. Furthermore, multifunctional coatings on aluminium and wood have a greater reflectivity than asphaltconcreteandpolymers.

Experimental outcomeson polymers covered with differentfilmsareshowninFigure10below.Forplastics inculcated with film of PVC, 5 percent TiO2/PVC film, 5 percent blue/PVC film, 1 percent blue 5 percent TiO2/PVC film, and 2 percent blue 3 percent TiO2/PVC film, the air temperature was up to 35.0 C, and the temperature was at a range of 63.1oC, 53.7oC, 58.3oC, 53.8 oC, and 53.1oC, respectively on the surface. Furthermore, whileusing5% blue/PVC film,thehighest cooling efficacy was determined to be 5oC, and 10oC when using other smart films. The findings of the experiments show that using multifunctional coatings comprising powders having thermochromic nature and particles of nano TiO2 can bring down the temperature of roof surface, significantly lowering building interior temperatures.

Fig.9.Spectralreflectancecomparison[16]

Fig.10.Surfacetemperature(a)differenceof temperature(b)forplasticscoveredwithvarious films.[16]

The roof is immediately presented to sunlight and receives the most heat during a bright day in the building, adding significantly to heat gain and boosting the structure's energy consumption. As a result, the reflectance valueof a building'sroofhasa majorimpact on solar heat uptake and consumption of energy. The reflectance of a conventional roof typically ranges between 20% and 30%. It is evident from the experimental outcomes that, in comparison to standard cool roofs, the novel roof proposed in this study,with thermochromic films has the potential to provide both cooling and warming effects during the summer and winter respectively. Innovative roofing techniques have been shown to lower building surface temperatures, in turn,potentiallyloweringheatingdemands.

Global warming has now become a modern day threat. It threatens the existence of everything on the planet andhashadasignificantinfluenceonwaterandenergy usage. A rise in ambient temperature, which raises the inside and external temperature levels of structures,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

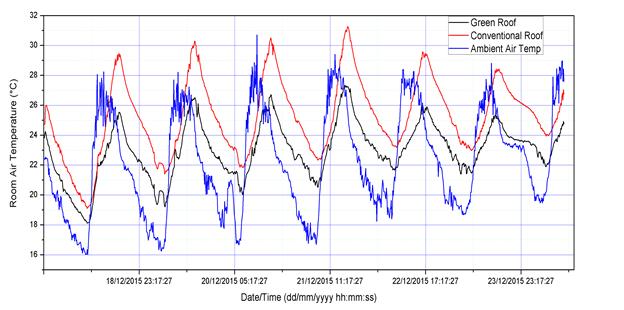

catalysestheuseofenergy intensiveandcostlysystems forair conditioning.Greenrooftopsareanexampleofa conceptforreducingusageofenergyandimprovingthe comfort of business and residential buildings. In 2001, Onmura et al[11] researched the evaporative cooling impactfromrooftoplawnbedsina3 storystructurein Japan, and it was established that the average temperature of the roof reduced from 6oC to 30oC throughout the day, resulting in a 50% reduction in heat flow. Niachou et al. [12] conducted a comprehensive investigation of thermal characteristics and an energy performance assessment using a mathematical technique in 2001. This research was carried out in a hotel in Greece. According to his conclusions, non insulated buildings saved the most energyoverthecourseofayearwith37%,followedby moderatelyinsulatedbuildingsat4%andbuildingsthat werewell insulated,exhibitedsavingsrateat2%.

Kumar, et al. [13] produced a computation of the cooling capacity of green roofs alongside solar thermal shading in 2005. The comparison was done using the case of a similar roof top garden atHaryana, and he observed that inculcating a green roof brought down averageinsidetemperatureby5.1oCwhencomparedto abareroof.Greenroofshaverecentlybeenstudiedasa bioclimatic method for improving building energy efficiency. Parizotto et al. [14] examined the green roof heat efficiency of a casual residence building in Brazil. The research was carried out during the warm and moderate warm seasons. During the hot season, the green roof brought down heat gain by 92 97% when compared to other roofing options, according to his research. Permpituck et al. [15] conducted an experimental study in Thailand on the energy consumption variation by employmentof roof lawn gardens. He experimented with different soil depths to seehowtheyaffectedtheoverallthermalperformance.

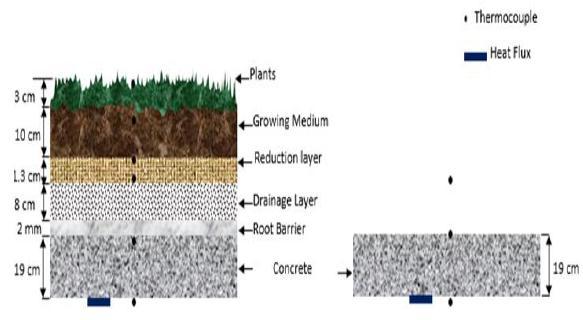

V Kumar et al. [10] computed the effect of green roofs on thermicperformance and capability ofcooling in India's climate that ismoderately warm. Tests were conducted on two identical models measuring 1.5 m m x1.5mx2.2m,eachhavinga19cmthickconcreteslab andabrickwallthatishollowandhas15cmthickness. AsillustratedinFig.11below,tworoomswerebuiltina manner so that shadows will not cover the walls and obstructsunlight.

Thetestroomsweresimilar,exceptthatonehadasimple roof of concrete and the other one had a so called,"Green roof," which generally consistof five layers from thebottom to top, as indicated in Table 1 given below. Polystyreneinsulationwithathicknessof5cm(Uvalueof 0.408W/m2K)wasemployed.`

RootBarrier 3millimeters Sheetof Polyethylene

Medium of Drainage 8centimeters ModerateSize

Medium of Retention 1.3centimeters Composite

Medium for Growing 10centimeters Soil

Plants 2 4centimeters Paspalum Notatum

Table.1. Greenroofsystemlayers[10]

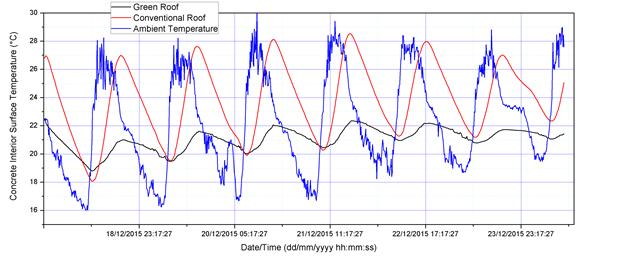

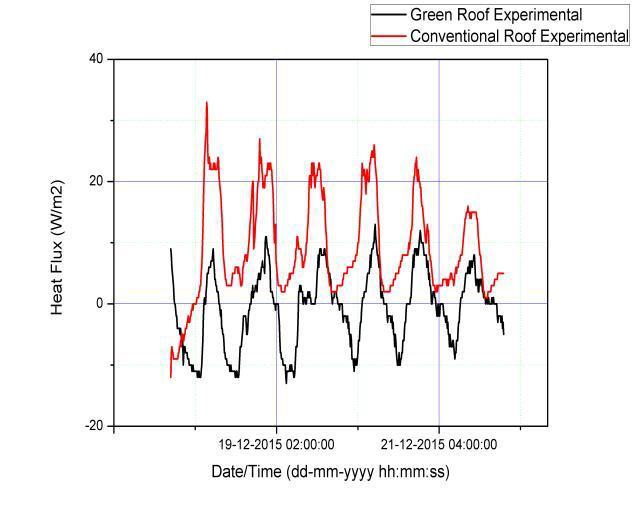

Two distinct types of roofs were put up to compute the effect of using green roofs on cooling potency: exposed roof (concrete slab) and onewith green roof layer. The measurements were taken between December 17th and December 24th, 2015. Figures 12(a) and 12(b) given below, illustrate the measurement points taken on the green roof layer and the conventional roof, respectively. The thermocouple was positioned in such a way that it could beused to monitor boththe temperature of the canopy of plant on the green roof and the retention medium effectively. Thetemperature of the surfaceand heatflowmeasurementswereobtainedinbothindoorand outdoor situations. All temperature data was taken every 10minutes,whileheatfluxwastakenevery15minutes.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

(a) (b) Fig 12. Measurement points of (a) Green roof layer. (b) Conventionalroof[10]

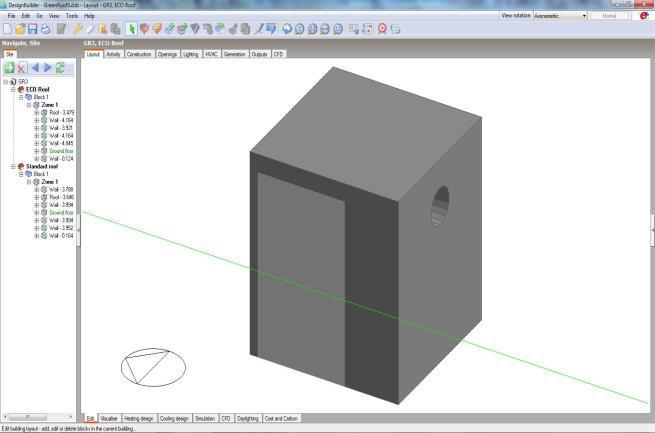

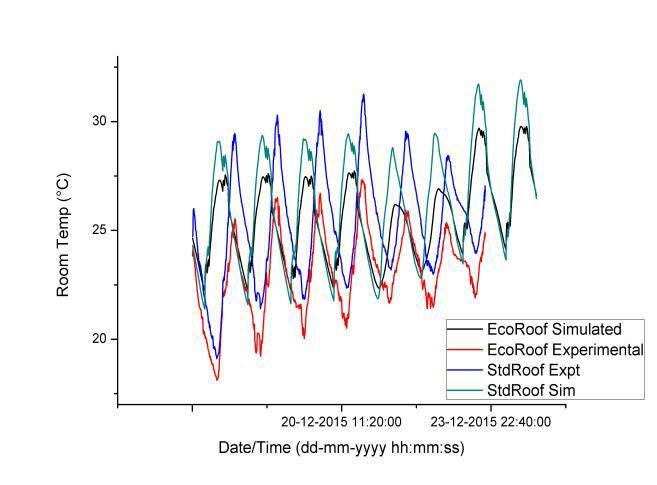

The temperature of boththe green roof and the exposedconcreteslabwererecordedusinga temperature datalogger(TC 08).TypeTthermocouplesweremadeuse oftomeasuretemperature.Heatfluxdatarecorder(LI19) wereemployedformeasuringheatfluxinW/m2.Heatflux sensors (Hukseflux HFP01) were made use of to monitor the flow of heat through rooms. The thermal energy simulation was performedon moderately warm days, considering theclimate boundaries of southern India. Design Buildersoftware(Version 5.00BETA) wasused to analyse the influence of Green Roof on the building consideredforthestudyincomparisontovariousflatroof coverings.Theroofcoatingandinsulationpropertieswere varied throughout the process. The office building model simulated, was implementedwithin the Energy Plus simulation environment with flat roof plan and experimentallyobservedparameterstoanalysetheGreen Roof performance on the two buildings. As illustrated in Fig. 13, the architectural design of the building was first executed by specifying interior thermal zones, geometry, etc.

Themaximuminternalsurfacetemperaturesofthetraditi onalconcrete slaband that of green roofs were 28.53oC and 22.39oC, respectively. Fig14(b) gives a comparative illustrationoftheinternalsurfacetemperatureofboth the exposed roof and the green roof. The peak gainof heat of theexposedroofcomparedtoagreenroofwasdiscovered tobe6.14oC.Thegreenroof'sinternalsurfacetemperature exhibits a profile that is attenuated throughout the experiment. The findings indicate that the green roof is beneficial. Due tothe prevalence of,plants and soil layers,the temperature dropped dramatically. When compared to the traditional roof, the room equippedwith the green roof had a lowertemperature throughout the trial.Onhotdays,thetemperaturesforthetraditionaland greenroofsendedupat31.5oCand27.1oC,respectively,at mid noon as shown in Fig.14(a). Throughout the trial, the maximum green roof roomtemperature appears to beconsistently lower than the traditional roof, having amaximumcomparativedifferenceof4.4oC.

Fig.13.Thebuildingmodelbuildingsimulatedemploying DesignBuilder[10]

(a) (b)

Fig14.Comparisonof(a)Roomairtemperature(b) Interiorsurfacetemperature[10]

The quantity of heat flow viathe two roofs is measured using heat flux sensors (HFP01) attached to the internal concrete slab surface. A data logger LI19 was used to

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

capture heat flow data at 15 minute intervals. Figure 15(a)shown below depicts the heat transfer history over the course of six days. Green roofs had lower heat flux peaks than conventional roofs, as could beseen in the figure. The simulations of green and conventional rooms demonstrate a high level of consistency with the experimental data as being illustrated in fig 15(b). In the experimental data, the temperature reduction in using green roof is depicted as an average of 4oC, but the simulation reveals a significantly smaller difference of 3.1oC degrees. It must also be mentioned that the temperatures associated with green roof represent a significant temporal difference from the traditional roof temperaturetrends.

discoveredthatroofswithadepthof20cm,30cm,and40 cm (soil depth) were all able to succeed in lowering the temperatureoftheroomtoasimilarextent.

On the current scenario of ever increasing energy demands, the proven need for large quantities of energy for maintaining thermal comfort of building ambience is not negligible. In this paper three among the most innovative solutions to the mentioned issue is being discussed, namely, PCM, Reflective coatings and green roofs. Here, two case studies have been considered to provefortheefficiencyandbenefitsofPCM.Fromthefirst casestudyitcanbeunderstoodthatPCMcanbeutilizedas aneffectivemethodtoreduceenergyspentforcoolingthe indoorambienceinextremehotclimate.Whilethesecond casestudyexhibitsthefactthatPCMisequallyefficientin extreme cold climate as it helps to gain control over the energy consumption for maintaining indoor temperature and meeting thermal comfort at the same time. Thus, considering the facts acquired hereby, we can conclude thatemployingPCMcanhelptocutshortthetotalenergy usage in a building regarding the achievement of thermal comfort. While examining the possibility extents of reflective coatings on building posterior, by conducting comparative trials on typical summer days, the overall performanceofnewroofingsystemsusingthermochromic sheets was also studied. The surface temperature was found to be lower as a result of the findings. Considering the studies regarding green roofs examines, it can be ascertainedthatonhotdays,greenroofshavebeenshown to have a significant impact on room air temperature as well as the interior and the roof’s external surface temperature.Theoverallheatinthetworoomsisrevealed to be vastly different i.e., rooms incorporating green roofsexhibited much lower temperature than that of a bareroof.

[1] Al Rashed, Abdullah AAA, Abdulwahab A. Alnaqi, and Jalal Alsarraf. "Energy saving of building envelopeusingpassivePCMtechnique:Acasestudy of Kuwait City climate conditions." Sustainable Energy Technologies and Assessments 46 (2021): 101254

[2] Li, Qing, et al. "Effect of sunspace and PCM louver combination on the energy saving of rural residences: Case study in a severe cold region of China." Sustainable Energy Technologies and Assessments45(2021):101126.

Moreover, it must be stated that the proposed model is extensively validatedusing a large collection of test data for air inside the room and plant canopy temperatures. According to a numerical study, the soil depth must be greater than 10 cm for being effective. The study

[3] Kheradmand M, Azenha M, de Aguiar JLB, Castro Gomes J. Experimental and numerical studies of hybrid PCM embedded in plastering mortar for

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

enhanced thermal behaviour of buildings. Energy 2016;94:250 61.

[4] SuW,DarkwaJ,KokogiannakisG.Numericalthermal evaluation of laminated binary microencapsulated phase change material drywall systems. Build Simul 2020;13(1):89 98.

[5] Chou H M, Chen C R, Nguyen V L. A new design of metal sheet cool roof using PCM. Energy Build 2013;57:42 50.

[6] Cer´on I, Neila J, Khayet M. Experimental tile with phase change materials (PCM) for building use. Energy Build 2011;43(8):1869 74. https://doi.org/10.1016/j.enbuild.2011.03.031.

[7] Zhang M, Medina MA, King JB. Development of a thermally enhanced frame wall with phase change materials for on peak air conditioning demand reduction and energy savings in residential buildings.IntJEnergyRes2005;29(9):795 809.

[8] Mourid A, El Alami M, Kuznik F. Experimental investigation on thermal behavior and reduction of energyconsumptioninarealscalebuildingbyusing phase change materials on its envelope. Sustain CitiesSoc2018;41:35 43.

[9] Chenxi Zhu, Jian Lv, Lingdong Chen, Weiqiang Lin, Jing Zhang, Jintao Yang, Jie Feng, Dark, heat reflective, anti ice rain and superhydrophobic cementconcretesurfaces,ConstructionandBuilding Materials,Volume 220,2019,Pages 21 28,ISSN 0950 0618

[10]Kumar, Vinod, and A. M. Mahalle. "Investigation of the thermal performance of green roof on a mild warm climate." International Journal of Renewable EnergyResearch(IJRER) 6.2(2016):487 493.

[11]S.Onmura, M. Matsumoto, S.Hokoi, Study on evaporative cooling effect of roof lawn gardens, EnergyandBuildings,Vol33,pp.653 666,2001

[12]A.Niachou, K Papakonstantinou, M Santamouris, A. Tsangrassoulis, G.Mihalakakou, Analysis of green roof thermal properties and investigation of its energy potential, Energy and buildings vol 33, pp 719 729,2001

[13]RakeshKumar,S.CKaushik,performanceevaluation of green roofs and solar shading for thermal protection of buildings, Buildings and Environment, Vol.40,pp.1505 1511,2005

[14]S.Parizotto,R.Lamberts,Investigationofgreenroof thermal performance in temperate climate: A case study of an experimental building in Florianopolis

city, Southern Brazil, Energy and Buildings vol.43, pp1712 1722,2011

[15]Sittipong Permpituck, Pichai namprakai, the energy consumption of roof lawns in Thailand, Renewable energy,Vol.40,pp.98 103,2012.

[16]Hu, Jianying, and Xiong Bill Yu. "Design and characterization of energy efficient roofing system with innovative TiO2 enhanced thermochromic films." Construction and Building Materials 223 (2019):1053 1062.

[17]C. Gray, Application of Adaptive Albedo Roofing Coatings in the Southeastern United States Dissertation, The University of Alabama at Birmingham,2015.

[18]H. Akbari, A.G. Touchaei, Modeling and labeling heterogeneous directional reflective roofing materials,Sol.Energ.Mat.Sol.Cells124(2014)192 210.

[19]T. Karlessi, M. Santamouris, K. Apostolakis, A. Synnefa, I. Livada, Development and testing of thermochromic coatings for buildings and urban structures,Sol.Energy83(4)(2009)538 551.

[20]T. Kamegawa, Y. Shimizu, H. Yamashita, Superhydrophobicsurfaceswithphotocatalytic self cleaning properties by nanocomposite coating of TiO2 and polytetrafluoroethylene, Adv. Mater. 24 (27)(2012)3697 3700.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1391