International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

EXPERIMENTAL

Abstract

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Abstract

1PG student of Deogiri Institute of Engineering and management studies, Aurangabad, 2Department of mechanical engineering, Aurangabad. ***

Heat generation in different industrial devices is very common problem. Fins are commonly used to dissipate heatbynaturalorforcedconvection.Finsareemployedon industrial devices such as heat exchanger, reciprocating compressor and engine, electric motor, transformer and many electronic devices. The material, dimensions and geometry of the fin is the challenging factor in today’s scenario, as optimum fin geometry can enhance heat transfer rate. It is observed that many manufacturers are using different fin geometry to increase the heat transfer rate such as rectangular, triangular fins with notches etc. Recently,theresearchhasbeencarriedoutonv shapedfin array. The comparative study between rectangular fin arrayandv shapedfinarrayshowsthatV shapedfinarray has large improvement on heat transfer rate. The basic objective of this experiment is to generate the experimental data for the V shaped fin array carrying a force convection. Hence to analyze the heat transfer rate fromthealuminumcastedv shapedfinarraywithoutslots on notches and with slots on notes by providing angles to thebasicfinplate.

Keywords: Fin array, Force convection, slots, experimental study

Heat generation in industrial product is common problem in industry. This heat generation can effect on a performanceoftheproductandalsoontheefficiency.The system of the product may lead to failure if there is a overheating of the product The heat transfer takes place bynaturalconvectionorforceconvection.Herpreferreda force convection for heat transfer through fins as it is economicalandhasalessstudydata.Finsareemployedto dissipate heat at faster rate, but proper geometry, no. of fins,spacingbetweenfinandfinmaterialisabigtaskfora designer.Increasingthenumberoffinscanalsodecreases the rate of heat transfer. Therefore, the exact number of finsisalsoaveryimportantfactor,asagreaternumberof

fins may lead to the resistance to the flow of air. Forced convectionisa mechanismoratypeoftransportinwhich fluidmotionisgeneratedbyanexternalsourcelikepump, fan, suction device etc. subject of thermal engineering. In general, the heat transfer from heated surfaces are enhanced by increasing the coefficient of convection heat transfer between a heated surface and it’s ambient or by fins and fins array to increase the surface area of heat transferorbybothmethods.Themostcommonlyusedfin arrayisrectangularfinarray.Lateron,triangular,vertical, diamond shaped fin array. Latest research is going on v shaped fin array. The researchers have also worked on V shaped fin array with different manufacturing process of finarraysuchasv shapedfinarraymanufacturedbyCNC, welding of fins on the flat plate, sticking the fins with the glueontheflatplate.Also,thedifferentmaterialisusedin manufacturing of the fins such as cast iron, aluminum, aluminumalloyetc.Inthepresentexperiment thefinsare manufactured in aluminum LM 16 material by sand casting method. The material selected is due to its higher thermal conductivity and material availability. The objective of the experiment is force convection heat transfer through Aluminum casted V shaped fin array withoutslotsandwithslotstothefins.

The experimental investigation is performed to check the force convection heat through Aluminum casted V shaped finarray withoutslotsandwithslotsto thefins.Thesand casted aluminum base plate is of dimension, height=390mm, width=200mm, thickness= 12mm. The testplateconsistsof20fins.2smallfinsand18largefins. Other dimensions are length= 100mm, width= 20mm and thickness= 5mm. The angle of fin is 300 from horizontal planeofthefinplatewhenkeptvertical.

The electrical power is supplied to the heater whichmountedonthebacksideofthetestplate.Theexact power supplied is measured by wattmeter. Below the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

surface plate two 12 volts fan are attached with SMPS for forcing the air. After steady state is reached the temperature readings were measured for the calculation. The flow chart of experimental procedure is shown in fig. whichshowsthestepshowexperimentiscarriedout.The powerinputsuppliedwas25W,50W,75Wand100W.The number of temperature readings measured on test plate were for 900 angles base temperature (tb)= 40; fin temperature (tf)= 40; slots temperature (ts)= 40; ambient temperature (ta)= 40. Similar procedure is done for the angle 600 and 300. For 600 the temperatures were measured and total number of readings were taken are : surfacetemperature(tb)=40;fintemperature(tf)=40;slot temperature (ts)= 40; ambient temperature (ta)= 40. Similarly, for 300 angles the surface temperature (ts)= 40; fintemperature(tf)=40;slottemperature(ts)=40;ambient temperature (ta)=40; This was the one part of the experiment whose surface plate having V shaped inclined fins. But the another readings were taken on the surface plate whose fins having a parallel 12mm distance slots onbothsidesofeachfins.Similarprocedurewasdoneon another surface plate which contains slots. Readings were takenontheinclinationof900,600 and300.Foreachangle we have taken total number of readings: surface temperature (tb)= 40; fin temperature (tf)= 40; fin slots temperature(ts)=40;ambienttemperature(ta)=40;Sothe totalnumberofreadingsforsurfaceplatewithoutslotson fin array are for surface plate (tb)= 120; fin temperature (tf)= 120; slots temperature (ts)= 120 and ambient temperature (ta)=120. Similarly the total number of readings for the surface plate having a slots in fin array are: for surface plate (tb)= 120; fin temperature (tf)= 120; slots temperature (ts)= 120 and ambient temperature (ta)=120. After having all the readings we took average temperature readings for each factor and calculations are done for the fin array. Then the graphs and excels are plotted and analyzed to calculate average heat transfer coefficient,Nusseltnumber, RayleighnumberandGrashof numberforboththesurfaceplateswithoutslotsonfinand with slots on fins. Again the 12 mm slots are taken on the fin parallelly. Slots were made on the fin with the help of milling machine. And then after applying angles the same temperature readings were taken. Total number of readings are : for surface plate (tb)= 120; fin temperature (tf)= 120; slots temperature (ts)= 120 and ambient temperature (ta)=120. Similarly, the total number of readings for the surface plate having a slots in fin array are: for surface plate (tb)= 120; fin temperature (tf)= 120; slots temperature (ts)= 120 and ambient temperature (ta)=120.

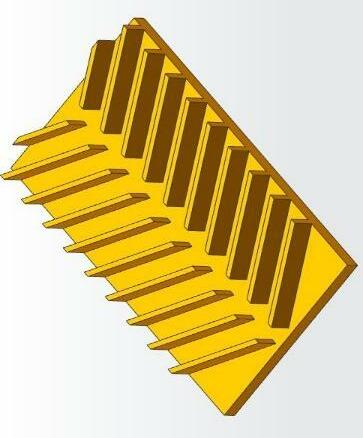

Fig3.1three dimensionalviewoffinarraywithout slotsinfin

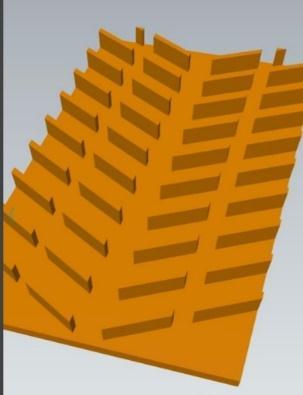

Fig3.2three dimensionalview offinarraywithslots

2 3 4 5

1

0

6 7 30 60 90

Fig4.1thevaluesareofheattransfercoefficient(ha)at differentinclinations

Fig4.2ValuesofAvg.HeatTransfercoefficientandAvg. NusseltNo.At25W

ha at 25W ha at 50W ha at 75W ha at 100W 0 10 20 30 40 50 60 70 80 30 60 90 Ha Nu 0 20 40 60 80 100 120 30 60 90 Ha Nu

Fig4.3ValuesofAvg.HeatTransfercoefficientandAvg. NusseltNo.At50W

Fig4.4ValuesofAvg.HeatTransfercoefficientandAvg. NusseltNo.At75W

Fig4.5ValuesofAvg.HeatTransfercoefficientandAvg. NusseltNo.At100W

50

40

30

20

0 20 40 60 80 100 120 30 60 90 Ha Nu 0.00 10.00 20.00 30.00 40.00 50.00 60.00 70.00 30 60 90 Ha Nu 0

60 30 60 90 Nu at 25W Nu at 50W Nu at 75W Nu at 100W

10

Fig4.6ValuesforwithoutSlotsofAvg.NusseltNo.(Nu) AgainstDifferentInclinations

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1299

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

60

40

20

0

Fig4.7ValuesforwithoutSlotsofAvg.Heattransfer coefficient(Ha)AgainstDifferentInclinations

6

4

80 30 60 90 Ha at 25W Ha at 50W Ha at 75W Ha at 100W 0

50

40

30

20

10

0

2

Fig4.8thevaluesofheattransfercoefficient(ha)at differentinclinations

40

30

20

10

8 30 60 90 ha at 25W ha at 50W 0

50 30 60 90 Ha Nu

Fig4.9ValuesofAvg.HeatTransfercoefficientandAvg. NusseltNo.at25W

Fig4.10ValuesofAvg.HeatTransfercoefficientandAvg. NusseltNo.at50W

80

60

40

60 30 60 90 Ha Nu 0

20

Fig4.11ValuesofAvg.HeatTransfercoefficientandAvg. NusseltNo.at75W

100 30 60 90 Ha Nu 0 10 20 30 40 50 60 70 30 60 90 Ha Nu

Fig4.12ValuesofAvg.HeatTransfercoefficientandAvg. NusseltNo.at100W

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

0 10 20 30 40 50 60 70 30 60 90

1.Heattransfercoefficientincreasesat25Wand75W.

2. Nusselt number and Heat transfer rate increases at 50W,75Wand100W.

3. The average Nusselt number is greater at 900 and 75W.

4.TheaverageHeattransferrateisgreaterat900 .

5.Heatlossismore

Fig4.13ValuesforwithSlotsofAvg.NusseltNo. (Nu) AgainstDifferentInclinations

Nu at 25W Nu at 50W Nu at 75W Nu at 100W 0 5 10 15 20 25 30 30 60 90

Ha at 25W Ha at 50W Ha at 75W Ha at 100W

Fig4.14ValuesforwithSlotsofAvg.Heattransfer coefficient(Ha)AgainstDifferentInclinations

5. Conclusion

A. Withoutslots

1.Heattransfercoefficientincreasesat25W,50Wand 75W.

2.HeattransferrateandNusseltnumberincreaseson 25Wand75W.

3.HeattransferrateandNusseltnumberdecreaseson 50W.

4.TheaverageNusseltnumber andHeattransferrate isgreaterat900 .

5.Theheatlossisless.

1. The present experiment investigation is carried outon300,600,900 inclinations.Theinvestigation may be extended to inclinations from 100 to 1800 withtheintervalof100inclinations.

2. Same experiment can be carried out on natural convection

7.

1. AreviewonHeatTransferfromDifferenttypesof Notch Fin Arrays under Forced Convection to increaseheatenergytransferMr.Sandip.N.Mane Lecturer Mechanical Department. SBGI Miraj and Mr. Sachin.S.Mane Lecturer Automobile Department.PVPITBudhgoan.

2. Enhancement of natural convection heat transfer from horizontal rectangular fin arrays with perforations in fin base* Guei Jang Huang, Shwin ChungWong*,Chun PeiLinDepartmentofPower Mechanical Engineering, National Tsing Hua University,Hsin Chu300,Taiwan,ROC

MODE Pravin Kamble PG student Shri Tuljabhavani College of Engineering, Tuljapur,Maharashtra Prof. S.N.Doijode Head, MED Shri Tuljabhavani College of Engineering, Tuljapur,Maharashtra Dr. Mrs. Geeta Lathkar Principal MGM’s College of Engineering, Nanded,Maharashtra.

4. Experimental Study of Forced Convection from Horizontal Rectangular Fins Array into Air Duct Saad Najeeb Shehab Department of Mechanical Engineering / College of Engineering/ Mustansiriyah University/ Baghdad Email:

5.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

saadnajeeb16@uomustansiriyah.edu.iq(Received 24April2018;accepted23July2018).

TRANSFER AND FRICTION CHARACTERISTICS OF AN ARRAY OF PERFORATED FINS UNDER LAMINAR FORCED CONVECTION A. Ahmadi Nadooshan1,* , Sh. Mohammadi1,M.Bayareh.

6. Numerical study on the mixed convection around inclined pin fins on a heated plate in vertical channels with various bypass ratios Jun Seok Lee, Man Yeong Ha, June Kee Min * School of Mechanical Engineering, Pusan National University, 2, Busandaehak ro 63beon gil, Geumjeong gu,Busan,46241,SouthKorea.

7. Theoritical Investigaion Of Convection Heat Transfer In Vertical Tubes Ramesh Chandra Nayak* , Ashish Kumar Patra**, Sharmistha Jena****(DepartmentofMechanicalEngineering, Swami Vivekananda School of Engineering and Technology,BBSR, Odisha, India,Pin 752054 **(Department of Electronics and Telecommunication Engineering, Swami Vivekananda School of Engineering and Technology,Bbsr,Odisha, India,Pin 752054 ***( DepartmentofComputerScienceandEngineering, Swami Vivekananda School of Engineering and Technology,Bbsr, Odisha India,Pin 752054 CorrespondingAuthor:RameshChandraNayak.

8. Numericalstudyofmixedconvectionheattransfer of various fin arrangements in a horizontal channel Mojtaba Mokhtari a,⇑ , M. Barzegar Gerdroodbary b,⇑ ,Rezvan Yeganehc , K.Fallahd aDepartment of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, Iran bDepartment of Mechanical Engineering, Babol Noshirvani University of Technology, Babol, Iran cDepartment of Chemical Engineering, Razi University, Kermanshah, Iran dDepartment of Mechanical Engineering, Islamic AzadUniversity,SariBranch,Iran.

9. Enhancement of Natural convection heat transfer coefficient by using V fin array Rameshwar B. Hagote, Sachin K. Dahake Student of mechanical Engg. Department, MET’s IOE, Adgaon, Nashik (Maharashtra,India).

10. Experimental Study of Forced Convection from Horizontal Rectangular Fins Array into Air Duct Saad Najeeb Shehab Department of Mechanical Engineering / College of Engineering/ Mustansiriyah University/ Baghdad Email: saadnajeeb16@uomustansiriyah.edu.iq(Received 24April2018;accepted23July2018).

11. PREDICTION OF NATURAL CONVECTION FROM AN ARRAY OF HORIZONTAL LINE H EAT SOURCES IN A L ARGE SPACE An gui Li Dept. of Environmental Engineering, Xi'an University of Architecture&Xi'an,Shaanxi,P.R.CHINA.

12. Forced Convection Heat Transfer Coefficient and Pressure Drop of Diamond Shaped Fin Array Shigeki Hirasawa*, Atsushi Fujiwara, Tsuyoshi Kawanami, Katsuaki Shirai Department of Mechanical Engineering, Kobe University, Kobe, Japan.