International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1 Prof, Structural Engineering Dept., Faculty of Engineering, Tanta University, Tanta, Egypt 2Assoc. Prof. Structural Engineering Dept., Faculty of Engineering, Tanta University, Tanta, Egypt 3M. Sc. Student., Faculty of Engineering, Tanta University, Tanta, Egypt ***

Abstract The construction industry has been asking for environmentally sustainable repair materials with a lower carbon footprint all around the world. Concrete containing considerable amounts ofPortlandcement willdeteriorate over time and will need to be repaired or replaced. Cementitious mortars, polymer modified cementitious mortars, resinous mortars, and other restorative materials have all beenused to fix the problem. Cement free geopolymer mortars with a high percentage of silicate aluminium and an alkaline activator solution are gaining popularity as long term repair materials. Geopolymer binders are preferred because they emit 70 80% less carbon dioxide and significantly less greenhouse gas than ordinary Portland cement. These new binders are in high demand because to their improved durability, sustainability, and environmental friendliness. The review divided into three key sections after introductory section to have a holistic understanding of the using geopolymer based materials as a repair and strengthing materials and to have gaps for future research. The first section presents properties of geopolymer based materials as a repair materials. The secand section covers articles on durability of geopolymer based materials against carbonation, sulphate, acids, chlorides and heat effects. The third section reviews studies on the repairs of Portland cement concrete by geopolymer based materials. Finally, conclusions summarise the findings of the review.

Key Words: Geopolymer based materials, Durability, Compressive strength, Bond strength, Repair and Strengthing.

Ingeneral,reinforcedconcretestructuresaredurableand can be used in infrastructure applications as they provide highstructuralstrengthandlong termdurability.However, iftheyareexposedtosevereenvironmentssuchasmarine environmentorexposeddirectlytodangeroussubstances, thereinforcedconcretestructuresdeterioraterapidly[1].

Ordinary Portland cement (OPC) has been used for the construction of various infrastructures like road construction, buildings,….etc [2]. However, OPC concrete undergoesdeteriorationduetothesimultaneousactionof mechanicalandthermalloads[3].Concretedeteriorationis manifested primarily through cracking, spalling [3,4],

surfacedeterioration,andseepageofconcrete[4]andde bonding of rebars [3]. Therefore, deteriorated structural elementsrequireefficientandsuccessfulrepairmaterialsto ensuretheircontinuedserviceability[3,5] Thedeterioration of OPC based structures in aging infrastructure are a continuouscauseofconcernworldwideduetothehighcosts associated to the protection, repair and rehabilitation of thesedefects[4,6].

Among the many repair and strengthening techniques, sectional enlargementisthe mostcommonone,for which the compatibility between the repair material and the concrete substrate is of great importance [7]. The most directmethodfordamagedconcreterepairistocoverthe substratesurfacewithrepairmaterials,whichresultsinthe inevitableformationofadhesiveinterfacebetweentheold concretesubstrateandnewrepairmaterials.Unfortunately, it was found that the adhesive interface is the weakest sectionoftherepairedstructures,anditspropertieswere alsorelativelyweakduetothelargenumberofdefectsand micro cracks[8].Inmostcases,alayerofinterfacialagentis coated on the substrate surface before covering repair materialsoverlay,andthepolymermodifiedcementitious materials is the most popular [9,10]. It is desirable to improveandinvestigatetheadhesiveinterfaceperformance for concrete repair, which can guarantee the whole work capability[8,11].

Thecommonly usedrepairmortarsweremadefromOPCor their derivatives, such as including supplementary cementitious materials blended OPC mortar, polymer modifiedcementmortar,ultra high performanceconcrete, reactive powder concrete, engineered cementitious composite,andmagnesiumphosphatecementmortar[7,12].

The term of geopolymers was initially proposed as a new materialbyDavidovitsin1978[15,16].Thefirstgeopolymer concrete was developed in 1990 (Davidovits 1990). Since then, researchers are continuously improving and developing mix proportions of geopolymer concrete for desired strength, sustainability and energy efficiency for construction[13].

Geopolymer resulting from the reaction of raw material containing high percentages of amorphous silica and alumina(suchaskaolin,miningwaste,flyash(FA),ground

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1272

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

granulatedblastfurnaceslag(GGBFS),ricehuskash(RHA), palm oil ash (POA), etc.) with alkaline activators (alkali hydroxide solutions and soluble silicates) [17 19] as a dissolution agent [17] in the room or high temperature environment[18,19].

Aluminosilicatemineralsweredissolvedinsolutions,then freeSiO4andAlO4tetrahedralunitswerereactedbysharing oxygenatoms.PolymericSi O Al Obondswhicharesimilar to amorphous feldspar were formed [20]. Actually, the geopolymerizationisinfluencedbytheabilityofaluminum ions to induce crystal structure and chemical reaction of SiO2skeleton[21].Previousstudiesshowthatgeopolymer concrete has excellent mechanical properties, high durability,lowshrinkage,andmaterialcost;approximately 10 30% lower than OPC concrete to chemical attacks fascinated the scientific community [22,23]. On the other hand, water mainly acts as the reaction medium in the geopolymerizationreactionandpromotesthedissolutionof aluminosilicate,whichreducesthewasterrequirement[24]. Abbasetal.[26]pointedoutthatthegeopolymerconcrete achieved a reduction in global warming potential by 61% and improved the human health category by 9.4%. Thus, geopolymerconcrete isconsidered the betteralternatives forOPCconcreteacrosssomerangeofapplicationsdueto thehighworldwideavailabilityofaluminosilicatematerials and excellent workability and mechanical properties, enablingengineeringprocessingusingthetrainedconcrete workers [26]. Although the utilization of industrial waste andreductionofcarbondioxidesisverymuchessential,the geopolymer has to look into the hardened properties requirementsintermsofqualityspecifiedforOPCconcrete. With this in mind, the durability of concrete subjected to aggressiveenvironmentshasbecomeacrucialissueforfield applications due to the increasing demand for the maintenance freeandlongservicelifeofconcretestructures, whichisalsooneofthemostmomentouspropertieswithin geopolymercommercialization[16].

Besidestheirsustainablenature,geopolymershaveseveral interesting features such as high strength, corrosion resistance, water resistance, enclosed metal ions, high temperatureresistance[15],adjustablethermalexpansion coefficient,andacidresistance[17].Geopolymersfindbroad range of applications in the field of transportation, emergency repairs, metallurgy, coating, membrane materials, and nuclear waste disposal. Despite significant commercialandtechnologicalpotentialgeopolymers’easy brittle character limits their extensive applications where greateffortsaremadetoovercomesuchshortcomings[15].

Advances in concrete repairs focus on low carbon alternativessuchastheuseofgeopolymers[13,14]asitis sustainable,environmentallyfriendlyandplaysasignificant role in waste management. These materials are not only environmentallyfriendly,butalsopresentcomparablebond strengthstoconventionalrepairs[14].

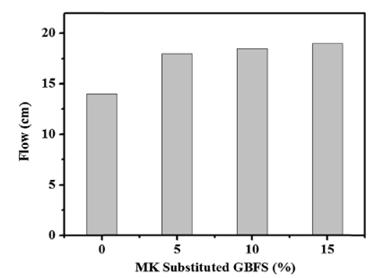

Theworkabilityofgeopolymermortarasarepairmaterial wasrecentlyinvestigated.Huseinetal.[27]investigatedthe influenceofmetakaolin(MK)ontheworkabilityandsetting timeofgeopolymermortarsbasedonGGBFS.IncreasedMK concentration in the matrix improved the workability and settingtimeofthepreparedgeopolymermortarssignificantly asshownin(Fig.1).

Morever,Tanakornetal.[28]investigatedtheinfluenceof sodiumhydroxideandthecalciumoxidetosilicateratioon geopolymermortarworkability.Anincreaseinthemolarity of sodium hydroxide could increase the initial and final settingtimeofgeopolymermortarwhenthepercentageof OPC replaced by FA was increased. FA (class C) was substitutedbyOPCwith0%,5%,10%,and15%toevaluate the impact of calcium oxide to silicate ratio. Besides, the additionofsteelslagcouldacceleratethesettingtime[29].

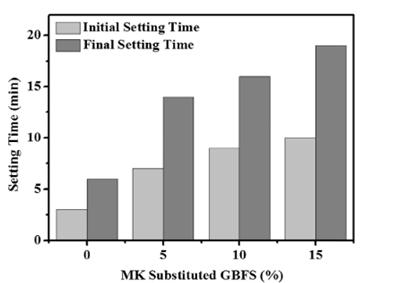

Moura et al. [30] studied the effects of different super plasticizer ratios (1%, 2%, and 3%) on the flow of geopolymermortar.Theflowofthealkaliactivatedmortars without superplasticizer was less than 50%. On the other hand, the mortars with more super plasticizer content displayed an enhanced flow as indicated in (Fig.2). The mortarswithahighcalciumhydroxidecontentandalowMK contentflowedbetter.Forbettersolubility,MK'shighBlaine finenessnecessitatedahighliquidphase.Meanwhile,athigh sodium hydroxide concentrations, flow was similarly reduced.Mortarswithasodiumhydroxideconcentrationof 10M and a calcium hydroxide content of 10% had the maximum flow.The mortarwas improvedbycombininga 3% superplasticizer component with a 10% calcium hydroxidecontentincreasedmortarflowfromlessthan50% toover90%[31].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

solutiontobinderratio,silicatetoaluminiumratio,silicateto sodium oxide, and calcium content are all factors that influencegeopolymermortarstrength.Theimpactofsomeof thesefactorsonthestrengthofgeopolymermortars(GPMs) isdiscussedinthefollowingsections[15]

2.2.1.1

Fig. 1. ImpactofMKsubstitutedGGBFSonflow geopolymermortars, a)Flow, b)Settingtime [27]

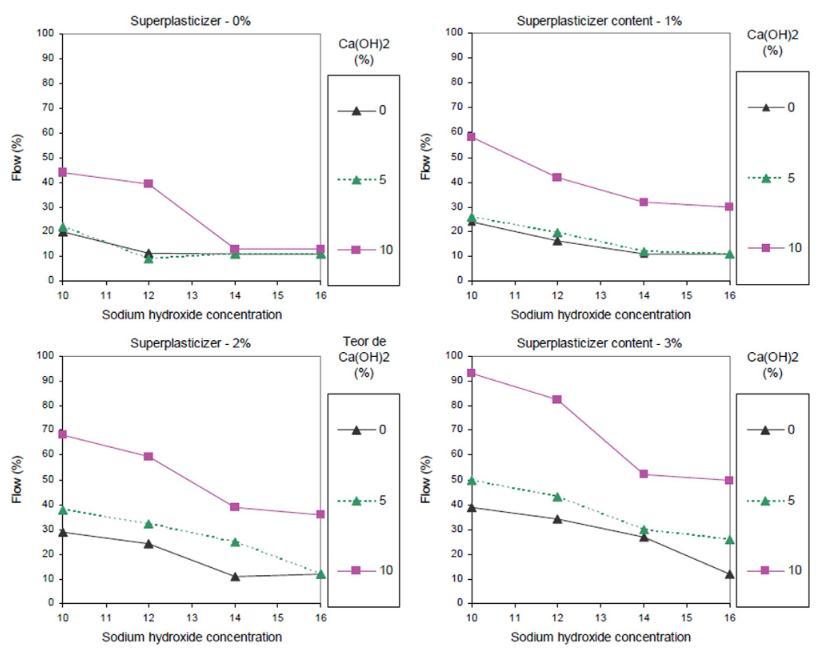

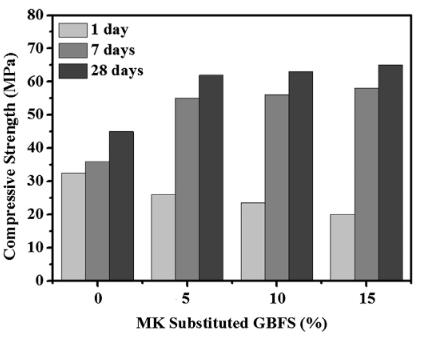

Huseinetal.[27]createdGPMsinwhichGGBFSwasreplaced by MK at 0%, 5%, 10%, and 15% levels. After 28 days of curing,thecompressivestrengthoftheresultantGPMswas foundtohaveincreasedfrom42MPato63.1MPa,withan increaseinMKcontentof10to15%,respectively.Theeffect ofMKreplacedGGBFSontheearlycompressivestrengthof GPMs is seen in (Fig.3) [27]. On the other hand,using MK improved the compressive strength with the best enhancement recorded at 20% MK [32]. The strength reduced with decrease in calcium content and curing temperatures.Witha1.08calciumtosilicateratioanda90°C ovencuringtemperature,lowstrengthwasobserved[33].

Tanakon et al. [28] employed FA class C and OPC to investigatetheeffectofcalciumratioonthebindingfeature of geopolymer mortar. FA was used in place of OPC, with percentages of 0%, 5%, 10%, and 15% respectively, increasingthecalciumlevelfromincreasedthecompressive strength.Furthermore,increasingthecalciumleveltohigh alkali(14M)increasedcompressivestrengthforthefirst10% andthereafterdecreasedit.

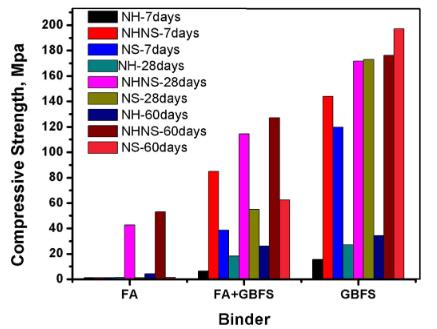

Phoongernkham et al. [34] investigated the effect of high calciumcontentwhenFAwasreplacedwithGGBFSat0%, 50%,and100%.ThecompressivestrengthofallNHandNS series was observed to rise as the GGBFS concentration increased.Thereadilyavailablefreecalciumionsthatreacted with silica and alumina to generate C (A) S H gels and coexisted with geopolymer gels were credited with this improvement[35,36].Furthermore,becausethereactionof GGBFSwithalkalisolutionsisanexothermal process,heat was generated to aid the geopolymerization process. As a result,anincreaseinGGBFScontentincreasedgeopolymer paste(GPP)compressivestrength[34].

Fig. 2. Soduimhydroxideconcentrationdependentflow variationofsuper plasticizerfordifferentcalcium hydroxidecontents[30]

The most valuable physical property of concrete is its compressivestrength,andhighearlystrengthisrequiredfor repair materials. Compressive strength influences other properties such as tensile strength, flexural strength, and modulus of elasticity. The ASTM C109/C109M standard is commonly used to determine the compressive strength of geopolymermortars.Bindertoaggregateratio,molarityof sodiumhydroxide,sodiumsilicatetosodiumhydroxideratio,

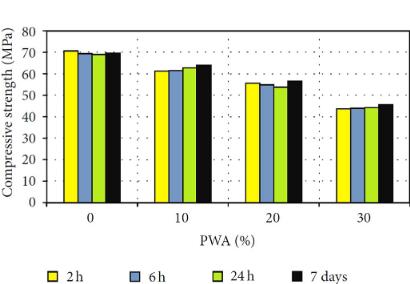

Asshownin(Fig.4),Hawa etal.[37]employedpara wood ash (PWA) class C to test its effect on the compressive strengthofMK basedGPM.The compressivestrength was foundtobehighinthefirsttwohours.Thiswaspartlydueto thefactthattheGPMsweremadeasahotmixtureandthen curedinanoven.Furthermore,particlesizeeffects(6.31mof MK vs. 25.13 m of PWA) were blamed for a decrease in compressive strength as PWA content increased.Active polymerization was caused by the increased surface to volume ratio of finer particles [38,39]. Another element contributingtothedecreasecouldbethereductionofSiand AlwhenMKwasreplacedwithPWA.Infact,theCaOinPWA did not participate in geopolymerization and was slowly hydrated.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Winnefeld et al. [40] discovered that high calcium content resultedinlowerstrengthduetopoorreactivitywithalkaline activatorsinFA basedgeopolymers.Itwasconfirmedthat compressivestrengthmightbeloweredbyaddingCaOtoraw materials.Despite this, encouraging results [41] were discoveredatacuringtemperatureof70°C.Mouraetal.[30] investigated the effects of CaO2 replacement in MK based geopolymerswith0%,5%,and10%CaO2.Itwasdiscovered thatreplacingMKwithCaO2 resultedina10%increasein compressivestrength.GGBFSandFAmunicipalsolidwaste incinerator(MSWI).FAwereusedaswastebinderinDaiet al. [42] .'s study of the effect of high content calcium on geopolymermortar.

Shuguang et al. [29] studied the effects of GGBFS replacementonMK basedgeopolymermortarswith0%and 20% GGBFS replacement. The compressive strength of cement repair material was found to be lower than the compressivestrengthofgeopolymericrepairmaterialwithor without steel slag. The higher early compressive strength achievedforgeopolymericrepairmaterialswithsteelslag.

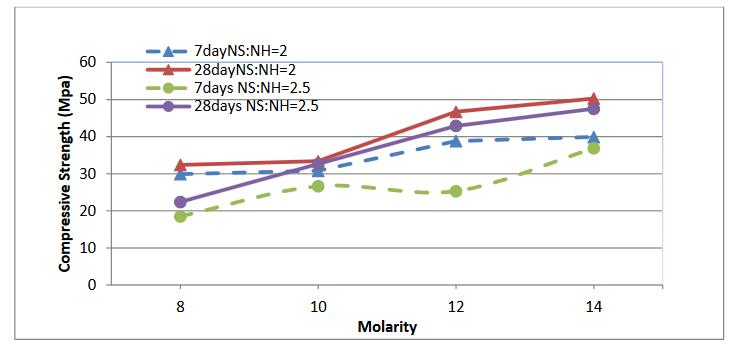

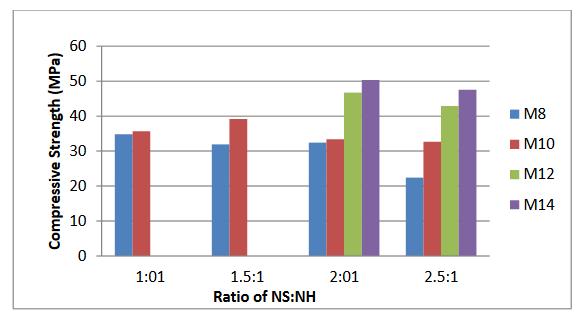

Tanakonetal.[28]investigatedtheeffectsofdifferentNaOH molarities (6M, 10M, and 14 M) on the development of compressive strength in geopolymer mortar. The study showed that as molarity increased, compressive strength increased as well. On the other hand, the effect of concentrationofNHsolutionintermsofmolarity(8M,10M, 12M,14M)theresultsshowthatthecompressivestrengthof the geopolymer mortar mixes increased with increase of concentration in terms of molarities of NaoH. The highest compressivestrengthachievedat14Mas50.3MPaat28day aspresentedin(Fig.5)[43].

Fig. 5.Effectofconcentrationofsodiumhydroxidesolution [43]

2.2.1.3

Fig .3. ImpactofMKsubstitutedGGBFSontheearly compressivestrengthofGPMs[27]

Phoongernkham et al. [34] reported the effect of different solutiontypesontheactivationprocessofwastematerials with a high silicate aluminate content. 3 types of solution sodium hydroxide (NH), sodium silicate (NS), and sodium hydroxidesodiumsilicate(NHNS)wereused.(Fig.6).clearly showsthata100%FAmixproducedlowearlystrengthsfor AllNH,NHNS,andNSseries.TheNHsolutionwascrucialin dissolutiontheSi4+andAL3+ionsfromrawmaterialsandin thesubsequentgeopolymerizationprocess[45].However,at ambient temperature, the strength growth of FA paste activatedbyeitherNHorNSwasshowntoberelativelylow [45 47].

Fig. 4.PWAdependent%compressivestrengthsfor differentmixureswithcurigageof4hinan oven[37]

At later ages, the use of NHNS showed a considerable improvement in strength development. The 7 day compressivestrengthofFApastewithNHNSwasverylow, but the compressive strengths of 28 day and 60 day old specimensweresubstantiallyhigher,with45.0and52.9MPa, respectively.Theslowerreactionrateatambienttemperature wasattributedforthelesserstrengthofFApasteearlyon.FA paste,ontheotherhand,developedstrengthinasimilarway toOPCconcreteovertime[47].ThepastewithNHandthe pastewithincreasedGGBFScomponent(FA+GGBFSpaste) produced lower strength than the pastes with NHNS and NS.The leaching of silica and alumina required NaOH, as

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

previouslystated.Nonetheless,atambienttemperature(23 °C), the leaching and subsequent reaction were decreased [48].WhenNSwasusedaloneorincombinationwithNH,the system produced more silicate. This aided the geopolymerization process, leading to higher compressive strength.Furthermore, at all curing ages, the FA + GGBFS pastewithNHNSoutperformedtheNHandNSpastes.TheFA +GGBFSblendwithNHNSwasconsideredthemosteffective alkaliactivatedbinderincombinationwithahighstrength mix.Sodium sulphate was also used to make high strength GBFS geopolymer mixtures [49]. After using four different alkaline solutions,the solutions were a mixture of sodium silicate(NS),sodiumhydroxide(NH),potassiumsilicate(KS) andpotassiumhydroxide(KH)asNS+NH,NS+KH,KS+NH andKS+KHitisnoticedthatthevaluesofthecompressive strengthofsodiumsilicate basedGPmortar(NN+NK)mixes were higher than potassium silicate based GP mortar (KN,KK)at7and28daysasshownin(fig.7)[50].Becauseof the reaction between CaO from GGBFS and SiO2 with subsequent formation of CSH, the paste with NS had the highestcompressivestrengthat28and60days[51].

According to Ismail et al. [51], alkali activation of GGBFS resultedinthedissolutionofCaandtheparticipationofSi andAlintheformationofCSHandCASHgel,resultinginhigh mechanicalstrength.Furthermore,thecompressivestrength ofgeopolymerwaspredominantlydeterminedbythemolar ratioofSiO2toAl2O3[52].TheratioofSiO2toAl2O3ofroughly 3.50 was found to form a high strength high calcium geopolymer[39].TheratioofSiO2/Al2O3inGGBFSpastewith NS was found to be 3.49.The compressive strength of this paste after 28 days of curing at ambient temperature was foundtobeextremelyhigh(171.7MPa).

Fig. 7.Compressivestrengthofmortarmixes[50] 2.2.1.4 Effect of sodium silicate to sodium hydroxide ratio

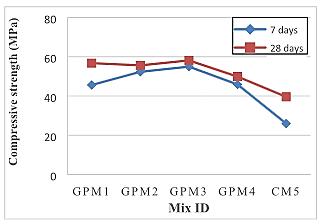

Mostresearches have previouslydealt withGPMas repair materials,withsodiumsilicatetosodiumhydroxidemolar ratios of 2.5 [30,37,44,53] and 2.0 [28,34] kept constant. However, the effect ratios of sodium silicate to sodium hydroxide solution by mass (1:1, 1.5:1, 2:1 and 2.5:1) was studied,and the results were as shown in (Fig.8) [43]. The impact of the sodium silicate to sodium hydroxide concentration ratio on the strength development of geopolymer as a repair material. Besids, sodium silicate solution is characterized by its SiO2 to Na2O weight ratio whichaffectsonstrengthasshowninTable1.

Fig .6.Bindernaturedependentcompressivestrengthof geopolymerpasts[34]

Fig .8 EffectofvaryingratioofSodiumSilicatetosodium hydroxidesolution[43]

Table1:TestresultsoneffectofSiO2 to Na2Oratio

Reference s SiO2 to Na2Oratio Results

Huseien etal.[27] 1.16

The geopolymer mortar with a solutionmolarityof14Mshowed highearlystrengthcomparedto geopolymermortarswithother

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

molarities(10Mand12M).

` Mirzaet al.[33] 2.0

An increase in the ratio (more than 2.0) can decrease the strength at room temperature. Furthermore, when geopolymer mortars were cured at oven temperature(60°C),thestrength of the mortars was increased at higher ratios The strength of geopolymer mortars was somewhatreducedasthecuring temperaturewasincreasedfrom 60to90°C.

compressive strength of the full height 200 mm AAC specimensrangedfrom26.7MPato40.3MPa[64].

Daietal. [42] (0.96,1.28, and1.91)

Foraratioof0.96,compressive strengthofupto47.1MPawas achieved. When the SiO2 to Na2Omolarratiowasraised,the compressive strength was also reduced. the participation of excessive Si ions in the geopolymerization process cause this reduction in the compressivestrength.Ataratio of1.91,thelowestcompressive strength(40.8MPa)wasfound.

Agoodbondstrengthandcompatibilitybetweentheexisting and repair materials are two of the most important characteristics for a repair material [54]. The friction and adhesionbetweentwosurfacesdeterminethebondstrength betweenthem[55 59].Itisthereforenecessarytotakeinto account the level of surface roughness [60]. The bond strengthisdeterminedfromthecombinationofcompressive stressandshearstress[61.62].

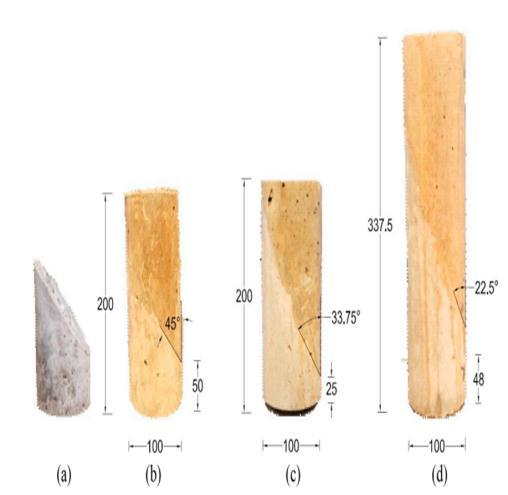

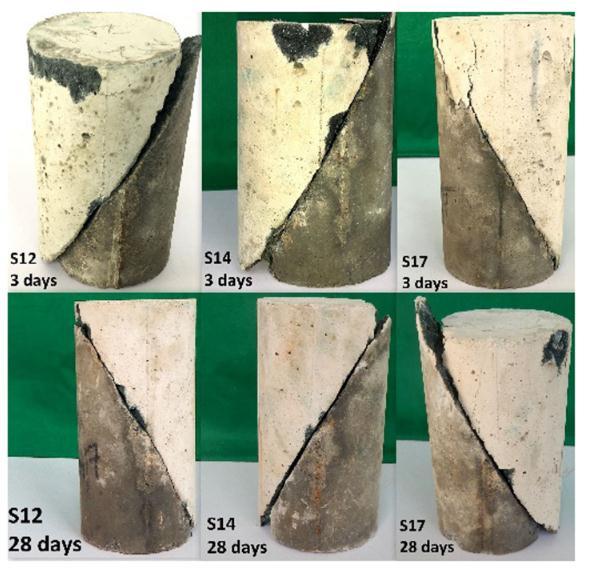

According to Momayez et al. [61], the measured adhesion strengthwasfoundtodecreasewiththetestingprocessin theorderofslantshear,bi surfaceshear,splitting,andpull off.Similarly,LaskarandTalukdar[63]Studiedbondstrength between GPC and PCC with slant angle 30° as shown in (Fig.9)afterthetest,itwasdiscoveredthatthebondbetween theGPCandPCCinterfacewasweakerthanthebondwithin theGPCorPCCmatrixinmixeswithlowbondstrength.The failure surface was along the GPC and PCC interface (see Fig.9).ThefailuresurfaceforGPCwithhigherbondstrength, ontheotherhand,wasnotonlyalongtheinterfacebutalsoin thematrixofGPCorPCC.asshownin(Fig.10).

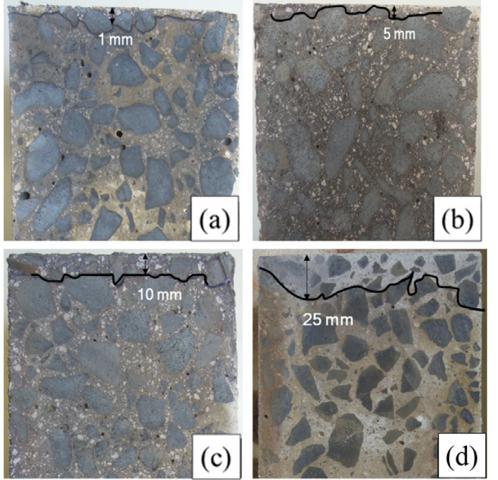

On the other hand, Gomaa et al.[64] Used different slant angles 45°, 33.75°, and 22.5° respectively and different heights of cylinders (200 and 337.5 mm) as shown in (Fig.11).Theresultswere,repairedat45°and22.5°exhibited anexcellentbondwherethesheardemandontherepairwas less than the bond between the substrate and repaired material.Repairsat33.75°displayedacombinationofsliding and damage to either thesubstrate, repaired,or both. The

Fig. 9. Slantsheartestspecimenswithfailureplanealong GPC PCCinterface[38]

Factor value:

Fig.10 .SlantsheartestspecimenswithcracksinGPCand PCCregion[38]

Fig. 11. CementConcretespecimens(a)beforerepairwith aninclinationangleof45°,andafterrepairwithinclination anglesof:(b)45°,(c)33.75°,and(d)22.5°beforeandafter repair[64]

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

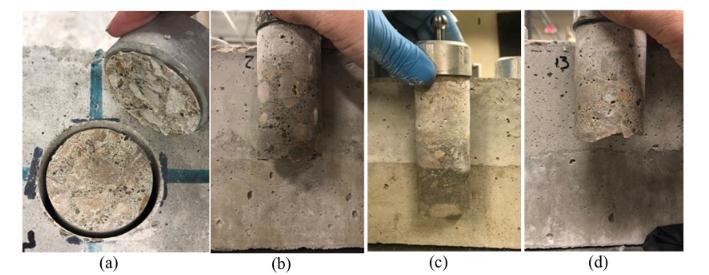

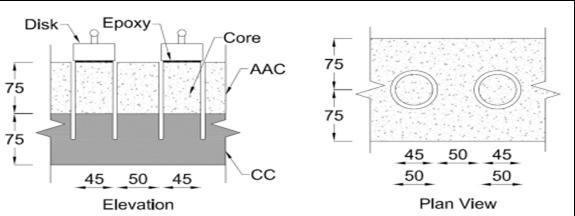

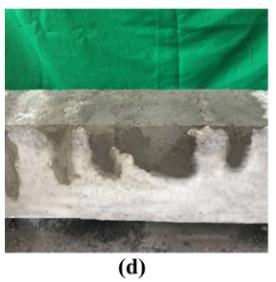

Cement concrete (CC) and alkali activated concrete (AAC) beams with no cold joints were prepared for comparison purposesaswellasthosewithcoldjointsandfull depthCC andAACspecimens.AlayerofCChavingaheightof75mm was placed in each; then, either no surface treatment (Fig.12,13),aconcretebondingadhesiveorsandblastingwas appliedtoeachCCsurface.Thereafter,alayerofAACmixture wasplacedagainsttheCCsurfaceofeachspecimenandthe repairedspeckledspecimenswerecuredasdescribedinthe slantsheartest[65].

Thefailureoftheinterfacebetweenthealuminiumdiscand therepairmaterialsshowedaweakepoxy,andthetestwas consideredafailedtest(Fig.14a).Thesurfacetreatmenthad aneffectonthefailuremodeoftherepairedbeamsforthe remainingbeams.Theinterfacesurfacebetweentherepair andsubstratematerialsfailedinaround90%oftherepaired beamswithnosurfacetreatmentand100%ofthosecoated with the adhesive (Fig. 14b), indicating weak bond strength.Intherepairmaterial,theremaining10%oftheno surface treatment specimens failed (Fig.14c).Furthermore, withintheCCsubstratematerial,100%ofthesandblasted beams failed (Fig.14d), suggesting a good binding strength.[64].

Figure 14 .Failureofthepull offspecimensin:(a)top surfaceoftherepairmaterial,(b)bondsurfacearea,(c) repairmaterial,and(d)substratematerial[64]

Durability of geopolymer based materials

Durability of geopolymer concrete refers to the ability to maintain properties for its service period of exposure to aggressive environments which related to the safety of constructionengineering[66].

According to Xie et al. [67], the durability of geopolymer concreteisregulatedbyanumberofparametersthatrequire morelaboratoryandfieldresearch.Table2alsoshowssome of the most current studies, as well as aluminosilicate precursorsandalkaliactivatorsolutions.

Table 2:Somecurrentstudiesondurabilityofgeopolymer concrete

Referenc e Activator Precursors Durability properties

Bondar etal.[68] KOH+Na2SiO3 NP Sulfate resistance

Fig. 12.CCsubstratesurfacebeforeplacingtheAAC,(a)no treatment,(b)concretebondingadhesive,and(c) sandblasting[65]

Bernalet al.[69] NaOH+Na2SiO3 FA+GGBFS Carbonation resistance

Ghazyet al.[50]

NaOH+Na2SiO3, KOH+Na2SiO3 NaoH+K2SiO3, KOH+K2SiO3

FA

Sulphte, sulphuricacid resistanceand water absorpation

Ariffinet al.[70] NaOH+Na2SiO3 FA+POFA Acidcorrosion resistance

El Sayed etal.[71] NaOH+Na2SiO3 GGBFS Sulfate resistance

Fig.13 .Geometryofthepull offtestbeams (dimensionsareinmm)[65]

Fernande z Jimenez etal.[72] Na2SiO3 FA Heatresistance

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Bernalet al.[73] NaOH+Na2SiO3 MK+GGBF S Chloride resistance

Prabuet al.[74] NaOH+K2SiO3, KOH +Na2SiO3 FA+RHA Acidandsulfate resistance

Khanet al.[75] NaOH+Na2SiO3 FA+GGBFS Carbonation resistance

Nkwaju etal.[76] NaOH+Na2SiO3 LS

Wet drycycles andheat resistance

Parket al.[77] Ca(OH)2 GGBFS Chloride resistance

K.Rames h[36] NaOH+Na2SiO3 GGBFS+FA Sulphuricacid, sodiumchloride resistance

WhereFAisflyash,GGBFSisgranulatedblastfurnaceslag, NPisnaturalpozzolan,LSislateriticsoil,POFAispalmoil fuelash.

Carbonationdamagesconcretestructuresbydecreasingthe alkalinityoftheporesolution,destroyingthesurfaceoxide filmonsteelbars,andeventuallyleadingtostructuralfailure duetointernalexpansionstress[79].

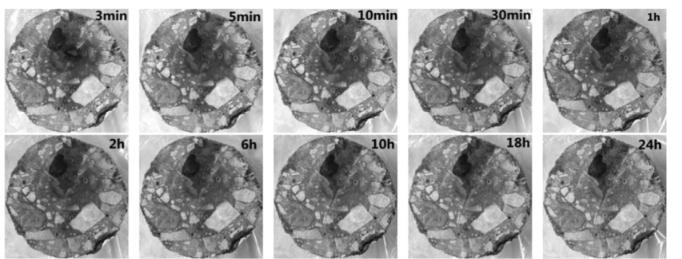

InOPC,thepHismostlycontrolledbythehydrationproduct calcium hydroxide, but in geopolymer concrete, the pH is solelycontrolledbytheporesolution.Duetothecreationof hydrogencarbonateandcarbonates,thepHofgeopolymer concrete decreases noticeably during carbonization [66]. Khanetal.[75]classifiedthedegreeofcarbonationaccording tothechangeofphenolphthaleincolor(includeuncarbonated area,partially carbonated area, and carbonated area), however,theborderbetweencoloredandcolorlessareasis unstable, which is quite different from OPC concrete carbonizationareaasshownin(Fig.15)[80,81].

Bernaletal.[69]observedthatthecompressivestrengthof fly ash/slag based geopolymer decreases linearly after carbonization,whichresultsintheformationofN A S Hgel. It is also reported that geopolymer concretes after carbonation have lower extent of reaction and lower mechanicalproperties[75 78].

Fig. 15.ColorchangeforGPCafteracarbonationtestwith 5%CO2[81]

Manyresearchershavealsoimprovedtheporestructureand reactant composition of geopolymer concrete by adding calcium hydroxide [85], Portland cement [85], nano TiO2 [86],microsilica[87],andslagcontent[82].Lietal.[83]dis covered that the slag activated with NaOH were more resistant (about 13.6 strength loss) to carbonation than NaOH/Na2SiO3(26%).Theadditionofnano TiO2refinesthe microstructure and improves carbonation resistance of fluidizedbedflyashbased geopolymerconcrete.Duanetal. [86]reportedthatthecarbona tiondepthdecreasedwiththe increase of nano TiO2, and the carbonation depths at 180 daysareonly42%tothereferencespecimenswith5wt% addition.Behfarniaetal.[87]investigatedcarbonationdepth of slag based geopolymer concrete produced via partially replacingslagbymicrosilicainproportionof5,10,and15 wt%.Carbonationdepthofconcretebeingcontrolledat4% acceleratedcarbonationintwocycleof14and28days.The resultsshowthatthereplacementslagwithmicrosilicahada pos itive effecton the properties of geopolymer with 32% and34%decreasesincarbonationdepthafter14and28days accelerated carbonation cycles, respectively. However, increasingthe content ofMK in the binder will lead tothe formation of secondary alumi nosilicate phases and increasingthesusceptibilitytocarbonization[84].

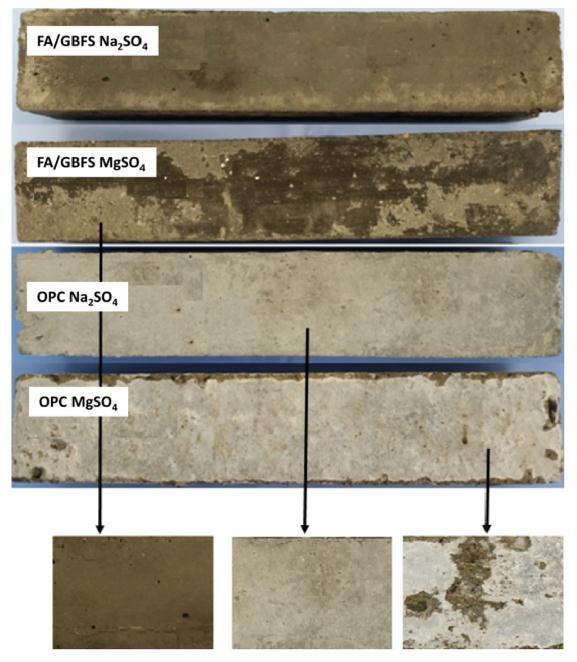

Geopolymererosioninasulphateenvironmenthasdifferent mechanismsdependingoncalciumconcentration.Duetothe similarities of hydration products, high calcium alkali activatedsystemshavesimilarerosionmechanismstoOPC. IncomparisontoMgSO4solution,high calciumsystemshave better resistance in Na2SO4, unlike low calcium systems.Exposure to Na2SO4 appears to encourage geopolymergelstructuralevolution,whileMg2+ insolution promoteshigh calciumsystemdecalcificationandM S Htype phasedecay[89].Saavedraetal.[89]discoveredthatwhen flyash/slaggeopolymerconcretewassubjectedtoMgSO4for 360 days, it lost 33 percent of its mechanical resistance, which was higher than the value inNa2SO4 solution.. Low

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1279

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

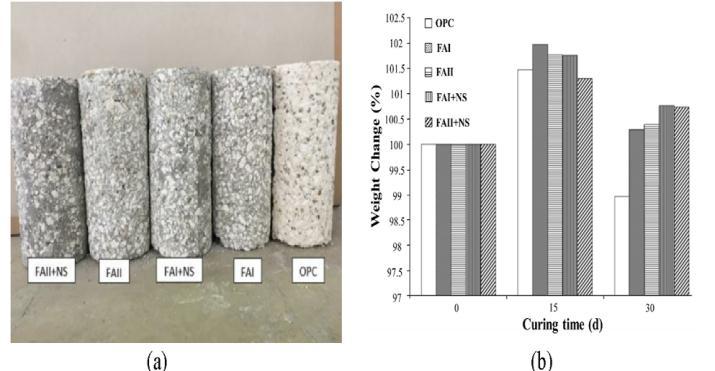

calciumalkali activatedsystems,ontheotherhand,allowfor ionexchangebetweenthesulphatesolutionandthenetwork structure, potentially making it more resistant to sulphate attack[88,90,91].Douglasetal.[92]foundthatafter90and 120 days of exposure to a 5 percent Na2SO4 solution, the visualappearance,mass,strength,expansion,anddynamic modulus of elasticity of slag based geopolymer concrete change little, outperforming OPC concrete. However, after 270days,theflyash/slaggeopolymerconcretehadalarger depositionofsaltsandcracks,andthephysicaldeterioration oftheOPCconcretewasmuchgreaterforthesameexposure periodsasshownin (Fig.16)[89].El Sayedetal.[71]found thataslag basedgeopolymeractivatedwith6wt%NaOHlost 49%ofitsstrengthafter6monthsofexposureto5%MgSO4, comparedto21%activatedNaOHandNa2SiO3(3:3),which could be due to excess hydroxide ions forming excess ettringite.Furthermore,thestrengthofconcreteactivatedby twodifferenttypesofactivatorsisremarkablysimilartothe strengthofconcretecuredatroomtemperature.

andSi O Albonds,resultinginfissuresorcrystallisationof zeolites[70,94].

Bakharevetal.[94]soakedslag basedgeopolymerconcrete in a pH 4 HAc solution for a year and found that the geopolymer lost 33% of itsstrengthcompared to 47% for OPC concrete.In comparison to cement paste, Fernandez Jimenez et al. [95] found that fly ash based geopolymer outperformedcementpasteintermsofcorrosionbehaviour and residual strength. When immersed in 5% H2SO4, the mechanicalpropertiesofflyash basedgeopolymerdegraded somewhatafter28days,accordingtoZhengetal.[64,99],but thecorrodedconcretesstillmettheacidsoakingsafetyindex ofthestandardGB50212 2002[100].

Thevisualappearanceofspecimenssubjectedto5%H2SO4 for30daysisshowninFig.17a[96].Duetothedecreased CaOcontent,theOPCconcretedisplayedsevereerosionwith softwhitedepositionsonthesurface,meanwhiletheflyash based geopolymer remained comparatively intact. The additionofnano silicahasagoodeffectondurability,butthe effect is not apparent under short term acid erosion, as shown in Fig.17. (b). According to Rajak et al. [98], geopolymer concretes with polypropylene fibre addition have higher durability than control, which they ascribe to polypropylene's high resistance to alcohol, organic acids, esters, and ketones, as well as its decreased capillary porosity.Under sulfuric acid attack, Thokchom et al. [97] discoveredthatspecimenswithhigherNa2Oconcentration lost alkalinity faster than those with lower Na2O content, whichhadhigherresidualcompressivestrength.

Fig.16 Visualappearanceofgeopolymerconcretesexposed to5%Na2SO4and5%MgSO4 solutionsfor270days[89]

The depolymerisation ofaluminosilicate polymers and the liberationofsilicicacidinfluenceacidcorrosionresistancein geopolymer concrete [70,93].Visual appearance, physical qualities, weight loss, and corrosion depth of geopolymer/cementconcretecanall beusedtodetermine the degree of acid corrosion [94,95].According to reports, geopolymerconcreteismoreresistanttoaciddamagethan OPCconcrete.Depolymerisationofaluminosilicatepolymers andliberationofsilicicacidinacidsolutionbreaktheSi O Si

Fig.17 .Visualappearance(a)andweightloss(b)of specimensin5%H2SO4 after30days[96]

Chloridebindingmechanismsforalkali activatedmaterials arelinkedinavarietyofways.Ismailetal.[101]andZhanget al. [102] believed that the chloride binding of fly ash slag basedgeopolymerswasprimarilyduetophysicaladsorption, butKeetal.[103]discoveredtwoformsofFriedel'ssaltina

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1280

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Na2CO3 activated slag containing CaCl2 solution.Because of thedifferencesinchemicalcharacteristicsofporefluids,the rapid chloride penetration test (RCPT) utilised for OPC is thoughttobeunsuitableforgeopolymer[104].

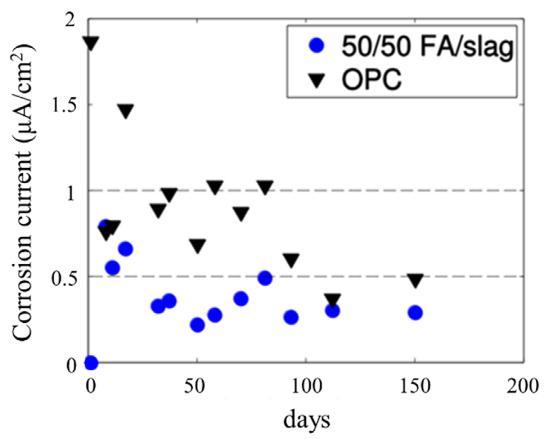

Previously,studiesonthechlorideresistanceofgeopolymer concrete were conducted using several methodologies, including(a)ASTMC1202orAASH TOT277,(b)NTBuild 492, and (c) NT Build 443 [105]. The rapid chloride permeabilitytest,forexample,isbasedontheASTMC1202 measurement of electrical conductivity, with the findings influencedbychangingsolutionchemistryoncurrentflow.As illustrated in (Fig.18), silver nitrate (AgNO3) solution may precipitatethechlorideionandiscommonlyusedtomeasure chloride penetration depths, and the binding gel mix proportion has a significant impact on chloride resistance [101].Ravikumaretal.[105]employedtotalchargepassedto measureNaOHandNa2SiO3activatedslag basedgeopolymer transportcoefficients,whichismoreaccurate.Accordingto earlier studies, the correlation between the electric acceleratedchloridetestandlong termchloridediffusion,as well as the testing method for chloride binding, should be establishedand improved [101,106,107]. Tennakoon etal. [108] discovered that the corrosion current of steel bars madeofflyash/slag basedgeopolymerconcretesubjectedto 0.6 M NaCl solution was lower than that of OPC concrete (Fig.19).

Furthermore,theauthors[108]discoveredthatOPCconcrete hadahigherapparentchloridediffusioncoefficientsolution than geopolymer concrete. Kayyali et al. [109] found that replacing cement with pro portions of slag up to 70% improvedthechlorideresistanceofslag basedgeopolymer concreteoverOPCconcrete.Furthermore,in30percentCaCl2 solutions, there was reduced swelling and cracking of geopolymerconcrete,andin5%MgCl2 solutions,therewas higherstrength[110 111].Figure20(d)furtherdemonstrates thatOPCconcretehasthedeepestchloridepenetrationdepth of25mm,whilegeopolymerconcreteshavedepthsof1to10 mm.Thereactionproducts,hydrotalcite,werediscoveredto absorb chloride ions by Kayyali et al. [109] and Shi et al. [112].

Ismail et al. [101] discovered that the trend of chloride migration coefficients is similar to the results of ponding experiments, and that chloride resistance is linked to structuralcompactnessandporestructure.Parketal.[77] investigatedthechlorideresistanceofslagconcreteactivated byvariousactivatorsina3.0%NaClsolutionfor6hoursat60 V constant voltage. Ca(OH)2 activated the lowest levels of degradation,owingtothecreationofCa(ClO)2 toeliminate freechlorides.Ravikumaretal.[105]alsonotethatchloride penetrationofslag basedgeopolymerconcreteactivatedby KOHandNaOHissimilartothatofOPCconcrete,although Na2SiO3 activated geopolymer has good resistance. The chlorideresistanceofgeopolymerconcretemadewithextra additionswaslikewisestrong. Zhangetal.[113]substituted

theslagwith30wt%lithiumslagparticles,whichresultedin asignificantreductioninchlorideionpenetration.

Fig. 18 .Visualappearancethe(a)slag,(b)slag:flyash=3: 1,(c)slag:flyash=1:1basedgeopolymerconcrete,and (d)OPCconcreteattheendofthepondingtest3.5%NaCl for28days[101]

Fig.19.Corrosioncurrentofsteelbarofgeopolymer comparedtoOPCconcretein0.6MNaClsolution[108].

Because building fires cause large economic losses and casualties, it is critical to improve the heat resistance of concrete in order to ensure the protection of people and property [116]. The hydration product of OPC paste is degraded and dehydrated at temperatures of around 300

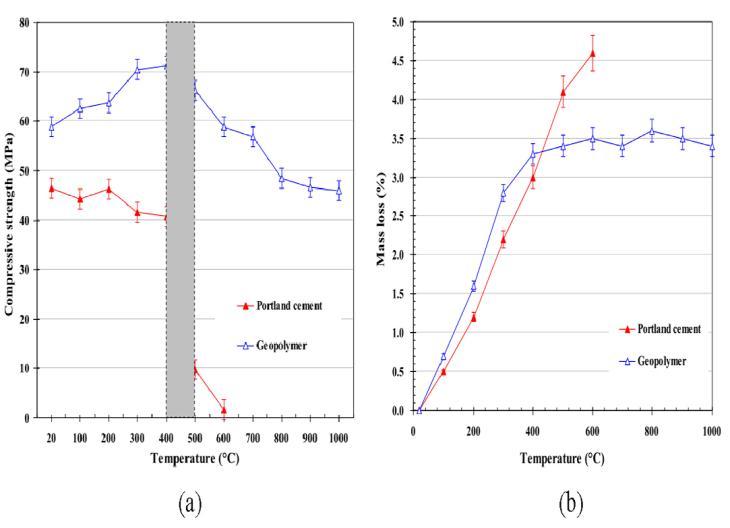

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

400°C,afterwhichwaterandentrainedairbreaktheinternal walls of the micropores, causing a rapid loss of strength [114,115]. When compared to OPC concrete, geopolymer concreteshaveahigherheatresistance.WhenGourleyetal. [117] evaluated the heat resistance of geopolymer and cement,theydiscoveredthattheformerisessentiallyatype of glass, unlike cement is a hydrate. Heat resistance of geopolymer ismeasuredusing visual appearance, residual strength, and thermal conductivity [115,118]. Duan et al. [94] looked into it. Temperature profile, compressive strength, and stability were used to measure thermal durability.(Fig.20a)illustratesthis.AlsoreportedInstability andshrinkageareadditionalsignsofgeopolymerconcrete's heatresistance.After600°Cexposure,geopolymerconcrete loses less mass than OPC concrete due to Ca (OH)2 decomposition of OPC (Fig.20b). Metakaolin based geopolymershaveanamorphousstructureandnophaseshift at1000°C,according toTemuujinetal. [119]. Perera etal. [120]discoveredthatat1200°Ccuring,phasewasnotmuch melted,primarilyintheformofleucite.AccordingtoYeetal. [121],atailing/slag basedgeopolymer'sstrengthreducesby morethan40MPaaftera1000°Cfire,butincreasesaftera 1200°C fire, which could be due to sintering and densification. The fly ash based geopolymer contractedby around1%between200and300°C,andanother0.6percent between700and800°C,accordingtoKongetal.[122].

Furthermore,itwasdiscoveredthatthegeopolymermortar coatingwascorrosionresistantandproducedstrongbonding tothereinforcingsteel[127].

Geopolymer concrete has recently been used as a pipeline coatingmaterial.Biogeniccorrosionofwastewaterpipelines was studied using three different coating materials [128]. Geopolymer,OPC,andnumerouscompositecoatingsmadeof geopolymer magnesium phosphate were used to produce these coating materials in wastewater pipelines. materials were investigated for accelerated biocorrosion after six monthsofcorrosion,thecoatingmaterials'flexuralstrength was measured. In comparison to the other coatings, the multiplephasecoatingshowedgoodcorrosionresistanceand bond strength, according to the test results. Furthermore, repairswithnewconcretemayresultinmacro cellcorrosion [129].

Fig. 20. Compressivestrengthchange(a)andweightloss (b)ofspecimenscuringatvarioustemperaturesfor28 days[114]

Alkali activated geopolymerconcretes have been reported fortheirfireandchlorideresistance,aswellas acorrosion resistantcoatingmaterial[122 125].

McAlorumetal.(2021)[126]createdanautomatedsensing coating of geopolymer for structural repairs. Curing aluminosilicatewithanalkalineactivatorsolutionat40°Cfor 1 3daysproducedabinderwithhighadhesiveproperties.

This was not looked into in the research. Al Majidi et al. (2019)[130]usedfibre reinforcedgeopolymerconcreteto strengthen beams and then exposed them to accelerated corrosion. GGBFS, silica fume, polyvinylalcohol, and steel fibreswerecombinedtomakeafibre reinforcedgeopolymer. Whencomparedtostandardsteel concretebeams,thetest resultsafterapplyinga fibrereinforcedgeopolymerjacket demonstrated higher corrosion resistance, reduced crack propagation,andhigherflexuralcapabilities.Incomparison to OPC, some researchers [131] produced a new type of geopolymer based composite piles with geogrid, polyvinyl chloride,andfibrereinforcedpolymerthatwerecorrosion resistantandveryductile.Shearstrengtheningofreinforced concrete beams was achieved using textile geopolymer concrete[132]. LaskarandTalukdar(2017)[133]presented ageopolymerrepairmethodcontainingultrafineGGBFS,FA and alkali activator with a suitable amount of superplasticizer. The geopolymer concrete's compact microstructure produced good bond strength and compressive strength.Similarly, Zanotti et al. (2017) [134] proposed using metakaolin geopolymer mortar to repair Portland cement concrete structures.OPC substrate and metakaolingeopolymermortarwithandwithoutpolyvinyl alcoholfibreswereused.Early agecrackingwasapparentin thespecimenswithmetakaolingeopolymermortarscuredin anambientenvironment,bothingeneralandattheinterface between OPC substrate concrete and geopolymer repair mortar.Howevercohesionwasfoundtobeimprovedwhen polyvinylalcoholfibreswereadded,aspreviouslyreported [135]. There are a few other important research on the flexural strength of geopolymer concrete beams [136], structural retrofitting [129,136 139] , and geopolymer concretebond slip[137].Steelfibrereinforcedgeopolymer matrixcompositeswereusedbyCarabbaetal.2017[140]to strengthen reinforced structures.The results show that reducingthemolarcontentoftheNaOHactivatingsolution improvestheinterfacialbondbehaviourbetweenmatrixand fibres,whichimprovestheeffectivenessofthestrengthening system'scompositeaction.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1282

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Researchershavealsousedgeopolymerconcretesmadeof MKandFandCclassesofFAforburiedinfrastructurerepairs andcomparedthemtoOPC[141]. Amongalltheothertypes of concrete, geopolymer concrete with class F FA was determined to be the most durable, while the other geopolymerconcreteswerealmostascomparableasOPC.

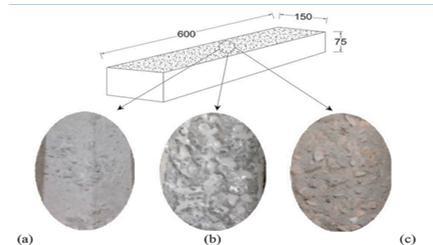

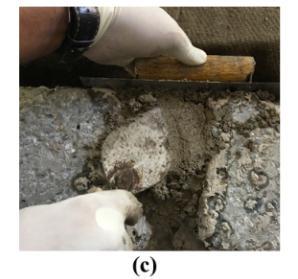

Laskaretal.2019[142] repaireddoublyreinforcedbeamsof 2 meter length of OPC with GGBFS and class F FA geopolymer.Reinforcedconcretebeamsweresubjectedto flexuralfailureafter28daysofcuring.Afterthebeamshave been loaded, cracks appear in various ratios as shown in (Fig.21) and then repaired by geopolymer and Portland cement mortar as shown in (Fig.22) for further flexural testing.

TheperformanceofthePCMrepairedfullydamagedRCbeam at 28 days was lower than that of the GPM repaired fully damagedRCbeamat3days.Therepairedbeam'sstiffness wasfoundtobehigherthanthatofthePCMrepairedbeam. DuetotheuseofGPMasarepairingagentversusPCMasa repairingagent,theappearanceofthefirstcrackwasdelayed comparedtothePCMrepairedbeam.Theearlycompressive andbondstrengthincreaseofGPMwascriticalinarresting the cracks and, as a result, the crack development and propagationintheGPMrepairedbeam.Incomparisontothe PCM repaired fully damaged RC beam, the PCM repaired partiallydamagedRCbeamhadahigherstiffness.Thevalues exhibitedbyGPMrepairedpartiallydamagedRCbeamswere muchhigherthanthoseexhibitedbyGPMandPCMfixedfully damaged RC beams. The flexural capacity of the repaired beamwithgeopolymermortarwasfoundtobebetterthan thatwithPortlandcementmortar.

Fig.22.(a)Airblower,(b)applyingpasteusingsyringe,(c) applyingmortarusingtrowel(d)RCbeamafterrepair [142]

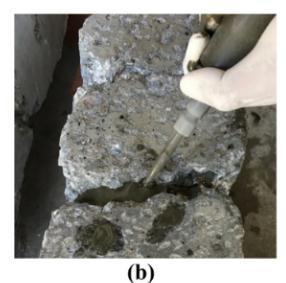

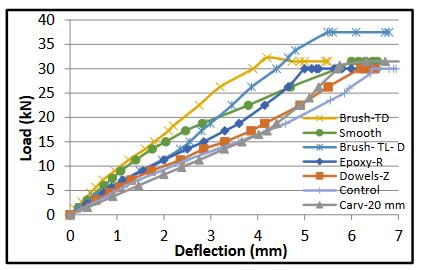

Ghazyetal.2021[143] usedthecementbasebondedoverlay techniquetoincreasetheflexuralcapacityofconcreteslabs by applying overlay layer of geopolymer concrete on an existingslab.Atfirst,theeffectofdifferenttypesofroughness onbondstrengthbetweensubstrateRCandGPCoverlaywas studied. for this the substrate concrete surfaces were roughenedbydifferenttechniquesshownin(Fig.23)andleft atambienttemperaturefor7daysthencastedtheoverlay.

All slabstestedafter3months themeasureddeflectionat midspan,crackspatternandfailuremodeoftestedslabsare shown in (Fig. 24, 25). According to results, the type of interface roughness determines the slab's ductile performance,notjusttheadditionofGPCtothetoppinganda stiffbrushwasusedtoroughenthesurfaceinthetransverse directions,whichreducedthecrackswidthandchangedthe failuremodetoonethatwasmoreductile.

21

Thecurrentreviewsummarizespreviousstudiesthatwere concernedwithusinggeopolymerbasedmaterialsasarepair andstrengtheningmaterialsthatcanbesummarizedinthe following:

1. Geopolymer mortars workability can be reduced by increasingsodiumhydroxideconcentrationandalsowitha highreplacementofMKandcalciumhydroxide.

2. The compressive strength is increased with elevated sodiumhydroxideconcentration.However,Thechemical compositions of the FA used resulted in changes in the compressive strength of geopolymer concrete.The compressivestrengthbasedFAincreasedwhenthecalcium concentrationwasincreased.

3. Alkaline activation of aluminosilicate wastes in the presence of silica fume and metakaolin using sodium hydroxideandsodiumsilicateintheratioof3:3wt.%leads to the formation of a geopolymer that possess an enhancement in both mechanical and microstructural properties.Theprocesscanhelpinanidealutilizationof demolitionwastesindisposal landfillsall overtheworld andproducevaluablesustainablematerials.

4. The durability of fly based geopolymer concrete is greatlygovernedbytheinternalconfigurationofalumino silicategelcomponentsinextremeenvironments.TheGPCs madewitha sodiumsilicateactivatorarelesscrystalline thanthosemadewithsodiumhydroxide.

5.ThedurabilityofgeopolymerconcreteisbetterthanOPC concrete. It displays as geopolymer concrete has lower strengthlossandslighterosioninacid,sulfate,andchloride solution,andminorsurfacecracklingsoccurredafterhigh temperatureexposure.However,geopolymerconcreteafter carbonation has a lower extent of reaction and lower mechanicalpropertiesmainlyduetoahigherCa/Siratioof C S HgelofOPCconcrete.

6. There is no significant changes in the mass and the compressivestrengthoftestspecimensafterexposureto acid up to one month. Exposure to sulphuric acidcauses damagetothesurfaceofheat curedgeopolymerconcrete testspecimensandcausesamasslossaftertheexposure. The severity of the damage depends on the acid’s concentrationandtheperiodofexposure.

7.Thegeopolymericrepairmaterialspossessbetterrepair characteristicsthancement basedrepairmaterials.

8.Geopolymer mortaronusingasconcreterepairingaget showbetterperformancethanPortlandcementmortar.A GGBFS based geopolymer mortar can be used to successfullyrepairreinforcedconcretestructuralmembers.

Thisreviewcanassistresearchersintheirfuturestudieson theuseofgeopolymerbasedmaterialsintherepairworkof deteriorated concrete and can also assist in the development of decision tools and strategies for maintenanceandrepairsforassetmanagersandownersto reducethissignificantcost.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[1]Melchers,R.E.,&Chaves,I.A.Servicelifeestimationof concrete infrastructures. Eco Efficient Repair and Rehabilitation of Concrete Infrastructures, 15 41(2018).. doi:10.1016/b978 0 08 102181 1.00002 2

[2] Amran,M.,Al Fakih,A.,Chu,S.H.,Fediuk,R.,Haruna,S., Azevedo,A.,&Vatin,N.Long termdurabilitypropertiesof geopolymer concrete: An in depth review. Case Studies in ConstructionMaterials,(2021). 15,e00661.

[3] Yadav,R.,KumarSingh,P.,&Chaturvedi,R.Enlargement of geo polymer compound material for the renovation of conventional concrete structures. Materials Today: Proceedings ,45,3534 3538. doi:10.1016/j.matpr.2020.12.974.

[4]Shi,Jinyan;Liu,Baoju;Qin,Jiali;Jiang,Junyi;Wu,Xiang; Tan, Jinxia (2020). Experimental study of performance of repair mortar: Evaluation of in situ tests and correlation analysis.JournalofBuildingEngineering,(2002),101325 doi:10.1016/j.jobe.2020.101325

[5]Shah,K.W.,&Huseien,G.F.(2020).RecycledCeramicsin Sustainable Concrete: Properties and Performance. CRC Press.

[6]Nodehi,M.(2021).Epoxy,polyesterandvinylesterbased polymer concrete: a review. Innovative Infrastructure Solutions,7(1),1 24.

[7]Wang,Y. S.,Peng,K. D.,Alrefaei,Y.,&Dai,J. G.(2021).The bondbetweengeopolymerrepairmortarsandOPCconcrete substrate:Strengthandmicroscopicinteractions.Cementand Concrete Composites, 119, 103991. doi:10.1016/j.cemconcomp.2021.103991

[8]Wu,X.,Tian,J.,Ma,H.,Zheng,Y.,Hu,S.,Wang,W.,...&Zhu, Z.(2020).Investigationoninterfacefracturepropertiesand nonlinear fracture model between ECC and concrete subjected to salt freeze thaw cycles. Construction and Building Materials, 259, 119785. doi:10.1016/j.conbuildmat.2020.119785.

[9]Saliah,S.N.M.,Nor,N.M.,AbdRahman,N.,Abdullah,S.,& Tahir, M. S. (2021). Evaluation of severely damaged reinforcedconcretebeamrepairedwithepoxyinjectionusing acoustic emission technique. Theoretical and Applied Fracture Mechanics, 112, 102890. doi:10.1016/j.tafmec.2020.102890.

[10]Modesti,L.A.,deVargas,A.S.,&Schneider,E.L.(2020). Repairing concrete with epoxy adhesives. International Journal of Adhesion and Adhesives, 101, 102645. doi: 10.1016/j.ijadhadh.2020.102645.

[11]Gao,S.,Zhao,X.,Qiao,J.,Guo,Y.,&Hu,G.(2019).Studyon the bonding properties of Engineered Cementitious Composites (ECC) and existing concrete exposed to high temperature.ConstructionandBuildingMaterials,196,330 344.doi:10.1016/j.conbuildmat.2018.11.136.

[12] Ghazy, M.. F, Taman M.H, El Ahwal R.. M. (2020). PROPERTIESOFREACTIVEPOWDERCONCRETEANDIT'S UTILIZING AS A REPAIR AND STRENGTHEN MATERIALS. MEJ.MansouraEngineeringJournal,42(3),21 29.

[13]Wasim,M.,Ngo,T.D.,&Law,D.(2021).Astate of the art review on the durability of geopolymer concrete for sustainablestructuresandinfrastructure.Constructionand Building Materials, 291, 123381. doi:10.1016/j.conbuildmat.2021.123381.

[14] McAlorum,J.,Vlachakis,C.,&Perry,M.(2021,May).A low costelectricalimpedanceanalyserforinterrogatingself sensing cement repairs. In 2021 IEEE International InstrumentationandMeasurementTechnologyConference (I2MTC)(pp.1 6).IEEE.

[15] Huseien, G. F., Mirza, J., Ismail, M., Ghoshal, S. K., & Hussein, A. A. (2017). Geopolymer mortars as sustainable repair material: A comprehensive review. Renewable and Sustainable Energy Reviews, 80, 54 74. doi:10.1016/j.rser.2017.05.076

[16] Chen, K., Wu, D., Xia, L., Cai, Q., & Zhang, Z. (2021). Geopolymer concrete durability subjected to aggressive environments Areviewofinfluencefactorsandcomparison with ordinary Portland cement. Construction and Building Materials, 279, 122496. doi:10.1016/j.conbuildmat.2021.122496

[17] Albidah, A. S. (2021). Effect of partial replacement of geopolymer binder materials on the fresh and mechanical properties:Areview.CeramicsInternational,47(11),14923 14943.doi:10.1016/j.ceramint.2021.02.127

[18] Zhang. P, Wang. K. X, Q.F. Li, J. Wang, Y.F. Ling, Fabricationandengineeringpropertiesofconcretesbasedon geopolymers/alkali activated binders A review, J. Clean. Prod.258(2020).120896.

[19]Zhang.H.Y, Kodur.V,Wu.B,Cao.L,Wang.F,Thermal behavior andmechanical properties of geopolymer mortar afterexposuretoelevatedtemperatures,Constr.Build.Mater. 109(4)(2016)17 24.

[20]Singh. B, Ishwarya. G, Gupta. M, Bhattacharyya. S. K, Geopolymer concrete: A review of some recent developments,Constr.Build.Mater.85(2015)78 90.

[21] Davidovits.J,GeopolymerChemistryandApplications, GeopolymerInstitute,Thirded.2014.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1285

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[22]Al mashhadani.M.M.,Canpolat.O,Aygörmez.Y,Uysal. M,ErdemS,Mechanicalandmicrostructuralcharacterization of fiber reinforced fly ash based geopolymer composites, Constr.Build.Mater.167(2018)505 513.

[23]Xie.T.Y,Visintin.P,Zhao.X.Y,Gravina.R,Mixdesignand mechanical properties of geopolymer and alkali activated concrete:Reviewofthestateofthe artandthedevelopment ofanewunifiedapproach,Constr.Build.Mater.256(2020). 119380.

[24]Sreevidya.V,Investigationsontheflexuralbehaviourof ferrogeopolymercompositeslabs,2014.

[25]Abbas.R,Khereby.M.A,Ghorab.H.Y,Elkhoshkhany.N, Preparation of geopolymerconcrete using Egyptiankaolin clayandthestudyofitsenvironmentaleffectsandeconomic cost,CleanTechnol.Environ.Policy22(4)(2020)669 687.

[26]Hassan.A,Arif.M,Shariq.M,Useofgeopolymerconcrete for a cleaner and sustainable environment A review of mechanicalpropertiesandmicrostructure,J.Clean.Prod.223 (2019)704 728.

[27]HuseienGF,MirzaJ,IsmailM,GhoshalS,AriffinMAM. Effectofmetakaolinreplacedgranulatedblastfurnaceslagon fresh and early strength properties of geopolymer mortar. AinShamsEngJ2016.

[28]Phoo ngernkhamT,SataV,HanjitsuwanS,RidtirudC, HatanakaS,ChindaprasirtP.Highcalciumflyashgeopolymer mortarcontainingPortlandcementforuseasrepairmaterial. ConstrBuildMater2015;98:482 8.

[29]Wang.HuS,Zhang.H.G,Ding.Q.Bondingandabrasion resistanceofgeopolymericrepairmaterialmadewithsteel slag.CemConcrCompos2008;30:239 44.

[30] Moura D, Vasconcelos E, Torgal FP, Ding Y. Concrete repair with geopolymeric mortars: influence of mortars compositionontheirworkabilityandmechanicalstrength.VI InternationalMaterialsSymposium(Materials2011)2011.

[31] Lee W, Van Deventer J. The effects of inorganic salt contaminationonthestrengthanddurabilityofgeopolymers. ColloidsSurfA:PhysicochemEngAsp2002;211:115 26.

[32] AbdElaty,M.A.A.,Ghazy,M.F.,&AbdElHameed,M..F. (2017). Optimization of geopolymer concrete by Principal ComponentAnalysis.ACIMaterialsJournal,114(2),253.

[33]HuseienGF,MirzaJ,IsmailM,HussinMW.Influenceof different curing temperatures and alkali activators on properties of GBFS geopolymer mortarscontaining flyash andpalm oilfuelash.ConstrBuildMater2016;125:122940.

[34]Phoo ngernkhamT,MaegawaA,MishimaN,HatanakaS, Chindaprasirt P. Effects of sodium hydroxide and sodium silicatesolutionsoncompressiveandshearbondstrengthsof FA GBFSgeopolymer.ConstrBuildMater2015;91:1 8.

[35] Haneefa KM, Santhanam M, Parida F. Performance characterizationofgeopolymercompositesforhotsodium exposed sacrificial layer in fast breeder reactors.Nucl Eng Des2013;265:542 53.

[36] KumarS,KumarR,MehrotraS.Influenceofgranulated blastfurnaceslagonthereaction,structureandpropertiesof flyashbasedgeopolymer.JMaterSci2010;45:607 15.

[37] Hawa A, Tonnayopas D, Prachasaree W. Performance evaluation and microstructure characterization of metakaolin based geopolymer containing oil palm ash. Sci WorldJ2013:2013.

[38] Van Jaarsveld J, Van Deventer J, Lukey G. The characterisation of source materials in fly ash based geopolymers.MaterLett2003;57:1272 80.

[39] Chindaprasirt P, De Silva P, Sagoe Crentsil K, HanjitsuwanS.EffectofSiO2andAl2O3onthesettingand hardeningofhighcalciumflyash basedgeopolymersystems. JMaterSci2012;47:4876 83.

[40]WinnefeldF,LeemannA,LucukM,SvobodaP,Neuroth M.Assessmentofphaseformationinalkaliactivatedlowand high calcium fly ashes in building materials. Constr Build Mater2010;24:1086 93.

[41] Temuujin J, Williams R, Van Riessen A. Effect of mechanical activation of fly ash on the properties of geopolymercuredatambienttemperature.JMaterProcess Technol2009;209:5276 80.

[42]DaiY,YangL,DingY,JhongC,ChengT,LinK.AStudyon ApplicationofGeopolymericGreenCement.

[43] Ghazy. M .F, Abd Elaty. M .A.A, and El Behary. N, MechanicalPropertiesofFiberReinforcedGeopolymerBased MaterialsInternationalConferenceonAdvancesinStructural andGeotechnicalEngineeringICASGE’1925 28March2019, Hurghada,Egypt.

[44]VasconcelosE,FernandesS,deAguiarB,Pacheco Torgal F. Concrete retrofitting G. Fahim Huseien et al. Renewable andSustainableEnergyReviews80(2017)54 74usingCFRP andgeopolymermortars.MaterSciForum:TransTechPubl 2013:427 32.

[45] Somna K, Jaturapitakkul C, Kajitvichyanukul P, ChindaprasirtP.NaOH activatedgroundflyashgeopolymer curedatambienttemperature.Fuel2011;90:2118 24.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1286

[46] Temuujin J, Williams R, Van Riessen A. Effect of mechanical activation of fly ash on the properties of geopolymercuredatambienttemperature.JMaterProcess Technol2009;209:5276 80.

[47] Temuujin J, Van Riessen A, Williams R. Influence of calciumcompoundsonthemechanicalpropertiesofflyash geopolymerpastes.JHazardMater2009;167:82 8.

[48] Rattanasak U, Chindaprasirt P. Influence of NaOH solutiononthesynthesisofflyashgeopolymer.MinerEng 2009;22:1073 8.

[49] Rashad A, Bai Y, Basheer P, Milestone N, Collier N. Hydration and properties of sodium sulfate activated slag. CemConcrCompos2013;37:20 9.

[50]Ghazy,M.F.,AbdElaty,M.A.,Taman,M.,&Eissa,M.E. (2022, April). Durability performance of geopolymer ferrocementpanelspreparedbydifferentalkalineactivators. InStructures(Vol.38,pp.168 183).Elsevier.

[51]IsmailI,BernalSA,ProvisJL,SanNicolasR,HamdanS, van Deventer JS. Modification of phase evolution in alkali activatedblastfurnaceslagbytheincorporationofflyash. CemConcrCompos2014;45:125 35.

[52] Duxson P, Fernández Jiménez A, Provis JL, Lukey GC, Palomo A, Van Deventer J. Geopolymer technology: the currentstateoftheart.JMaterSci2007;42:2917 33.

[53] Torgal FP, Gomes J, Jalali S. Bond strength between concrete substance and repair materials: comparisons betweentungstenminewastegeopolymericbinderversus currentcommercialrepairproducts;2006.

[54]Pacheco Torgal.F,BarrosodeAguia. J,Ding.Y,Tahri.W, Baklouti. S,23 performanceofalkali activatedmortarsfor therepairandstrengtheningofOPCcon crete,Handbookof Alkali ActivatedCements,MortarsandConcretes,Woodhead Publishing,Oxford,2015,pp.627 641.

[55]Randl.N,Designrecommendationsforinterfaceshear transferinfibModelCode2010,Struct.Concr.14(3)(2013) 230 241.

[56]Mohamad.M.E,Ibrahim.I.S,Abdullah.R,Rahman.A.B.A, Kueh.A.B.H,Usman.J,Frictionandcohesioncoefficientsof compositeconcrete to concretebond, Cem.Concr.Compos. 56(2015)1 14.

[57] Gadri. K, Guettala. A, Evaluation of bond strength betweensandconcreteasnewrepairmaterialandordinary concrete substrate (the surface roughness effect), Constr.Build.Mater.157(2017)1133 1144.

[58]Tayeh.B.A,AbuBakar.B.H,MegatJohari. M.A,Voo.Y.L, Mechanical and per meability properties of the interface between normal concrete substrate and ultra high performancefiberconcreteoverlay,Constr.Build.Mater.36 (2012)538 548.

[59] Júlio. E.N.B.S, Branco. F.A.B, Silva. V.T.D,. Concrete to concrete bond strength.Influence of the roughness of the substratesurface,Constr.Build.Mater.18(9)(2004)675 681.

[60]Perez.F,Bissonnette.B,Gagné.R,Parametersaffecting the debonding risk of bonded overlays used on reinforced concreteslabsubjectedtoflexuralloading,Mater.Struct.42 (5)(2009)645 662.

[61]Momayez.A,Ehsani.M.R,Ramezanianpour.A.A,Rajaie. H, Comparison of methodsfor evaluating bond strength betweenconcretesubstrateandrepairmaterials,Cem.Concr. Res.35(4)(2005)748 757.

[62]Momayez. A, A.A.R.H.R.,Ehsani. M.R, Bi surfaceshear testforevaluatingbondbetweenexistingandnewconcrete, MaterialsJournal101(2)(2004).

[63] Laskar. S.M, Talukdar. S, Preparation and tests for workability,compressiveandbondstrengthofultra fineslag basedgeopolymerasconcreterepairingagent,Constr.Build. Mater.15(154)(2017)176 190.

[64]Gomaa,E.,Gheni,A.,&ElGawady,M.A.(2020).Repairof ordinary Portland cement concrete using ambient cured alkaliactivated concrete: Interfacial behavior.Cement and Concrete Research, 129, 105968. doi:10.1016/j.cemconres.2019.105968.

[65]ASTM C1059,StandardSpecificationforLatexAgents forBondingFreshtoHardenedConcrete,AmericanSociety forTestingMaterials,2013.

[66] Chen, K., Wu, D., Xia, L., Cai, Q., & Zhang, Z. (2021). Geopolymer concrete durability subjected to aggressive environments Areviewofinfluencefactorsandcomparison with ordinary Portland cement. Construction and Building Materials,279,122496. doi:10.1016/j.conbuildmat.2021.122496.

[67]Xie.T.Y,Visintin.P,ZhaoX.Y,Gravina.R,Mixdesignand mechanical properties of geopolymer and alkali activated concrete:Reviewofthestate of the artandthedevelopment ofanewunifiedapproach,Constr.Build.Mater.256(2020). 119380.

[68] Bondar. D, Lynsdale. C.J, Milestone. N.B, Hassani. N, Sulfateresistanceofalkaliactivatedpozzolans,Int.J.Concr. Struct.Mater.9(2015)145 158.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1287

[69]Bernal.S.A,Provis.J.L,Walkley.B,Nicolas.R.S,Gehman. J.D,Brice.D.G,A.R.Kilcullen,P.Duxson,J.S.J.vanDeventer,Gel nanostructureinalkali activatedbindersbasedonslagand fly ash, and effects of accelerated carbonation, Cem. ConcrRes.53(2013)127 144.

[70] M.A.M. Ariffin, M.A.R. Bhutta, M.W. Hussin, M. Mohd Tahir, N. Aziah, Sulfuric acid resistance of blended ash geopolymerconcrete,Constr.Build.Mater.43(2013)80 86.

[71] El Sayed. H.A, Abo. E.E.S, Khater. H.M, Hasanein. S.A, Resistanceofalkali activatedwater cooledslaggeopolymer tosulphateattack,Ceram.Sili.55(2011)153 160.

[72]Fernandez Jimenez.A,Pastor.J.Y,Martin.A,Palomo.A, High temperatureresistanceinalkali activatedcement,J.Am. Ceram.Soc.93(10)(2010)3411 3417.

[73] Bernal. S.A, R.M. de Gutierrez, Provis. J.L, Engineering and durability properties of concretes based on alkali activatedgranulatedblastfurnaceslag/metakaolinblends, Constr.Build.Mater.33(2012)99 108.

[74] Prabu. B, Shalini. A, Kumar. J.K, Rice husk ash based geopolymer concrete Areview, Chem. Sci. Rev. Lett. 3 (2014)288 294.

[75] Khan. M.S.H, Noushini. A., Castel. A., Carbonation of a low calciumflyashgeopolymerconcrete,Mag.Concr.Res.69 (1)(2017)24 34.

[76]Nkwaju.R.Y,Djobo.J.N.Y,Huisken.J.N.F,Dentou.J.G.N, Courard. L, Iron rich laterite bagasse fibers based geopolymercomposite:Mechanical,durabilityandinsulating properties,Appl.ClaySci.183(2019).105333.

[77] Park. J.W, Ann. K.Y, Cho. C.G, Resistance of alkali activatedslagconcretetochloride inducedcorrosion,Adv. Mater.Sci.Eng.2015(2015)1 7.

[78] Fernandez. B.M, Simons. S.J.R, Hills. C.D, Carey. P.J, A review of accelerated carbonation technology in the treatment of cement based materials and sequestration of CO2,J.Hazard.Mater.112(3)(2004)193 205.

[79] Liu, R, Jiang. L, Xu. J, Xiong. C, Song. Z, Influence of carbonationonchlorideinducedreinforcementcorrosionin simulatedconcreteporesolutions,Constr.Build.Mater.56 (2014)16 20.

[80]Chang.C.F,Chen.J.W,Theexperimentalinvestigationof concrete carbonation depth, Cem. Concr. Res. 36 (2006) 1760 1767.

[81] Li.Z.G,Li.S,Carbonationresistanceofflyashand blastfurnaceslagbasedgeopolymerconcrete,Constr. Build.Mater.163(2018)668 680.

[82] Li.Z.G,Li.S,Carbonationresistanceofflyashand blastfurnaceslagbasedgeopolymerconcrete,Constr. Build.Mater.163(2018)668 680.

[83]Li.N,Farzadnia.N,Shi.C.J,Microstructuralchangesin alkali activated slag mortars induced by accelerated carbonation,Cem.Concr.Res.100(2017)214 226.

[84]Bernal.S.A,R.M.deGutierrez,Provis.J.L,V.Rose,Effect of silicate modulus and metakaolin incorporation on the carbonationofalkalisilicate activatedslags,Cem.Concr.Res. 40 (2010) 898 907.

[85]Huang.G.D,Ji.Y.S,Li.J,Hou.Z.H,Jin.C,Useofslakedlime and Portland cement to improve the resistance of MSWI bottomash GBFSgeopolymerconcreteagainstcarbonation, Constr.Build.Mater.166(2018)290 300.

[86] P. Duan, C.J. Yan, W.J. Luo, W. Zhou, Effects of adding nano TiO2 on compressive strength, drying shrinkage, carbonationandmicrostructureoffluidizedbedflyashbased geopolymerpaste,Constr.Build.Mater.106(2016)115 125.

[87]Behfarnia.K,Rostami.M,Anassessmentonparameters affectingthecarbonationofalkali activatedslagconcrete,J. Clean.Prod.157(2017)1 9.

[88]Wang.A.G,Zheng.Y,Zhang.Z.H,Zhang.K.W,Liu.K.W,Li. Y,Shi.L,Sun.D.S,Thedurabilityofalkali activatedmaterials in comparison with ordinary Portland cements and concretes:Areview,Engineering6(6)(2020)695 706.

[89]Saavedra.W.G.V,Angulo.D.E,MejíadeGutiérrez.R,Fly ash slag geopolymer concrete: resistance to sodium and magnesiumsulfateattack,J.Mater.Civ.Eng.28(12)(2016) 04016148.

[90] Rodríguez. E, Bernal. S, R.M.d. Gutiérrez, Puertas. F, Alternative concrete based on alkali activated slag, Mater. Constr. 58 (291) (2008) 53 67.

[91]Alcamand.H.A,Borges.P.H.R,Silva.F.A,Trindade.A.C.C, Theeffectofmatrixcompositionandcalciumcontentonthe sulfatedurabilityofmetakaolinandmetakaolin/slagalkali activatedmortars,Ceram.Int.44(5)(2018)5037 5044.

[92]Douglas.E,Bilodeau.A,Malhotra.V.M,Propertiesand durabilityofalkali activatedslagconcrete,ACIMater.J.89 (1992).

[93]Bakharev.T,Resistanceofgeopolymermaterialstoacid attack,Cem.Concr.Res.35(2005)658 670.

[94] Fernandez Jimenez. A, Garcia Lodeiro. I, Palomo. A, Durabilityofalkali activatedflyashcementitiousmaterials,J MaterSci42(2007)3055 3065.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1288

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[95]Cevik.A,Alzeebaree. R,Humur. G,Nis.A,Gulsan.M.E, Effect of nano silica on the chemical durability and mechanical performance of fly ash based geopolymer concrete,Ceram.Int.44(11)(2018)12253 12264.

[96] Thokchom. S, Ghosh. P, Ghosh. S, Effect of water absorption, porosity and sorptivity on durability of geopolymermortars,ARPNJ.Eng.Appl.Sci.4 (2009)28 32.

[97]Rajak.M,Rai.B,Effectofmicropolypropylenefiberon the performance of fly ash based geopolymer concrete, J. Appl.Eng.Sci.9(1)(2019)97 108.

[98]Vafaei.M,Allahverdi.A,Dong.P,Bassim.N,Durability performance of geopolymer cement based on fly ash and calcium aluminate cement in mild concentration acid solutions,J.Sustain.Cem BasedMater.8(5)(2019)290 308.

[99]Zheng.J.R,L.Liu.N,Xie.L.X, Propertiesofthemortar andconcreteofalkali activatedfly ashcementingmaterials, Con.5(2009)77 79.Chinese.

[100]Ismail.I,Bernal.S.A,Provis.J.L,SanNicolas.R,Brice D.G,Kilcullen.A.R,Hamdan.S,J.vanDeventer.S.J,Influenceof fly ash on the water and chloride permeability of alkali activatedslagmortarsandconcretes,Constr.Build.Mater.48 (2013) 1187 1201.

[101]Zhang.J,Shi.C.J,Zhang.Z.H,Chloridebindingof alkali activatedslag/flyashcements,Constr.Build.Mater. 226(2019)21 31.

[102]Ke.X.Y,Bernal.S.A,Hussein.O.H,Provis.J.L,Chloride bindingandmobilityinsodiumcarbonate activatedslag pastesandmortars,Mater.Struct.50(6)(2017).

[103]Shi.C,Strengthporestructureandpermeabilityof alkaliactivatedslagmortars,Cem.Concr.Res.26(12) (1996)1789 1799.

[104]Ravikumar.D,Neithalath.N,Electricallyinduced chlorideiontransportinalkaliactivatedslagconcretesand theinfluenceofmicrostructure,Cem.Concr.Res.47(5) (2013)31 42.

[105]Hu.X,C.Shi.J,Shi.Z.G,Zhang.L.Y,Compressive strength,porestructureandchloridetransportproperties ofalkali activatedslag/flyashmortars,Cem.Concr. Compos.104(2019).103392.

[106]Zhang.J,Shi.C.J,Zhang.Z.H,Qu.Z.H,Durabilityof alkali activatedmaterialsinaggressiveenvironments:A reviewonrecentstudies,Constr.Build.Mater.152(2017) 598 613.

[107]Tennakoon.C.,Shayan.A,Sanjayan.J.G,Xu.A, Chlorideingressandsteelcorrosioningeopolymer

concretebasedonlongtermtests,Mater.Des.116(2017) 287 299.

[108] Kayyali. O, Khan. M.S.H, Ahmed. M.S, The role of hydrotalciteinchloridebindingandcorrosionprotectionin concretes with ground granulated blast furnace slag, Cem. Concr.Compos.34(8)(2012)936 945

[109] Shi. C.J, Corrosion resistance of alkali activated slag cement,Adv.Cem.Res.15(2003)77 81.

[110] Heikal. M, Nassar. El Sayed. M.Y, Ibrahim,. G, S.M,. Physico chemical,mechanical,microstructureanddurability characteristicsofalkaliactivatedEgyptianslag,Constr.Build. Mater.69(2014)60 72.

[111]Shi.J.J,Deng.C.H,Y.Zhang.M,Earlycorrosionbehavior of rebars embedded in the alkali activated slag mortar, J. Build.Mater.19(6)(2016)969 975.

[112] Zhang. L.F, Chen. J.X, Li. S.W, Examination study of alkali activated slag lithium slag concrete. J. Build. Mater. 9(4)(2006)488 492,Chinese.

[113] Duan. P, Yan. C.J, Zhou. W, Luo. W.J, Shen. C.H, An investigation of the microstructure and durability of a fluidizedbedflyash metakaolingeopolymerafterheatand acid exposure, Mater. Des. 74 (2015) 125 137

[114]Fernandez Jimenez.A,Pastor.J.Y,Martin.A,Palomo.A, High temperatureresistanceinalkali activatedcement,J.Am. Ceram.Soc.93(10)(2010)3411 3417.

[115] Fire Brigade of Police Bureau, People’s Republic of China, 2020. Fire Statistica Yearbook of China in 2018 (in Chinese).

[116]Gourley.J.T,Johnson.G.B,DevelopmentsinGeopolymer Precast Concrete, in:J.Davidovits (Ed.), World congress geopolymer, Geopolymer Institute, Saint Quentin, France, 2005,pp.139 143.

[117]Zhang.H.Y,Kodur. V,Cao.L,Qi.S.L,Fiber reinforced geopolymersforfireresistanceapplications,in:H.Yao(Ed.), Inproceedingsofinternationalconferenceonperformance basedfireandfireprotectionengineering(ICPFFPE2013), China,2013.

[118] Temuujin. J, Rickard. W, Lee. M, van Riessen. A, Preparation and thermal properties of fire resistant metakaolin based geopolymer type coatings, J. Non Cryst. Solids357(5)(2011)1399 1404.

[119] Perera. D.S, Trautman. R.L, Geopolymers with the potentialforuseasrefractorycastables,Adv.Technol.Mater. Process7(2)(2005)187 190.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

[120]Ye.J.Y,Zhang.W.S,Shi.D,Performanceevolutionsof tailing slag based geopolymer under severe conditions, J. Sustain.Cem BasedMater.4(2)(2015)101 115.

[121] Kong. D.L, Sanjayan. J.G, Damage behavior of geopolymercompositesexposedtoelevatedtemperatures, Cem. Concr. Compos. 30 (2008) 986 991.

[122] Jiang. C, Wang. A, Bao. X, Chen. Z, Ni. T, Wang. Z, Protective geopolymer coatings containing multi componentialprecursors:preparationandbasicproperties characterization,Materials13(16)(2020)3448.

[123]Biondi.L,Perry.M,Vlachakis.C,Wu.Z,A.Hamilton,J. McAlorum,Ambientcured flyash geopolymercoatings for concrete,Materials12(6)(2019)923.

[124] Saafi. M, Piukovics. G, Ye. J, Hybrid graphene/geopolymeric cement as a superionic conductor forstructuralhealthmonitoringapplications,SmartMater. Struct.25(10)(2016)105018.

[125] Perry. M, Saafi. M, Fusiek. G, Niewczas. P, Hybrid optical fibre/geopolymer sensors for structural health monitoringofconcretestructures,SmartMater.Struct.24(4) (2015)045011.

[126]McAlorum.J,Perry.M,Vlachakis.C,Biondi.L,Lavoie.B, Roboticspraycoatingofself sensingmetakaolingeopolymer forconcretemonitoring,Autom.Constr.121(2021)103415.

[127]SharkawiA,TamanM,AfefyHM,HegazyY.Efficiencyof geopolymervs.highstrengthgroutasrepairingmaterialfor reinforcedcementitiouselements.InStructures2020Oct1 (Vol.27,pp.330 342).Elsevier.

[128]Roghanian.N,Banthia.N,Developmentofasustainable coating and repair material to prevent bio corrosion in concretesewerandwaste waterpipes,Cem.Concr.Compos. 1(100)(2019)99 107.

[129] Wasim.M,Hussain.R.R,Ali.B.M,Repairvulnerability ofcorrosionpatchrepairsatthesteelintersectionareasof reinforcedconcreteslabsinfluencedbyharshweather,Ind. Eng.Chem.Res.53(7)(2014)2656 2660.

[130] Al MajidiMH,LampropoulosAP,CundyAB,Tsioulou OT,AlrekabiS.Flexuralperformanceofreinforcedconcrete beams strengthened with fibre reinforced geopolymer concreteunderacceleratedcorrosion.Structures2019Jun1 (Vol.19,pp.394 410).

[131] Zhang. H, Hadi, M.N, Geogrid confined pervious geopolymerconcretepileswithFRP PVC confinedconcrete core:conceptandbehaviour,Constr.Build.Mater.30(211) (2019)12 25.

[132] Zhang. H.Y, Yan. J, Kodur. V, Cao. L, Mechanical behaviorofconcretebeamsshearstrengthenedwithtextile reinforcedgeopolymermortar,Eng.Struct.1(196)(2019) 109348.

[133] Laskar. S.M, Talukdar. S, Preparation and tests for workability,compressiveandbondstrengthofultra fineslag basedgeopolymerasconcreterepairingagent,Constr.Build. Mater.15(154)(2017)176 190.

[134] Zanotti. C, Borges. P.H, Bhutta. A, Banthia. N, Bond strength between concrete substrate and metakaolin geopolymerrepairmortar:effectofcuringregimeandPVA fiberreinforcement,Cem.Concr.Compos.1(80)(2017)307 316.

[135] Zanotti. C, Banthia. N, Plizzari. G, A study of some factors affecting bond in cementitious fiber reinforced repairs,Cem.Concr.Res.1(63)(2014)117126.

[136] Fan. X, Zhang. M, Experimental study on flexural behaviourofinorganicpolymerconcretebeamsreinforced withbasaltrebar,Compos.BEng.15(93)(2016)174 183.

[137]Maranan.G,Manalo.A,Karunasena.K,Benmokrane.B, Bondstress slipbehavior:caseofGFRPbarsingeopolymer concrete,J.Mater.Civ.Eng.27(1)(2015)04014116.

[138] Bencardino. F, Condello. A, Eco friendly external strengtheningsystemforexistingreinforcedconcretebeams, Compos.BEng.15(93)(2016)163 173.

[139] Kriven.W.M,Gordon.M,Ervin.B.L,Reis.H,Corrosion protection assessment of concrete reinforcing bars with a geopolymer coating, Dev. Porous, Biol. Geopolym. Ceram. (2008)373 381.

[140]Carabba.L,Santandrea.M,Carloni.C,Manzi.S,Bignozzi. M.C, Steel fiber reinforced geopolymer matrix (S FRGM) composites applied to reinforced concrete structures for strengtheningapplications:apreliminarystudy,Compos.B Eng.1(128)(2017)83 90.

[141]Montes.C,Allouche.E.N,Evaluationofthepotentialof geopolymer mortar in the rehabilitation of buried infrastructure,Struct.Infrastruct.Eng.8(1)(2012)89 98.

[142]Laskar.S.M,Talukdar.S,Astudyontheperformanceof damagedRCmembersrepairedusingultra fineslagbased geopolymer mortar, Constr. Build. Mater. 30 (217) (2019) 216 225.

[143] Ghazy. M.F, Abd Elaty. M.A, Taman. M.H, Nasr. N.A. (2021). Efficiency of Interfacial Bond Technique between Geopolymer and Portland Cement Concrete Layers on the FlexuralBehaviorofSlabshavingaCompositeSection,Vol: 08,No:01,pp:2395 0072.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1290