International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

1M.TECH. (Structural engineering) student, Department of Civil engineering, Younus College of Engineering and Technology, Kollam, Kerala, India

2Assistant Professor, Department of Civil engineering, Younus College of Engineering and Technology, Kollam, Kerala, India ***

Abstract This research paper is about recent works have shown the feasibility of using shape memory alloys (SMA) in structural rehabilitation projects, especially for flexural strengthening. SMA is an alloythat canbedeformedwhen cold but returns to its pre deformed shapewhenheated. This paper presents a numerical investigation on the performance of reinforced concreteT beam usingSMA, consideringanexisting reinforced concreteT beam bridge. Internalstrengthening has been done using Nickel Titanium (Ni Ti) SMA as reinforcement numerical analysis done with ANSYS 18.1 workbench. External strengthening of T beam bridgewith Ni Ti, and copper nickel (Cu Ni) as U shapedclips, it connectedto the weakest portion of the existing bridge. Determined the external and internal strengthening of reinforced concrete T beam with various types of SMA.

Key Words: Shapememoryalloys(SMA),Superelasticity, Ni TiSMA,SMAUclips

Reinforcedconcretebuildingsrepresentoneofthe most popular structures in developing countries.[1] The designofareinforcedconcretebuildingtakesintoaccount safety considerations under service loads but does not includeseismicconsiderationsinparticular.Furthermore, reinforced concrete buildings require regular monitoring, evaluation,maintenanceandrepairatregularintervaldueto ageing and deterioration. Lack of proper detailing, poor constructionpractice,andpropermaintenancehascaused devastationinmanycases,includingpermanentdamageand failure of many buildings and structures during an earthquake. Seismic hazards and their associated damage following earthquake events often render the structure economicallynotpossibletorepair.

Tomitigatethesesortsofproblems,designersoften useaperformancebasedapproachwhichallowsdesigning structural members with enhanced deformation capacity, ductility, energy dissipation capacity, and reduced permanentdeformation.Thisperformancebasedapproach ensures that following major earthquake events, the structure can be restored to a serviceable state with minimumrepairs.

[2]Therehabilitationofcivilengineeringstructures and structural strengthening is a strategic field in the construction sector due to the ageing of existing infrastructures (including bridges, buildings and others). Manyresearchworkshavebeencarriedoutinthelastfew decades on different strengthening systems to control the failuremechanismsofexistingstructuresbyincreasingtheir safety and lifetime. One of the most critical failures in concrete structures is shear failure given its fragile instantaneousnatureandthegeneralinabilitytowarnusers before collapse occurs. For this reason, it is sometimes necessarytostrengthenexistingstructuresto avoidshear failuresespeciallywhenthestructuremaybesubjectedto significantseismicactions.

However, most strengthening systems used to increase shear strength are passive; that is, strengthening elementsdonotstarttocollaboratewithresistantactions untilthereisachangeinthestructure’sbalancenewloads ordeformations.

Among them, super elastic Shape Memory Alloy (SMA)isoneofthepromisingsolutions,andithasushered inaneweraintermsofoverallperformanceofthestructure. The novelty of this material is its ability to undergo large deformationandreturntoitsoriginalshapethroughstress removal (super elasticity) or heating (SMA effect). [1] In particular,SMAhasdistinctthermomechanicalproperties, including super elasticity, SMA effect, and hysteretic damping.Thesepropertiescanbeeffectivelyutilizedinthe beamunderreversedcyclicloading.Recentresearchworks have shown that SMA can be used together with new orexisting reinforced concrete structures to provide them with new functionalities or to increase their safety and resilience.

ForthenumericalanalysisofthereinforcedconcreteT beam bridgewasconstructedasthemodelofChamakkavuBridge the details as shown in table 1. The bridge is located at Venmony village on the border of Alappuzha and Pathanamthitta districts across the Achankovil river were developedusingnonlinearfiniteelementanalysisprogram, ANSYS18.1

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Bridgetype

PrestressedT beam bridge

Totalspan 60m

Numberoflongitudinal girders 4

Numberofcross girders 4

Gradeofconcrete M30forthewhole structrues

Spacingofgirder 2625mm

Gradeofsteel HYSDFe415 Carriageway 7.5m Effectivespanofthe bridge 20m

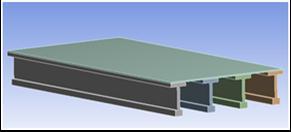

For the analysis, the dead load and vehicle load are consideredbyIRC:6 2000detailsasshownintable2 The figure1showsthegeometricaldiagramofT beambridge. The four numbers of longitudinal and cross girders are modelledbyaneffectivespanof20m.

Table 2: Detailsofdeadloadandvehicleload

Deadweightofslab 6.00 kN/m

Deadweightof wearingcoats 1.76 kN/m

Weightofthe vehicleIRCclassAA 350 kN

LoadingArea 850×3600 mm Spacing 2050 mm

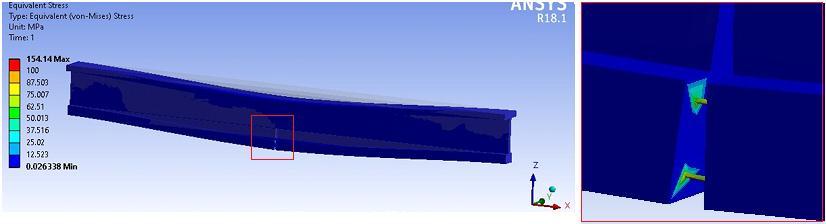

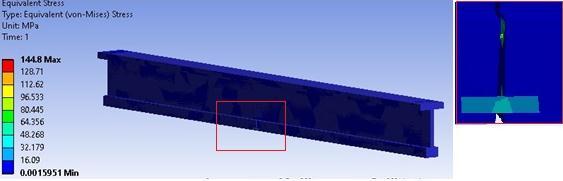

Fig -2:MaximumequivalentstressofasingleT beam girder

Fig 1:GeometricalmodelofT beambridge

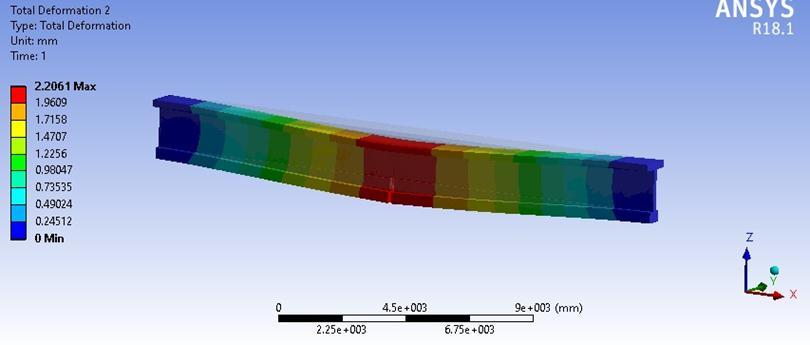

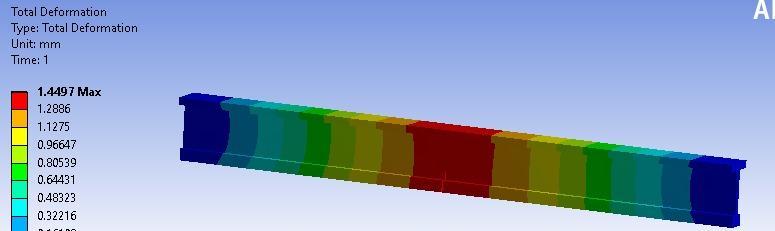

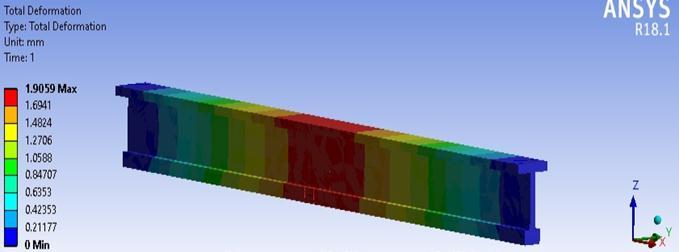

Fromtheanalysis,themaximumequivalentstressobtained as154.141MPa.Thetotaldeformationisobtainedas2.206 mm,andthemaximumprincipalstressisobtained145.721 MPaasshowinfigure2,3.

Fig 3:TotaldeformationofasingleT beamgirder

2.2 Analysis of Single T Beam with Ni Ti SMA as Reinforcement (STN 2)

2.2.1 Material Properties of Ni Ti SMA

Ni Tibasedshapememoryalloyisthemostusefulofallkinds of SMA. The Ni Ti alloy exhibits common shape memory behaviorandisrestoredtoitsoriginalshapeafteritisheated more than its phase transformation temperature. When heatedtothistemperature,thealloytransformsfromitslow temperature monoclinic Martensitic structure to the high temperaturecubicAusteniticstructureasshowninfigure4. ThematerialpropertiesofNi TiSMAasshownintable3

Table 3: Detailsofdeadloadandvehicleload

Properties

Low temperatureNi-Ti

Density(g/cc) 6.45

YieldStrength(MPa) 195 ElongationatBreak% 15.5 ModulusofElasticity(GPa) 28.0

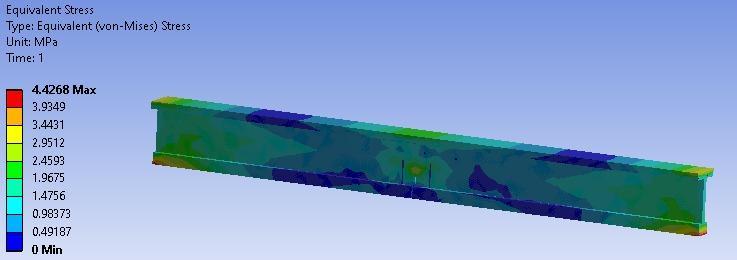

Fromtheanalysis,themaximumequivalentstressobtained as 4.426 MPa. The total deformation is obtained as 1.449 mm, and the maximum principal stress is abtained 3.860 MPaasshowinfigure4,5

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

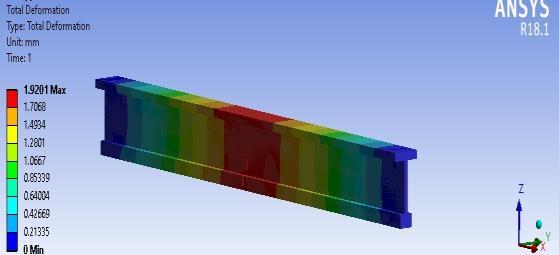

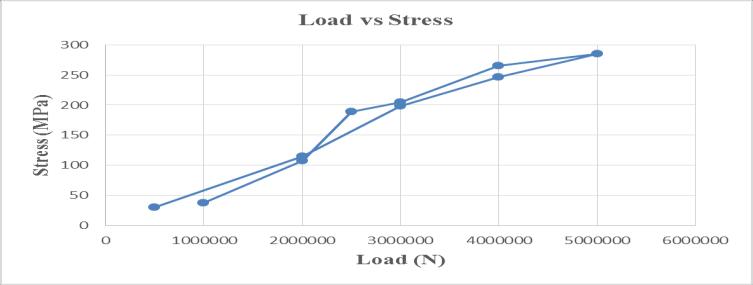

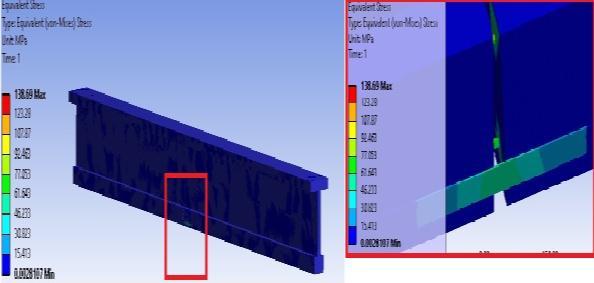

Fromtheanalysis,themaximumequivalentstressobtained as144.811MPa.Thetotaldeformationisobtained1.920mm, the axial stress is obtained 284.8 MPa. The maximum principal stress obtained as 136.811MPa. The FOS is obtainedbydividingtheyieldstresswiththeobtainedstress anditis1.346.Asshowninfigure7,8,9

Fig -4:MaximumequivalentstressofasingleT beam girder

Fig -5:TotaldeformationofasingleT beamgirder

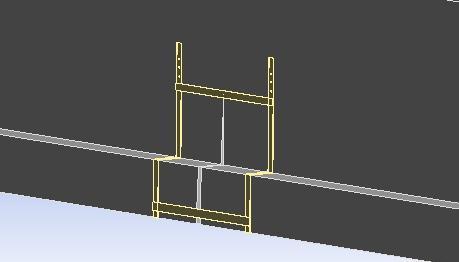

The model was designed with Ni Ti SMA U shaped clips externally connected in single T beam girder. U clips are connected externally with 2 inch SA 193 bolts. A193 B7 materialisastandardmaterialspecificationforchromium molybdenumalloysteelfastenersforuseinhightensile,high temperatureandspecialpurposeapplicationsasshownin figure6.

Fig 8:MaximumequivalentstressofsingleT beamgirder withNi TiU shapedclips

Fig 6:GeometricaldiagramwithNi TiSMA

Fig 9:LoadvsStressgraphofNi TiU shapedclips

2.4 Analysis of Single T Beam with Cu Ni SMA U Shaped

The model was designed with Cu Ni SMA U shaped clips externallyconnectedinsingleT beamgirder.Thematerial propertiesofCu NiSMAU shapedclipsasshownintable4

Table 4: MaterialpropertiesofCu NiSMA

Properties Cu Ni10Fe1

Density(g/cc) 8.9 MeltingRange oC 1105 1140 Electricalconductivity(S/m) 5.5 ModulusofElasticity(GPa) 123

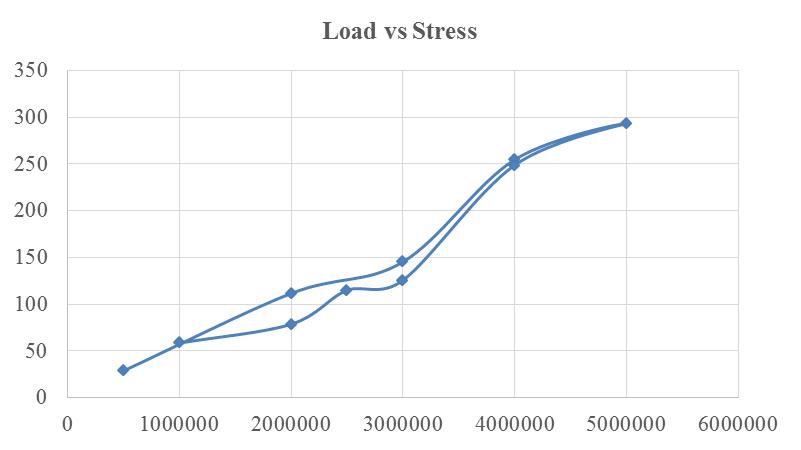

Fromtheanalysis,maximumequivalentstressobtainedas 138.691MPa.Thetotaldeformationisobtained1.905mm, the axial stress is obtained 293.6 MPa. The maximum principalstressobtainedas131.911MPa.TheFOSisobtained bydividingtheyieldstresswiththeobtainedstressanditis 1.045.

Fig -7:TotaldeformationofsingleT beamgirderwithNi TiU shapedclips

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 5: ResultsbasedonEquivalentstresscriteria

Specifications Stress value (MPa) Deformation (mm)

Fig 10: MaximumequivalentstressofsingleT beam girderwithCu NiU shapedclips

STB1 154.141 2.206 STN2 4.4268 1.449 STB3 144.811 1.920 STC4 138.691 1.905

Table 6: ComparisondeformationwithSMAas reinforcement

Specifications Deformation (mm) % Decrease in deformation

STB1 2.206 STN2 1.449 34.315

Fig 11: TotaldeformationofsingleT beamgirderwith Cu NiU shapedclips

Table 7: ComparisonofdeformationwithSMAU shaped clips

Specifications Deformation (mm) % Decrease in stress

STB1 2.206 STN3 1.920 12.96 STC4 1.905 13.64

Fig 12: LoadvsStressgraphofCu NiU shapedclips

Table 5, list out the parameters such as deformation and stressofreinforcedconcreteT beamwithSMAsubjectedto static and dynamic loading conditions. Table 6 listed out percentagedecreasesindeformation.Hereitisevidentthat reinforcedconcreteT beamwithNi Tiasreinforcementis suitable for reduce the crack width, but it is being uneconomic because the high cost of Ni Ti SMA. Also the different types of SMA U shaped clip parameters such as deformationlistoutTable7showslessdeformation.Cu Ni U shaped clips are less deformation than Ni Ti U shaped SMA.

A numerical investigation was conducted to optimize the reinforcedconcreteT beambridgegirderusingNi TiSMAas reinforcement and SMA U clips (Ni Ti, & Cu Ni). Based on analysis,thefollowingconclusionsaremade:

DesignandanalysisofreinforcedconcreteTbeam bridgeusingfiniteelementprogramsuchasANSYS ispossible.

Ni TiSMAusedasreinforcementinT beambridge girderismoreefficientthanexistingnormalT beam bridge girder under static and dynamic loading conditions.

Single T beam girder with Ni Ti as reinforcement shows 34.31% less deformation as compared to normal T beam girder under static and dynamic loadingconditions.

SingleT beamgirderwithexternallyconnectedNi TiU shapedclipsshows12.94%lessdeformation

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

ascomparedtoanormalT beamgirderunderstatic anddynamicloadingconditions.

Structural Safety." AIUB Journal of Science and Engineering,pp.116 125.

SingleT beamgirderwithexternallyconnectedCu NiU shapedclipsshows13.644%lessdeformation ascomparedtoanormalT beamgirderunderstatic anddynamicloadingconditions.

Cu NiSMAU clipsshowsbetterperformancethan Fe Mn SiandNi TiSMAU clips.

[8] HerediaRosa,Diego,AlexanderRileyHartloper,Albano Antonio Sousa, Dimitrios Lignos, Masoud Motavalli, ElyasGhafouri,(2019),“Behaviorofiron basedshape memoryalloysundercyclicloadinghistories”.InFifth Conference on Smart Monitoring, Assessment and RehabilitationofCivilStructures.

WhileconsideringlongerlengthofT beambridge Ni Tireinforcementbecomesuneconomical becauseNi TiSMAshowshighercost.

[9] Hosseini A, Michels J, Izadi M, Ghafoori E, (2019). “A Comparative Study Between Fe SMA and CFRP Reinforcements for Prestressed Strengthening of Metallic Structures”. Construction and Building Materialsvol 226,pp.976 992.

While considering a sudden crack on the existing reinforced concrete T beam it can repair with U clips without affecting the transportation. This methodiseconomicallysafe.

[1] Raza, Saim, Julien Michels, and Moslem Shahverdi, (2022),“UniaxialBehaviorofPre StressedIron Based Shape Memory Alloy Rebars Under Cyclic Loading Reversals”. Construction and Building Materials 326,pp.126900.

[2] Abavisani, Iman, Omid Rezaifar, and Ali Kheyroddin, (2021), “Multifunctional Properties of Shape Memory Materials in Civil Engineering Applications: A State of the Art Review”. Journal of Building Engineering vol 44,pp.102657.

[3] Jakub Vujtech , Jose Campose, Ryjacek P, Ghafoori E, (2021), “Iron Based Shape Memory Alloy for Strengthening of 113 Year Bridge”. Engineering Structuresvol 248,pp.113231.

[4] Siddiquee K. N, Billah A. M, Issa A, (2021), “Seismic Collapse Safety and Response Modification Factor of ConcreteFrameBuildingsReinforcedWithSuperElastic ShapeMemoryAlloy(SMA)Rebar”.JournalofBuilding Engineering42,pp.102468.

[5] Varughese,Kezia,RaafatEl Hacha,(2020),“Designand behaviour of steel braced frame reinforced with NiTi SMAwires”.EngineeringStructures212,pp.110502.

[6] AntoniCladera,MontoyaCoronadL.A,Ruiz PinillaJ.G, Ribas, (2020), “Shear Strengthening of Slender ReinforcedConcreteT ShapedBeamsusingIron Based ShapeMemoryAlloyStrips”.EngineeringStructuresvol 221,pp.111018.

[7] Hasnat, Abul, Safkat Tajwar Ahmed, Hafiz Ahmed, (2020),"AReviewofUtilizingShapeMemoryAlloyin

[10] Oller, Eva, Mireia Pujol, Antonio Mari, (2019), “Contribution Of Externally Bonded FRP Shear Reinforcement To The Shear Strength Of RC Beams”. CompositesPartB:Engineering164,pp.235 248.

[11] Kinam,SugyuLee,YeongmoYeon,KyusanJung,(2018), “Flexural Response of Reinforced Concrete Beams Strengthened With Near Surface Mounted Fe Based Shape Memory Alloy Strip”. International Journal of ConcreteStructuresandMaterials12,pp.1 13.

[12] Menna, Costantino, Ferdinando Auricchio, Domenico Asprone,(2015),“ApplicationsofShapeMemoryAlloys In Structural Engineering”. In Shape memory alloy engineering,pp.369 403.

[13] CladeraA,WeberB,Leinenbach,CzaderskiC,Shahverdi, MotavalliM, (2014),“Iron BasedShapeMemoryAlloys For Civil Engineering Structures: an Overview”. ConstructionandBuildingMaterials63,pp.281 293.

[14] Abdulridha, Alaa, (2013), “Behavior and Modeling of SuperElasticShapeMemoryAlloyReinforcedConcrete Beams”.EngineeringStructuresvol 49,pp.893 904.

[15] Song,Gangbing,N.Ma,andH N.Li.(2006),“Applications ofshapememoryalloysincivilstructures”.Engineering structures28,pp.1266 1274

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |