International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1PG Student, Department of Production Engineering, GEC Thrissur, Kerala, India 2Assistant Professor, Department of Production Engineering, GEC Thrissur, Kerala, India ***

Abstract - The customer satisfaction is one of the keys that lead to the success of every business organization. It is the extent of the products that meets the customer demands. This differentiates the organization from the competitors in the market and gives the competitive advantage. This paper aims to evaluate processes in a tread rubber manufacturing company and to find out the process capability using DMAIC (Define, Measure, Analyze, Improve and Control) methodology. This paper also investigates about various kinds of defects in the tread rubber manufacturing. The DMAIC methodology improves the process and enhances the quality of the product. The problems in tread rubber manufacturing are variation in the tread rubber dimension and some defects which appear in the extrusion process. Using this DMAIC methodology the process capability can be improved and other defects can be rectified by various modifications.

Key Words: Six Sigma, DMAIC, Defect Analysis, Process Capability, Tread rubber manufacturing.

Todaythetechnologyisevolvingdaybyday.Manyproducts are invented and evolved by using these technologies in order to fulfil the need of the people. The needs of the customers are always changed over the time. An organizationwillonlysucceedbysatisfyingtheneedofthe customer.Inthecurrentpandemicscenario,everybusiness is build over the trust and relationship between the customer and manufacturer. The evolution of the tyres makesthelifeofthemaneasyandfaster.Theincreaseinthe number of vehicles increases the demand of the tyres rapidly.Thequality,performanceanddurabilityofthetyres areveryimportantinthesatisfactionofthecustomers.The qualitytyresmustconformtoitsspecificationsandfreefrom anykindofdefects.Therearemanymethodologiesandtools used by the companies for the continuous improvement. Among them, DMAIC methodology is a well known improvement cycle used by the companies. The DMAIC methodologyisanimprovementcyclewhichcanbeusedin every process. It is the acronym for Define, Measure, Analyze,ImproveandControl.

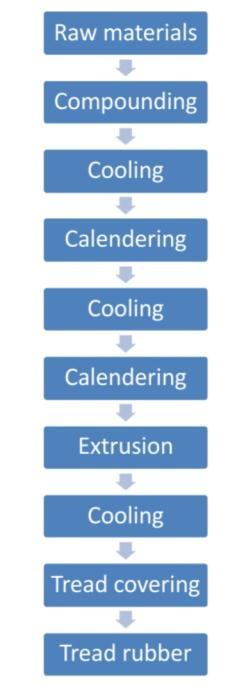

Thetreadrubbercompoundistheintermediateformofthe actualtyre.Itistheportionthatprovidestheadequategrip andfrictionontheroad.Asithasmorecontactontheroads, thereisahighchanceforwearandtear.Sothequalityofthe treadisverysignificantindeterminingtheperformanceof eachtyre.Thetreadrubberismanufacturedbya seriesof processessuchasmixing,calendaring,extrusionetc.Theraw materials used for the tread rubber are natural rubber, syntheticrubber,carbon,chemicalsetc.Therawmaterials aremixedinanintermixerandthenitundergoaseriesof calendaring.Finallyitisextrudedthroughaparticulardie.

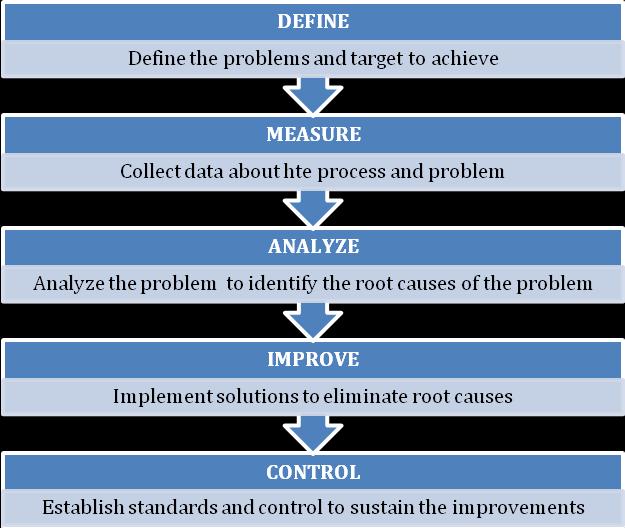

DMAICisanimportantqualitymanagementtoolthatcanbe used as a method of quality improvement among many others. DMAIC is an abbreviation for Define Measure Analyze Improve Control. This method is based on the Deming cycle of process improvement. It is the process of improvingmanydifferentareasoftheenterprise.TheDMAIC cycleismadeupoffiveinterconnectedstages[3].

Fig 1: DMAICmethodology

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The improvement in every aspects of the production processincreasesthequalityofproductsandtherebyvalue of the company. The DMAIC methodology helps to understand the problems related to the process, its constraints etc. It will solve every issue regarding the process,wastage,andqualityinordertomaketheprocess more efficient and reliable. This methodology has a systematicway to rectifyanykindofproblems. There are many tools that are used under DMAIC for improving the process.InthisprojectDMAICmethodologywillimprovethe currentprocessbyrectifyingeachdefect.

ThisinitialstageoftheDMAICmethodologyiscriticaltothe project's success, and a thorough characterization of its componentsisrequired.Tothatpurpose,aprojectplanwas created, which defined the challenge and the goals to be achieved,aswellasthescopeandteamsparticipating.

defectssuchasbubbles,cracks,softregioninthecentreof theextrudateandsharpedgesonthetreadrubber.

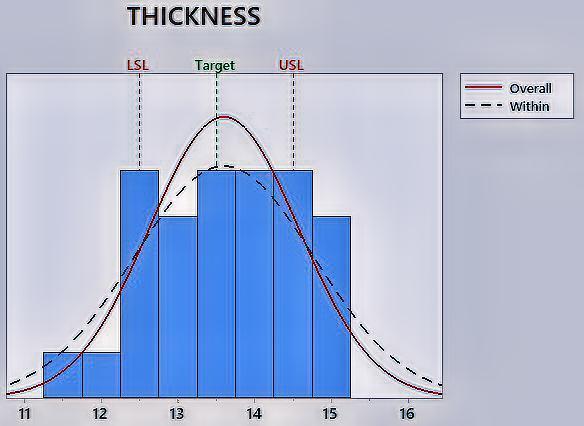

In this phase, information gathered in order to assess processcapabilities.Analyzingtheprocessontheextrusion lines was part of a data collection inorder to identify the defects. The dimensions of 30 samples of T DURA tread rubber were measured and process capability index and process capability ratio are determined in order to check whether the process is capable or not. For width, process capability index (Cpk) is 0.64 and process capability ratio (Cp) is 0.65. For thickness, Cpk and Cp are 0.59 and 0.62 respectively Fromthisphase,itisclearthatprocessisnot capable.

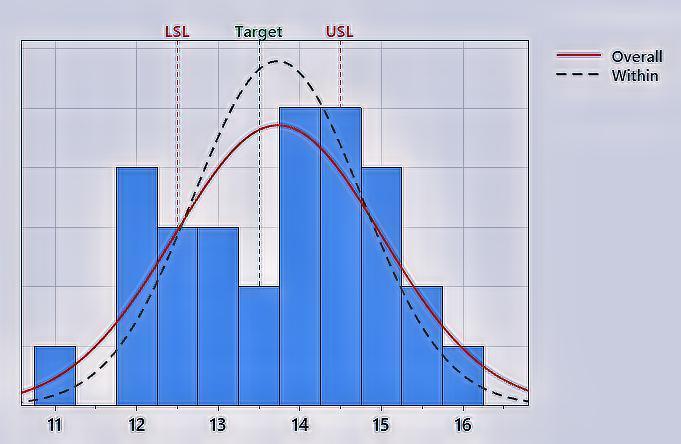

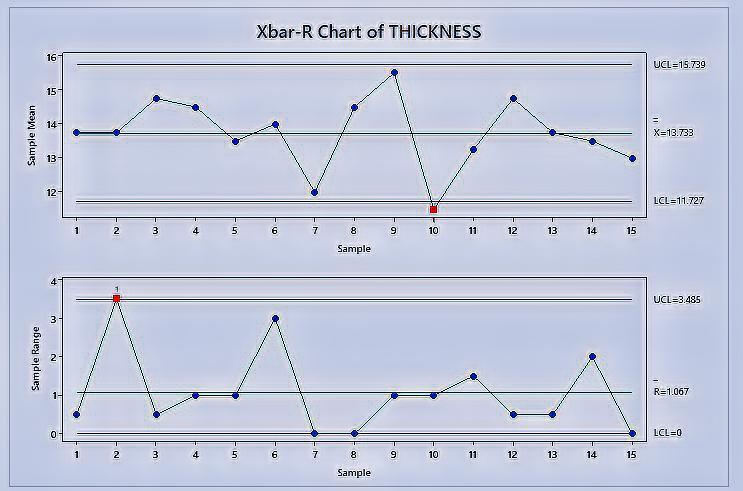

The goal of this phase was to identify the fundamental causes of defects and reasonsof variation in the process. Duringtheanalyzephase,theprocesswasstudiedtoidentify potentialapproachestobridgethegapsbetweenthecurrent quality performance of the process and the target established.Thex barandR chartarequalitycontrolcharts thatareusedtoevaluatethemeanandvariationofaprocess based on samples collected over a specific time period. In both charts,control limits are used to track the mean and variationoftheprocessasitprogresses.Fromthecontrol chartofwidthandthickness,thedeviationfromtargetvalue areidentified.Forexample, analysisofthicknessisshown below.

In the first phase, the processes of tread rubber manufacturingareevaluatedandstudied.Thetreadrubber is manufactured by a series of processes such as mixing, calendaring,extrusion etc.Theraw materialsusedfor the treadrubberarenaturalrubber,syntheticrubber,carbon, chemicalsetc.Theproblemsareidentifiedandtheproject goals and objectives are defined to improve the current process. The problems identified in the tread rubber manufacturing are fluctuation in the extrudate geometry,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fromthex barandR chart,itisclearthatthevariationsof thicknessareundercontrol.Buttheprocessisnotcapableto conform the product to the required specification limit. A processisconsideredtobecompetentifalmost100percent of its output meets the standards. Here process is in command while still failing to meet specification requirements.Thisresultissameasforwidth.

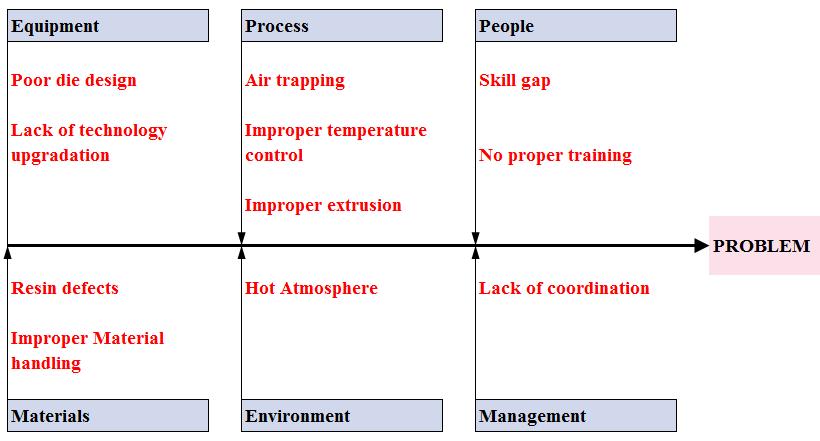

Followingdataanalysis,anIshikawadiagramwascreatedto establishcause and effectrelationships.

The common failure or flaws in the rubber is same as of everyextrusionprocess.Thethreemaincausesaremould design, material selection, and processing. Failures occur duringprocessinginmanycircumstances,andthesefailures produce defects in extruded components such as rough surface,extrudersurging,thicknessvariation,unevenwall thickness, diameter variation, and centering difficulty. Processing flaws in extrusion goods include a lack of understanding of the processing procedure, the use of insufficientorobsoletemachines,alackofskilledpersonnel, machine breakdown, and inappropriate working surroundings.

During the improvement phase, various approaches to accomplish things better and faster at a lower cost were examined.Theremediesforthedefectsareidentified.The percentageoflosswouldbereducediftheabovesolutions wereused.

Table 2: Remediesforthedefects

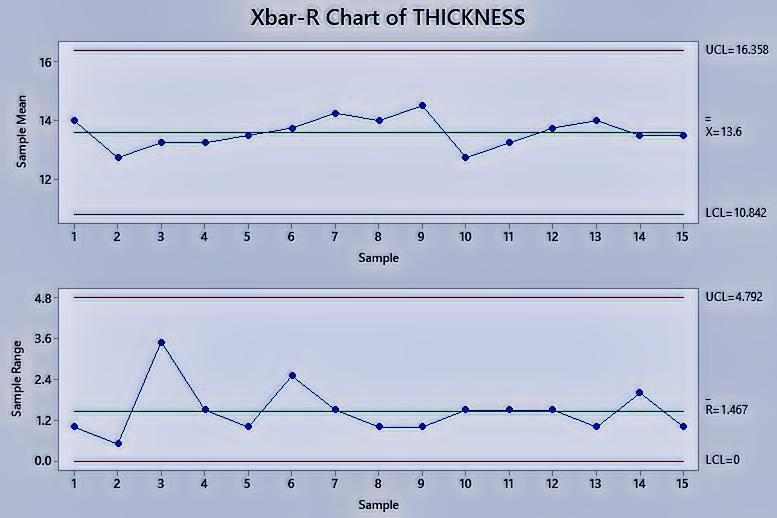

Theimplementationisnotsoeasy.Personnelareresistantto change.Theyarecontentwiththewaythingsare.Itrequires moresupport from the management. Theimplementation mayrequirecapitalinvestment.Themeasurementprocessis repeatedafterimplementation.Thenewprocesscapability indexandprocesscapabilityratioaredetermined Forwidth, processcapabilityindex(Cpk)is0.69andprocesscapability ratio(Cp)is0.7.Forthickness,CpkandCpare0.75and0.65 respectively.Analysisafterimplementationisshownbelow.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

AftertheimplementationwecanseetheProcesscapability indexCpkandProcesscapabilityratioCpareincreased.The variations of both width and thickness are under control. Theprocessismuchcapabletoconformtheproducttothe requiredspecificationlimit.Theprocessisconsideredtobe competent if almost 100 percent of its output meets the standards. Here process is not 100 percent perfect but it meetsspecificationrequirementsprecisely.

Table 3: Beforeimplementation PROCESS CAPABILITY INDICES BEFORE AFTER

Chart 3: Deviationofthickness

Chart 4:

From the control chart of thickness, we can see the deviations from target value are reduced. Here the dimensions are more conform to the target value. The process capability is increased. This result is same as for width.

Thecontrolstageverifiesthequalityofthemodifiedprocess to determine whether the changes introduced during the enhancestagearesufficientandongoing.Italsomanagesthe process'sfuturestateinordertolimitdeparturefromthe objectivesandassurethatthecorrectionismadebeforeit has a negative impact on the process's outcome. The progressmadeinpreviousstepsmustbemaintainedfora long time in order for the organization to continue to succeed. We use the control phase to keep these process improvementsgoing

Processcapabilityindex Cpk 0.64 0.69 Processcapabilityratio Cp 0.65 0.7

Table 4: Afterimplementation PROCESS CAPABILITY INDICES BEFORE AFTER

Processcapabilityindex Cpk 0.64 0.69 Processcapabilityratio Cp 0.65 0.7

Inthefirstphase,problemisidentifiedandtheprojectgoals andobjectivesaredefinedtoimprovethecurrentprocess.In the second phase, process capability index and process capabilityratioaredetermined inordertocheck whether the process is capable or not. From the findings it is clear thattheprocessneedsimprovement.Inthethirdphasethe remediesforthedefectsidentified.Somemodificationsare doneandnewprocesscapabilityisdeterminedinthefourth phase.Actuallytechnologyupgradationisrequired.Inthe fifth phase control is to be achieved for continuous improvement.

Thetechnologyupgradationisneeded.Anextruderhaving automatictemperatureandpressurecontrolisrequired.

2.

Proper training is needed in each operations for the employersisnecessary

3.

Themaintenanceistobedoneinaplannedmanner

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[1] Kiran, D.R., 2017. Chapter 18 Process Capability.TotalQualityManagement,pp.255 259.

[2] Desai, T.N. and Shrivastava, R.L., (2008), October. Six Sigma a new direction to quality and productivity management. InProceedings of the World Congress on Engineering and Computer Science(Vol.6).SanFrancisco,CA:Elsevier.

[3] Smętkowska, M. and Mrugalska, B., (2018). Using Six Sigma DMAIC to improve the quality of the production process: a case study.Procedia Social andBehavioralSciences,238,pp.590 596.

[4] Gupta,Vet.al(2018).Six sigmaapplicationintire manufacturing company: a case study.Journal of IndustrialEngineeringInternational,14(3),pp.511 520.

[5] Arcidiacono,G.andNuzzi,S.,(2017).Areviewofthe fundamentals on process capability, process performance, and process sigma, and an introduction to process sigma split.International Journal of Applied Engineering Research,12(14), pp.4556 4570.

[6] Odeyinka, O.F et.al (2021). Process Capability Analysis in a Polypropylene Bag Manufacturing Company.Journal of Applied Sciences and EnvironmentalManagement,25(8),pp.1477 1482.

[7] Khan,J.Get.al(2014).Defectsinextrusionprocess andtheirimpactonproductquality.International journal of mechanical engineering and robotics research,3(3),p.187.

[8] Subagyo,I.Eet.al(2020).BenefitsandChallengesof Dmaic Methodology Implementation in Service Companies: an Exploratory Study.Jurnal Aplikasi Manajemen,18(4),pp.814 824.

[9] Chakraborty, A. and Tan, K.C., (2012). Case study analysis of Six Sigma implementation in service organisations.Business Process Management Journal

[10] Deeb, S. et.al (2018). A generic framework to supporttheimplementationofsixsigmaapproach in SMEs.IFAC PapersOnLine,51(11),pp.921 926

[11] Evans, J.R. and Lindsay, W.M.,(2014).An introductiontoSixSigmaandprocessimprovement CengageLearning.

[12] Nelson,L.S.,(1999).Technicalaids:Thecalculation of process capability indices.Journal of Quality Technology,31(2),p.249.

[13] Kabir,M.E.et.al(2013).Productivityimprovement by using Six Sigma.International Journal of EngineeringandTechnology,3(12),pp.1056 1084.

[14] Erameh, A.A., et.al (2016). Process capability analysis of a centre lathe turning process.Engineering,8(03),p.79.

[15] Montororing, Y.D.R (2022). Production process improvements to minimize product defects using DMAIC six sigma statistical tool and FMEA at PT KAEF.InJournalofPhysics:ConferenceSeries(Vol. 2157,No.1,p.012032).IOPPublishing.

[16] Mensah, B., et.al (2018). Preparation and characterizationofrubberblendsforindustrialtire treadfabrication.InternationalJournalofPolymer Science,2018

[17] Barbosa,B.,et.al(2017).Solvingqualityproblemsin tyre production preparation process: a practical approach.Procedia Manufacturing,11, pp.1239 1246.

[18] Amonkar, K. and Kittur, J.K., (2019). Productivity improvement in tyre manufacturing plant.International Journal of Advance Research, IdeasandInnovationsinTechnology,5(3),pp.918 925.

[19] Aslan,N.Y.,(2016).Minimizingthedefectrateusing sixsigmaDMAICmethod;acasestudyinSUPSAN AŞ.

[20] Shokeen,S.,(2015).Areviewonrubbercompound mixing in Banbury mixer at time industries.International Journal of Innovative ResearchinTechnology,2,pp.232 236.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |