International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Lecturer, Dept. of Mechanical Engineering, Thiagarajar Polytechnic College, Alagappanagar, Kerala, India ***

Abstract - The quality of work material’s surfaces after undergone various manufacturingprocessesisveryimportant in determining the functional performance of a component throughout the services. Application of coolant and lubricant in manufacturing operations such as turning, milling, grinding, rolling, etc. has been proven to improve the surface integrity of the work materials. In this paper, the application of cryogenic coolant in hard turning operations, and effect of Ball Burnishing operations was investigated in terms of its effects on surface integrity of the work materials which includes surface finish,microstructuralchanges,refinementof grain size, formation of white layer, residual stresses of internal subsurface layer, and surface hardness. Cryogenic application reduce the value of surface finish, but it allow for more comprehensive martensitic transformation, reduce the grain size, prevent the formation of white layer at the subsurface, reduce the tensile residual stresses and increase compressive stressed area, and finallyincreasethehardnessof the work material. Burnishing is a cold working process in which plastic deformation occurs by applying a pressure through a ball or roller on metallic surfaces. It is a finishing and strengthening process. Improvements in surface finish, surface hardness, wear resistance,fatigueresistance,yieldand tensile strength and corrosion resistance can be achieved by the application of this process. In this paper, sequential process of hard turning withandwithoutcryogenicprecooling of the work piece and ball burnishing operation is carried out. The main hypothesis tested in concerns with the fact that cryogenic pre coolingslightlydeterioratessurfacefinishbutat the same time it enhance mechanical and servicepropertiesof the subsurface layer. 2D and 3D surface roughness, micro hardness of surface were studied.

Key Words: Hard turning, Successful Hard Turning, Cryogenic machining, Burnishing, Surface & subsurface characterizations etc.

Hard turning is an important process because all manufacturersarecontinuallyseekingwaystomanufacture their parts with lower cost, higher quality, rapid setups, lower investment, and smaller tooling inventory while eliminatingnon valueaddedactivities[1].Themigrationof processingfromgrinderstolathescansatisfyeachandevery one of these goals. The surface property of work material whichundergoneaftervariousmanufacturingprocesshasa

greatimportanceindeterminethefunctionalperformanceof a component throughout the service. The application of coolant and lubrication during the machining operations suchasturning,milling,grindingetc helpstoimprovethe surfaceintegrityoftheworkmaterials[2].Inthispaper,the applicationofcryogeniccoolantinhardturningoperations, andeffectofBallBurnishingoperationswereinvestigatedin termsofitseffectsonsurfaceintegrityoftheworkmaterials which includes surface finish, micro structural changes, refinementofgrainsize,formationofwhitelayer,residual stresses of internal subsurface layer, and surface hardness[3].

Cryogenicapplicationisabletoreducethevalueof surface roughness, allow for more comprehensive martensitictransformation, reducethegrainsize, prevent theformation of white layer atthesubsurface, reduce the tensileresidualstressesandincreasecompressivestresses area, and finally increase the hardness of the work material[6].Inconclusion,cryogenicapplicationinalotof manufacturingprocesseshasbeendeterminedtobeableto enhanceandimprovethequalityoftheworkpiecesurface, consequently, boost the functional performance of the components.

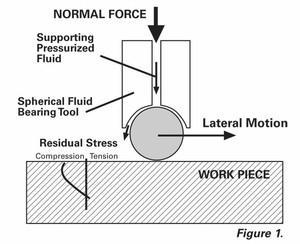

Burnishing is a cold working process in which plasticdeformationoccursbyapplyingapressurethrougha ball or roller on metallic surfaces[4]. It is a finishing and strengthening process. Improvements in surface finish, surfacehardness,wearresistance,fatigueresistance,yield and tensile strength and corrosion resistance can be achievedbytheapplicationofthisprocess.

Functionalperformanceofaworkmaterialsuchas fatigue strength, corrosion rate, fracture toughness, and tribologicalbehavior(suchasfriction,wearandlubrication, and accuracy of dimensions) are highly dependent on the surface properties. The integrity of the external surface topography (surface finish), microstructure, mechanical propertiesandresidualstressesofinternalsubsurfacelayers are among the properties of a machined surface that affecting the functional performance. Therefore, surface integrityhasbeenasubjectofinteresttomanyresearchers inordertoenhancethefunctionalperformanceofwork.

Many techniques have been investigated for the purpose of improving the quality of surface integrity in

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

machining. Gentle machining is claimed to be able to enhancethesurfaceintegrityofmachinedsurfacecompared toconventionalmachining.Gentlemachiningcanbedefined asmachiningina“lowstressconditions”whichwillresultin little heat generated at the cutting zone[3]. In order to achieve the low stress conditions in machining, many attemptshavebeenexplored,andapplicationofcuttingfluid is among one of them. Cutting fluid is applied during machining for the function of cooling and lubrication. Coolant is important to cool the heat generation zone in machiningprocess;meanwhilelubricantisusedtominimize thefrictionbetweenthetool,chipandworkpieceinterface. Methodsofcuttingfluidapplicationincludefloodmachining, near drymachiningandalsocryogenicmachining.Cryogenic acts as coolant to reduce the temperature generated in machining process. Cryogenic coolant uses liquid gaseous suchasliquidnitrogen(LN2)orliquidcarbondioxide(CO2) toreducethetemperatureatthecuttingzone[6].materials.

Cryogenic machining is more advantageous comparedtotheusageofconventionalcuttingfluidinterms of eco friendly in such a way that the liquid gas used will evaporateintotheairandbecomepartoftheatmosphere[7]. The evaporation of the gaseous also eliminate the cost of cutting fluid disposal. A lot of researches have been conductedtostudythebenefitsofcryogenicapplicationin manufacturingprocesses.Cryogenicapplicationisclaimedto improve process sustainability, increase material removal rate(MRR),enhancethetoollife,improveproductqualityof machinedpartsandenhancesurfaceintegrity[12].

Hardturningisdefinedastheprocessofsinglepoint cuttingin workpiecesthathavehardnessvaluesmorethan 45 HRC but more specifically the ranges are 58 68 HRC range[8].ThemostcommonlyusedcuttingtoolsareCubic Boron Nitride (CBN), Ceramic and sometimes Cementite. Selection of tool choice should be matched with the application,desiredproductionrates,surfacefinish,quality andoperatingcostgoals.Themostprominentselectionof cuttingtoolisCBNforthemoredemandingapplicationsof size,finishinganditcan alsoused for thosecomponents whichhadbeentransitionedfromgrinding.In2001thesales of CBN tools exceeded $250 million, providing an idea of broad use of this technology. The CBN cutting tools are availableinseveralgradesandselectionshouldbeproperly matchtherequirements.Asanexample,alowcontentCBN insertedtoolwillnotperformwellinaninterruptedcutting application because it lacks the necessary toughness[8]. Generally, high content CBN inserted tool have higher toughnesswhereaslowcontentinsertedtoolprovidelonger toollifeinstraightturningapplications.

In thebeginningofninetieshardturningwasreally startedtodevelop.Thereasonforthiswastheavailabilityof newtoolmaterialsandthecapabilityofdesigningofturning machine(lathe)thatwasrigid,stableandaccurate,which wereenoughtosuccessfullyfinishhardturningoperation. These developments which leads to made that the hard turningisapossiblealternativetogrindingasanaccurate finishingoperation[5].Hardturningcaneffectivelyreplace the pre grind roughing operations. If one lists the current applications of hard turning it would certainly be a voluminous document. In olden days the following few industrieswerethecommonlyusedhardturningtechnology Automotive, bearing, marine, punch and die, mold, hydraulicsandpneumatics,machinetoolandaerospace.But now a days many industries segments are adopting hard turningbecauseitisanunavoidablemachiningoperation.

The typical materials, which are routinely hard turned, includethoseofthefollowingbroadcategorydescriptions:

Steelalloys

Bearingsteels

Hotandcoldworktoolsteels

Highspeedsteels

DieSteels

Casehardenedsteels

Intheabovefigure1HRC62hardpartisbeingmachined withoutcoolant,anditisclearthatthechiptemperatureis extremely high, and in fact the cutting zone in dry operations,isnormallyintherangeof925degreesCelsius. The localized heating that occurs at the tool tip tends to easier inthecuttingaction,sincetheheatgeneratedatthe tooltipbeginstoannealandsoftenthematerialjustaheadof thetool,makingiteasiertoshear[8].Ameasurementofthe hardnessofthecutchipswillfrequentlyshowvalues,which arebelowone halfofthehardnessofthebasematerial.This will also explain improvement in tool life in some applications because the material has been annealed to lower hardness levels.Hard turned surfaces frequently producedwhitelayer,whichisduetoeithersevereplastic

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

deformation that causes rapid grain refinement or phase transformationsasaresultofrapidheatingandquenching.

Successful hard turning is dependent upon the entire machining system and not just certain discrete elements. As a way of summary the following items are relatedtosuccessfulhardturningapplications.

Amachinewithahighdynamicstiffness.

Efficientworkholdingdevices.

A correctly chosen CBN grade or other tooling materialtype.

Highqualitycuttingedges.

Rigidtoolmounts.

Appropriatemachiningparameters.

Workpiecerigidity.

Chipmanagementandcoolingsystems

Goodvibrationdampingcharacteristics

The cryogenic machining is a process of jetting a small quantity of liquid nitrogen in to the rake phase of cuttingtool.DuringthecuttingprocessliquidnitrogenLN2 canbestoredwitha bulktankoutsidethebuildingoritcan bestoredveryclosetomachinebyapressurizedcylinder, fromthereitcanbetransportedthroughavacuumlines[7]. There is a control box integrated with the machine controllerwhichprovides signalfirliquidnitrogen LN2 to flowaccordingtothe demandthroughflexiblelinesintothe specificallydesignednozzles.Thenozzlesarefixedintothe clamp or which are mounted close to the tool. The nozzle discharges a stable precise LN2 jet towards the chip tool interface.

TheLiquidNitrogenisusedasacoolantincryogenic machining.Theliquidnitrogenusingin machiningprocess, it evaporated suddenly and return back to atmosphere, when it is delivered to cutting zone. During evaporation takes place there is no residue to contaminate the parts, chips,machinetooloroperator[9].

The friction coefficient is reduced on tool chip interface

LiquidNitrogenisappliedincuttingzonewhichis superior than other conventional coolants in loweringthecuttingtemperature.

Lower in abrasion and chemical wear which increasesintoollife.

Increasedmaterialremovalratewithnoincreasein tool wear and also cutting tool change over cost, whichresultsinhigherproductivity

Improved machined part surface quality with the absenceofmechanicalandchemicaldegradationof themachinedsurface

Liquid nitrogen can store and transport with less costandveryeasy.

Burnishingis theplastic deformationof a surface due to sliding contact with another object. Visually, burnishing smears the texture of a rough surface and makes it shinier[4].Burnishingmayoccuronanyslidingsurfaceifthe contact stress locally exceeds the yield strength of the material.Burnishingprocessesareusedinmanufacturingto improvethesize,shape,surfacefinish,orsurfacehardnessof a work piece. It is essentially for forming operation that occurs on a small scale. The benefits of burnishing often include: Combats fatigue failure, prevents corrosion and stress concentration, textures surfaces to eliminate visual

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

defects,closesporosity,createssurfacecompressiveresidual stress[11].

Thereareseveralformsofburnishingprocesses;the mostcommonarerollerburnishingandballburnishing.In bothcases,aburnishingtoolrunsagainsttheworkpieceand plasticallydeformsitssurface[4].Incaseof ballburnishing, itrubs,andatincaseofrollerburnishingitgenerallyrotates androlls.Theworkpiecemaybeatambienttemperature,or heatedtoreducetheforcesandwearonthetool.Thetoolis usually hardened and coated with special materials to increaseitslife.

Ball burnishing, can be used as a replacement for otherborefinishingoperationssuchasgrinding,honing,or polishing[11]. A burnishing tool consists of one or more over sized balls that are pushed through a hole. Ball burnishing is also used as a deburring operation. It is especially useful for removing the burr in the middle of a throughholethatwasdrilledfrombothsides.

Hardturningconditionswereasfollows:

cuttingspeedof150m/min,

variable feed rate of 0.075 (HT1/CHT1), 0.1 (HT2/CHT2)and0.125(HT3/CHT3)mm/rev,

depthofcutof0.15mm/rev.

Both hard turning processes were performed on a conventionallatheandaCNCturningcenter.

Table - 1: Specificationofdryandcryogenichardturning operations

Dryhardturning Cryogenichardturning

Feedrate mm/rev code Feedrate mm/rev code

0.075 HT1 0.075 CHT1 0.10 HT2 0.10 CHT2 0.125 HT3 0.125 CHT3

Incaserollerburnishingwascarriedoutbystatic ball. The burnishing tool (ball) consist of 12mm diameter madebyCeramic(Si3N4).Thedesiredloadisgeneratedby springbasedpressurecontrolsystem.

Burnishingconditionswereasfollows:burnishing speedof25m/min,burnishingfeed fb of0.05(HT1/CHT1+ B1), 0.075 (HT2/CHT2 + B2) and 0.1 (HT3/CHT3 + B3) mm/rev,whichwasalwayslowerthanturningfeed ft and thetoolcorrectionof0.25mmintheCNCcontrolsystem.

The experiment setup consist of Work piece material,toolingandmachiningconditions.Hardmachining trialswereperformedonthespecimenmadeof41Cr4steel with Rockwell’s hardness of 57±1 HRC. Here very low content(about60%)CBNtoolwereused.Theworkpieceis madeintotwostate1) Drystate 2) Cryogenic Pre cooledstate

Incaseofcryogenicpre cooledstate,theworkpieceis kept into a specially cooled chamber with liquid nitrogen (LN2).The cryogenic treatment carried out on work piece about3 4minutes.Themachiningofcryogenictreatedwork piece(frozenmaterial)iscarriedoutafter 30s.This30sis takenfortransferringtheworkpiece fromcoolingchamber tothemachinetool.

MultipassBurnishingconsistingof4passes(HT2+ B2 M/CHT2 + B2 M),and one pass (HT1 + B1/CHT1 + B1, HT2 + B2/CHT2 + B2,HT3 + B3/CHT3 + B3) burnishing operationsafterdryandcryogenicturningoperationswere performedatconstantloadofabout600N.Bothhardturning andburnishingoperationswereperformedonaCNCturning center,OkumaGenosL200E M[13].

Table 2: Specificationsofburnishingoperations

Feedrate fb (mm/rev) Code

0.05 B1 0.075 B2,B2M 0.10 B3

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

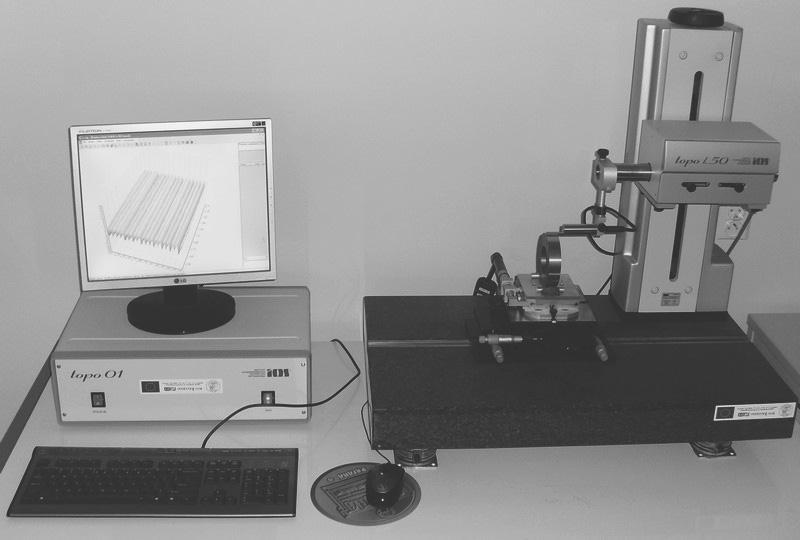

AProfilometerwithadiamondstylusataradiusof 2μmwereusedforrecordingsurfaceprofiles/topographies, andalsoestimatingroughnessparameterof2Dand3Don thescannedareasofworkpiece.LECOhardnesstesterswith aBerkovishidenterataloadof50Gwereusedformeasuring themicrohardnessofmachinedandpolishedsamplesacross thesubsurface.Thevariationofhardnessabout100μmin the subsurface layer is determined. There is a chance to interference of indentations. To avoid this interference of indentations, the measurements are taken on oblique sectionsinclinedatanangleof30 totheoutersurface.The strain hardening rates related to the maximum values of microhardnessinthesubsurfacelayerwerecomputed.

A scanning microscope, model HITACHIS 3400N whichis equipped with X raydiffractionheadEDS,model THEMONORAN System Six were used for examining the changesofmicrostructureandtexturebyburnishingprocess .Theimagesobtainedfrommicroscopesuchas(BSE,SEM) were recorded. The sections, which are mechanically and chemicallypolishedwere,performedinthisanalysis

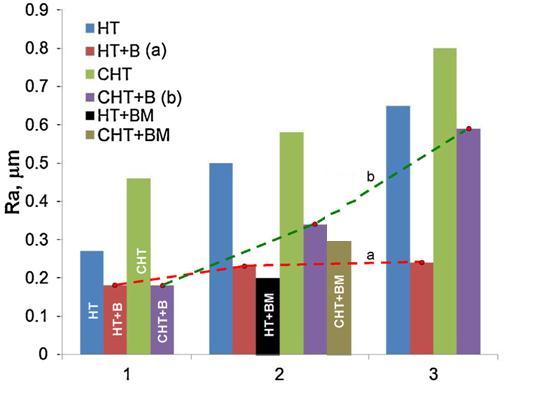

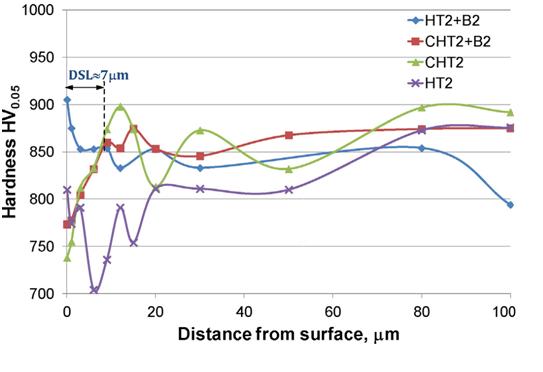

Burnishing process leads to change the initially turned surfacesintheirshapeandgeometricalfeaturesasshownin Fig.6.TheRaparameterisrepresentedinverticaldistance, whichisreducedbyburnishingprocesswithdifferentfeed asshowninFig.6.TheRaparameterisreducedbyburnishing process but this effect is more noticeable in dry HT. The minimumvalueof Ra=0.18 µmwasobtainedforvariant1 (HT/CHT+B1).FromFig.6wecanunderstandthat,incase of cryogenic HT process produces a higher peak value profile.But burnishingprocessisabletochangethis turned profiles effectively (by reducing Ra parameter) at smaller feeds[13].Theeffectofburnishingprocessleadsto increased hardness, strength and also coarser microstructure of the freezing work piece. Cryogenically cooled harder material are brittle and chip removal depends upon the brittle fracture.

Cryogeniccoolingoftheworkpieceleadstosuddenincrease instrengthandhardnessofworkpiece,whichresulthigher cuttingresistance[7].Foranexample,thehardnessofAISI E52100bearingsteelincreasestwotimeswhentemperature decreasesfromabout100◦ Ctoabout−200◦ C.Asaresult, whenhardnessofmaterialincreases,thesurfacefinishafter machining is very poor than the surface finish of lower hardnessmaterialaftermachining.

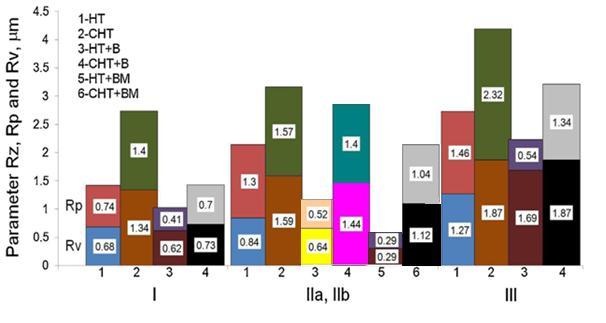

ThesecondobservationisthatthecomponentofRz isRpandRv.TheRzisdependson theinitialprofileshape, asshown inFig7.Dependingontheturningfeed,thepeak height Rp reduced to 45 75%, but the valley depth Rv is reducedonaverage,of10%.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

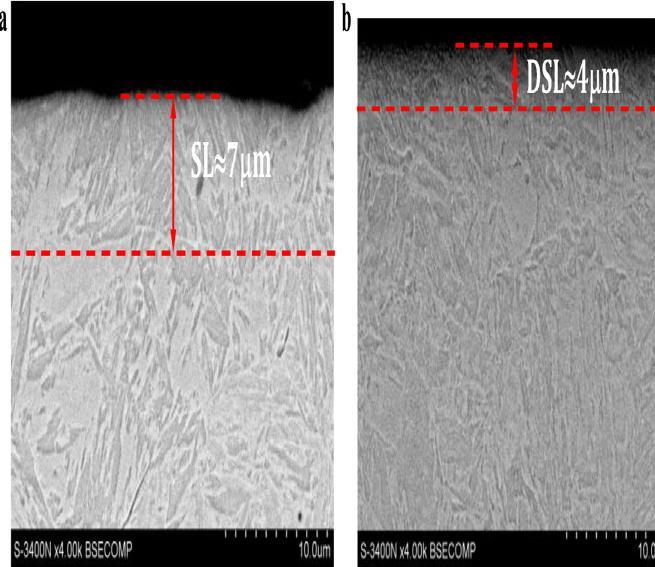

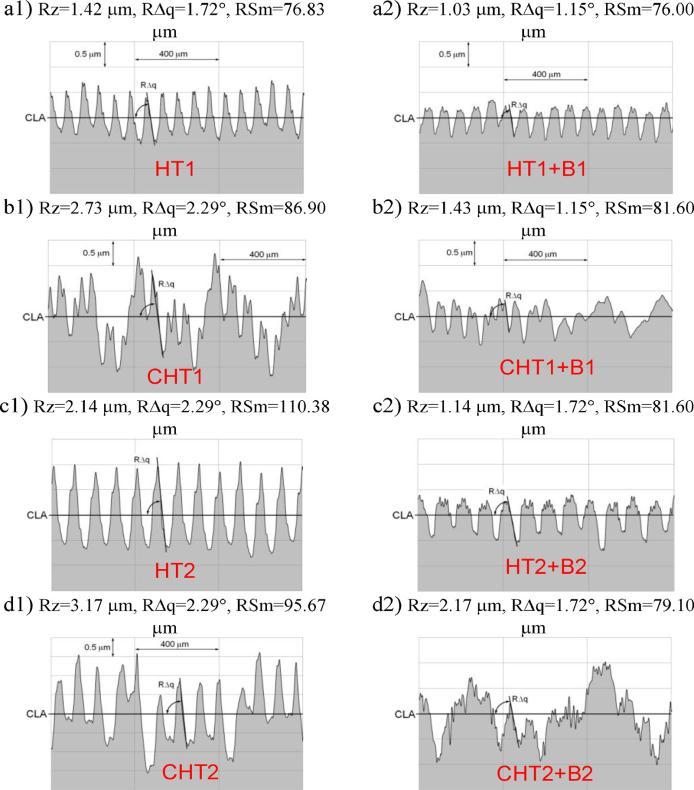

Distribution of micro hardness in the subsurface layeratadistanceof100µmfromthesurfaceismeasured using LECO hardness tester MHT Series 200 with a Berkovich indenter at a load of 50G. In case of dry hard turning and after burnishing made that maximum micro hardness is localized close to the surface. But in case of cryogeniccoolingthemaximumhardnessistoshifttothe pointbeneaththesurface(12 15µm).Themaximummicro hardness in case of dry hard turning is measured directly underneath the generated surface was about 830 MPa. In case of burnishing (HT2+B2) this value is 905Mpa[13].In caseofcryogenichardturningprocess(CHT2)processwhite layerisnotproduced. The resultof microhardnessin the zoneadjacenttothesurfaceisabout740MPa.Whichcanbe increasedslightlybyburnishingto775MPa.

Fig.8indicatesthatdryhardturning(HT1)produces asurfaceprofilehavinganintervalofregulartoolnose.The feed value is equal to Rsm Parameters. The slope R q, generallynotgreaterthan20.Inthecaseof(HT1+B1/CHT1 + B1), burnishing produces a profile which removes the sharp peaks with in Rp height. The Rsm parameter does changepractically.Inthecaseof (HT2+B2)and(HT3+B3) higherirregularitiesarepartiallybreakintosmallerpieces andseverelydeformed,and whichisflattenedfinally.The newmodifiedprofileswere producedwhich havinglower spacings between peaks[13]. For example, RSm decreases almostthreetimes(124.50µmvs.44.94µm)formulti pass burnishing(HT2+B2M).

Fig 9; Microhardnessandstrain hardeningeffects

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

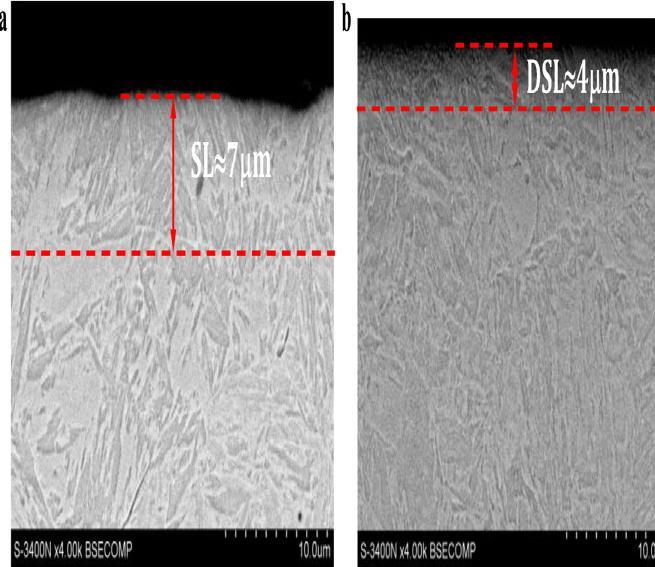

The SEM/BSE techniques were used for Micro structural analysis and EDS technique is used for phase content measurements. The EDS technique also helps to identifythestructuraleffectofburnishingprocessandalsoit helpstodeterminethechemicalcompositionofthesurface layer. The above figures shows BSE micro photographs of surface layer (SL) produced by dry hard turning and cryogenic hard turning. It also indicates the modifications inducedbysequentialburnishing.Inthecaseofcryogenic machining surface of the work piece will be cold during machiningandItisshieldedbyafrozenskin.TheIRcamera isusedfordeterminingthecuttingtemperature..Itindicates that600Kand800K(correspondinglyabout300 500°C)for cryogenic machining and in case of dry hard turning with cuttingspeedof150m/minwasabout800°C[13].Fromthe resultofIRcamerathemicrostructuredoesnotchangeafter hardmachiningofcryogenicallypre cooledworkpiecedue to low cutting temperature. But the of SEM analyses performed, it indicates that after cryogenic treatment the content of retained austenite decreases and surface layer formation is very low (less intensive). The BSE images indicate that, the work piece, which pre cooled by liquid nitrogenwillnotproducedwhitelayer(WL).Butincasedry hardturning(dryHT)whitelayerisformedanditpenetrate about3µmbelowthemachinedsurface.Atthesametime, whilemachiningtheworkpiecewhichisprecooledbyliquid nitrogenproducedsubmicrondispersivecarbides.Thewhite layer (WL) is restored in the form of a nano crystalline homogeneouslayerafterburnishing(HT2+B2).Inthiscase indicate that after burnishing severely deformed surface layer(DSL)isformedjustbelowthewhitelayerabout7µm thickness.Thisimagealsoshowsmartensitestructurewith thegrainboundariesofretainedaustenite

Fromtheabovestudywecanconcludethat,

In hard turning, the burnishing process is able to modifysurfaceandsubsurfacelayer.

Cryogenicprecoolinginmaterials(workpiece)can be used as a additional control on the effect of burnishing.

Burnished surfaces which are exactly flattened havea betterbearingproperties.

The best response results were obtained at the lowestvalueofburnishingfeed.Feedrateisalsothe most significant factor in the roller burnishing process.

hardeningratioisintherangeof5 10%depending ontheinitialstateofwork piece(withorwithout cryogenicpre cooling).

White layer formation can be controlled by cryogenicprecoolingofworkpiece.

Apartfromhighhardnessofthesteelmachined,the surface layer is additionally strain hardened by burnishing. For extremely hard steel, the strain

White layer (WL) is not formed in hard turning (CHT+B)ofcryogenicprecooledworkpieceand the thicknessofsublayerisreducd.

The fine martensite formation by a specific deformationinballburnishingoperation isthebasicmechanismofincreasingthehardnessof surfacelayer.

[1] W.Grzesik,“AdvancedMachiningProcessesofMetallic Materials”,Elsevier;2008.

[2] G. Byrne, D. Dornfeld, B. Denkena, “Advancing cutting technology”, Annals of the CIRP 52/2 (2003) 483 507

[3] Serope kalpakjian , steven r schmid , “Manufacturing engineeringand technology”fifthedition2006

[4] B. Zabkar, J. Kopač , “An investigation into roller burnishingprocess”. Journal ofproductionengineering, 2013

[5] W.Grzesik,J.Rech,T.Wanat,“Surfacefinishonhardened bearing steel parts produced by super hard and abrasive tools”. International Journal of MachineTools and Manufacturing 2007; 47:255 62.

[6] F Pušavec, E. Govekar, J. Kopac, I.S. Jawahir , “The influenceofcryogeniccoolingonprocessstabilityinturning operations”, CIRP Annals Manufacturing Technology, 2011;60:101 104

[7] Y.Yildiz,M.Nalbant,”Areviewofcryogeniccoolingin machiningprocesses”, InternationalJournalofMachineTools and Manufacture, 2008; 47:947 64.

[8]Z.Zurecki,R.Ghosh,J.H.Frey,“Investigationofwhitelayer formedinconventionalandcryogenichardturningofsteels, International Mechanical Engineering Congress and Exposition, ASME,2003, 1 10.

[9]. Z. Zhao, S.Y. Hong, “Cooling strategies for cryogenic machiningfromamaterialsviewpoint”, Journal of Materials Engineering and Performance , 1992;1:669 78

[10] S.AbdulKalam1,A.Azad,M.Omkumar,GiriSankar.S, R.Vajubunnisa Begum, “Elimination of White Layer formationduringHardTurningofAISID3Steeltoimprove

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fatiguelife”,Journal of Mechanical and Civil Engineering Jun. 2015 volume 12 PP 07 14

[11] DeepakMahajan,RavindraTajane,“AReviewonBall BurnishingProcess”, International Journal of Scientific and Research Publications,2013 Volume 3.

[12] D.Umbrello,Z.Pu,S.Caruso,J.C.Outeiro, “The effects of cryogeniccoolingonsurfaceintegrity in hardmachining”. Elsevier, 2012.

[13] W. Grzesik, K.˙Zak, “Producing high quality hardened parts using sequential hard turning and ball burnishing operation”, Elsevier 2013.