International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

GOVINDA SINGH P A P E R I N F O A B S T R A C TKeywords:

Hydrogenenergy

Renewableenergy

Solidpolymerelectrolyte

4 strokeICengine

Diaphragmcompressor

Electrolyzer

Fuelcell

HydrogenStoragetank

Alternator

Hydrogen power has a high recommendation over low carbon and purity, high energy density, and efficient conversion; expected to play an important role in India. It analyzes the research status and prospects for the development of various technologies in hydrogen production, hydrogen storage, and hydrogen utilization.Onthisbasis,specifictechnologiesareproposedforthedevelopment of renewable energy and integrated hydroelectric resources. Solid polymer electrolyte (SPE) electrolysis for hydrogen production and solid hydrogen storage materials is a potential development in the direction of hydrogen production and hydrogen storage. Technologies such as hydrogen fuel cell and hydrogen gas as fuel for the 4 stroke IC engine interface should be developed simultaneously. The production of hydrogen gas from a photovoltaic grid capable of generating fuel cell power and internal combustion 4 stroke engine technology can effectively solve the dependence on renewable energy. At the same time, hydrogen energy can detect the connections of multiple energy networks,andtheprospectsforitsfutureuseinintegratedenergyserviceparks are much broader. This system will not only be used for irrigation without interruption but will also be used to meet the needs of the home load without thegrid.

INTRODUCTION

The widespread use of fossil fuels has brought about a variety of environmental, ecological, and global climate changes [1]. Large scale implementation of periodic renewable energy. Systems need to close the temporary and space gap between supply and demand [2]. Reducing fossil fuels has been strongly suggested under international frameworks, including the Sustainable Development Goals(SDGs)andthe ParisAgreement[2]. Increasingtheuseofrenewableenergysources(RES)in energy mixing has become a challenge for energy engineers and scientists around the world. Although mixed energy systems based on RES (HRES) have attracted the attention of a sustainable energy market, efficientuseofsolar photovoltaic(PV)orwindpoweris difficult, especially for local power grids [3]. This is due to their flexible nature and intervals, due to their dependence on weather conditions. Thus, independent renewable energy sources cannot guarantee reliable powersupply.Acommonsolutiontothisproblemisthe use of HRES to combine both short term energy storage options (batteries, capacitors, flywheels, or compressed

air) and long term hydrogen like power storage [3]. Withnearly1.3billionpeopleintheworld(orabout1in 5)withoutelectricityin2010,thechallengeofproviding reliable and affordable services remains the biggest global challenge facing the world in this century [4]. Although the expansion of the grid is still the preferred method of expanding the rural grid of medium to low rural grid may not be financially viable or not at all [4]. Off grid options can be helpful in such situations. In addition, efforts to use renewable energy are often focused on a single technology [4]. For example, Solar Home Systems (SHS), solar photovoltaic systems and micro hydropower have been widely used, but such optionsareoftenincapableofprovidingconsumerneeds adequately and reliably due to limited service availability resulting from diversity of resources [4]. Relianceonasingletechnologyoftenleadstoanincrease in system size, thus increasing initial costs. The hybrid systemdesigncanovercomethetemporaryenvironment of renewable energy sources (RES), the problem of excessive size and improve the reliability of the supply.

COMET: A combination of multiple-energy technologies - Another alternative to renewable energy, based on solar energy and hydrogen fuel for effective irrigation in drought stricken Indian regions.Department of Mechanical Engineering & Institute of Engineering and Technology Dr. Rammanohar Lohia Awadh University Ayodhya U.P.

International Research Journal

of

Engineering

and

Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

However,mixedsystemshavereceivedlimitedattention due to their complex growth and almost no work has everconsideredtheissueofreliableelectricitysupplyin ruralareas[4].

Inremoteruralareas,theneedforelectricitycanbemet using HRES, but their introduction has reduced the lack of economic efficiency and technological adaptation. Air power lines, which are very expensive, are often extendedtonaturalareastodistributeelectricityforsale to consumers. These infrastructures have a detrimental effect on the environment and, more importantly, kill nativeandmigratorybirds, a critical issueinthecaseof endangered species [3]. Among the various renewable resources, photovoltaic power generation (PV) is reported to have the greatest potential. To improve the usability of PV, a number of methods have been tested, especially under power to X concepts [2]. Power to gas and power to liquid can be key components in a sustainable future energy system that includes electricity,mobility,heating,andchemicalfields.Power to gas has become a major technology for converting electricity into gas, especially with hydrogen as an energy carrier, which is one of the most important options for sustainable hydrogen production [2]. Irrigation systems, in rural and arid areas of India with poor access to grid electricity, are limited to diesel generators.Thediesel basedirrigationsystemisamajor cause of climate change, depletion of fuel depots, rising operating costs and diesel, maintenance problems that encourage the search for alternative energy system [5]. Currently, solar PV irrigation system is considered a separate irrigation solution. Demonstrates economic, environmentalandtechnologicalefficiencyoveradiesel based irrigation system. Currently, the battery storage system is not included in the solar irrigation system in

Indiaduetoitshighcostandmaintenanceproblem.And the importance of energy conservation should be considered in times of great need and adverse weather conditions. Indeed, in the case of long term energy storage,itisbesttouseanefficient,effectiveandreliable hydrogen system. Hydrogen production in water will graduallyreplacefossilfuelsandbecomeamajorenergy carrier in the second half of the 21st century. Water is often regarded as a stable and pure source of hydrogen production, especially when the term renewable energy isused[5].Thehydrogenfuel basedirrigationsystemis a different solution to meet the current agricultural needs instead of pressuring the Indian economy. This is another solution that will work effectively and be environmentally friendly. A straight couple of DC water pumps with a solar system where the converter and storage can be used for irrigation have been evaluated effectivelyandefficiently.InIndia,moderateirrigationis required3to5hoursa dayforcultivationandthesun's rays are available for 7 to 8 hours. About 50 percent of the sun's rays are used to power the load. The use of 50% of unused radiation by any storage system can not only reduce the size of the solar panel but also reduce the earth used to set the solar panel. Therefore, farmers canusealotoflandtofarm.Inthis paper,aDCpumpis selected to design and mimic a hydrogen based fuel cell irrigation system in India. This study was conducted using the development tool: HOMER pro (Hybrid Optimization of Multiple Energy Resources) simulation software for the economic development model test model, which reduces energy production costs to meet the ultimate energy requirement on a net basis. current costs. Thus, HOMER based hydrogen fuel cell irrigation system is analyzed and designed as a renewable green energy technology by reducing the energy storage requirement,improvingefficiencyandreliability[5].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

2. Literature review

The motive of the literature evaluation supplied here is twofold: first, thisoffers evidenceof understandinghole that justifies the need for these paintings; and 2d, it additionally presents a guide for the technique used in the take a look at and is a supply of information for assessment, triangulation and referencing. Given the above cause, we use the literature to reveal the constraints of present studies through focusing especiallyonstudiesthattrustedHOMERbecauseofthe analytical tool. HOMER (Hybrid Optimization Model for electric powered Renewables), advanced via NREL (national Renewable power Laboratory, USA) seems repeatedlyintheliteratureasadesiredtool[4].itcould dealwithabigsetoftechnologies(inclusiveofPV,wind, hydro, fuel cells, and boilers), masses (AC/DC, thermal and hydrogen), and can perform hourly simulations. HOMERisanoptimizationtoolthisisusedtodecidethe gadget configuration for decentralized systems. it has been used both to analyze the off grid electrification troubles in the developed as well as growing countries. in the case of developed international locations, frequently advanced gasoline systems together with hydrogen are taken into consideration. For developing international locations, a huge wide variety of research exist and a detailed evaluation of this literature is beyondthescopeofthispaper.rather,weareawareofa selected set for our reason. through a huge number of simulations,the observeobservedthat thePV hydrogen fuel becomes cost powerful because the demand increases. however, this examination focuses on the fundamental wishes as such and does now not encompass effective use of energy. The cost of power from gas cellular based totally electricity generation against the fee of delivery from the grid for a rural hospitalinIndia,makinguseofHOMERsimulations.The consequences showed beyond a distance of forty four km from the grid, the price of supply from an off grid supplyislessexpensive.Thesepaintingsjustconsidered the demand of a rural sanatorium and turned into not part of any traditional rural electrification program. it has been analyzed that the gold standard design and making plans of renewable power based micro grid gadget for a hypothetical rural community in which the baseloadissixhundredkW andtheheightloadis1183 kW, with an everyday electricity requirement of 5000 kWh/day. The observation considers sun, wind, hydro and diesel sources for power generation. even though they take a look at considering electricity calls for over 24 h, the basic terms and hypothetical nature of the assumptions make the work unrealistic for plenty off grid areas of developing countries. The look at uses a hypotheticalcaseofirrigationofoneHectarelandwitha peak call of 5 7 kW. it can be seen that the hybrid alternatives have often taken into consideration a confined set of technologies. moreover, maximum studies concentrate on presenting energy merely for home purposes and do no longer recall the electricity

demandforagricultural,irrigation,communityfunctions and for small scale enterprise units for the socio monetary development of the entire region. the load profiles are also now not cautiously considered in many cases. these troubles are considered within the present observation,therebybridgingtheunderstandinggap.

The social attractiveness of renewable power (RE) infrastructureplaysacriticalpositioninthefurtherance of the RE transition and social science research facilitates a better understanding of the elements that affect the attractiveness and expansion of such technologies. at the same time as much, preceding research are targeted renewable sources of fuels and powerwhichincludeethanol,wind,andhydroandaren't particular to solar, they may be nonetheless broadly relevant, emphasizing power improvement as a social count with technical components as opposed to a technical count with social components [6]. The three dimensional social popularity framework movements past designations of humans as simple supporters or warringpartiesandrecognizesthattheacceptanceofRE is a complex social response. paintings are primarily based on hydrogen gas and renewables in trendy, the constructsdevelopedarecarriedoutheretoagrovoltaics because of the similarities between huge tracts of agricultural land being appropriated for sun strength generation. As new strength technology inclusive of agrovoltaics goes beyond the area of interest applications to grow to be extra well known, the dimensions of social attractiveness, inclusive of the possibilities and barriers related to each dimension and theirinterconnections,canhelpinformchoice makingto decorate the growth of agrovoltaic development [6]. the latest research maintains that the social dimensions of developingenergystructuresarepossiblythemaximum vital, as preceding endeavors in India reveal that the social aspect of development can ultimately determine the fulfilment of a sun task. The paradoxical social gap describes excessive public assistance for hydrogen fuel butlowfulfilmentforconcretelocaltraits,highlightinga discrepancythatisrestrictingtheproliferationofRE[7]. Public opinion surveys were performed to verify this social hole in regards to solar power, finding robust Indian aid for large scale sun yet eminent opposition to neighborhoodtasks.theoverallsuperbmindsettowards thesunhasefficaciouslymisledapplicableactorstomiss social popularity as an invaluable detail of development similarly widening the distance between challenge notion and ultimate implementation. because social recognition is pivotal to energy transitions, this examination reflects a proactive attempt to recognize agrovoltaics from a solar industry expert’s angle to better understand the opportunities and limitations of agrovoltaic systems; the responses centered on issues associatedwithsocialreputationandpublicperceptions, consequently this paper places the findings from this researchintothecontextofsocialreputationframework.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

2.1. Market dominance

The market size of renewable energy adoption includes market acceptance and adoption of technology by consumers, investors, and firms. The growth of RE founding depends on how technology enters the market and stimulates investment and that business related issues and types of revenue, including local decisions, play an important role in the acceptance of various market players. From an investor's point of view, reliability of RE technology is critical to its implementation. However, the lack of reliable information for participants is understood to be a very common obstacle to market acceptance. To investigate situations that promote market acceptance, three key factorsareimportant: competitivecosts of installation/ production; methods of obtaining information and feedback;andaccesstofinancing.

2.2. Community adaptation

By building on the importance of the RE environment context, research has turned to addressing social resistance and geographical conflicts. Numerous studies have shown that the successful implementation of RE programs requires sensitivity to local community preferences and values. Research focused on the RE community side finds that local support is the most important factor in making projects real. Research has found that location based factors have a significant impact on community perceptions and attitudes. Therefore, consideration and acceptance of community preferences and values is the result of gaining public acceptance ofa solar space project. However, it isfound that rural residents see hydrogen fuel and irrigation basedonsolarenergyasanopportunitytoprotecttheir farmingenvironmentinotheruses,thuspreservingrural ownership.Withoutthesupportofrurallandownersand farmers, large PV will be severely limited and the successful implementation of agrovoltaic systems will depend on the farmer 's acceptance. Because solar projectsrepresentinglocal communities are expected to have high levels of acceptance, it will be important that the design and scale of agrovoltaic systems are aligned withruralownershipandinterests[6].

2.2.1. Stakeholder participation

Within the realm of social acceptance, stakeholder engagementandparticipatorydecision makingarewell recognized strategies that contribute to high levels of acceptance and successful RE development. Asking for public participation effectively ensures that local voices areheard,considered,andincludedintheproject,giving developers a direct opportunity to demonstrate local priorities in RE development. Observing the principles andprinciplesofthecommunity,bothbetterunderstood and managed through public participation, is more important and strategic, as a collectively designed

system allows for local acceptance rather than resistance. Consideration of all stakeholders involved in organizing participatory capacity may contribute to the creation of a project that generates local benefits: the financialbenefitsfromtheREprojectremainsocialanda sense of solidarity and pride often matures among citizens[6].

2.3. Socio-Political approval

The socio-political dimension of acceptance includes policy makers and key stakeholders. Research on the socio-political acceptance of FE has sought to understand this dimension, using both public opinion surveys aimed at measuring factors influencing support for FE and research on government policies and incentives.Policiesthatprovidefinancialincentiveslead togreatersocial acceptance ofsolarenergy,especiallyif host communities benefit most [8]. The implementation of solar energy is ultimately a local political decision, as municipal governments and zoning boards involve members of the relevant community and provide a forumtoincludepublicviews,soanawarenessthatsolar projectswork in the context ofa local policyisessential for successful development. Applying these research findings to the emerging agrovoltaic concept requires investigating how policy measures, public engagement models, and social institutions can help promote social acceptanceofsuchdevelopments[6].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

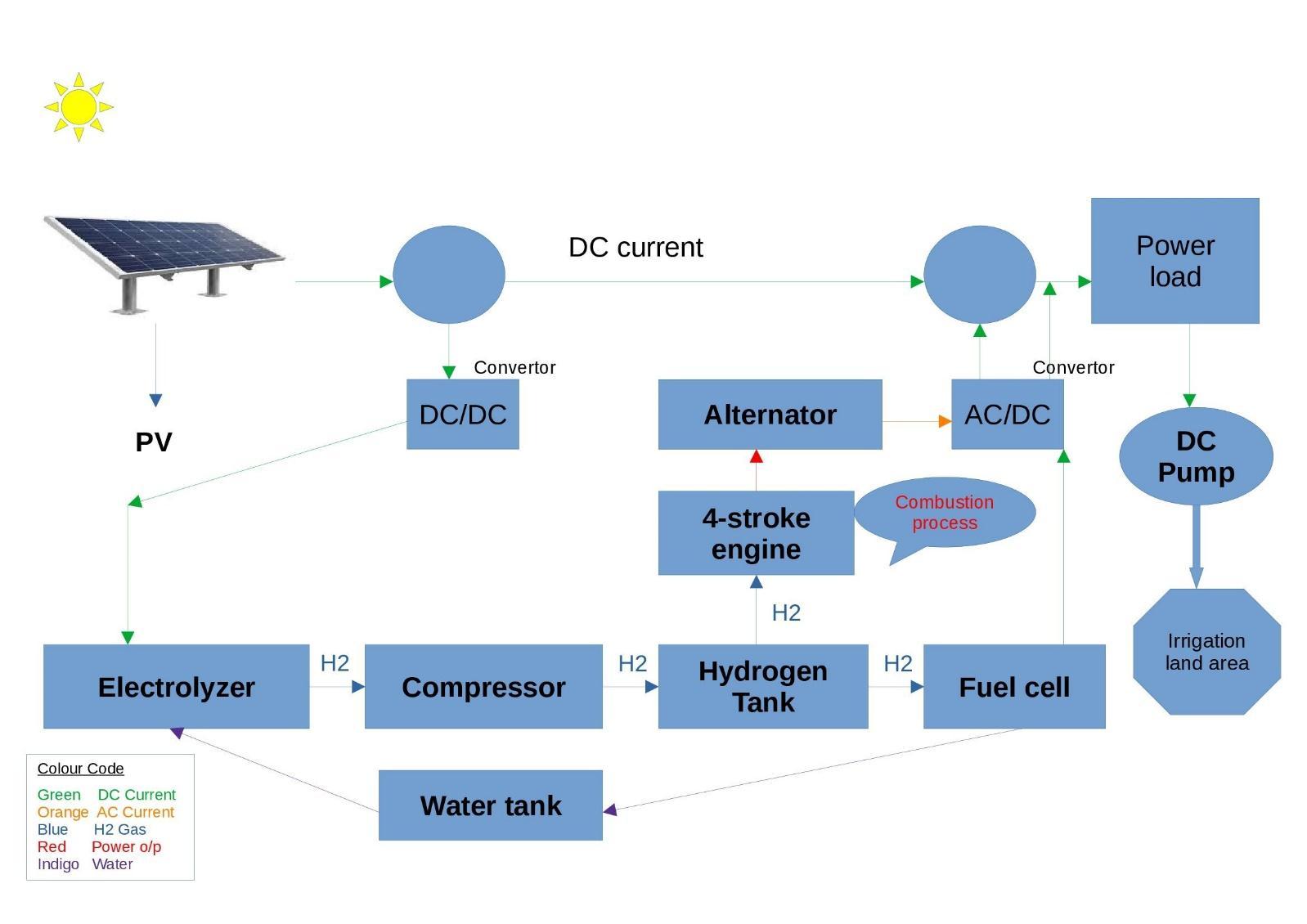

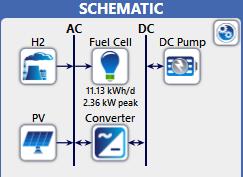

Fig.1 The proposed Hydrogen based Irrigation system

3.System Description

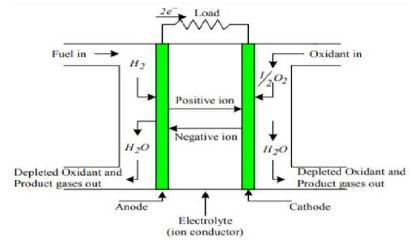

The schematic system shown in Figure 1 below can be divided into four subsystems: solar photovoltaic (PV) system, fuel cell (FC) system, DC submersible Pump and 4-stroke IC engine backup. Solar photovoltaic system and 4-stroke IC engine with alternator is the main systemthatgenerateselectricitytomeettheelectricload demand by converting solar energy into direct current electricity. Before sending electrical power to the load, anAC/DCconverterisrequiredtoobtainDC[9].

The proposed fuel cell system can be divided into four specific stages: (1) hydrogen generation stage, (2) Hydrogen storage stage (3) Backup stage (4-stroke IC engine)and(4)usestage.

The hydrogen production cycle will begin in the electrolyzer,wherewaterwillbeconvertedtohydrogen using electricity from photovoltaic modules. This hydrogen will be compressed and stored in steel compositetanks.Whennecessary,hydrogenwillbesent to the fuel cell and 4-stroke IC engine for combustion, which will produce the demanded electricity [3]. The hydrogen produced is stored in a hydrogen tank. Hydrogen storage will play an important role when the weather is unsuitable, overnight or when demand

exceeds the capacity to generate electricity from the PV system.Thisstoredhydrogenwillbesuppliedtothefuel cell(FC)whichwillgenerateelectricitytofullymeetthe demandvia a DC/DCconverter,asintheelectrolyzer,in this case to increase the voltage. In order to minimize water consumption, the water produced by the fuel cell isstoredinawatertank,andwaterissuppliedfromthe tank[9] when the electrolyzer needs it. Apart from all these stages, in case of failure of the above-mentioned powersupplyforanyreasonthatmaycausetechnicalor physicaldamage,anadditionalbackup,thatis,a4-stroke IC engine with hydrogen gas burning, is provided in the system for uninterrupted irrigation. It will provide brakingpoweroutputtotheconnectedalternatorwhich will generate AC current. This AC current will be convertedtoDCcurrentthroughtheAC/DCconverterto drivetheDCsubmersiblepump.

In use, hydrogen is fed into the fuel cell to generate electricity to drive the DC Submersible Pump to lift water.TheentirestageandprocessisshowninFigure1. Storage hydrogen will play a leading role at night or in anysystemfailure.Inthisrole,thestoredhydrogen will feedthefuelcell,andthefuelcellwillusethishydrogen to generate electricity that will fully meet the irrigation waterdemand[5].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

2.1 Hydrogen as a fuel

Due to the following properties of hydrogen which contributetoitsuseasafuel:

•widerangeofflammability

•lowignitionenergy

•smallquenchingdistance

•highself ignitiontemperature

•highflamespeedatstoichiometricratios

•highdiffusivity

•verylowdensity[10]

Wide range of flammability

Hydrogen has a broad flammability range than all other fuels.Asa result,hydrogen canbe burnedinaninternal combustion engine on a wide range of air fuel mixtures. Asignificantbenefitofthisisthathydrogencanrunona leanmixture.Aleanmixtureisoneinwhichtheamount of fuel is less than the theoretical, stoichiometric or chemicallyideal amountrequiredforcombustion witha givenamountofair.Thisiswhyitisquiteeasytostarta hydrogenengine[10].

Low ignition energy

Hydrogenhasaverylowignitionenergy.Theamountof energy required to ignite hydrogen is about an order of magnitude less than that required for gasoline. This allows hydrogen engines to ignite lean mixtures and ensurespromptignition[10].

Small quenching distance

Hydrogen has a small extinguishing distance, shorter than gasoline. As a result, the hydrogen flames move closer to the cylinder wall than other fuels before extinguishing. Therefore, it is more difficult to put out a hydrogen flame than a gasoline flame. The shorter extinguishingdistance canalsoincreasethe tendency to backfire as the flame of a hydrogen air mixture passes more easily a nearly closed intake valve than a hydrocarbon airflame.

High self ignition temperature

Hydrogenhasarelativelyhighself ignitiontemperature. This has important implications when a hydrogen air mixture is compressed. In fact, the auto ignition temperature is an important factor in determining what compressionratioanenginecanuse,asthetemperature rise during compression is related to the compression

3.2 Hydrogen infrastructure

The development of the hydrogen infrastructure is a major obstacle to the widespread adoption of H2FC technologies. There is a perception that an all encompassing "hydrogen economy" must be established

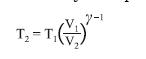

ratio. The temperature increase is shown by the equation:

(1)

whereisit:

V1/V2=thecompressionratio

T1=absoluteinitialtemperature

T2=absolutefinaltemperature

γ=ratioofspecificheats

The temperature cannot exceed the hydrogen selfignition temperature without causing premature ignition.Therefore,theabsolutefinaltemperaturelimits the compression ratio. The high self-ignition temperatureofhydrogenmakesitpossibletousehigher compression ratios in a hydrogen engine than in a hydrocarbonengine[10].

High flame rate

Hydrogen has a high flame rate at stoichiometric ratios. Undertheseconditions,theflamevelocityofhydrogenis almostanorderofmagnitudehigher(faster)thanthatof gasoline. This means that hydrogen engines can get closertothethermodynamicallyidealenginecycle.With leaner mixtures, however, the flame speed decreases significantly[10].

High diffusivity

Hydrogen has a very high diffusivity. This airborne ability is considerably greater than gasoline and is beneficial for two main reasons. First, it facilitates the formationofauniformmixtureoffuelandair.Second,if a leak of hydrogen develops, the hydrogen is rapidly dispersed. Therefore, unsafe conditions can be avoided orminimized[10].

Low density

Hydrogen H has a very low density. This results in two problems when used in an internal combustion engine. First, a very large volume is required to store enough hydrogen to provide a vehicle with adequate driving range. Secondly, the energy density of a hydrogen air mixtureisreduced,andthereforethepoweroutput[10].

with enormous costs and duplication of existing energy infrastructure. Developing a cost efficient infrastructure fromtheseoptionsthatcanevolveovertimeasdemand develops is a significant challenge. Centralized production methods based on new distribution networks, synonymous with a vision of the hydrogen economy. There are also incremental and less

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

infrastructural pathways, which use existing gas or electricity networks and reduce large upfront costs, albeit at the expense of lower efficiency. Indeed, H2Mobilityconcludedthatjust100smallfuelingstations with on site hydrogen production would be enough to supply the majority of India's population in the early stages of the transition to fuel cell vehicles, with additional infrastructure implemented as demand increases.Thissuggeststhatinfrastructuredevelopment maynotbeaschallengingassomehavesuggested.

4. Methodology

The system was proposed to continue the supply of electricity to the irrigation sector through unconventionalsources.Themethodologyofthisproject was developed to design hydrogen fuel cell and hydrogen gas as a fuel for 4 stroke internal combustion enginesystemusingHOMERinFig.2,theproceduresare discussedbelow:

Month mm L/Hectare Month mm L/Hectare

JAN 13 1,30,000 JUL 307 30,70,000

FEB 13 1,30,000 AUG 258 25,80,000

MAR 17 1,70,000 SEP 162 16,20,000

APR 12 1,20,000 OCT 75 7,50,000

MAY 55 5,50,000 NOV 17 1,70,000

JUN 92 9,20,000 DEC 11 1,10,000

TABLE I

Precipitation

4.2 Selection of DC Pump

in INDIA[12]

For this project, a 1.1 kW submersible DC solar pump wasselectedwhichhasaflowrateof55LPMwith20m waterheightandthesolarpumpcanlift3300l/hourat rated output [13]. Five hectares of sample land were takentoirrigateforthehypotheticalsystemproject.The monthly average daily water pumping load can be calculated using formula (1) which incorporates the (1)

Fig. 2. DC pump based irrigation in HOMER PRO

4.1 Experimental study of the system

The proposed system is designed for the whole national territory,inparticularforthoseareaswheremostofthe irrigationdependsonthedieselpumportheconnection to the grid. Here solar energy is used for electrolysis of watertoproducehydrogen whichisfurtherusedtorun thefuelcelltopowerthesubmersibleDC pumptopump ground water for irrigation and in other cases if failure occurs,asbackuphydrogengasproducedbyelectrolysis the process will be used to run a 4 stroke internal combustionenginewhichwouldbecoupledwitha5KVA alternatorwhichwillbeconvertedtoDCviaaconverter andusedtodriveasubmersibleDCpumpforcontinuous irrigation. Irrigation depends on rainfall, soil characteristics, local climate and crop characteristics. Depending on India's weather conditions, irrigation is required from January to May and from October to December. India's average monthly rainfall is described in Table I [11]. On paper, 8,60,000 liters / hectare of average water per month are needed for rice, wheat, cotton, peanuts, vegetables, etc. The running time of the system is considered 3 7 hours for the calculation but the time is not limited, it would vary season by season. Hence,wheneverwaterisneeded,itisenoughtosupply.

amountof precipitation[14]. 5

3. Monthly averaged load DC submersible pump 10 jan feb mar ap r may ju n ju l au g s e p o c t n o v d e c KW h / m on t h © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page121

International Research Journal

of

Engineering

and

Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

4.3 Fuel Cell

Fig. 4. Solar DC submersible Pump Homer Pro Analysis

Cathode equation: O2 + 4e + 4H+ = 2H2O O2 + 2H2 = 2H2O + HEAT + Electricity

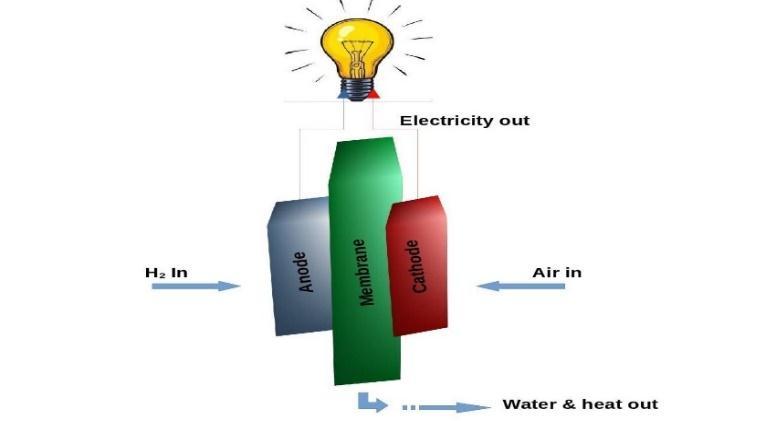

The fuel cell is an electrochemical engine that produces electricity by oxidation / reduction reactions. A fuel cell consists of an electrolytic membrane sandwiched between two catalyst-coated electrodes (anode and cathode).Oxygen(air)passesthroughoneelectrodeand hydrogenthroughtheother,generatingelectricity,water and heat in fig. 5 [16]. Fuel cells are the opposite of electrolysis: hydrogen and oxygen are combined to produceelectricity.Hydrogenfuelcellsareveryefficient

and only produce water as a byproduct, but they are expensive to build. However, due to high costs and safety, hydrogen will not produce electricity on a large scale. In the anodic section, the gaseous hydrogen oxidizes,releasingelectronsandcreatingH+ions[17].

Fig. 5 Schematics of fuel cell

Anode equation: 2H2 = 4H+ + 4e

Atthecathode,oxygenreactswiththeelectronsofthe electrodesandtheH+ionsoftheelectrolyteandwater. Herewateristhewasteproducttakenfromthecell[18].

There are various other types of FC systems. However, they work on a similar principle. Three components are required for a fuel cell system: an anode, a cathode and anelectrolyte.FCsareclassifiedaccordingtothetypeof electrolytic material used. A FC can be made up of hundredsofindividualcells,buteachhasthesamethree basiccomponents.Theelectrolyteislocatedbetweenthe cathode and the anode. Figure 6 illustrates a schematic of an operation diagram of the polymer electrolyte FC (PEMFC).ThistypeFCisalsoknownasprotonexchange membraneFC.PEMFCiswhatismostcommonlyusedin mobile power applications, such as vehicles. While the electrolytic material used varies depending on the type ofFC,thegeneral functionofFCisasfollows:fuel (pure hydrogen)isfedintotheanodecompartmentofthefuel cellwhileairorpureoxygenisfedintothe cathodeside oftheFC.Ontheanodesideofthecell,theelectronsare separatedasthegastriestoproduceitswaythroughthe electrolyte membrane. The membrane acts as a filter to separate electrons and hydrogen ions allowing only the passage of hydrogen ions. In the cathode compartment, the hydrogen ions that have passed through the membrane combine with the oxygen atoms from the supply air to produce H2O as a by-product; heat is also produced as a by-product. Unlike internal combustion engines,wherethefuelismixedwithairandfuel,inaFC there is a separation of the fuel and oxidizer without combustion of the fuel. Therefore, FCs do not produce theharmful emissionsproduced byinternal combustion engines.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

This work is negative since it is the input work done on thegas.Theidealgaslawissuitableupto100barand,at higherpressures,thegaslawequationpredictsagreater demandforwork.At350barand500bar,thisdeviation is4and9%morethanwhatisrequiredbytheidealgas law. By evaluating the work required to compress hydrogen,weshouldcompareitwiththespecificenergy content of hydrogen, 33 kWh kg − 1. In this context, about 10% of the available work is dedicated to the compressionofhydrogenupto500bars.

Fig. 6 Fuel Cell Working Diagram

4.4 Electrolyzer

Through the electrolysis process, an electrolyser converts electrical energy into chemical energy which produces hydrogen through an electrochemical process. Electrolysis is the process by which electricity divides water into hydrogen and oxygen. In this project, the solar photovoltaic system and the 4-stroke IC motor generate electricity to create a chemical reaction in the electrolyser for the production of hydrogen [19]. In this project, a PEM electrolyser is used which works according to the principle of electrolysis [20]. The PEM electrolyser does not require liquid electrolyte, which simplifies design and use in the field. The electrolyte is an acidic polymeric membrane. PEM electrolysers can potentially be designed for operating pressures up to 100 bar and are suitable for both stationary and mobile applications.Themaindisadvantageofthistechnologyis the limited life of the membranes. The main advantages ofPEMoverotherelectrolysersarethehigherturndown ratio, which increases safety thanks to the absence of KOH electrolytes, a more compact design thanks to higher densities and higher operating pressures. The performance of PEM electrolysers is expected to be significantly improved by additional work in material developmentandcellstackdesign[21].

Anode Reaction: 2H2O = O2 + 4H+ + 4e

Cathode Reaction: 4H+ + 4e = 2H2

4.5 Compressor

Whenconsideringhydrogenfortheinternalcombustion engine,hydrogencompressedto500bars(insomecases only 150 bar) is generally considered the most costeffective technology. This is because it meets the requirements for range (> 250 miles) and sufficiently low refueling time (<5 minutes). Compression of hydrogentakeswork.The waythisisdoneis byusing a set of compressors at the desired compression. Gradual compressionisclosetotheisothermalprocess[22].

In order for this system to work efficiently, we are introducingahydrogenmembranecompressor,whichis a reciprocating compressor that reciprocates in a cylindertocompressthegas.Diaphragmcompressorisa special type of volumetric compressor with a large compression ratio, good sealing performance, and the compressed gas is not polluted by lubricating oil and other solid impurities. Therefore, it is suitable for compressing high purity, rare and precious, flammable, explosive, toxic and noxious, corrosive and highpressure gases. It has a special name as it has a special diaphragmthatseparatesthecompressedmediumfrom the outside. The diaphragm compressor can also be referredtosimplyasadiaphragmcompressor.Duetoits special structure, the reciprocatingoxygenlowpressure diaphragm compressor does not need lubrication and the sealing performance is very good. The compressed mediumisnotincontactwithanyslidingagent,soitcan compress the gas with a very high purity, generally reachingapurityof99.999%,whichismoresuitablefor compression. In addition, membrane compressors are alsoparticularlysuitablefor corrosive,radioactive,toxic and explosive gases. The diaphragm compressor has goodheatdissipationandcanadopta highcompression ratio, so its pressure range is wide and the discharge pressure can go up to 500MPa. It is used in the food industry, the chemical industry of the petroleum industry, the electronics industry, nuclear power plants, aerospace, military equipment, medicine, scientific researchandotherfields[23].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

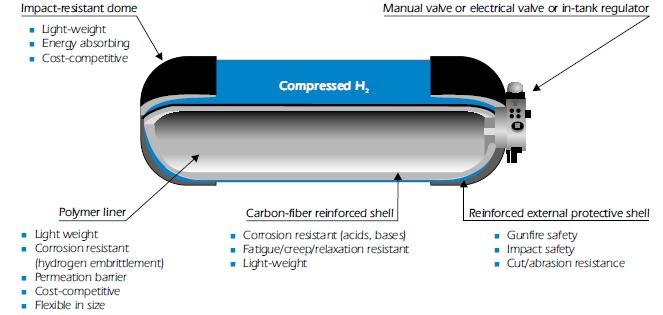

4.6 Hydrogen Tank

Storinghydrogenincompressedgaseousformoffersthe simpleststoragesolution.Afixedenergystoragesystem is necessary to meet the load demand when the energy produced is insufficient. The hydrogen gas storage system has an economic and technical advantage over the battery storage system for long-term storage. Compressedhydrogenismainlystoredincylinderswith hemisphericalcaps,similartothoseusedforthestorage of natural gas and other process gases [24]. The connection between the hydrogen storage tank and the fuel cell is internal in HOMER PRO. In this system, the hydrogen accumulation acts as a backup of the system during the non-operation of the photovoltaic system or intheeventofanothertechnicalfailure.Intheeventofa photovoltaic or non-functioning failure, the hydrogen gas from the storage will be injected through the nozzle into the 4-stroke IC engine where the combustion process rotates the alternator shaft which confirms the output for the submersible DC pump. which ensures uninterrupted power supply to the system and governs the continuous irrigation process. A schematic of a hydrogenstoragetankisshowninfigure8.Hereweare usingthestorageofa10kg(netweightofhydrogengas) cylinderfromthegogglemanufacturerGemini[25].

Fig. 8 Schematics of Hydrogen storage tank

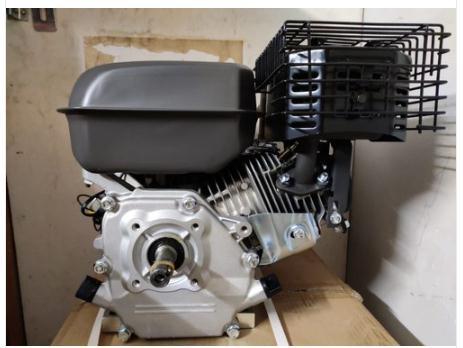

4.7 4-Stroke IC Engine

Anefficientparallelsystemisdesignedtoactasabackup for the COMET which includes the combustion of hydrogen in a 4-stroke IC engine. For this, we use a 196cc 3-liter 4-stroke engine from VED firms which would be modified by a disc-shaped combustion chamber (with flat piston and chamber ceiling). The most challenging part of burning hydrogen in an IC engineischeckingthepre-ignitionandknocks.However, to solve this problem, we have to redesign the engine, especially the combustion chamber and the cooling system. A disc-shaped combustion chamber (with flat piston and chamber ceiling) can be used to reduce turbulence within the chamber. The shape of the disc reduces the radial and tangential low velocity components and cancels the amplification of the input vortex during compression. Since unburned hydrocarbons are not a problem in hydrogen engines, a largebore/strokeratiocanbeusedwiththisengine.To accommodatethewiderrangeofflamespeedsoccurring overawiderrangeofequivalenceratios,twosparkplugs are required. The cooling system should be redesigned to provide uniform flow to all places that need to be cooled. At the same time, second measures can be used to decrease the probability of pre-ignition by applying two small exhaust valves instead of a single large one, which develops an effective evacuation system, through whichtheexhaustgasesofthecombustionchamberwill be replaced with fresh air. Here in fig 8, the combustion chamberofthe4-strokeenginewillbemodifiedwiththe flatpistondiscchamberasshowninfig9.

Fig 7. Nova Swiss MK-Diaphragm CompressorVolume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Fig. 11. 5KVA Alternator

4.9 Solar Photo-voltaic cell

The Solar system is generally designed and sized to power electrical accessories in direct and / or alternating current. This consists of a connected photovoltaic solar module a solar charge controller, a converter or an inverter [9]. Solar panels generate energy from the sun by converting sunlight into zeroemissionDCelectricitythatissuppliedtoanelectrolyser thatproduceshydrogengas.Indiaislocatedbetweenthe latitudeof20.5937°Northandthelongitudeof78.9629 ° East [26]. The average global solar radiation is 6.50 kWh / m2 / day as the same monthly average solar radiationdatainHOMERproisshowninFig.11.

Fig. 10 Modification of 4-stoke IC engine combustion chamber

4.8 Alternator

An alternator is an electrical generator that converts mechanical energy into electrical energy in the form of alternating current. For reasons of cost and simplicity, most alternators use a rotating magnetic field with a stationary armature. Occasionally a linear alternator or rotating armature with a stationary magnetic field is used.Inprinciple,anyACelectricgeneratorcanbecalled an alternator, but usually the term refers to small rotating machines powered by automotive engines and other internal combustion engines. An alternator that usesapermanentmagnetforitsmagneticfieldiscalleda magneto. Alternators in power plants driven by steam turbines are called turbo alternators. Large 50 or 60 Hz three phase alternators in power plants generate most of the world's electricity, which is distributed by power grids. Here In our system, we are using a 5KVA alternator from Ayush electric company, as shown in figure 10, which would be coupled with a 4 stroke IC motor to produce AC and be converted to DC to run the main load for one. uninterrupted watering. However, it would run the compressor as well and then the main loadofacompressorwillbecutoffandconnectedtothis ACalternator.

Fig. 12 Month- wise solar radiations

5. Simulation and Result

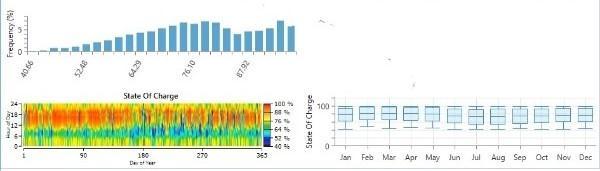

ThesystemissimulatedinHOMERProbycalculatingthe average demand, a different size of the combination of parts. The system is optimized for demand and load management.SystemspecificationsareshowninTableI.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

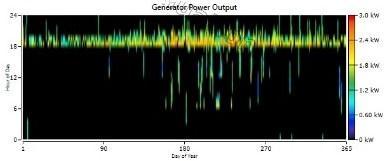

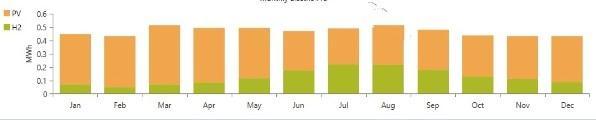

TheprimaryDCloadofthesystemconsumes1535kWh / year from fuel cells and 389 kWh / year more from backup production (combustion of hydrogen gas paired with 4-stroke IC engines with 5 KVA alternator). The photovoltaic output and backup production are used by the electrolyser to produce 106 kg / year of hydrogen gas.Theaveragemonthlyelectricityproductionisshown inFigure13byPVandFC.

Table. II System specification

InHOMERPro,thedesignoptimizesthesystemfor1kW flat photovoltaic panels, 2 kW fuel cells,1 k Welectrolyser and 10 kg hydrogen tank capacity. Table III. shows the production and consumption of the entiresystem. According to the simulation result, the total electricity produced per year is 6040 KWh. The solar photovoltaic produces 4105 kWh / year and the fuelcells generate 1535 kWh / year and 400 kWh / year of reserve production (combustion of hydrogen gas in pairs of 4-stroke IC engines with 5 KVA alternator), which represent the 68%, 25% and 7% of the total productionrespectively.

S.No. Parts Production Consumption

I Electrolyzer( kg/year) 106

Fig. 13 Month-wise averaged power production by PV & FC

Figure14showstheannualhydrogenproductionandDC load consumption. 61Kg / year of pure hydrogen produced is used as fuel for a fuel cell which provides 1535kWh/yearofelectricitytorunthesubmersibleDC pump. However, an additional production of hydrogen gas is also produced, i.e. 45 kg / year as a reserve (combustion of hydrogen gas in pairs of 4-stroke IC engines with 5 KVA alternator) for the continuous operationoftheirrigationproject.

II Electrolyzer( KWh/year) 3100 III PV(kWh/yea r) 4105 IV FC(kg/year) 61 V FC(kWh/yea r) 1535 VI DC submersible pump(kWh/ Year)

VII Alternator (kWh/year) 400

VIII 4stroke Engine (IC)(Kg/Yea r)

1924

45

IX Other Accessories 1016

Table III Simulated & Proposed Result of the overall system

Fig. 14 Year-wise production of H2 & consumption of prime DC load

Thenetpresentcost(NPC)ofthesystemis$5645which isapproximately4.5lakhrupeesaccordingtotheIndian currency. The cost of energy (COE) is $ 0.0897 which is about 7 rupees per kWh according to the Indian system and the operating cost of this system is $ 17.6 per year which would be approx. 1,373 rupees respectively in Indian currency. The various costs of the system are showninTableIV.Thewholesystemisdesignedforthe production of hydrogen in the field. Hence, there is the involvement of small transportation costs. The initial costoftheprojectis higherthantheconventionaldiesel irrigationsystem,butacostwillbelowerin25yearsdue to the low maintenance costs. On the other hand, for a diesel irrigation system a diesel pump has a low initial costbutoperationandmaintenancecostsriseeveryyear due to the growth of diesel price. From the 2nd year of installation, diesel prices will rise 4-7% annually.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

The usual output of a diesel engine is about 3 kWh per litre of diesel. A 5-hectare area is considered for designing theproposed system and if the same system is designed fora diesel pump, it will consume 511-litre diesel and will emit 800 kgs of CO2 per year. So, the per year fuel cost

will be 577 $(45,006 Rupees) for a diesel-based irrigation system compared to the proposed system, the total cost (only for diesel) will be 14,425 $ (11.25 lakhs Rupees) for 25 years which is more than Net present cost (NPC) of Solar PV-Hydrogen Fuel Cell backup by hydrogen gas combustion in 4-stroke IC engine couple with 5KVA alternator System. Now if the cost of the diesel engine and per year maintenance cost are considered then it is clear that this designed system is lessexpensivethanthedieselirrigationsystem[27].

Now let us compare with State grid electricity metered chargesi.e.,COEis0.0897$/kWh(7Rupees/kWh).From table III total units utilized by DC submersible load i.e., 1924 kWh/year which cost around 172 $/year (13,468 Rupees/year). Now if we calculate the metered charges over 25 years withan inflation of2-3% it wouldcostus 7500$(5.85lakhsRupees)whichismuchmorethanthe Net present cost (NPC) of Solar PV-Hydrogen Fuel Cell backup by hydrogen gas combustion in 4-stroke IC engine couple with 5KVA alternator System. Now if the cost on grid state electricity metered charges to cost is considered then it is clear that this designed system is less expensive over on the grid state electricity metered irrigationsystem.

6. Conclusion

Compared tothe existing system, the installationcostof the designed system is high but with the progressive development of the technology, the prices of the componentsusedinthesystemwilldecreaseinthenear future.Furthermore,theoperatingandmaintenancecost of the proposed system is very low and there is no significant replacement cost in 25 years of the project except for the electrolyzer. As a new phase of COMET renewable energy (combination of several energy technologies), through this document a hydrogen-based storage system is promoted for a wide use in every sector. Nowadays we see cooking gas, meaning LPG is now supplied through piping connection and a communityischargedwithmeteredratesthataremuch cheaper than LPG cylinders. So, in the same way, who knows that in the near future a wide use of gaseous hydrogen would require the same distribution system andwouldcertainlyreducethedollarsoftheoverallcost of the system [28]. This safe use of hydrogen gas expandsthewayitcanbeusedforirrigationpurposesin the agricultural sector rather than using a conventional battery storage system. Furthermore, the system operates at zero carbon emissions, however a very low amountofcarbonemissionswillevolvenotdirectlyfrom thesystembutindirectlyduetothechemicalreactionof atmospheric vapors [29]. Where conventional diesel systems or thermal power plants are in an alarming phase for carbon emissions. Hence, it can be said that COMET (Combination of Multiple Energy Technologies) would be a non- renewable energy alternative based on solarenergyandhydrogenfuelforeffectiveirrigationin droughtpronestatesofIndiawillbetheunconventional solutionforthenextenergycrisis.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

REFERENCES

[1] N. Norouzi, “Assessment of Technological Path of Hydrogen Energy Industry Development: A Review,” Iranian Journal of Energy and Environment,vol.12,no.4,pp.273 284,2021,DOI:10.5829/ijee.2021.12.04.01.

[2] Y. Kikuchi, T. Ichikawa, M. Sugiyama, and M. Koyama, “Battery assisted low cost hydrogen production from solar energy:Rationaltargetsettingforfuturetechnologysystems,” International Journal of Hydrogen Energy,vol.44,no. 3,pp.1451 1465,2019,DOI:10.1016/j.ijhydene.2018.11.119.

[3] J. Carroquino et al., “Combined production of electricity and hydrogen from solar energy and its use in the wine sector,” Renewable Energy,vol.122,pp.251 263,2018,DOI:10.1016/j.renene.2018.01.106.

[4] R. Sen and S. C. Bhattacharyya, “Off-grid electricity generation with renewable energy technologies in India: An applicationofHOMER,” Renewable Energy,vol.62,pp.388 398,2014,DOI:10.1016/j.renene.2013.07.028.

[5] T.Khadem,S.M.B.Billah,S.Barua,andM.S.Hossain,“HOMERbasedhydrogenfuelcellsystemdesignforirrigation inBangladesh,” 4th International Conference on Advances in Electrical Engineering, ICAEE 2017,vol.2018-Janua,no. September,pp.445 449,2017,DOI:10.1109/ICAEE.2017.8255397.

[6] A. S. Pascaris, C. Schelly, L. Burnham, and J. M. Pearce, “Integrating solar energy with agriculture: Industry perspectivesonthemarket,community,andsocio-politicaldimensionsofagrivoltaics,” Energy Research and Social Science,vol.75,no.March,p.102023,2021,DOI:10.1016/j.erss.2021.102023.

[7] B. Luo, D. Ye, and L. Wang, “Recent Progress on Integrated Energy Conversion and Storage Systems,” Advanced Science,vol.4,no.9,pp.1 15,2017,DOI:10.1002/advs.201700104.

[8] Z. Abdin and W. Mérida, “Hybrid energy systems for off-grid power supply and hydrogen production based on renewableenergy:Atechno-economicanalysis,” Energy Conversion and Management,vol.196,no.June,pp.1068 1079,2019,DOI:10.1016/j.enconman.2019.06.068.

[9] S. Peláez-Peláez, A. Colmenar-Santos, C. Pérez-Molina, A. E. Rosales, and E. Rosales-Asensio, “Techno-economic analysisofaheatandpowercombinationsystembasedonhybridphotovoltaic-fuelcellsystemsusinghydrogenas anenergyvector,” Energy,vol.224,2021,DOI:10.1016/j.energy.2021.120110.

[10] L.Walter,“HydrogenUseinInternalCombustionEngines,” Hydrogen Fuel Cell Engines,pp.3 1to3 23,2001.

[11] M.O.F.AgricultureandF.Welfare,“DROUGHTMANAGEMENTPLAN”.

[12] “Area_Weighted_Monthly_Seasonal_And_Annual_RainfallTill2014.”

[13] A. K. Tiwari and V. R. Kalamkar, “Performance investigations of solar water pumping system using helical pump under the outdoor condition of Nagpur, India,” Renewable Energy, vol. 97, pp. 737 745, Nov. 2016, DOI: 10.1016/j.renene.2016.06.021.

[14] R.Vagani,“SolarWaterPumpSystemTsavoEastNationalParkFeasibilityStudyReport,”no.February2012.

[15] M.N.I.SarkarandH.R.Ghosh,“Techno-economicanalysisandchallengesofsolar-poweredpumpsdissemination in Bangladesh,” Sustainable Energy Technologies and Assessments, vol. 20, pp. 33 46, Apr. 2017, DOI: 10.1016/J.SETA.2017.02.013.

[16] M. Chahartaghi and A. Nikzad, “Exergy, environmental, and performance evaluations of a solar water pump system,” Sustainable Energy Technologies and Assessments,vol.43,Feb.2021,DOI:10.1016/j.seta.2020.100933.

[17] A. Ajanovic and R. Haas, “Prospects and impediments for hydrogen and fuel cell vehicles in the transport sector,” International Journal of Hydrogen Energy, vol. 46, no. 16, pp. 10049 10058, Mar. 2021, DOI: 10.1016/J.IJHYDENE.2020.03.122.

[18] H.YuandC.Hebling,“FuelCells:Microsystems,” Encyclopedia of Materials: Science and Technology,pp.1 13,2005, DOI:10.1016/B0-08-043152-6/02020-9.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

[19] P.J.Jadhav,N.Sawant,andA.M.Panicker,“Technicalparadigmsinelectricitysupplyforirrigationpumps:Caseof Maharashtra, India,” Energy for Sustainable Development, vol. 58, pp. 50 62, Oct. 2020, DOI: 10.1016/j.esd.2020.07.005.

[20] K. Chau, A. Djire, and F. Khan, “Review and analysis of the hydrogen production technologies from a safety perspective,” International Journal of Hydrogen Energy, vol. 47, no. 29, pp. 13990 14007, Apr. 2022, DOI: 10.1016/J.IJHYDENE.2022.02.127.

[21] M. A. Valenzuela and B. Zapata, “Hydrogen production,” Hydro processing of Heavy Oils and Residua, pp. 313 338, 2007,DOI:10.1299/jsmemag.119.1169_182.

[22] “Compressed Hydrogen - an overview | ScienceDirect Topics.” https://www.sciencedirect.com/topics/engineering/compressed-hydrogen(accessedJun.13,2022).

[23] A.Ajanovic andR.Haas,“Economicprospectsandpolicyframework forhydrogenasfuel inthetransportsector,” Energy Policy,vol.123,pp.280 288,Dec.2018,DOI:10.1016/J.ENPOL.2018.08.063.

[24] O. S. Burheim, “Hydrogen for Energy Storage,” Engineering Energy Storage, pp. 147 192, Jan. 2017, DOI: 10.1016/B978-0-12-814100-7.00008 0.

[25] D.Nash,D.Aklil,E.Johnson,R.Gazey,andV.Ortisi,“Hydrogenstorage:Compressedgas,” Comprehensive Renewable Energy,vol.4,pp.131 155,2012,DOI:10.1016/B978-0-08 087872 0.00413 3.

[26] P. K. S. Rathore, S. S. Das, and D. S. Chauhan, “Perspectives of solar photovoltaic water pumping for irrigation in India,” Energy Strategy Reviews,vol.22,pp.385 395,Nov.2018,DOI:10.1016/j.esr.2018.10.009.

[27] A. Ajanovic, M. Sayer, and R. Haas, “The economics and the environmental benignity of different colors of hydrogen,” International Journal of Hydrogen Energy,Mar.2022,DOI:10.1016/J.IJHYDENE.2022.02.094.

[28] M. Niajalili, P. Mayeli, M. Naghashzadegan, and A. H. Poshtiri, “Techno-economic feasibility of off-grid solar irrigationforaricepaddyinGuilanprovinceinIran:Acasestudy,” Solar Energy,vol.150,pp.546 557,2017,DOI: 10.1016/j.solener.2017.05.012.

[29] S.B.Walker,D.vanLanen,U.Mukherjee,andM.Fowler,“Greenhousegasemissionsreductionsfromapplications of Power-to Gas in power generation,” Sustainable Energy Technologies and Assessments, vol. 20, pp. 25 32, Apr. 2017,DOI:10.1016/j.seta.2017.02.003.

[30] TheIndiaMetrologicalDepartment(IMD),“AnnualRainfalldata”.