Durability of Recycled Aggregate Concrete with Conventional and Equivalent Mortar Volume Method: A Review

Nazneen Nazeer1 , Praveen Mathew2

1P G Student, Dept. of Civil Engineering, Mar Athanasius College of Engineering, Kothamangalam, Kerala, India

2Professor, Dept. of Civil Engineering, Mar Athanasius College of Engineering, Kothamangalam, Kerala, India ***

Abstract - Recycling construction wastes to prepare structural concrete is an effective measure to solve the dual problems of resource shortage and environmental pollution. RA is an alternative and reliable source for replacement of naturalaggregates. The concrete structures in service always subject tothe coupled effect of multiple environmental factors such as chloride attack, carbonation, water penetration and aggressive agent penetration etc., which accelerates the deterioration of durability. Durability resistance of recycled aggregate concrete with diverse substitution rates using conventional mix proportion compared with equivalent mortar volume method under different factors are reviewed in this paper. Durability resistance of RAC with conventional and equivalent mortar volume mix method results from several research are consolidated in this review paper.

Key Words: Chloride attack, Durability, RAC (Recycled Aggregate Concrete), RCA (Recycled Coarse Aggregate), Carbonation, EMV (Equivalent Mortar Volume).

1. INTRODUCTION

In the new context of a circular economy where the environmental aspect is highlighted, the exploitation of naturalresourcesandgenerationofwastemustbereduced. Therecycling ofthe oldconcretes can contributeto reduce theextraction of the natural resources and to reduce the waste deposit areas. For the resources conservation, cleaner production and sustainable development, RAC is considered as an ideal alternative to the traditional concrete.Therefore,exploringthefeasibilityofRACusedas structure concrete to expand the application range and improve utilization rate of C&DWs is significant. Durability is one of the main topic of concern while using recycled aggregates in concrete constructions. The concrete structures in service always subjecttothecoupledeffectof multiple environmental factors such as chloride attack, sulphate attack, carbonation, and aggressive agent penetration etc., which accelerates the deterioration of durability. The properties related to the durability are usually the risks of steel reinforcement corrosion (carbonation, chloride penetration, air/water permeability, porosity).

2. RECYCLED AGGREGATE

British standard BS 8500 2 (BSI, 2006) defines RCA as recycledaggregatewithmaximummasonry/finescontent of 5%, maximum lightweight material/asphalt content of 0.5% and maximum other foreign materials content of 1%. Recycling of demolished concrete into aggregate is environmentally beneficial by preserving natural resources, by waste reduction and by preserving landfill space. The properties of recycled aggregate mainly depends on the properties of its parent aggregate concrete and also on the quantity and quality of cement mortar, which is attached to the grains of recycled aggregate andonrecyclingmethods.

Fig 1:Recycledaggregateofsizerange12.5mmand 20mm

From practical experience, Mirjana shown that the bulk densityofrecycledaggregatewasontheaverageby10% lowercomparedtothebulkdensityofnaturalaggregates [2].The researchers from the University of Hong Kong recommend that the amount of recycled aggregate in structural concrete should range from 20% to 30%, in orderto ensure that the maximum water absorption of aggregate used is less than 5%. [3]The water absorption value of the classically recycled coarse aggregate ranges within the interval from 3.5% to 10%, and for the fine aggregate, within the range of 5.5% to 13% from the resultsof Marinković [3].

3.PROPERTIES OF RECYCLED AGGREGATE CONCRETE

From studies of Sherif Yehia, concrete made with RA showedless durability due to high pore volume which led to high permeability and water absorption. High water absorption isdue to cement paste adhered on the aggregate surface [9]. More water is needed for RAC to achieve similar workability to that of NAC due to higher absorption capacity of recycled aggregate, due to the presenceofimpuritiesandattachedcementhydrates.As the RA content increases in the mix, the workability reduces especially at lower w/c ratio [10]. Malesev experimentsshowedthatfor50to100%replacementof virgin aggregates with the recycled aggregatedecreases the compressive strength by 5 to 25 % and a reduction ofupto10%insplittensilestrengthwasobservedwhen virgin aggregate was substituted with recycled aggregate,alsoflexural strengthreductionwas observed to be10% that of RAC [11]. Specific gravity and bulk density are relatively low for recycled aggregates when compared to fresh granite aggregate. This is mainly due to the high water absorption of the RA, as mortar has higherporositythan aggregates and as the size of recycled aggregate increases, achieved strength increases [12].

4. MIX DESIGN METHODS

4.1 Conventional method

In studies made by Emmanuel, the conventional methods include the absolute volume approach according to the American Concrete Institute (ACI) standard or the Department of Environment (DoE) concrete mix design method given by the British specification[13]. Apercentageofnatural aggregates are replacedwithrecycledaggregatesinthismethodwithout quantitativelyconsideringtheattachedoldmortaronthe recycled aggregate. Conventional methods require more cementcontentcomparedtothatproportioned usingthe EMV mix design method [13]. Here RCA is treated asa homogenousmaterialasthatofnaturalaggregate.

4.1 Equivalent mortar volume method

RCA is considered as a two-phase material comprising residual mortar and original virgin aggregate. In the proposedmethod,theRCAconcretemixisproportioned to have the same TM volume as a companion concrete mix made entirely with fresh NAs, with the companion mixmadewiththesametypeofcoarseaggregateasthat in RCA. The salient feature of the proposed mix design method is the treatment of RM in RCA as part of the TM contentofRCAconcrete.

Fig -2: Recycledaggregatescontainingattached mortar

Fig -3: Recycledaggregatesdevoidofattachedmortar aftertreatment

Concreteproportionedbasedonthisconceptisshownto havethesameorsuperiorfreshandhardenedproperties comparedto equivalent conventional concrete with the same amount ofmortar [14]. Steps in determination of equivalent mortar volume mix method involves: Determination of companion concrete mix proportions made with natural aggregate. That is the determination ofrequiredRCAandfreshnaturalaggregateproportions in companion RCA concrete mix. Determination of required water, cement, and fine aggregate proportions and minimum replacement ratio in RCA concretemix. Maximum residual mortar content in RCA concrete mix made with 100% RCA through an equation given by G. Fathifazl and through an experiment the residual mortarcontentofrecycledaggregatecanbemeasured.

5. DURABILITY FACTORS

5.1 Chloride attack

. All RCA-concrete examples made from mixtures proportioned using the EMV approach were found to haveapparentchloridediffusioncoefficientsofthesame order of magnitude as specimens made from traditional structural-

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

grade concrete. In fact, RCA-concrete specimens without additional cementitious ingredients and proportioned using the EMV approach had apparent chloride diffusion coefficients that were lower than those of specimens prepared of mixture and proportioned using the traditionalmethod.Theresistance withsubstitutionrate.

determinantsofhowlongrecycledconcretewilllastina challenging environment. Therefore, concrete and RCA modification procedures might be taken into consideration inorder to increase the RAC's durability and utilisation rate. [1] This condition is caused by the oldmortar'shighporosityandmicrocracks, which cause a high permeability for chloride ions. The F-T cycles make this damage worse. The resistivity of recycled aggregate concrete to chloride ion penetration wasstill lower than that of regular aggregate concrete after ten yearsofoutdoorexposure. Flyashgreatlyincreasedthe concretemixture'sresistancetochlorideionpenetration [16].

5.2 Freeze thaw cycles

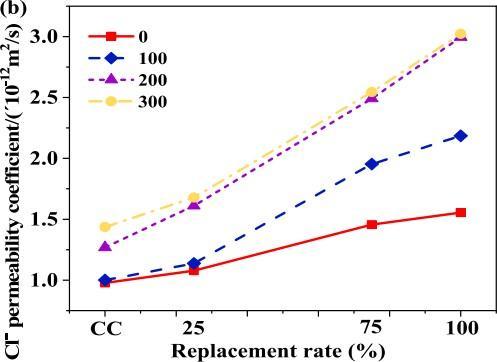

Fig -4: The variation trend of chloride diffusion coefficient

tochloridepenetrationofRCA-concretespecimensmade of mixtures proportioned by the EMV method was improvedby theadditionofsupplementarycementitious materials (fly ash or bfs) as partial replacement for ordinary portland cement. . In comparison to the reduction brought about by the inclusionof fly ash, the addition of bfs decreased the apparent diffusion coefficient of RCA-concrete mixes created using theEMV method by 120 200 percent. According to Abdelgadir Abbas'analysis, using the EMV approach in combination withadditionalcementitiouselementsresultsinconcrete that is highly resistant to chloride penetration. [6] Concrete's resistance to chloride corrosion was evaluated. At four separate F-T cycles, the total passed chargewithregardtotheRACwascalculated(0,100,200 and 300 cycles). It demonstrated a substantial link between the overall charge passing amount, the RCA substitutionlevel,andthenumberofF-Tcycles.According to ASTM C1202 (2012), the ability of chloride to penetrate is low for total passed charges between 1000 and2000,moderateforchargesbetween2000and4000, andhighforchargesbeyond4000coulombs.Asshown

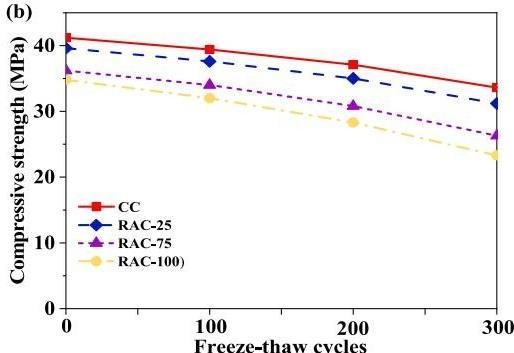

Fig -5:Compressivestrengthofrecycledconventional concrete(conventionalmixmethod)

However, the EMV approach provides concrete with greater resilience to freeze-and-thaw action than RCAconcrete proportioned by conventional mix design method [6] becauselower total mortar content in RCAconcrete can be attained using this method. More chloride ions can enter the RAC specimens thanks to a

AccordingtotheASTMC666-97protocol,rapidfreezing and thawing in water was used for the freeze-and-thaw experiments [15]. For a maximum of 300 cycles, the relative dynamic modulus of the test prisms was measuredinordertotrack thefreeze-and-thawdamage. By taking an accurate transverse frequency reading of the specimens, one can calculate the relative dynamic modulus. The durability factor served as a representation of how well concrete performed in freeze-and-thaw conditions. A strong resistance to freeze- and-thaw action can be observed in RCAconcrete mixes proportioned by the traditional mix designmethod(100percent RCA content) or by the EMV method (63.5 percent and 74.3 percent RCA content for RCA-concrete made with RCA- MO and RCA-VA, respectively). in Fig. 4, the results revealed that, with the exception of RAC- 25, all RAC had a high level of permeability after 300 F-T cycles. The ancient mortar's excessive porosity and microcrackson the RCAsurface are the cause of the high chloride ion permeability. More chloride ions can enter the RAC specimens because there are more holes and microcracksthat have created and connected flow channels. In addition tosulphoaluminate cement, fly ash andsilicafumearemineral admixturesthatcanincrease the durability of concrete. The quality of RCA and the type of concrete used are the main

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

rise in F-T cycles, more holes and microcracks, and the formation of interconnected flowpathways.

5.3 Carbonation

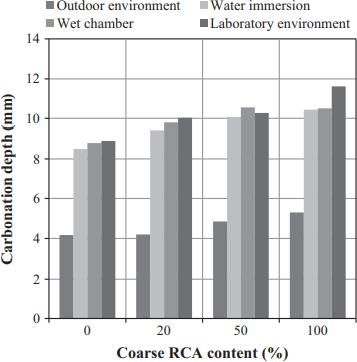

AsetupbasedonadvicefromRILEMwasusedtoconduct a carbonation test. The carbonation depths of RCAconcrete, both with and without additional cementitious ingredients,arewithintherangeanticipatedforordinary structural-grade concrete. The least amount of carbonation was found in RCA- concrete specimens without additional cementitious ingredients,followed by examples with fly ash. The reserve alkalinity of the concrete's binder is the primary factor impacting the carbonation of RCA-concrete, according to specimens created with concrete proportioned using the EMV method. It was discovered that specimens with a high cement

contenthadahighresistancetocarbonation.The carbonationcoefficient for mixes created using the EMV approach, however, was lower or equivalent to that of mixes created using the conventional method for specimens containing fly ash [6]. Concrete's carbonation coefficient improved asrecycled aggregate and fly ash contentsincreased[16].Ifallotherparametersareequal, largercarbonationdepthsresult fromtheassimilationof increasing amounts of RA. Concrete made entirely of coarse RCA has the potential to carbonate at up to twice the rate of similar NAC mixes. Regarding the RA type effectoncarbonation,it wasdiscoveredthatRMAcreate deeper carbonation depths than RCA for a given replacement level. In an MRA blend, the depth of carbonation in the final concrete increases as the RMA con- tent increases. Since concrete porosity and carbonationareintimatelyrelated,it followsthatadding moreporousRAwillmakeconcretemorepermeableand so allow for deeper carbonation. An efficient way to improve mechanical performance and decrease carbonation in RAC mixes is to lower the w/c ratio with the use of water lowering admixtures. It was also determined thatcontrolling the quality and quantity of RA in the mix is preferred because these factors have a stronger impact on this characteristic than reducing the w/cratiobyaddingwater-reducingadmixtures.

Fig -6:Carbonateddepthofconcretecuredindifferent environments(adaptedfromAmorimetal.)

The use of mineral additions as cement replacement causes greater carbonation depths than those of mixes withoutthem.ThishappensbecausetheCa(OH)2content decreases thus lowering the pH of concrete. Nevertheless, irrespective of the presence of RCA, the difference in carbonation depth is similarover time to that of the corresponding NAC, with or without any mineraladditions[17].

5.4 Water penetration

Testwasperformedbyintroducingthespecimensintoa deviceinwhichtheyweresubmittedtoawaterpressure equal to 500 kPa for a period of 72 hr, after that specimen is cut in half in order to determine the water penetration depth. Each mix class result of the water permeabilitytestwasobtainedfromtheaverageofthree different specimens. The results for every ACI mix, compared to their correspondent EMV ones, show higher water penetration. There also seems to be an improvementwhencomparingthespecimensbytypeof RCA.In the majority of the cases, the use of the novel method improves the concrete behavior on this specific property when comparing it to the conventional RAC and, when using smallreplacementamountsofRCA,the EMV method achieves similar values to those of a conventionalconcrete.Thesebehaviorscanbeexplained by the concrete mixes characteristics as it has been mentioned before, whichare certainlyclosertothoseof a NAC than to a conventionally designed RAC [15]. ACI based mixes proportioned by the EMVmethod, in both 0.45 and 0.6 w/c ratios, show better behavior in the capillary absorption and water penetration properties thantheRACpreparedwithconventionalmethods.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

6. CONCLUSIONS

EMV method proved to be the most efficient method of mix proportioning rather than the conventional replacement of aggregate method. Reducing the total mortar content in concrete was the main reason to achievebetterresultsinstrengthanddurability.Alsothe physicalfeaturesofrecycledaggregatelikeroughtexture and angular nature contributes to strength characteristics of recycled concrete. Adjustments in mix proportioning helped to achieve more durable mix. Studies relating to durability issues regarding recycled aggregateconcretearestillgoingonworldwide.

REFERENCES

[1] Pinghua Zhu, Yali Hao, Hui Liu, Xinjie Wang a , Lei “Durabilityevaluationofrecycledaggregateconcreteina complex environment”, Journal of Cleaner Production Volume9,Issue3,Pages6883-6899,2020.

[2] Mirjana Malešev1, Vlastimir Radonjanin1, Gordana Broćeta. “Properties of recycled aggregate concrete” ContemporaryMaterials,2014.

[3] S. Marinković, V. Radonjanin, M. Malešev, I. Ignjatović, Recycled aggregate in structure concretes technology, properties, application, in Serbian: Vol. 2,2009.

[4] Y. Ballim, M.G Alexander.“Guiding principles in developing the South African approach to durability index testing of concrete, Sixth International Conference onDurabilityofConcreteStructures,2018.

[5] Gholamreza Fathifazl, A. Ghani Razaqpur, O. Burkan Isgor,AbdelgadirAbbas,BenoitFournier,andSimonFoo. “Bond performance of deformed steel bars in concrete produced with coarse recycled concrete aggregate” Cement&ConcreteComposites,2012.

[6] Abdelgadir Abbas a , Gholamreza Fathifazl b , O. BurkanIsgor c, A. Ghani Razaqpur d , Benoit Fournier e ,SimonFoo

.(2009).“Durability of recycled aggregate concrete designed with equivalent mortar volume method” Cement&ConcreteComposites31,555 563,2009.

[7] Jeonghyun Kim,“Properties of recycled aggregate concrete designed with equivalent mortar volume mix design”Constructionandbuildingmaterials,301,2021.

[8] Hoai-Bao Le a,b , Quoc-Bao Bui, “Recycled aggregate concretes Astate-of-the-artfromthemicrostructureto thestructuralperformance”,2020.

[9] Sherif Yehia, Kareem Helal, Anaam Abusharkh, AmaniZaher,andHibaIstaitiyeh”StrengthandDurability EvaluationofRecycledAggregateConcrete”International JournalofConcreteStructuresandMaterials,2015.

[10] Xiao,J.,Fana,L.Y.,&Huang,X.(2012b).Anoverview of study on recycled aggregate concrete in China ,ACI MaterialsJournal,2011.

[11] Malesˇev, M, Radonjanin, V., & Marinkovic´, S. Recycled concrete as aggregate for structural concrete production. Sustainability, 2(5), 1204 1225. doi:10.3390/su2051204.2010.

[12] Padmini, A. K., Ramamurthy, K., & Mathews, M. S. (2009).Influenceofparentconcreteonthepropertiesof recycled aggregate concrete. Construction and Building Materials,23(2),829 836.

[13] Emmanuel E. Anike. Messaoud Saidani. Eshmaiel Ganjian.Mark Tyrer. Adegoke O. Olubanwo. “Evaluation of conventional and equivalent mortar volume mix design methods for recycled aggregate concrete” MaterialsandStructures,2020.

[14] G. Fathifazl1 ; A. Abbas2 ; A. G. Razaqpur3 ; O. B. Isgor4 ; B. Fournier5 ; and S. Foo, New Mixture Proportioning Method forConcrete Made with Coarse Recycled Concrete Aggregate, journal of materials in civilengineering,2009.

[15] C. Jiméneza, M. Barraa, S. Vallsa, D. Apontea, E. Vázquez, “Durability of recycled aggregate concrete designed with the Equivalent Mortar Volume (EMV) method: Validation under the Spanish context and its adaptation to Bolomey methodology”, Materiales de Construcción,2014.

[16] Shi-CongKou. Chi-SunPoon, “Long-term mechanical and durabilitypropertiesofrecycledaggregateconcrete preparedwiththeincorporationofflyash”,Cementand ConcreteComposites,2013.

[17] R.V. Silva, R. Neves, J. de Brito, R.K. Dhir, “Carbonation behaviour of recycled aggregate concrete”, Cement&ConcreteComposites,2015.