International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

1Student, Dept. of Civil Engineering, St.Joseph’s College of Engineering& Technology, Kerala, India

2Asisstant Professor, Dept. of Civil Engineering, St.Joseph’s College of Engineering& Technology, Kerala, India ***

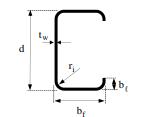

Abstract Steel is an important constructionmaterialsince ancient days. Among steel, ColdFormedSteel(CFS)aregetting more popular due to its advantages including light weight, high strength to weight ratio, resistance to fire etc. These are the sections which are shaped near room temperature. CFS channel sections are commonly used nowadays as bearing and non load bearing walls, partition walls, in multi rise buildings, framings. In this channel sections the holes are provided in the web portion for plumbing services and installation of ducts. However such opening made the section more vulnerable to failures including web crippling and web buckling. In this paper various parameters which affect the web crippling capacity of the channel sections are analyzed and the analysis is also done to find the optimum location of web holes in the channel sections.

Key Words: ColdFormedSteelSections,WebCrippling,Web Buckling

Advancedstructuresarequitecommoninnowadaysdueto growthinconstructionindustry,Duetothisadvancement many industries are looking forward to develop and use sustainable building materials. Steel is an important construction material using nowadays due to its innumerableadvantageswhichmakeitasaperfectoption formodernbuildingconstruction.Therearemainly2types of steel used for the construction purposes. 1) Hot Rolled Steel Sections2)ColdFormed Steel Sections.Asthename indicates, CFS sections are the sections which are rolled, bended,pressedorshapedatnearroomtemperature.Wedo not need to provide extra heat for shaping them as it is requiredinhotrolledsteelsections.Inhotrollingprocess steelisrolledbyprovidinghightemperaturewhichismore than 1700 Fahrenheit. But such hot rolled steel have a tendencytoshrinkwhencooloff, thusgivinglesscontrolon sizeandshape.AdvantagesofCFSsectionsoverHotRolled Steel Sections includes CFS does not shrink, no heat is required to form shape, light weight, non combustible, won’t absorb moisture, resist fire and termites and high strengthtoweightratio.Nowadaysopeningsareprovidedin thewebportionofchannelsectionforeaseofinstallationof electrical or plumbing devices. Such holes result in the sections becoming more vulnerable to failures especially underconcentratedloadsappliednearthewebholes.Two commontypeoffailuresinCFSsectionsinclude1)Crippling

Failure2)BucklingFailure.Webcripplingfailureoccurredin CFS members at the web flange junction. This failure is mainly seen in the web elements due to the concentrated loads which are delivered through flange of the channel sections. The main reason for this failure is due to the applicationofstaticanddynamicloadstransversallywhich causes direct crushing of web. Buckling is another failure mode in CFS sections due to its thin walled cross section causinglossofstability.Thisfailureoccurswhenthecritical buckling stress in web is less than the compressive stress acting vertically.Itoccursbeforeyielding.

To perform the analysis on web crippling capacity of cold formedchannelsectionswithandwithoutopening

Tounderstandeffectofbearinglength,insidebentradius, web depth and flange width on web crippling capacity of channelsections.

Tostudyeffectofwebopeningandwebopeninglocationsin the web crippling and buckling capacity of the channel sections

1) Modeling and analysis of channel sections with and withoutholeinANSYSWorkbenchbyvaryingparameters

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

BearingLength

InsideBentRadius

WebDepth

FlangeWidth 2)ModelingandanalysisofchannelsectionsinANSYSby varyingwebholesdiametersandwebholelocations 3) Comparisonofresultsandgraphsofallmodelsforweb cripplingandwebbucklingstrength.

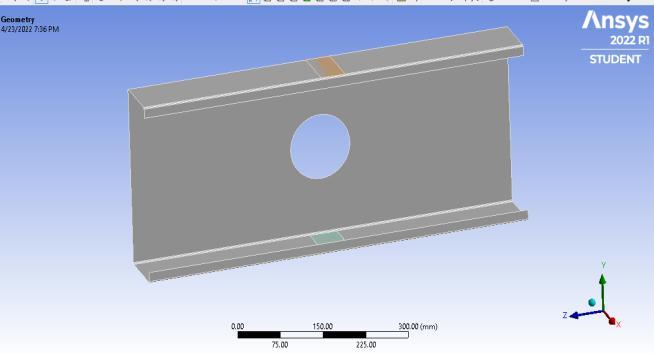

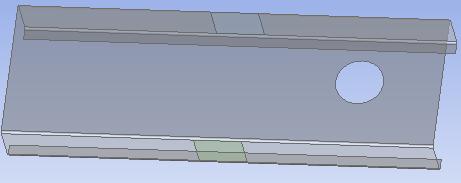

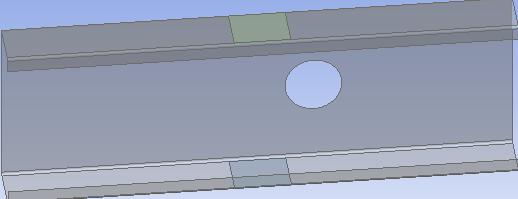

Channelsectionswithandwithoutwebholesaremodeledin ANSYS Workbench 2022. Material properties and section dimensionsarediscussedbelow.

Steelwiththefollowingpropertiesareusedformodelingthe channelsections

Poisson’sratio=0.3

YieldStrength=450Mpa

TangentStrength=0Mpa

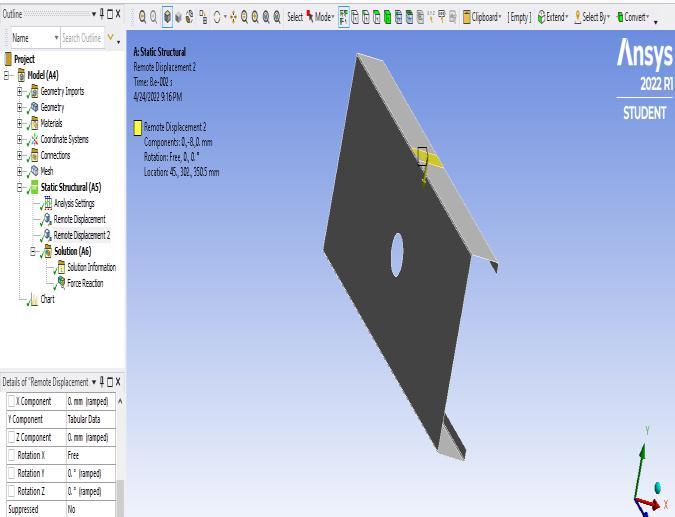

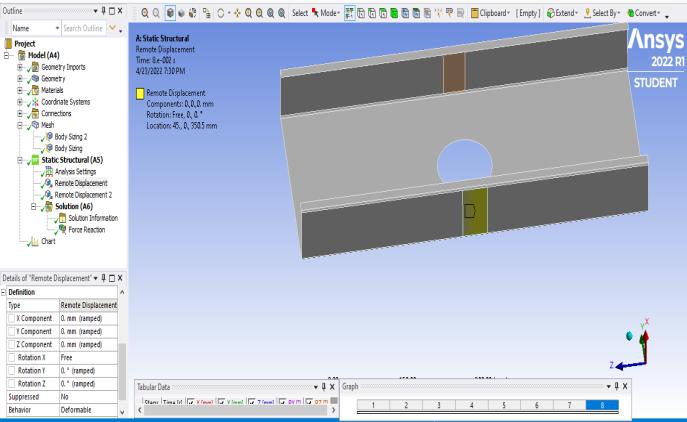

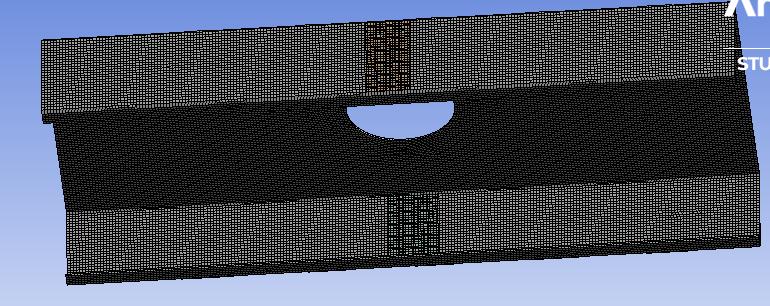

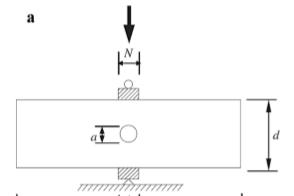

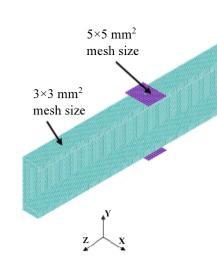

Sectionusedischannelsectionwithandwithouthole.One loading plate and one supporting plate are provided. The meshsizeis5mmx5mmmeshforbearingplatesand3mmx 3mmmeshsizeisadoptedforbeam.Generallyprovidethe length of bearing plate as 50mm. Boundary Conditions includeforloadingplatetranslationinyaxisis 8,rotation aboutxaxisisfreeandallothertranslations&rotationsare fixedandforthesupportingplateallmovementsarefixed whereasrotationaboutxaxisisfree

Fig 3:Meshing

Fig 4:BoundaryConditionsforLoadingPlate

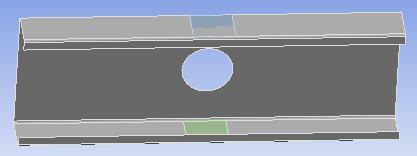

Fig 2:ChannelSectionWithHole

Fig 5:BoundaryConditionsforSupportingPlate

Fig -6:Schematicdiagramofmodeledchannelsection

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Bearingplateisusedtotransferconcentratedcompressive forces between two structural elements. Bearing length is thelengthalongthebeamunderwhichahighconcentration ofstressesistransferredtothesupportingstructurebelow.

Sectionused 150x45x13mm i) withouthole ii) withhole(diameterofhole=60mm)

Fig 7:Sectionwithbearingplates

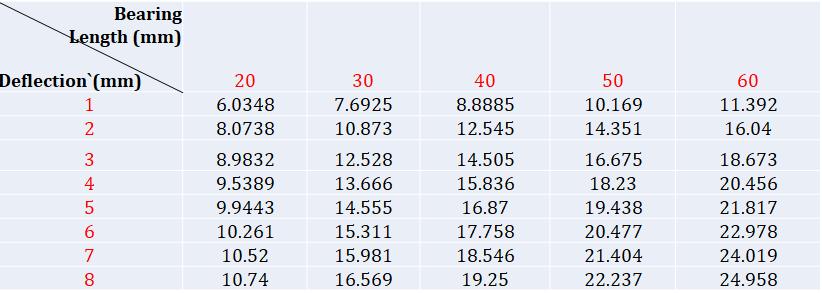

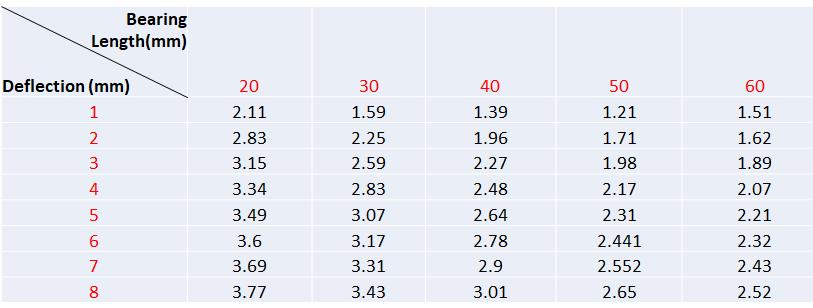

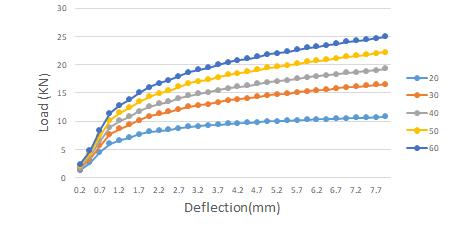

The above mentioned channel sections are modeled by varying bearing length from 20 mm to 60 mm in order to find the effect of bearing length on the strength of the channelsections.Thetabulardatashowingtheresultsare givenbelow

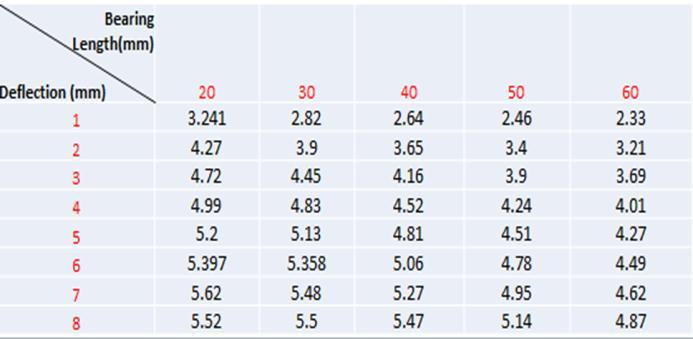

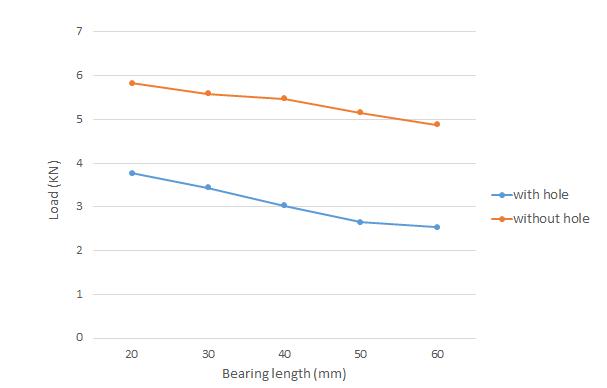

Table 1: WebCripplingLoad(KN)inChannelSection withoutholecorrespondingtodifferentbearinglength

Table 3: WebCripplingLoad(KN)inChannelSection withholecorrespondingtodifferentbearinglength

Table -2: WebBucklingLoad(KN)inChannelSection withoutholecorrespondingtodifferentbearinglength

Table -4: WebBucklingLoad(KN)inChannelSectionwith holecorrespondingtodifferentbearinglength

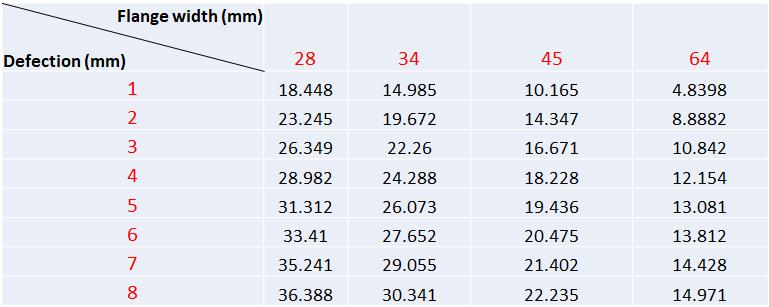

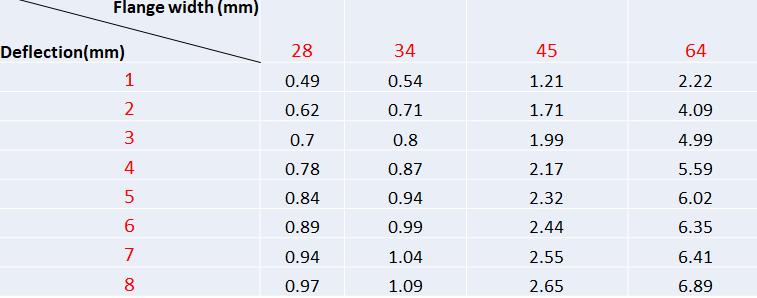

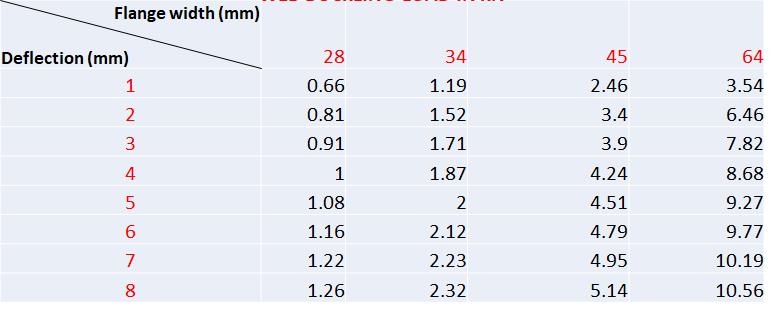

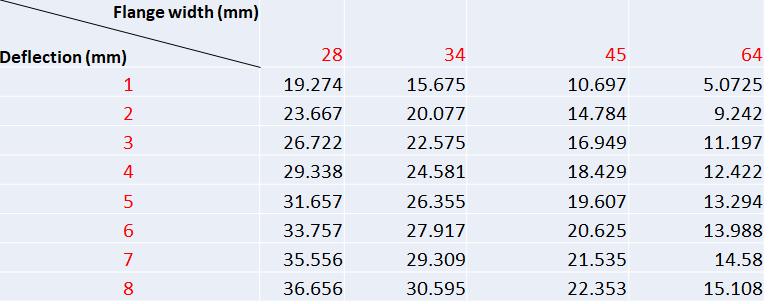

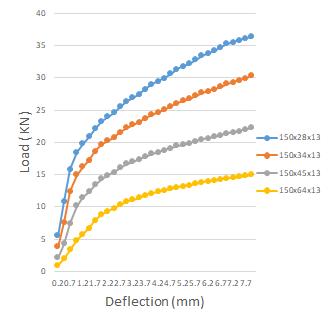

Inordertodeterminetheeffectofflangewidthonthe web crippling capacity of the channel sections four modelsofchannelsectionswithandwithoutholesare modelledandanalysed.Inthissectiontheflangewidth isvariedbetween28mmto64mm.

Sectionsmodelledinclude 150x28x13mm 150x34x13mm 150x45x13mm 150x64x13mm

Fig 8:Channelsectionwithbf=flangeWidth

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

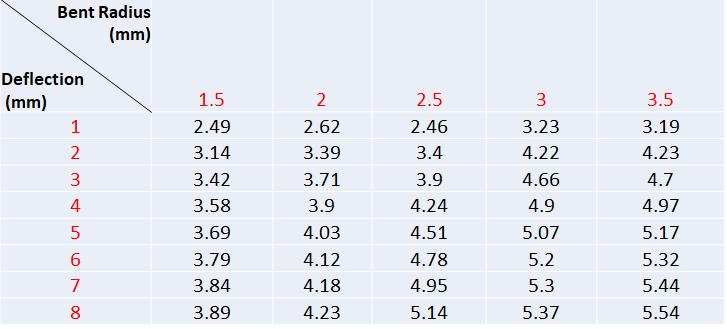

Table 5: WebCripplingLoad(KN)inChannelSection withoutholecorrespondingtodifferentflangewidth

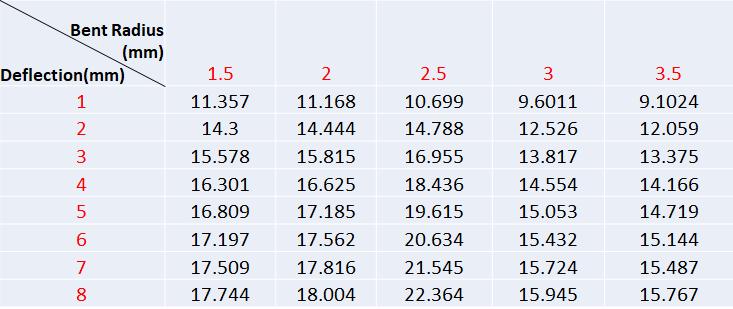

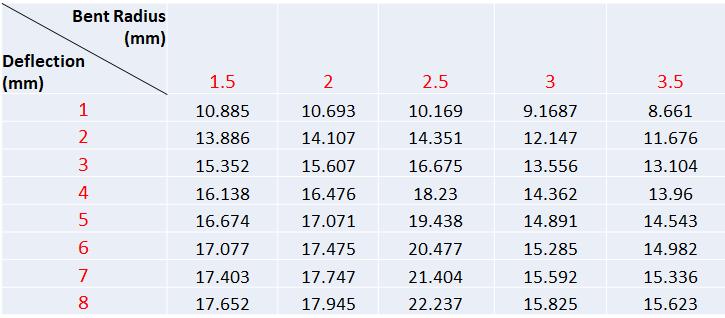

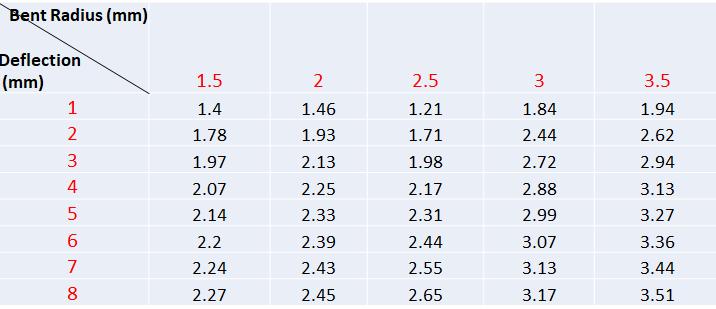

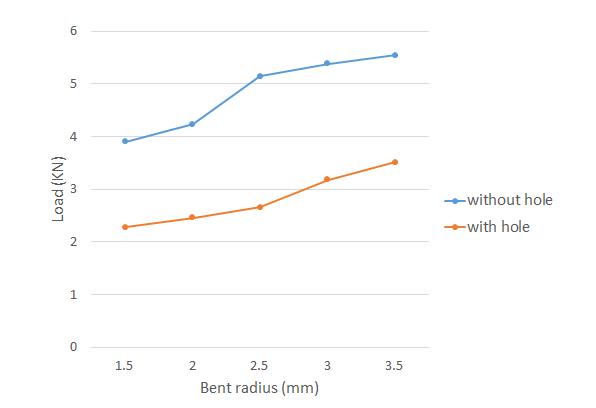

2.5 Varying Bent Radius

Sectionused 150x45x13mm i) Withouthole ii) withhole(diameter=60mm)

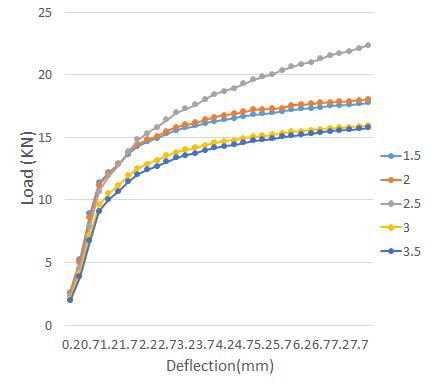

Innerbentradiusisvaried between1.5mmto3.5mmin thisanalyse.

Table -6: WebBucklingLoad(KN)inChannelSection withoutholecorrespondingtodifferentflangewidth

Fig -9:ChannelsectionwithRi=BentRadius

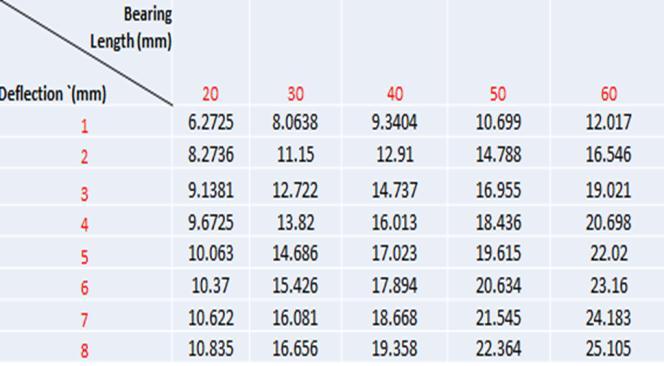

Table 9: WebCripplingLoad(KN)inChannelSection withoutholecorrespondingtodifferentbentradius

Table 7: WebCripplingLoad(KN)inChannelSection withholecorrespondingtodifferentflangewidth

Table -8: WebBucklingLoad(KN)inChannelSectionwith holecorrespondingtodifferentflangewidth

Table -10: WebBucklingLoad(KN)inChannel Sectionwithoutholecorrespondingtodifferentbent radius

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 11: WebCripplingLoad(KN)inChannelSection withholecorrespondingtodifferentbentradius

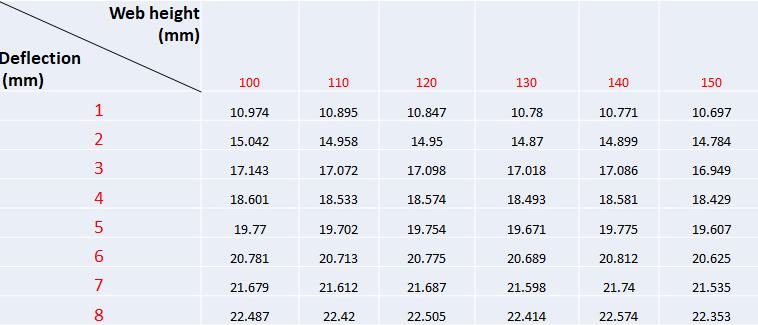

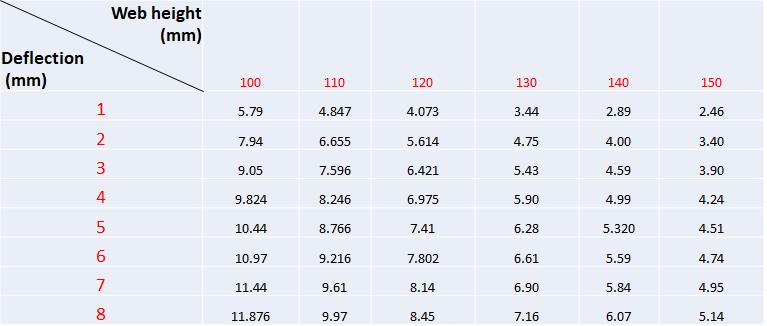

Table 13: WebCripplingLoad(KN)inChannelSection withoutholecorrespondingtodifferentwebheight

Table 12: WebBucklingLoad(KN)inChannelSection withholecorrespondingtodifferentbentradius

Table 14: WebBucklingLoad(KN)inChannelSection withoutholecorrespondingtodifferentwebheight

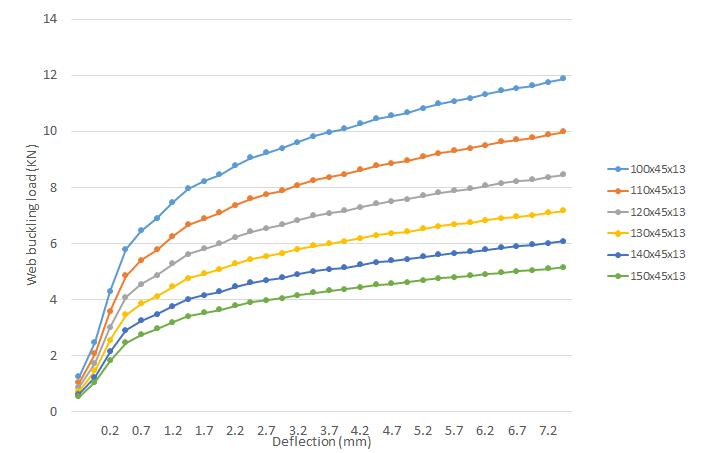

Slendernessofthewebportionplaysimportantroleinthe strengthofthechannelsection.Inordertoknowtheeffectof height of the web portion in web crippling capacity, six channelsectionsaremodeledbyvaryingwebheightfrom 100mmto150mm. Sectionsmodeledare

100x45x13mm

110x45x13mm

120x45x13mm

130x45x13mm

140x45x13mm

150x45x13mm

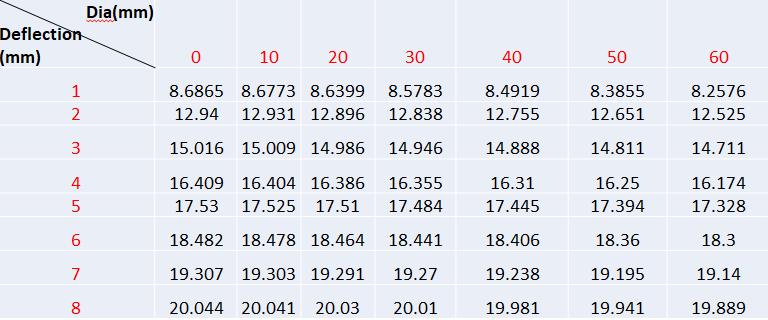

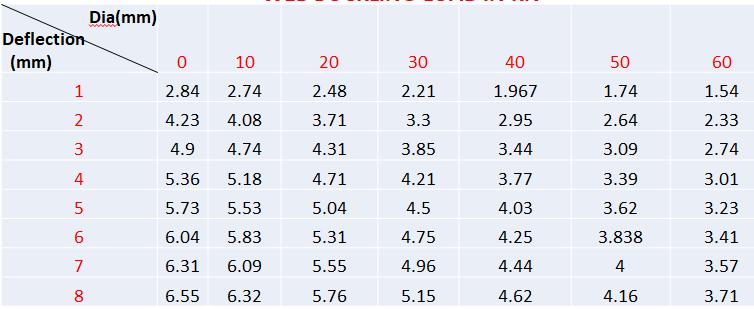

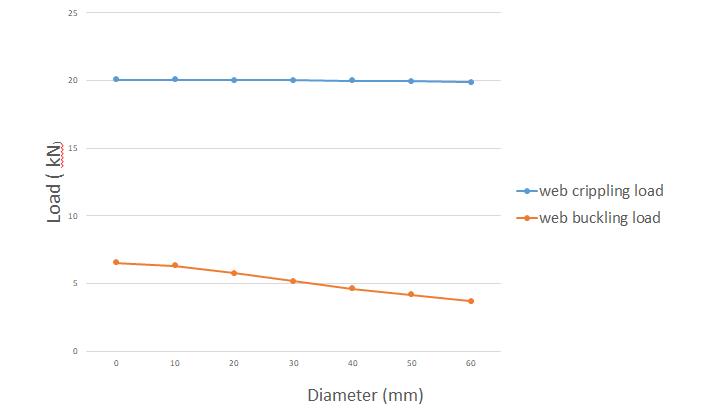

Opening areprovidedinthewebportionforinstallationof ducts,electricalandplumbingservices.Howeversuchholes can reduce the strength of the channel sections to some extent. In order to know the effect of holes in the web crippling capacity of the channel section, sections are modeledbyprovidingholeswithvaryingdiameterunderthe bearing plate and the analyses are conducted on. The diameterusedintheseanalysesisvariedbetween0mmto 60mmandthechannelsectionusedis150x50mmx13mm

Fig 10:ModeledFigureinANSYS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 15: WebCripplingLoad(KN)inChannelSection withoutholecorrespondingtodifferentwebheight

Fig 12:x/h=0.6

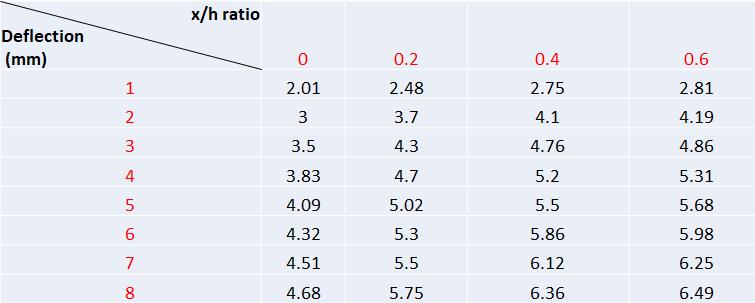

Table 17: WebCripplingLoad(KN)inChannelSection correspondingtodifferentx/hratio

Table 16: WebBucklingLoad(KN)inChannelSection withoutholecorrespondingtodifferentwebheight

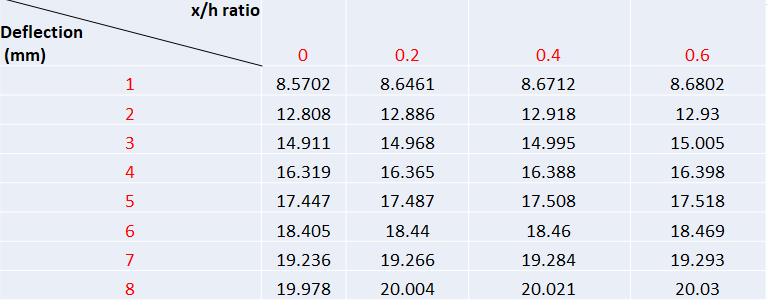

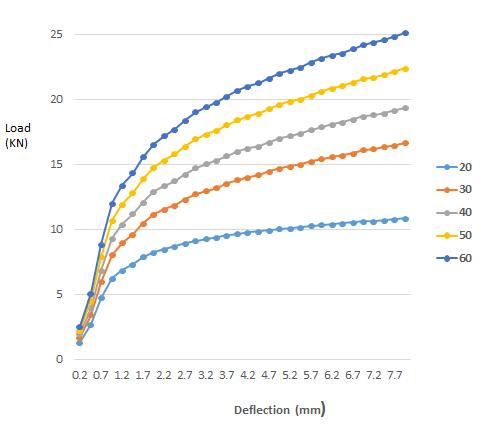

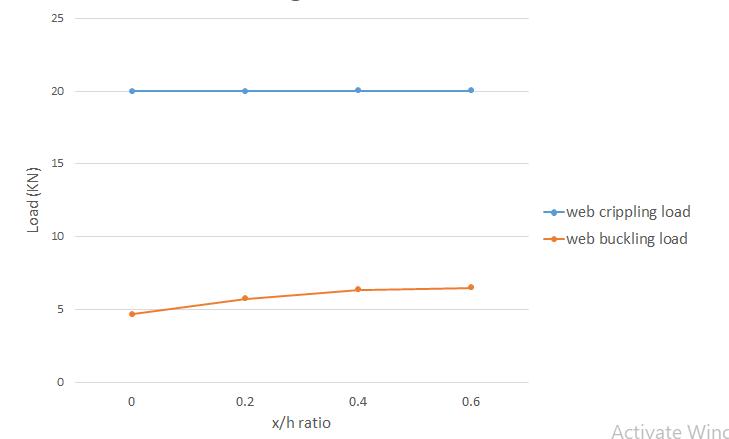

Locationsofwebholes have agreateffectindetermining thestrength ofthechannel sections.In order toknow the effectofthelocationsofwebholesinthechannelsections differentmodelsareanalyzedbyvaryingthedistanceofweb holesfromthebearingplates.Thedistancefromthebearing plates(x)toheightofthechannelsection(h)isvariedfrom0 to0.6

Table 18: WebBucklingLoad(KN)inChannelSection correspondingtox/hratio

Fig 11:x/h=0

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Bearinglengthplaysanimportantroleindeterminingthe web crippling capacity of the channel section. With the increaseinthebearinglengththewebcripplingcapacityof the channel section increases. From the analysis it was clearedthatwebcripplingcapacityofchannelsectionswith bearinglength60mmisgreaterthan20mm.Thebuckling strengthofthechannelsectionsdecreaseswithincreasein thebearinglength.Byprovidingthewebholesthestrengthof thechannelsectionsdecreases,sothereisahugedecreasein web buckling strength of the channel section with hole comparedwiththesectionswithouthole

3.2Effect

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Flange width affect the web crippling capacity of the channel sections. Web crippling capacity is high for 150x28x13mmandisvery lowfor150x64x13mm.From theanalysesitisclearthatwithincreaseintheflangewidth ofthechannelsectionwebcripplingcapacitydecreases.With the increase in the flange width web buckling strength increases.

In the analysis with the bent radius of the channel sections is varied between 1.5 mm to 3.5 mm. From the analysisitisclearthatthechannelsectionswithbentradius 2.5mmshowhighwebcripplingcapacitycomparedtoother sections.Thewebcripplingcapacityofthechannelsections increasefrom1.5mmto2.5mm.Beyond2.5mmtheweb cripplingcapacityofthechannelsectionincrease

WebHeightaffectsthestrengthofthechannelsections.In theanalysisthewebheightofthechannelsectionsisvaried between100mmto150mm.Fromtheanalysisitiscleared that the channel sections having more web height is more vulnerabletofailure.Thewebbucklingloadof100x45x13 mm channel section is very high compared to that of the sectionhavingdimensions150x45x13mm.

Intheanalysisthewebholeswithvariousdiametersis provided at the center of the channel section, under the bearingplateinordertoknowhowitaffectsthestrengthof thechannelsection.Diameterofholeusedinthesectionis variedbetween0mmto60mm.Fromtheanalysisitisclear thatprovidingholesdirectlyunderthebearingplatedonot makeahugeeffectinreducingthewebcripplingcapacityof the channel sections. However it has a drastic effect in

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page986

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

reducing the buckling strength of the channel sections. By increasingthediameterofwebholesthebucklingstrengthof thechannelsectionsisreduced.

Fromtheanalysisitisclearthatthelocationofwebholes does not affect the web crippling capacity of the channel sections. But at the same time it affects the web buckling strengthofthechannelsections.Themodelwithx/hratio0.6 havinghighbucklingstrengthcomparedtothesectionwith x/hratio0.Byincreasingthedistanceofwebholesfromthe bearing plate the web buckling strength of the channel sectionsincrease.

This paper is mainly aimed to know more about the web crippling capacity of the channel sections. Different parameterslikelengthofthebearingplate,innerbentradius, webheight,flangewidth,diameterofwebholeandlocation ofwebholesvariedinchannelsectionsinordertoknowhow itaffectthewebcripplingandwebbucklingstrengthofthe sections and came to the conclusion that web crippling capacity ofthechannel sections increases withincreasein bearing length and bent radius up to 2.5 mm. With the increaseintheflangewidthofthechannelsectiontheweb cripplingcapacitydecreases.Howeverthediameterofweb hole,locationofthewebholesandheightofthewebportion donotaffectthewebcripplingcapacityinalargeextentbut affect the web buckling strength. Decrease in the holes diametersandincreaseinthex/hratiocanincreasetheweb bucklingstrengthofthechannelsections.Atthesametime increaseinthewebheightcandecreasethestrengthofthe channelsections.

[1] A. McIntosh, P. Gatheeshgar, K. Poologanathan, S. Gunalan, S. Navaratnam, C. Higgins, Web crippling of cold formedcarbonsteel,stainlesssteel,andaluminium channels:Investigationanddesign,J.Constr.SteelRes. 179(2021)106538

[2] B.Chen,K.Roy,Z.Fang,A.Uzzaman,Y.Chi,J.B.P.Lim, Web crippling capacity of fastened cold formed steel channels with edge stiffened web holes, un stiffened web holes and plain webs under two flange loading, Thin WalledStruct.163(2021)107666.

[3] S.Hareindirasarma ,K.Elilarasi B.Janarthanan,Effect of circular holes on the web crippling capacity of cold formedLiteSteelbeamsunderInterior Two Flangeload case,Thin Walled Structures Volume 166, September 2021,108135

[4] Gatheeshgar.P,Poologanathan,K.Gunalan,S.,Shyha,I., Daniel,K.T.,andCorradia,M.,“Optimaldesignofcold formedsteellippedchannelbeams:Combinedbending, shear, and web crippling”, Structures , Volume 28, December2020,Pages825 836.

[5] Wu.C, Zhang.L.,Tam,L., Yan,L., and He, L., “Effect of bearinglengthonwebcripplingbehaviorofpultruded GFRPchannel section”,Composite Structures,Volume 253,1December2020,112810

[6] K. Elilarasi, B. Janarthanan, Effect of web holes on the web crippling capacity of cold formed litesteel beams under end two flangeload case,Structures25 (2020) 411 425,

[7] A.Sena ABB, Abdelfattah F.A, M.S Soliman, An experimentallyverifiednewapproachforwebcrippling designofcold formedsteelZ Sections.JConstrSteelRes 2020;164:105813.

[8] Abu SenaABB,AbdelfattahFA,SolimanMS,SalehMSR. An experimentally verified new approach for web cripplingdesignofcold formedsteelZ Sections.JConstr SteelRes(2020);164:105813.

[9] Janarthanan B, Mahendran M, Gunalan S. Numerical modellingofwebcripplingfailuresincold formedsteel unlipped channel sections. J Constr Steel Res (2019) 158:486 501.

[10] B. Janarthanan, L. Sundararajah, M. Mahendran, P. Keerthan, S. Gunalan, Web crippling behaviour and designofcold formedsteelsections,Thin WalledStruct. 140(2019)387 403

[11] ]R.Heurkens,H.Hofmeyer , M.Mahendran, H.Snijder Direct strength method for web crippling lipped

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

channelsunderEOFandIOFloading.Thin WallStruct (2018)123:126 41

[12] S.Gunalan, M.Mahendran.Webcripplingtestsofcold formed steel channels under two flange load cases. J ConstrSteelRes2015;110:1 15

[13] E.Steau,M.Mahendran,P.Keerthan,Webcripplingtests of rivet fastened rectangular hollow flange channel beamsundertwoflangeloadcases,Thin WalledStruct. 95(2015)262 275

[14] Y.Chen , X.Chen, C.Wang C. Experimental and finite elementanalysisresearchoncold formedsteellipped channel beams under web crippling. Thin Wall Struct (2015);87:41 52.

[15] KeerthanP,MahendranM,SteauE.Experimentalstudy of web crippling behaviour of hollow flange channel beams under two flange load cases. Thin Wall Struct 2014;85:207 19.

[16] A. Uzzaman, J.B.P. Lim, D. Nash, J. Rhodes, B. Young, Effectofoffsetwebholesonwebcripplingstrengthof cold formed steel channel sections under end two flangeloadingcondition,Thin WalledStruct.65(2013) 34 48

[17] M.Macdonald, M.Heiyantuduwa,Adesignruleforweb crippling of cold formed steel lipped channel beams basedonnonlinearFEA.Thin WallStruct2012;53:123 130.

[18] J. Rhodes, D.Nash . An investigation of web crushing behaviour in thin walled beams. Thin Wall Struct (1998)32:207 30.

[19] K.S.Sivakumaran,K.M.Zielonka,Webcripplingstrength ofthin walledsteelmemberswithwebopening,Thin Walled Struct. 8 (1989) 295 319, http://dx. doi.org/10.1016/0263 8231(89)90035 9.

[20] W.W. Yu, C.S. Davis, Cold formed steel members with perforated elements, ASCE J. Struct. Div. 99 (1973) 2061 2077

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |