International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Experimental study on durability properties of concrete with fine aggregate partially replaced by waste crushed glass

Aalla Sri Latha1 , N. Bhargav21PG Student, Department of Civil Engineering, Nova College of Engineering and Technology, Affiliated to JNTU Kakinada, Vegavaram, Jangareddygudem, West Godavari (District), A.P 534447.

2Guide, Assistant Professor of Civil Engineering, Nova College of Engineering and Technology, Affiliated to JNTU Kakinada, Vegavaram, Jangareddygudem, West Godavari (District), A.P 534447 ***

Abstract - Concrete is one of the largest consumed materials all over the world. River sand is one of the ingredients used in Concrete preparation. As increased constructionpracticesleadstohighdemandinconsumption ofingredientsofconcrete.Sandisoneofthesignificantraw materials.It’sgettingdepletedduetoexcessivedigging.This affectsthenearbylocalitiesaswellthestabilityofhydraulic structuresnearby.TheEnvironmentaleffectsanddepletion of natural materials dragging the researchers ‘attention towardsnewsustainablematerialsintheconstructionfield. At the same time Dumpingof solid wastes in to precious openlandsleadstotheinventionofalternativesustainable materials in the production of concrete. In this research work, waste crushed glass was used in different proportionsinconcretepreparationaspartialreplacement forfineaggregate.Glasswasusedin10%,20%,30%and 40% ofsand weight for different grades ofconcretelike M30andM45.Mechanicalanddurabilitypropertiesforall threedifferentgradeswereevaluatedandcomparedwith the conventional concrete. This research is aimed to carryout tests to find out Strength properties in compression,tensile and flexuralonM30andM45grades of concrete after curing of 7, 14, 28 and 90 days. The evaluated values were compared with conventional concreteof same day’s strength. The strength tests were carried out for all the grades mentioned. A concrete structure is said to be durable, if it performs with its intended level of functionality and serviceability for an expected life. Durable concrete must have the ability to withstandweatheringconditionstowhichitisexposedand nottodeteriorate.Concretewilldeteriorateduetoadverse mechanical, physical, or chemical causes. Durability tests suchasAcidattacktestwerecarriedonConcretewithglass. The current research work describes the optimum percentage of fine aggregate replacement with glass in concrete.IntheresearchconcreteofM30andM45Grades prepared for testing mechanical as well as Durability propertieswithglassin10%,20%,30%and40%byweight ofriversand.Foralltwogradestestedfromtheresultsit wasfoundthat30%replacementiseffective.

Key Words: ConcreteWorkability,TestforCompression, Strengthintension,FlexuralStrength,Durabilitytests,Acid attacktest,Rapidchloridepenetrationtest.

1. INTRODUCTION

Thepresentresearchworkistodoexperimentalstudyon generating concrete with Waste crushed glass. Fine aggregatetotalwaspartlysupplantedwithunusedcrumpled glass in preparation of specimens. The normal sand was swappedbywastecut glassinpercentagesof0,10,20,30 and40. Inthisstudy,M30andM45gradesofconcreteand concretespecimensareprepared Tostudyontheprepared M30 and M45 grade concrete as per the mix design workabilitytest,Strengthsincompression,split tensile and flexure. Compression test on 150 mm cube, Tension test withof150x300mmcylindersFlexuretestonprismsofsize 500mmLengthandcross section100x100mm Byusingthe industrial wastes in concrete, we can save the natural resourcesaswellastoovercometheproblemofdumping wastematerialsonland.

1.1 Cement

In the research grade OPC53 cement approving to IS 269 updated in 2015 was used. Adhesive (Cement) is of the importantingredientsinconcretemixwhichwillbindallthe materials in concrete. Numerous experiments were conducted to find out the specific gravity, Initial and final settingtime,NormalConsistencyandcompressivestrength inlaboratoryandthevalueswereevaluated.

Table 1: Formatofcementintegrated

Ingredient % SiO2 19.7 Al2O3 5.67 Fe2O3 4.68 CaO 61.81 MgO 0.84 SO3 2.48 IronOxide 1.21

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 2: Modulusoffinenessforfineaggregate SI. No

Siev e size mm

Retaine d mass on sieve (gms)

on % mass retained on sieve Sieve (gms) 1 20 0 0 0 100 2 10 0 0 0 100 3 4.75 8 8 0.8 99.2 4 2.36 39 47 4.7 95.3 5 1.18 210 257 25.7 74.3 6 600 340 597 59.7 40.3 7 300 311 908 90.8 9.2 8 150 92 1000 100 0 Tota l 1000 257.7

Cumulativ e mass retained Cumulativ e % of mass Passin g throug h Sieve

2. MIX DESIGN

TherangeofingredientsforM30andM45mixconcreteas per IS 456 2000, IS 10262 2009 & ACI 211 Methods are listedbelow.

Table 5: MixDesignofM30 Cement W.CG C.A SP W /C ratio SI Mix F.A .No kg/m3

1 MCG0 351 736.16 0 1195 0 0.45 2 MCG10 351 662.5 73.6 1139 5.2 0.45 3 MCG20 351 588.96 147.2 1139 5.2 0.45 4 MCG30 351 515.36 220.8 1139 5.2 0.45

Table 6: MixDesignofM45

Table 3: Modulusofcoarseaggregate

SI.N o.

Sieve Size mm

Mass retaine d (gms)

Cumulativ e Mass retained (gms)

Cumulativ e % % mass retained passin g 1 80 0 0 0 100 2 40 0 0 0 100 3 20 200 200 4 96 4 10 4400 4600 92 8 5 4.75 400 5000 100 0 6 2.36 0 0 0 0 7 1.18 0 0 0 0 8 600μ m 0 0 0 0 9 300 μm 0 0 0 0 10 150 μm 0 0 0 0 Table 4: Crushedglassproperties SI. No. Property Value 1 Specificgravity 2.6 2 Finenessmodulus 2.64

SI. Mix

Cemen t F.A C.A W/ C rati o

S P WCG N o kg/m3

1 MCGO 400 702.46 8 1190.2 1 0.4 6 0 2 MCG1 0 400 632.22 1190.2 1 0.4 6 70.2

3 MCG2 0 400 561.97 1190.2 1 0.4 6 140.5

4 MCG4 5 400 491.73 1190.2 1 0.4 6 210.7 4

3. METHODOLOGY

Workabilityisthecapacityofdoingaworkwithconcrete is defined as the ease with which we can mix, convey, place,compressedandfinishtheconcrete.Assessmentfor workabilityforthemixeswasexaminedforgettingslump values. In this study Slump cone test was adopted for gettingtheslumpvaluesfortheproportionedmix.Slump cone is the one apparatus with which we can find workability of the mix both in field and laboratory. The slumpconeconsistsofaconicalshapeoflowerdiameter 200mmandupperdiameter100mmandofheight 300 mmmadewitha6mmthicksheetalongwiththetamping rod.

Fig 1:WorkabilityTest

3.1. COMPRESSION TEST

Compressive strength of the cube tested in 2000 kN compressiontestingmachineaspertheguidelinesgiven inIS5161959.Themachinegivingthefailureloadhasa least count of 10 kN. The cube was positioned in the machineandthe loadonthecubeisappliedat arateof 14N/mm2 /minute till the failure of specimen and the failureorultimateloadisnoted.Thestrengthofcubein compressionwillbecalculateddividingtheultimateload with cross sectional area of the cube. This test is conductedonspecimensfor7,14,28and90dayscuring, asshowninfig 1.

Tensionisfoundatextremestressesthematerialcanresist by straining prior to cracking. The test is conducted by placing specimen between upper and lower platters of machine.Theformulatobeused inevaluatingtheyielding values in tension is expressed as stated below in the currenteffort;thistrialhasbeenconductedoncylindrical specimensafter7,1428and90dayscuring.

Fig 2:Specimentestincompression

3.2. TENSILE TEST

The test was led in 2000 kN capacity machine which is used forcompressive strength testingasshown in fig 2 Thecylindersofdiameter150mmandlength300mmare tested.Experimentwasprecededconferringtoguidelines giveninIS:5816:1999.Atthespecimenfailuretheloadis noted.Atthecrackformation,thesplittingtensilestrength isfound.Mainaimintendedforthistestistoknowloadat which specimen crack at the boundaries. Strength in

Fig 3:CylindricalTestforspecimen

3.3. FLEXURAL STRENGTH

Theresistingpowerofspecimentostandagainstbending istermedasstrengthinflexurealsocalledasmodulusof ruptureorbendingstrengthofmaterial.Theexamination iscarriedafter7,14and28and90daysofcuringofbeams. The marks must be given on the beam specimen with definitedistanceasperIndianstandardstheloadshould act at middle third of the specimen and need to be correctly positioned on the roller supports. Load was appliedslowlywithoutanyshocks. Theextremeloadon whichthebeamfailedwastakenasflexuralloadresisted bythespecimen.Thebeamshavebeencastaspertheguide lines the Indian codes mentioned in IS 516 and was updatedin1959

Fig 4:FlexureTestforspecimen

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

4. RESULTS AND DISCUSSION

Samplesof180cubes,180cylindersand180prismswere used for experimental work to get the mechanical properties.Totalof90cylinderswith100mmdiameter and50mmthickforRCPTtestand15specimensofsize 300mmdiameterand100mmthickforAbrasiontest.The fine aggregate was substituted with crumpled glass in percentages 0, 10, 20, 30and 40. For each mix with replacementspecimenswereprepared,experimentsdone on7,14,28daysage.WithoutWCGpercentagecalledas Nominal mix. For test samples the intended strength of concrete was adopted as M30 and M45 grades. The designed mixes were arrived based on code IS10262 2009andACI 211.

Table 7: Cubespecimensnumberprepared

S.NO Mix Proposition

Cube specimens size150mm 7 Dyas 14 Days 28 Days 90 Days

1 MCG0 3 3 3 3 2 MCG10 3 3 3 3 3 MCG20 3 3 3 3 4 MCG30 3 3 3 3 5 MCG45 3 3 3 3

Table 8: Cylindricalspecimensnumberprepared

S.NO Mix Proposition

No. of Cube specimens (150x150x150mm) 7Dyas 14 Days 28 Days 90 Days 1 MCG0 3 3 3 3 2 MCG10 3 3 3 3 3 MCG20 3 3 3 3 4 MCG30 3 3 3 3 5 MCG45 3 3 3 3

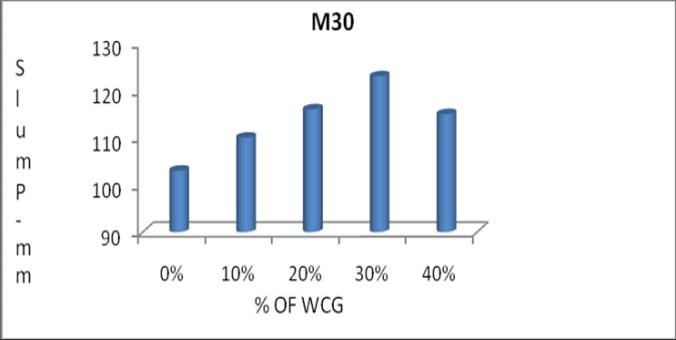

Chart 1: M30Workability

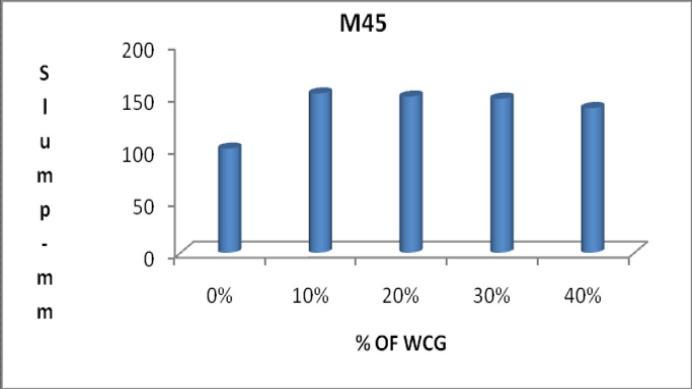

Chart 2: M45Workability

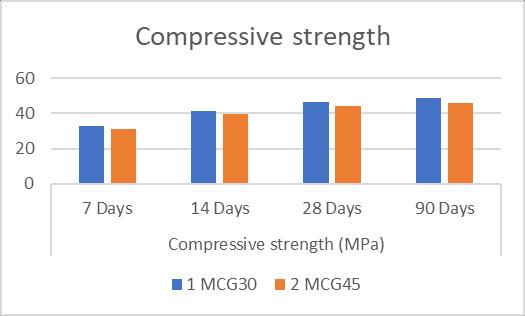

Table 9: CompressiveforM30andM45

S.NO Mix

Compressive strength (MPa) 7 Days 14 Days 28 Days 90 Days 1 MCG30 33.12 41.65 46.76 48.5 2 MCG45 31.04 39.91 44.35 46

Chart 3: CompressiveM30andM45

Sr.No MIX Strength in Tension MPa 7 Days 14 Days 28 Days 90 Days 1 MCG30 3.25 3.85 4.5 5.3 2 MCG45 2.82 2.62 3.7 4.5

Table 10: TensileStrengthforM30andM45

Sr.No Mix Designation Strength In Flexure (MPa) 7 Days 14 Days 28 Days 90 Days 1 MCG30 4.15 5.57 7.65 8.45 2 MCG45 3.85 4.87 6.92 7.45

Table 11: FlexurestrengthforM30andM45

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[2] ToOgundairoetal. “Sustainable use of recycled waste glass as an alternative Material for buildingconstruction“ConferenceSeriesMaterials ScienceandEngineering NOV2019

[3] Mohammed Seddik “Properties of glass concrete” Conference Series: Materials Science and Engineering

[4] H. Dabiri et.el “The Influence of Replacing Sand with Waste Glass Particle on the Physical and Mechanical Parameters of Concrete” civil engineeringjournalAUG 2018

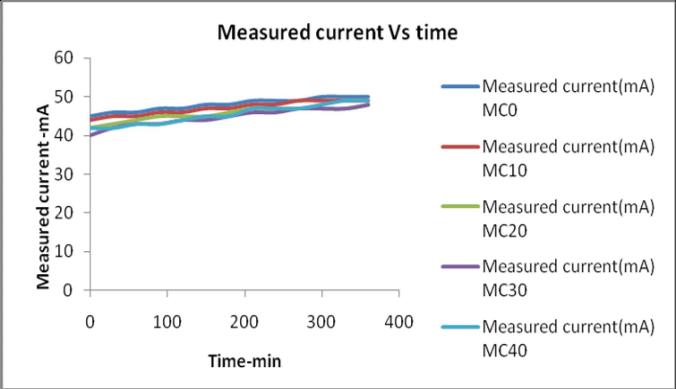

Chart 4: RCPTValuesforM45

5. CONCLUSIONS

ByusingmorefractionofUnusedCut glassinconcretethe freshpropertiesofconcreteincreasesbyadditionof super plasticizer,indicatedbyincreaseininslumpvaluesdueto smooth & no absorbing surface of glass for all grades of concretei.e.M30andM45.

1. ForM30gradeconcreteCompressivestrengthat 90daysincrementwasfoundas15.5%compared withNormalConcrete.

2. ForM45gradeconcreteCompressivestrengthat 90daysincrementwasfoundas14.2%compared withNormalConcrete.

3. ForM30gradeconcreteSplittensilestrengthat90 daysincrementwasfoundas15.5%comparedwith NormalConcrete.

4. ForM45gradeconcreteSplittensilestrengthat90 daysincrementwasfoundas42.5%comparedwith NormalConcrete.

5. For M30 grade concrete Flexural strength at 90 days increment was found as 32.5% compared WithNormalConcrete.

6. For M45 grade concrete Flexural strength at 90 days increment was found as 25.5% compared WithNormalConcrete.

7. FromRapidchloridepermeabilitytestitwasfound that for30%replacementthemeasuredcurrent was less for all grades of concrete implies 30% replacementismoreeffective.

REFERENCES

[1] AmanRoyPatilAssesstheAppearanceofConcrete byusingWasteGlassasAggregateVolume6Issue6 June2019

[5] Bhupendra Singh Shekhawat etal “Utilisation of Waste Glass Powder in Concrete A Literature Review “ International Journal of Innovative ResearchinScience,EngineeringandTechnology

An ISO 3297: 2007 Certified Organization) Vol. 3, Issue7,July2014.

[6] M.Adaway&Y.Wang“Recycledglassasapartial replacement for fine aggregate in structural concrete Effects on compressive strength” Ejse/InternationalSpecialIssue:ElectronicJournal ofStructuralEngineering14(1)2015.

[7] SadoonAbdalla,Mizi Fan “Charecterstics of concrete with Waste Glass as Fine Aggregate replacement”.ISSN:2321 0869 Volume 2 Issue 6, June2014.

[8] IqbalMalik et al. “Study of Concrete Involving Usage of Waste Glassas Partial Replacement of FineAggregate”e ISSN:2250 3021,p ISSN:2278 8719 Volume 3 Issue 7,July 2013.

[9] Tung Chai Ling et al. “Management and recycling of waste glass in concreteproducts: CurrentsituationsinHonKong”(2012) ELSEVIER.

[10] Tomas. ‘’Use of Recycled Glass Bottles as Fine AggregatesinConcreteMixture”Volume 61(2013) pageno 17.

[11] Ahmad SHAYAN. “Value added Utilization of Waste Glass in Concrete” IABSE symposium Melbourne2002.

[12] Jadhav G Set al. “Partially Replacement Of Waste Toughen Glass As Fine Aggregate In Concrete”ISSN:2347 1697Volume3Issue9May 2016.

[13] Weihua et al.” Glass Crete as construction material” ACI Materials journal March/April 2000.79