International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Design of Automatic Chlorinator For Elevated Storage Reservoir

Khan Zaid Ashfaque1 , Dr. Parag A. Sadgir21MTech Student, Department of Civil Engineering, College of Engineering Pune, India 411005, 2Professor, Department of Civil Engineering, College of Engineering Pune, India 411005. ***

Abstract - In rural areas of India where there is no water treatment plant present for the treatment of drinking water, the drinking water is just directly chlorinated as a safety measure. The untreated water is directly pumped to the Elevated Storage Reservoir (ESR) and the water is chlorinated by adding bleaching powder in the ESR. To add the bleaching powder in the ESR a man has to climb up on the ESR and then put the bleaching powder from the top. An automatic chlorinator is a piece of equipment that automatically dispenses chlorine into the inlet pipe. Rather than putting the bleaching powder directly into ESR you would place it into your automatic chlorinator and allow it to dispense at your set rate. In this paper the design of an automatic chlorinator is shown with tested model results to minimize the manual effort for chlorination.

Key Words: Drinking water, Chlorination, Bleaching Powder, ESR , Automatic chlorinator.

1. INTRODUCTION

As piped water delivery systems spread during the 19th century, treated water storage gained significance. The need to safeguard water sources from contamination and deterioration as well as the increasingly sophisticated operation of supply systemshasmotivateditssubsequentdevelopment.Storagefortreatedwatermaybeofferedwithinthetreatmentfacilityor further downstream; it may be housed in elevated tanks or at ground level In Rural areas of India convectional water treatmentplantsarenotpresent,peopleusuallytakewaterdirectlyfromriverorgroundwaterwhichcancontainawidearray ofvirusesorbacteria.Sotopreventhealthhazardsfromthiswaterithastobedisinfected.Disinfectionis carriedoutbyusing chlorineintheformofBleachingpowderorSodiumHypochlorite. Thewaterispumpedtoelevatedstoragereservoirs(ESR) located in villages and then supplied to households from ESR. Before releasing the water from the ESR bleaching powder is added in the ESR for the disinfection purpose. To add the bleaching powder in the ESR a man has to climb up on the ESR carryingbagofbleachingpowderandtheputthebleachingpowderfromthetop.Tominimizethismanualeffortwecanyou aninlineautomaticchlorinatorandattachittotheinletpipeofESR,sothechlorineisaddedintheinletpipecarryingwaterin theESRandgetmixedautomaticallywithsufficientcontacttimeforthechlorinetoreact.

2. DESIGN OF AUTOMATIC CHLORINATOR

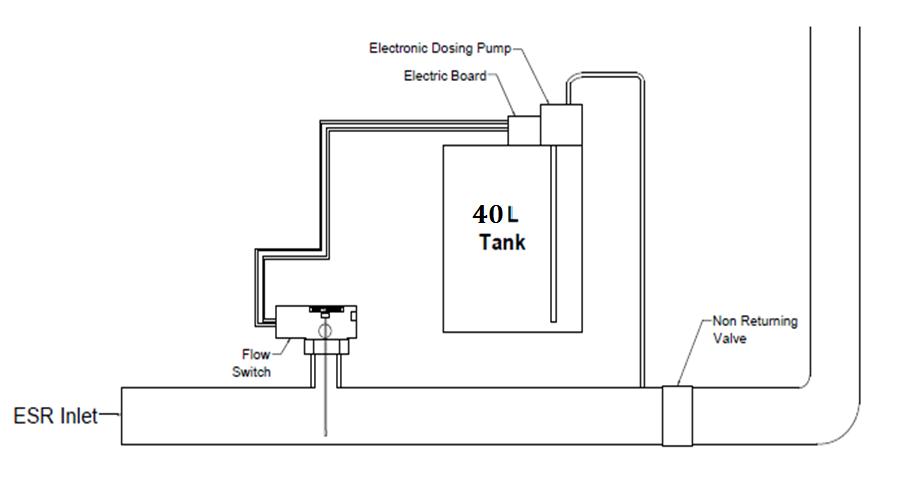

Design of Automatic chlorinator is simple and cost effective. It is easy to install. Flow switch, Chemical Dosing pump, non returnvalveand40literstankwasusedtodesignanautomaticchlorinator.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig – 1:DesignofAutomaticChlorinator

2.1 Working

Whenthe waterstartsflowingintheinletpipeof theESR,the flowswitchdetects itandactasa switchtoclosethe circuit of the power supply of the dosing pump. As the circuit closes the dosing pump starts. The dosing pump suck the chlorinefromthe50LtankandstartsinjectingthechlorineintheinletpipecarryingwaterintheESR.Wecansettherequired doseofchlorineonthedosingpump.TopreventdamagetodosingpumpfromthebackflowfromtheESRanon returnvalve isinstalledjustafterthejointofdosingpumpoutletpipeandtheinletpipeofESR.

2.2 Estimation of Rate of Chlorine

TherearedifferentsizesofESRpresentbasedontherequirementofthevillage.A40,000literscapacityofESRwas consideredforthecalculationofrateofchlorinerequired. Chlorinedosage of5mg/l wasconsideredforthe designpurpose. Bleachingpowdercontaining33%concentrationofchlorineisconsidered.

Aftercalculation,wegettherateofthedosingpumpas5LPHrate,andwehavetoadd0.75kgofbleachingpowderin 40Lwaterinthe40Ltankofchlorinator, sothechlorinatorwillinjectbleachingpowderinliquidformattherateof26.041 mg/s.

Wecancalculatetherequiredsettingofdosing pumpandrateofchlorinationasabovefordifferentsizesofESRand flowratesintheinletpipe.

3.MODEL

Aworkingmodeloftheautomaticchlorinatorwasmadeandtested. WaterfromMulariver,Punewastakenasthesourceof wateronwhichchlorinationwasdonebyusingtheautomaticchlorinatormodel.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig – 2:AutomaticChlorinatorModel

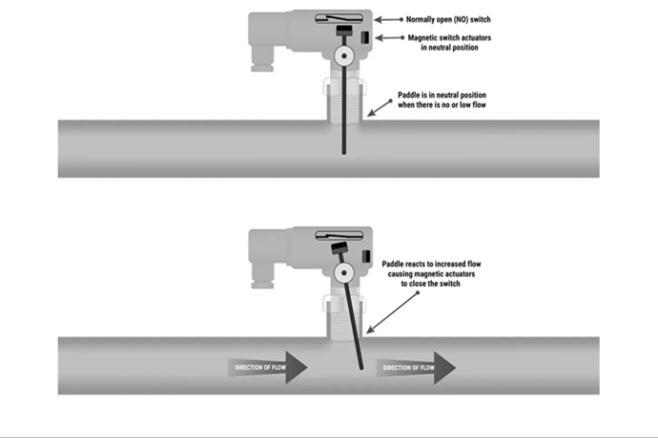

3.1 Flow Switch

Aflowswitchisatoolusedtostartandstopanelectriccurrentinacircuit,justlikeallotherswitches.Aflowswitchis crucialformonitoringandmanagingtheflowrateofprocessmedia,suchassteam,liquids,andgases,inanindustrialsystem. Flowswitchesactivateactionsinmultiplemachinesthroughoutasystemtoofferon/offflowcontrolofprocessmedia,helping tomaintainsafeandcontrolledratesofflow.Therearemanytypesofflowswitchesavailableonthemarkettodaythatoperate inavarietyofdifferentways,butallflowswitchessharethepropertythatwhentheflowrate reachesaswitch'sset point,it caneitheropenorclosethecircuit,whichresultsinanaction:whetherit'sopeningorclosingthecircuitorswitchingon oroff adevice. Flowswitchesareeithernormallyopen(NO)ornormallyclosed(NC).Thisisreferringtotheswitch'sdefaultsetting. ANOswitchleavesthecircuitopen(OFF)until it isotherwisetriggered.ANCswitchkeepsthecircuitclosed(ON)until it is otherwisetriggered.Itisofferedinthemarketforbetween1500and2000rupees.

Fig 3: WorkingofPaddletypeFlowswitch

Fig 4: Flowswitch

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig – 5: Flowswitchinstalledinthemodel

3.2 Dosing Pump

Apositivedisplacementpumpcalledadosingpumpisusedtoinjectchemicalsorothermaterialsintoaflowofwater,gas,or steam. Small dosing pumps offer an incredibly precise flow rate for optimal control. They serve as the focal point of an integrateddosingsystemcreatedforthechemicalindustry'sautonomouschemicaldispersion.Theapplicationsandindustries coveredbythisdefinitionofdosagespanfromfoodprocessingtowastewatertreatment.Itcomeswithvariousrangeofflow rate. Dosing pump with 0 6 LPH flow rate range was used in the model. It is electromagnetic operated mechanically acute diaphragmtypedosingpump.Itismoldedwith40%glassfilledPolypropylene bodyandspacer.Allothercomponentsareof plastics, resistant to chemicals and even components are of plastics, resistant to chemicals. It is driven by solenoid coil and electronic pulsar. Power consumption is less than 75 Watts. It is available in the market with the price range of Rs 4700 to 8000(6LPHvariant)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

3.3 Chlorine Tank

Atankof40Lcapacitywasusedinthemodeltostorethechlorine.

Fig 9: ChlorineTank

3.4 Water tank

Water tank 0f 300 L capacity was used as a source of water in the model to create the flow in the pipe to which automaticchlorinatormodelisattached.Thepipesusedareof40mmdiameter.

Fig 10: WaterTank(300L)

3.5 Estimation of Rate of Chlorine for Model

TankCapacityof300litersistakenasthesourceofwaterwith15minutesastimeofflow,soweget0.33 l/s offlowinthe40 mm pipe. Considering chlorine dosage as 5 mg/l, total chlorine required is 1.5 g and bleaching powder required is 4.5 g (containing33%chlorine).Taking25litersofinthechlorinatortankandmixing75gofbleachingpowdertogettherequired concentration of chlorine. Rate of Dosing pump was set on 6 LPH so that it injects 1.5 liter of water with 4.5 g of bleaching powderin15minutes.

4. RESULTS

WaterfromMulariver,Punewastakeninthe300literstankasthesourceofwater.MPNtestwasconductedtocheck thepresenceofbacteriainthewater.TheMPNtestshowed4 2 1positivesamplesin10ml,1mland0.1ml respectivelyi.e 26MPNvaluewhichmeans26coliforms per100mlofsample.Thenthewaterwaspassedthroughthepipeofthemodeland automaticchlorinator was runto see the working efficiency of automaticchlorinator. The doseofchlorine wascalculatedas givenaboveinsection3.5.Waterfromtheoutletwascollectedandtestedaftergiving1hrcontacttimeforchlorination.The

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

MPN test of the chlorinated water gave 0 0 0 positive tubes i.e 0 MPN value. This shows that the automatic chlorinator workedsuccessfullyandcanbeusedtochlorinatewateroftheESR

5. CONCLUSIONS

InlinechlorinationsystemcanbeusedsafelyusedtochlorinatewateroftheESR.UsingthisAutomaticchlorinatorwe canminimizethemanualeffortsforthechlorinationintheESR.Thecostofautomaticchlorinatorislowthuseconomical.The easeofprocesswillencouragethechlorinationofwaterandthusleadingtohealthylifeofpeople.

REFERENCES

[1] TrucT.Ngo,JeremiahMedina,DavidWhite,DanfordJooste,KarlyJerman,JeremyHagen,JoannePeterson,ElCercado, San Juan. Design And Implementation Of An Alternative, Low cost Water Chlorination System In El Cercado, DominicanRepublic.InternationalJournalOfModernEngineering,Volume18,Number2,2018.

[2] Javier Gámiz, Yolanda Bolea1, Antoni Grau, Juan Gámiz, Francisco Luque, Juan Migue Vargas. Automation Of Chlorination Process For Drinking Water Treatment Plant: Control Strategies. Institute Of Electrical And Electronics Engineer10thInternationalConferenceOnIndustrialInformatics2012

[3] AmyJPickering,YoshikaCrider,Sonia Sultana,Jenna Swarthout,FrederickGBGoddard,SyedAnjerul Islam,Shreyan Sen,RagaAyyagari,StephenPLuby.EffectOfIn lineDrinkingWaterChlorinationAtThePointOfCollectionOnChild Diarrhoea In Urban Bangladesh: A Double blind, Cluster randomised Controlled Trial. The Lancet Global Health Volume7,Issue9,September2019

[4] Julie E. Powers, Cynthia Mcmurry, Sarah Gannon, Adam Drolet, Jared Oremo, Linden Klein, Yoshika Crider, Jennifer Davis And Amy J. Pickering Design, Performance, And Demand For A Novel In line Chlorine Doser To Increase Safe WaterAccess.NaturePartnerJournal,CleanWater2021

[5] JustineRayner,Travis Yates,MyriamJosephandDanieleLantagne.Sustainedeffectivenessofautomaticchlorinators installed in community scale water distribution systems during an emergency recovery project in Haiti. Journal of Water,SanitationandHygieneforDevelopment2016

[6] Nuhu Amin, Yoshika S. Crider, Leanne Unicomb, Kishor K. Das, Partha Sarathi Gope, Zahid Hayat Mahmud, M Sirajul Islam, Jennifer Davis, Stephen P. Luby and Amy J. Pickering Field trial of an automated batch chlorinator system at shared water points in an urban community of Dhaka, Bangladesh. Journal of Water, Sanitation and Hygiene for Development2016