International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

1

Abstract Liquid fuels like furnace oil are predominantly used in industrial application. The lack of proper utilizationof oil leads to the loss of money in industries. The project is conducting in Kairali Structural Fabrications Private Limited (KSFPL) which is an ISO 9001 2015 Company in Angamaly, Ernakulam. This company manufactures LPG (Liquefied petroleum gas) cylinders for Bharath Petroleum Corporation Limited, Indian Oil Corporation and Hindustan Petroleum. This project mainly aims in reduction of the furnace oil consumption duringthestressrelievingoperationtakingplace for the cylinder manufacturing. The stress relieving operation is an important operation function for reducing the internal stresses caused by secondary processes such as welding, machining, or cold forming. For the operation of the furnace there is preheating of the entire furnace in which it takes hours to heat the entire furnace before starting the operation which consumes a large amount of fuel. For obtaining maximum efficiency or lesser fuel consumption the entire furnace operations should take place continuouslywithlarger number of works without any delay in the processing. If furnace is operated more than one time in a day the fuel consumed for heating will be very large as the initial heating of furnace is needed in both cases. In this project continues operation of the furnace without delay is taken as the objective to reduce fuel consumption per cylinder. The different lean tools such as 5why, cause and effect diagram or Ishikawa diagram and value stream mapping (VSM) are employed to identify the above problem leading to fuel consumption and its root cause which is the delay in the production of cylinder and reduced number of cylinders processed per day in KSFPL less than 1000 cylinderswhichisa batch to be heat treated in a day. The continues operation of the furnace can be made possible by making a value stream map (VSM) which helps to identify the various operationsthat are bottleneck for the entire operations and more time consuming operations.Valuestreammapping(VSM)isdefined as a lean tool that employs a flowchart documenting every step in the process. After identifying the time consuming process the lean tools can be employed to make changestothe entire production operations. After current state VSM it is identified the process taking highest lead time. But this problem can be easily rectified and done the modified state VSM and find out that the production of 1000 cylinders per day is possible. This shows that the problem is associated with man, material and machines which is 3M’s causing the delay. A

fishbone diagram is made based on the plantand 3M’s causing delay. Then the future state VSM is made for eliminatingmost of the problems identified using lean practices. Then the improvements in the future state map can be suggested to the company which helps in reducing the fuel consumption and thereby reduction of fuel cost.

Key Words: Lean, Value stream mapping (VSM), Current state VSM, Modified state VSM, Future state VSM, Ishikawa diagram

Astheindustriesanddifferentcompaniesaroundthe world is moving towards a competitive environment in which they need to withstand the needs and problems associated with the customers and competitors. The best waytoachievecompetitiveadvantageisthroughreducing thewastagesandeffectiveutilizationoftheresources.This can be achieved through the implementation of lean practices in the manufacturing and service industries in which it helps in maximizing the profits and thereby reducing the wastages within the manufacturing organization.Theterm“lean”denotesthesystemwhichuses small amount of inputs and produces a large amount of output as produced by the traditional manufacturing systemswithvarietyofproductstothecustomers.Themain aimofleanistoreducethe7majortypesofwastesinkaizen such as waiting, transportation, overproduction, over processing, inventory wastage, unwanted motion and defects.Forachievingleannesstherearedifferentleantools such as Kanban, Kaizen, 5s, fishbone diagram, pareto analysis,5whyanalaysisandVSMetc.,

Themainaimofthisprojectistousetheselean tools and practices in the company Kairali structural fabricationprivatelimited(KSFPL)Angamalyandtoidentify themajorproblemthatisaffectingthecompany.Thenuse thesedifferenttoolstofindthesolutionsfortheproblems. The company manufactures LPG cylinders for Bharath Petroleum,IndianOilCorporationandHindustanPetroleum. At first stage the problem identification was done and identifiedthattheincreasedfuelconsumptionwasthemajor probleminthecompany.Thereasonfortheproblemwasno continuesbatchproductionof1000cylinderswashappening

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

inthefurnace.Theinitialfuelconsumptionforpreheatingof furnace is very high and for reducing the consumption continuesoperationsarerequiredatlargernumberinaday. Thecompanyhastoprocess1000cylinderswhichisabatch inthefurnaceperdaybuttheyarenotabletodothatsoby gettinginto1000cylindersperdaymarkwecanreducethe amountoffuelassociatedwithacylinder.Itisidentifiedthat as the number of cylinders processing increases the fuel consumption reduces by plotting graph between fuel consumptionandcylindersusedperday.Therootcausesfor the problem was identified using the 5why analysis and fishbonediagram.Thenforidentifyingtheprocessescausing thehigherleadtimeandanalyzingthemanufacturingsystem a Value steam mapping (VSM) was done in which it is consisted of current state VSM in which it identifies the currentstatusofproductflowandinformationflowandthe differenttimecalculationsaredoneandmappedtheentire manufacturingsystemuptofurnaceoperation.Usingthisthe process with highest lead time is identified. Then the modified or ideal state VSM was done by rectifying the problem of highest lead time. Then after this the major problemswasidentifiedasitisclearthatcontinuesfurnace operationof1000cylinders waspossible.Thenthefuture state value stream map is made with kaizen focus on different areasto beimprovedand providedsolutionsfor that problems using 5s, kanban, Kaizen etc. Then the solutionsthatareidentifiedandmappedissuggestedtothe company.

•Toidentifythemajorproblemaffectingthecompany

•Tousedifferentleantoolstoidentifytheproblems.

•Applicationofdifferentleantoolstoidentifythesolutions fortheproblemsidentified.

•Suggestingthesolutionstothecompany.

P.GSaleeshyaet.al[1]statedthatLeanmanufacturingis anemergingconceptintheIndianmanufacturingscenario. Manysmallandmediumscaleenterprisesinthecountryare aiming at becoming lean and thereby improving their productivity.Thispaperdealswithacasestudyinonesuch enterprisethatdealswiththemanufacturingandassemblyof offsetprintingmachineryinIndia. Thoroughanalysisofthe variousvendorsandprocessesthattheproductgoesthrough wasdoneandtheprocessflowwasmappedusingVSM.Lean tools like Pareto analysis, five why analysis, source inspection, etc., were used to identify and eliminate the variousfactorsthatledtodelay.Leanisarelativelymodern managementconceptwhichaimsateliminatingwastesand increasingefficiency.Theterm‘lean’denotesasystemthat utilisesless,intermsofallinputs,tocreatethesameoutputs

as those created by a traditional mass production system, whilecontributingincreasedvarietiesfortheendcustomer.

S. Vinodh et.al [2] VSM is selected as a technique for solving the problem existing in the case organization. The currentstatemapismadeusingdifferentobservationsand calculations.Thefuturestatemapisthencreated,alongwith variousimprovementproposals.Forvalidatingperformance improvements, a simulation approach is used. The lean manufacturingsystemenablesthemanufacturingsystemto achieve maximum productivity with minimal capital investment and material rejection. The uniqueness of this projectisthat,inadditiontotheuseofVSM,theimprovement inleanperformancemeasureswascalculated.Asimulationof the production line was also run before and after the recommendedproposalswereimplemented.Theoutcomeof thisstudyhasleadtotheimplementationofstageinspection (SI), fool proofing of jigs and fixtures, etc. in the case company. One of the important techniques of lean manufacturingisVSMwhichisfocusedonthemicro analysis ofmanufacturingprocesses.Hefoundoutthatthepractical adoption of VSM for ensuring leanness in manufacturing industrialscenarioisfoundtobefeeble.

DineshSethet.al[3]statedthattheapplicationofVSM isaprovenapproachforlean basedimprovements.Typically, this becomes challenging, when applied for complex production environments. The purpose of this paper is to demonstrate, how with some approximations and simplificationsinVSMapplication,leancanbesuccessfully achievedintheseenvironments.Theresearchfollowscase study method and systematically guides about the segregation and treatment of non value adding(NVA) and value adding(VA)activitiesofheavy dutyindustrialpower transformermakingprocess.ThestudyestablishesthatVSM application based lean messages remain same for both simpleandcomplexenvironments.

. Nihal A Siddiquia et.al [4] Liquefied Petroleum Gas (LPG)Cylindersaremanufacturedandtestedunderstringent norms before they get certified by Bureau of Indian Standards (BIS) for market use. These LPG cylinders are designed and manufactured as per Indian standard. Normally, cylinders are produced in batches from raw material specified in Indian standards and tested before dispatching to market. It gives data on the manufacturing processoftheLPGcylinderinIndiaanddifferenttests.

S.Vinodhet.al[5]leanmanufacturingisfocussedonthe reconfiguration and restructuring of business processes basedonwasteelimination,therebyenablingcostreduction. VSM is one of the most important lean manufacturing techniqueswhichiscapableoftrackingthewastesexistingin themanufacturingprocesses.ItwasdiscoveredthattheVSM implementationcontributedtoasignificantreductioninlead time,totalcycletime,workinprogress,anddefects,aswellas anoticeableimprovementinuptimeandon timedelivery.He

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

claimsthatVSMisaneffectiveleanmanufacturingtechnique that could be used in an industrial setting to improve leannessandhelporganisationsachievecompetitiveness.

Antor Habib Chowdhury [6] states that Value Stream Mapping is a lean tool used for reducing lead time, uncovering waste in production and supply process by identifyingnon value addingstepsfirstandthenremoving them. Future state map gives us the view how a manufacturing plant can operate in improved design comparing to the current situation. Improved stage of informationflow,materialflowandtimeflowaredisplayed inthefuturestatemap.Thismethodisnoteasytouseinthe case of complex production processes characterized by multipleflowsthatmerge.ApplyingleantoolssuchasKaizen, Go see&5S turnouttobehelpfulforbettermaterialand informationflowthroughouttheproductionsystemwhich reduceleadtime.

SahooA.Ket.al[7] Thispaperdescribesanapplication ofvaluestreammapping(VSM).Consequently,thepresent and future states of value stream maps are constructed to improvetheproductionprocessbyidentifyingwasteandits sources.Thecompanyproducesforgingsforrailways,oiland gas,andthemachinetoolsector,andalsoprecisionforging componentsfortheautomobilesectors.Itwasobservedthat asmallerbatchsizealwaysresultsinalowerwaitingtime. Thecompletesuccessoftheapplicationofleanphilosophyin thelongruninthecompanydependsonclosecooperation betweentheshopfloorpersonnelandthemanagement.

Bhim Singh S.K, et.al [8] This paper discuss the lean implementation process andits quantified benefits for the productionindustrywiththehelpofvaluestreammapping (VSM). Both current and future state maps of the organization’sshopfloorscenariosarediscussedusingVSM techniquesinordertohighlightimprovementareasandto bridgethegapbetweentheexistingstateandtheproposed stateofshopflooroftheselectedindustry.Aftercomparison ofthecurrentandfuturestateofshopflooroftheselected industry it is found that it has halped in saving time in differentareas.

Grewal,C.S.[9]statesthatValueStreamMapping(VSM) hasemergedasthepreferredmethodforimplementingand supporting the lean approach. VSM is a useful tool for identifyingwasteandareasforimprovement.VSMallowsa company to see the entire process in both its current and desired future states, and to create a road map that prioritisesprojectsor tasksto bridge the gap between the current and future (lean) states. VSM is a graphical representationoftheentirevaluechain

Abdulmalek,F.A.et.al[10]The‘‘lean’’approachhasbeen applied morefrequently indiscrete manufacturingthanin the continuous/process sector, mainly because of several perceivedbarriersinthelatterenvironmentthathavecaused managerstobereluctanttomaketherequiredcommitment.

This paper describe a case where lean principles were adapted for the process sector for application at a large integratedsteelmill.

Thefollowingstepsarefollowedforthecompletionof theproject.

I Identificationofthecompany

II.Identificationoftheproblem

III.Literaturereview

IV. Done cost analysis and made graphs relating fuel consumptionandnumberofcylindersprocessedinaday.

V. Identifying the root causes through 5why analysis and Ishikawadiagramorcauseandeffectdiagram

VI.Valuestreammappingofthecurrentcondition

VII.ModifiedorIdealstatevaluestreammap

VIII.Futurestateortobestatevaluestreammapping

IX.Suggestingthechangestothecompany

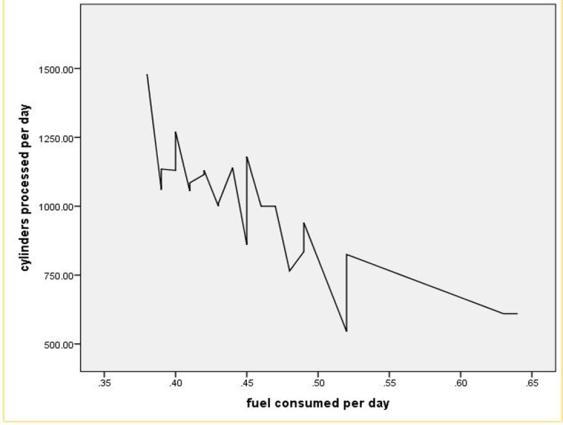

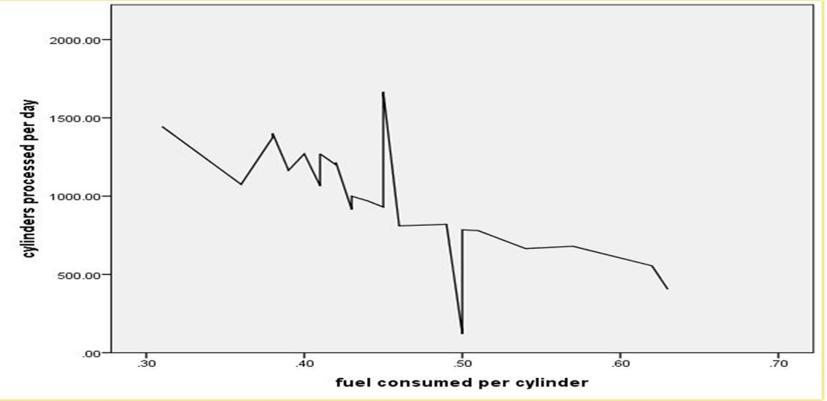

Ananalysisbasedonthecostandfuelconsumptionof thecylinderperdayisdoneforthemonthsNovemberand December for identifying the relation between the fuel consumptionandthenumberofcylindersprocessedperday. Thefollowinggraphswereobtained.Thegraphsinfig 1and fig 2itisevidentthatasthenumberofcylindersprocessed increases the consumption per cylinder also reduces. In KSFPL1000numbersofcylinderisabatchtobetreatedin thefurnaceinaday.Asthedatashowstheyarenotabletodo so.Thisincreasesthefuelusedpercylinderinaday.Sothe numberofcylinderstobetreatedistobekept1000forfuel savings.

Fig 1:Graphfornumberofcylindersproducedand consumptionpercylinderperdayofNovember

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig 2:Graphfornumberofcylindersproducedand consumptionpercylinderperdayofDecember

5whyanalysisisdonetoidentifytherootcauseofthe problemandtheanalysisquestionsareasfollows,

•Whythecostofoilhasincreased?

oTheincreaseisbecauseoftheincreaseinconsumption.

•Whytheconsumptionhasincreased?

oIthasincreasedasthecontinuesfurnaceoperationisnot takingplace.

•Whythecontinuesfurnaceoperationsarenothappening?

o Because there was delays in the furnace operations due lackofcylindersforprocessingandalsopowercutoffisalso aproblem.

•Whythelackofcylinderstakeplace?

oBecauseitisduetotheincreasedtimeconsumptionforthe preprocessesbeforethefurnaceoperations.

•Whythetimeishighfortheaboveprocesses?

oLackofproperarrangement,rework,machinebreakdown.

From the 5 why analysis it is identified that the lack of properarrangement,reworkandmachinebreakdownare someoftherootcauses.

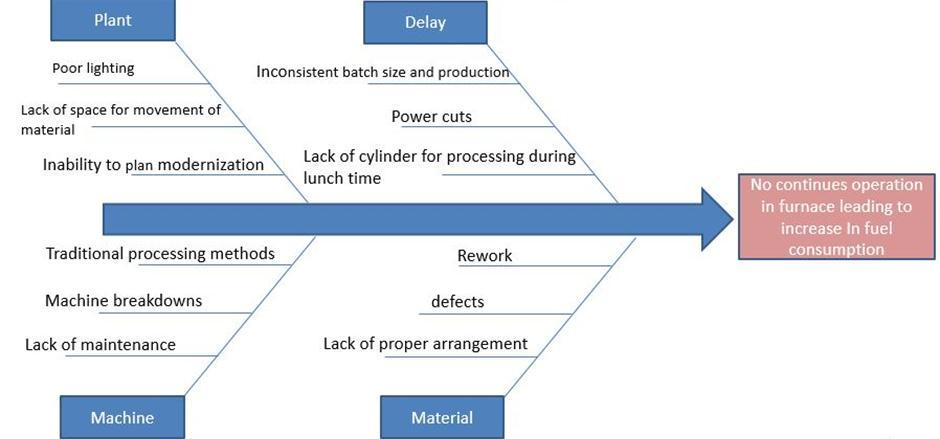

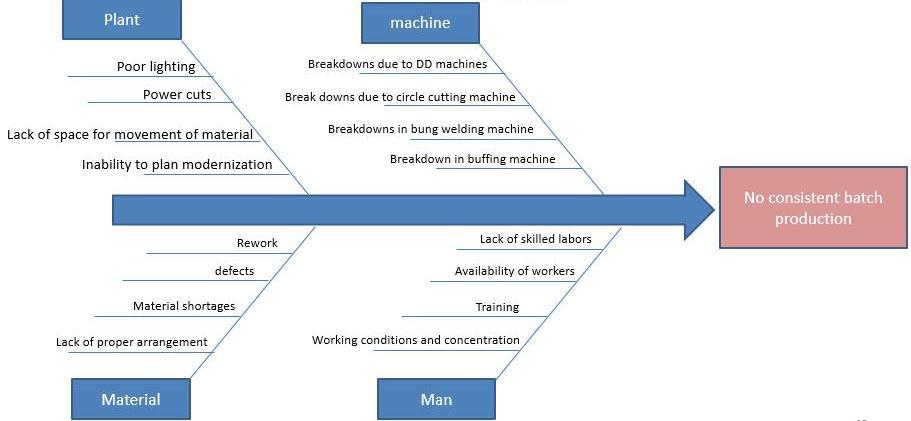

ThecauseandeffectdiagramorIshikawadiagramis also used to identify root causes for the lack of continues operationinfurnaceleadingtoincreaseinfuelconsumption. Thefig 3indicatestheIshikawadiagramforidentificationof therootcausesforthelackofcontinuesfurnaceoperation.

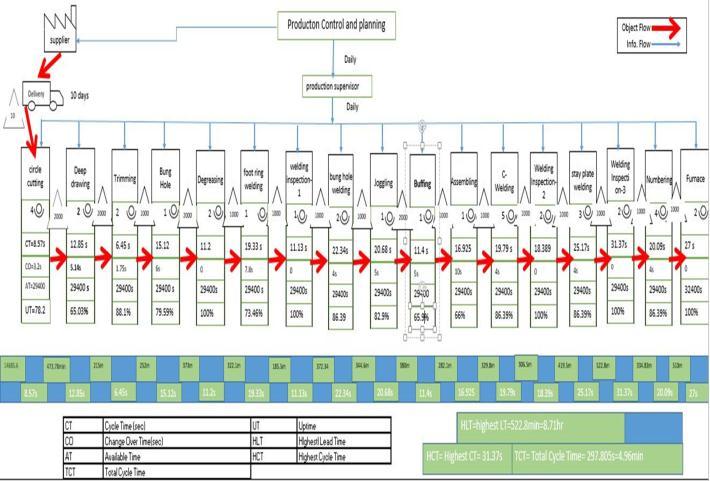

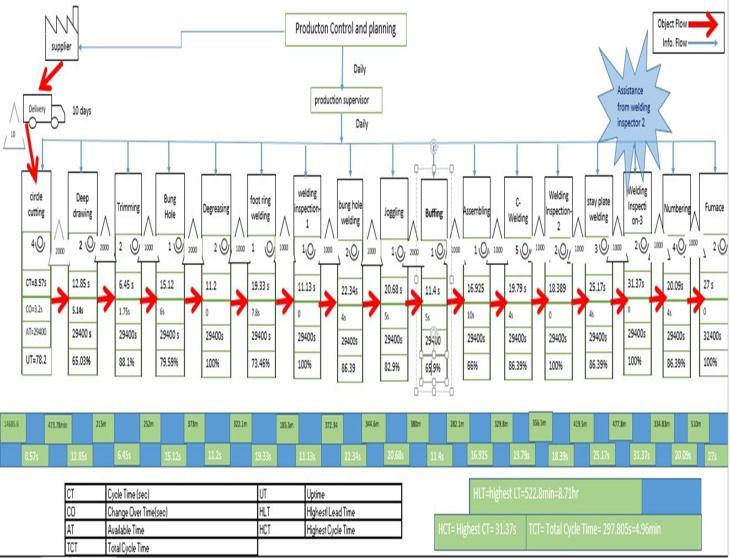

Current state value stream map maps the entire process flow and product flow across the manufacturing organisationfromsuppliertothecustomer.Inourcurrent state value stream map as shown in fig 4 the mapping is donefromsuppliertothefurnaceoperationaccordingtothe requirementoftheproject.

Fig-4: currentorasisstateVSM

Higher lead time identification and sample calculation is givenbelow,

Forweldinginspection3,

Workinghours=9.00Amto6.00Pm=9hours

Cycletime=31.37sec

Changeovertime=0sec

Employees=2

Leadtime =numberofinventory×cycletime

=1000×31.37=31370sec=522.8min=8.71hr

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Here this inspection has the highest lead time and this is slowing the entire production time =8.71hr for 1000 cylinders

Alsohighestcycletime=31.37sec

Majorfocusistobegiveninthisareafor gettingthe1000 batchproduction

Available production time per day= total available time break

=9×60 .83(50min)×60 =490min=29400sec=8.16hr

Uptime= (available production time change over time)÷availableproductiontime =(29400 0)÷29400 =100%

From the available time and highest lead time the time neededextrafor1000cylinderis =Highestleadtime availableproductiontime =8.71 8.16=.55hr=33min

33minisrequiredextraforinspecting63cylinders.

This problem can be resolved by making some changesandisshowninthemodifiedvaluestreammap

Themodifiedoridealstatemapisthemodifiedversion of the current state map under ideal conditions and it is showninthebelowfigurefig 5.

Afteranalyzingthecurrentstatemaptheprocesswith highestleadtimeisfindoutandtheremedyforthisproblem isfoundoutdepictedinthemodifiedstatevaluestreammap asshownintheabovefig 5.Thesolutionwasidentifiedas follows,

• The highest lead time was founded for the welding inspection3whichis=522.8min=8.71hr.

• It is 33min more than the available time of 8.16 hr (490min).

•This33minisneededmoreforinspecting63cylindersto complete1000cylinders.

•Alsotheleadtimeforweldinginspection2isfoundedout as 306.5min= 5.10hr which is 3.06 hour less than the availabletime.

•Soinmodifiedvaluestreammapanextra50minisgiven from the inspector 2 for assisting the inspector 3 for achievingthe1000cylinderbatchperday.

•Thiscanbeachievedeasilyasthedistancebetweentwois only10.4meter.

•Thentheleadtimeforweldinginspection2isincreasedto 356.5min and for welding inspection 3 it is reduced to 477.8hr(45minreduced)with5mindelayformovement.

• This kaizen focus reduced the lead time for welding inspection3.

Analysisaftermodifiedvaluestreammap,

•Fromthemodifiedvaluestreammapitisevidentthatthe production of a batch of 1000 cylinders is possible with smallchanges.

•Butherewecanseethattheyarenotabletofurnace1000 cylinders per day this pinpoint that there are other major problemswithintheproduction.

• This pinpoint to different problems which are identified earlierusing5whyanalysisandIshikavadiagramandthese canbeclassifiedbasedonthe3M’swhichareman,machine andmaterialandtheplant.

• These can be shown in detail using a new Ishikawa diagramasshowninfig 6.

Fig 5: modifiedoridealstateVSM

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

• As shown in the modified state VSM by using a small changeitisidentifiedthatthebatchproductionwaspossible withintheavailabletime.

•Thisleadstotheidentificationofthemajorcausesofthe inconsistent batch production which are the 3M’s Man, MaterialsandMachines.

• The main causes which are man, material, machine and plant are finded out using the Ishikawa diagram which causesinconsistentbatchproduction.

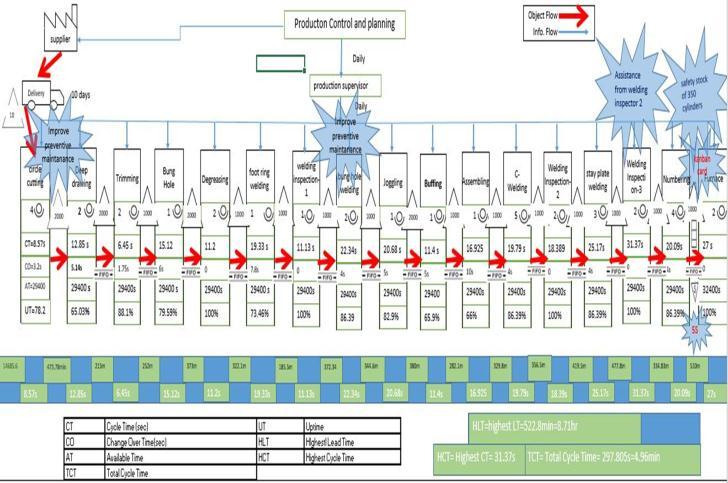

•Asaresultthefuturestatevaluestreammapismade as shown in the below figure fig 7 with kaizen focus on differentareastobeimprovedbyusingdifferentleantools suchaskaizen,5s,andkanban.

Fig-6: Ishikawadiagramorcauseandeffectdiagram

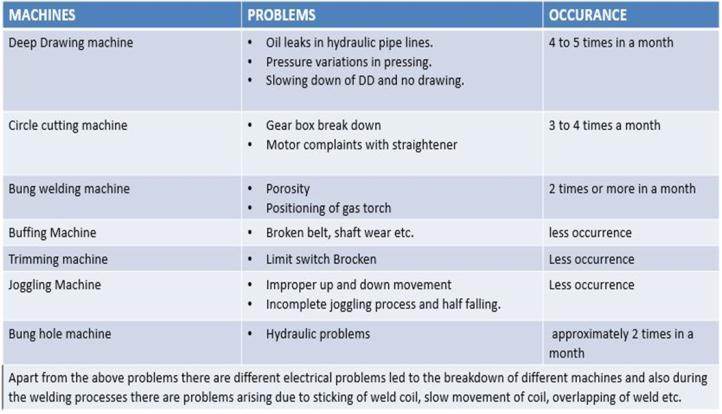

Table 1:Machinesandassociatedproblems

Thefuturestatevaluestreammapafterincorporatingthe different solution for the different problems discussed beforeisshowninthefig 7.

The table 1 denotes the major machines and the problemscausedbyitanditsoccurrence

The future state value stream map is plotted with solutionsformostoftheproblemsidentifiedanddiscussed intheresultsanddiscussions.

• UsingthecostanalysisandthegraphsIhaveidentifiedthe majorproblemoffuelconsumptioninwhichasthenumber ofcylindersprocessingdecreasesthefuelconsumptionper cylinderincreases.

• Throughdirectobservations,Groupdiscussions,Making questionersandinterviewswithemployeesIhavedonethe rootcauseanalysisusingtheIshikawadiagramand5why analysisandidentifiedthemajorcauses.

•ThenVSMmappingwasusedtoidentifytheprocesseswith higherleadtimescausingthedelay.

• In current state VSM it is identified that the welding inspection 3 is having higher lead time to inspect 1000 cylinderswhichishinderingthebatchproduction.

Fig-7: Futureortobestatevaluestreammap

Astheproblemswiththemachinesareamajorcausefor the delays and the inconsistent batch production the maintenanceofthemachineistobeconsideredforthe firstkaizenfocusandalsoshowninthefig7.

•ItisfoundoutfromthemaintenanceteamandVSMthat theyaremainlyfocusingonthebreakdownmaintenancein which maintenance is done only after the machine breakdown.

•Itisalsoidentifiedthattheoperatorswhoareoperating themachinesarenotwellawareofearlyidentificationofthe problems.

•Alsotherewascasesinwhichtherequiredpartsarenot availablewhenamachinebreakdownoccurred.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

•AsaresultthefuturestateVSMfirstkaizenfocusisgiven toimprovingthepreventivemaintenance.

• The preventive maintenance can be done by proper checkingandanalysisofdifferentmachinesandfindingout those parts or things should cause a breakdown and rectifyingitearlier.

•MajorfocusistobegiventomachineslikeDeepDrawing machine,circlecuttingmachineandbungweldingmachine.

• For improved preventive maintenance the operators of thesemachinesshouldbetrainedandteachtoidentifythe causeofdifferentproblemswithinamachine.

•Beforestartingthemachinesatleast15minutesistobe allottedforcheckingthemachinesandalsothereshouldbe conversationsbetweenmaintenanceteamandtheoperators aboutthemachines.

• It will increase the expertise and knowledge of the operator.

• Proper lubrications and maintenance should be done in properintervalsindaily,weeklyandmonthlybasis.

• Also if a breakdown occurs there should be stock of requiredpartsandmaterialsforthefasterrecovery.

Thesecondkaizenfocusisonfurnacewhichisconsisted ofallocationofthesafetystock,5sandkanbancard.

•A350cylindersistobesetasasafetystockforfurnace operationtocompensateforanydelaysorbreakdownof themachines.

•The350cylindersafetystockistakenbecause50%ofthe totalleadtimecanbetakenassafetystockinwhichitis500 cylinders.

•Buthereastherewillbe60minutesdelayforstartingthe furnaceapproximately100ormorecylinderswillcameto thefurnaceso350cylindersistakenassafetystock.

•This350cylinderscanbeoperatedfor2hrand37minsif thereisadelayoccurred.

•Thistimecanbeutilizedtorecovertheproductionprocess byrectifyingtheproblemsorrepairsandthissafetystockis tobefilledfornextoperationsifutilized.

•Thecylinderswillbeplacedinorderinwhichtheywillbe processedin“firstinfirstoutmethod”.

•Thecylinderswillbestackedinpairof2inwhichtheywill beplacedfromoneendofthefurnaceinordertotheother endandshouldbeprocessedfromthefirstend.

•Thiswaysafetystockcylinderswillbereplacedwithnew cylinderseveryday.

Areacalculationforsafetystock, Outerdiameterofacylinder=319mm=31.9cm=.319m Circularareaforacylinder= πr²=π×.1595²=0.079m²

Thereforefor175(350Nos)cylindersthearearequired =175×0.079=13.82m²

13.82m²areaisrequiredforsafetystockof350cylinders

Totalavailablearea=(mainarea unusablearea) =((5.5×4.4) (1.7×1.4)) =21.82m²

Totalnumberofcylindersthatcanbestacked =21.82÷0.079 =276.2=552cylinders

Sosafetystockcanbeeasilyplacedinthisarea

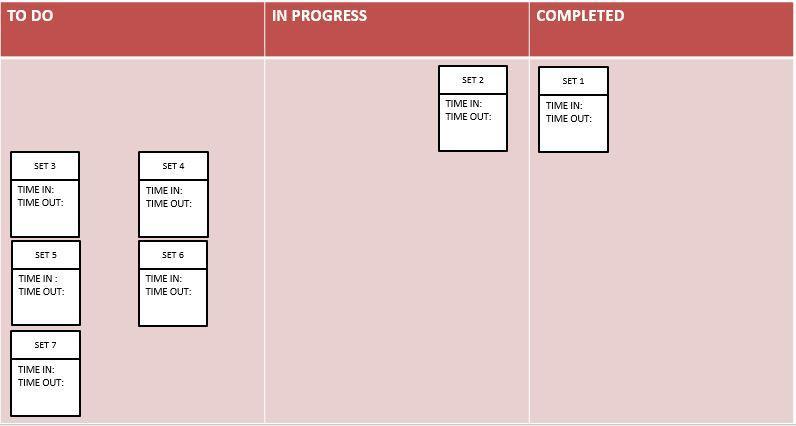

Here a Kanban card which is another kaizen focus utilizedtoidentifythenumberofcylindersremaining perdayforsafetystock.

Here the 350 cylinders are made into 7 sets and the kanban card is used to analyze whether the required safetystockispresent.

Forthe350cylindersof7setsthespacein whichthe cylinders are placed is partitioned into different plots andeachcylinderswillbeallocatedinrequiredareasin FIFO(first in first out) order through 5s(sort, set in order,standardize,shine,sustain).

Thishelpsintheorderlymanagementofcylinderstothe furnace.

Thekanbancardforthesafetystockallocationisshown inthefig 8for7setsof50cylinderscombiningthe350 cylinderssafetystock.

Fig 8: Kanbancardforsafetystock

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The third kaizen focus on consideration is 5s on the numberpunchingareainwhichtheworkersareusing 10 dies for number punching in the foot ring and the stayplate.

Here the dies are placed in normal boards or nearest surfaces in which there is no specific place for these dies.

This causes confusion in selecting the dies while working.

To avoid this a box is to be introduced to place these dieswithnumbersprintedwithrespecttoeachdies.

By this the worker can easily identify the die number and access the dies and can place this box and dies safely.

Theothermajorfocusareasareasfollows,

Application of 5S is to ensure proper cleaning of the entire production area and also to remove unwanted materialslyingintheworkplace.

Thelightingintheareashouldbeimprovedbyadding more lights and proper cleaning of the wall for giving workersgoodatmospheretowork.

Another consideration is to add an employee who is skilledforsubstitutingforstayplatebodywelding.

Akaizen(continuesimprovement)awarenesssessionis to be done by involving all the employees in the company and should made them capable towards the longlastingchange.

Atlasttheabovementionedkaizenfocusonthefuture statevaluestreammapandthesolutionsthathaveidentified aresuggestedtothecompanyforimprovementindifferent areas in the manufacturing system and to reduce fuel consumption by continues batch production of 1000 cylindersperday.

Fromtheprojectitisidentifiedthattheleanpractices canbeeasilyappliedinamanufacturingcompanytoidentify theproblemsandrootcauseofeachproblems.Astheproject focuses on suggesting solutions for reducing the fuel consumptionthroughleanpracticesbyobtainingconsistent batchproduction.Thedifferentleantoolssuchas5Whys, fish bone diagram or Ishikawa diagram were effectively utilized to analyze the root causes in different areas. VSM helped to map the material and information flow along different processes and to calculate the lead times to find processwithhigherleadtimes.Thishelpedinmakingthe modified value stream map which helped to identify the

solution for process having highest lead time and thereby finding out the major causes of the inconsistent batch production.Thenthefuturestatevaluestreammapismade applyingdifferentleanpracticessuchas5s,kaizen,kanban etc. for achieving continues batch production of 1000 cylinderswhichreducesthefuelconsumption.Thisproject helpedtoformulatedifferentsuggestionsforthecompany from the future state VSM to achieve continues batch production

[1] Saleeshya, A. Sneha, C. Karthikeyan, C. Sreenu, A.K. Rohith (2015), Lean practices in machinery manufacturingindustries acasestudy,Int.J.Logistics SystemsandManagement,Vol.20,No.4,2015

[2] S. Vinodh, M. Somanaathan K.R. Arvind, (2013),Developmentofvaluestreammapforachieving leanness in a manufacturing organization, Journal of Engineering, Design and Technology, Vol. 11 Iss 2 pp. 129 141.

[3] Dinesh Seth, Nitin Seth & Pratik Dhariwal (2017) Applicationofvaluestreammapping(VSM)forleanand cycle time reduction in complex production environments, Production Planning & Control The Management of Operations ISSN: 0953 7287 (Print) 1366 5871

[4] Nihal A Siddiquia, Akula Ramakrishnab, P Sojan Lalc (2013),Review on liquefied petroleum gas cylinder design and manufacturing process as per Indian standard,is3196(part1):2006,InternationalJournalof AdvancedEngineeringTechnologyE ISSN0976 3945

[5] S. Vinodh, K.R. Arvind, M. Somanaathan, (2010),"Application of value stream mapping in an Indiancamshaftmanufacturingorganisation",Journalof Manufacturing Technology Management, Vol. 21 Iss 7 pp.888 900

[6] Antor Habib Chowdhury (2016), Application of Lean Tool ValueStreamMapping(VSM),ScholarsJournalof EngineeringandTechnology,4(10):482 488

[7] Sahoo, A.K., Singh, N.K., Shankar, R. and Tiwari, M.K. (2008),“Leanphilosophy:implementationinaforging company”,Int.J.Adv.Manuf.Technol.,Vol.36Nos5/6, pp.451 62.

[8] BhimSinghS.K.GargS.K.SharmaChandandeepGrewal, (2010),"Lean implementation and its benefits to productionindustry",InternationalJournalofLeanSix Sigma,Vol.1Iss2pp.157 168

[9] Grewal, C.S. (2008), “An initiative to implement lean manufacturingusingvaluestream mappingina small

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

company”, International Journal of Manufacturing TechnologyandManagement,Vol.15Nos3/4,pp.404 17

[10] Abdulmalek,F.A.andRajgopal,J.(2007),Analyzingthe benefits of lean manufacturing and value stream mapping via simulation: A process sector case study, InternationalJournalofProductionEconomics,Vol.107 No.1,pp.223 36.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal