International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Abstract - External wrapping of FRP (Fiber reinforced polymer) has become a popular technique in retrofitting of structures, because of light weight, easy handling and fast installation. FRP sheets helps in strengthening of structures, delays the buckling, and they do not corrode. So that they can prevent corrosion of steel structures in marine environment. In this paper Retrofitting and Strengthening of steel tubular section using FRP is studied. Here elliptical steel tubular section is used as the control specimen. FRP is fully wrapped around the steel tubular section. Comparison of different FRP sheets were used in the study, they are CFRP, AFRP, and GFRP. Ansys 2021 software is used for the study. Various analysis was conducted and the performance of the steel tubular section is studied. Specimens wrapped by FRP shows a better result than the specimen without FRP. FRPs will increase the load carrying capacity and delays the buckling action in specimens with FRP wrapping. Among all the FRPs, CFRP shows a better result than AFRP and GFRP. CFRP wrapping has a better compression load, flexural and buckling values than AFRP and GFRP.

Key Words: Finite Element Analysis, FRP wrapping, Steel tubular section, Strengthening, Buckling

FRP(fiber reinforcedpolymer)isachemicalcomponent.It consistsofamatrixandfiber.Itisgenerallyusedinindustries likeconstruction,transport,andmarinetomakestructures resistanttodeformation. Apartfromthatitalsoimprovesthe strength, safety, durability and reduces the formation of cracks. Askilledpersonwillbeneededfortheinstallation processofFRP.InstallationofFRPsheetsaroundstructural components includes the following steps, like site preparation, in which surface should be free from wet condition,becausetheycausetheformationofbubbles.The next step is surface preparation. The surface should be cleanedandroughenedtoensurestrongbondbetweenresin andFRP.Finalstepisthatepoxyisappliedonthesurfaceand thenFRPsheetisinstalled

Severalstudieswereconductedtofindoutthebehaviorof FRP strengthenedsteelstructures,subjectedtostaticaxial compression loading, and therefore the results are well documented in many analysis articles [6]. Polymer technologyhavenewdevelopmentsinfibersandFRP(fiber reinforced polymer) in order to improve the behavior of concretestructures.SinceFRPhavehighdurabilityandlight weightithasbeenwidelyutilizedinconstructionfield[9]. Retrofitting of construction concrete and steel structures from natural calamities like earthquakes, fire, and flood become a necessary activity. So, the introduction of FRP material is a great advantage for structural components. Manypreviousexperimentalstudieshaveagoodimpacton retrofitting structural components using fiber reinforced polymers.[8].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

TostudytheeffectofFRPonasteeltubular section.

Severaltestswerecarriedouttofindcompressive behavior,flexuralbehaviorandstaticbuckling.

To study the effect of FRP on a steel tubular section. Different frp sheet are used in the study, they are CFRP (carbonfiberpolymer),AFRP(aramidfiberpolymer),GFRP (glassfiberpolymer).

SoftwareusedformodellingisAnsys2021.

Materialpropertyofparentspecimen

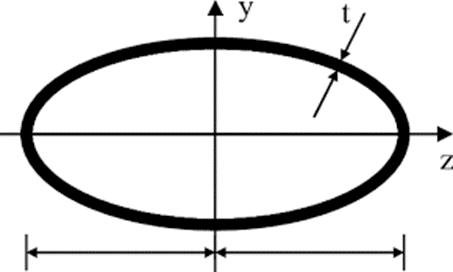

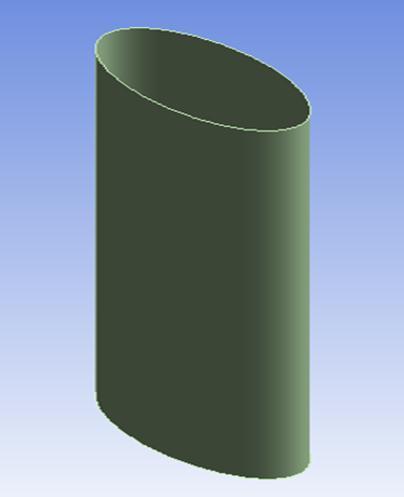

• Crosssection : z=203.3mm,y=101.6mm

• Thickness : 2.75mm

• Length : 496.74mm

• Density : 7850kg/mm³

• Poisson’sRatio : 0.3

• Young’smodulus: 2E+05Mpa

• Yieldstrength : 350Mpa

BilinearisotropicHardeningisgivenwith

Bulkmodulus1.6667e+05Mpa, Shearmodulus76923Mpaand Tangentmodulus2000Mpa.

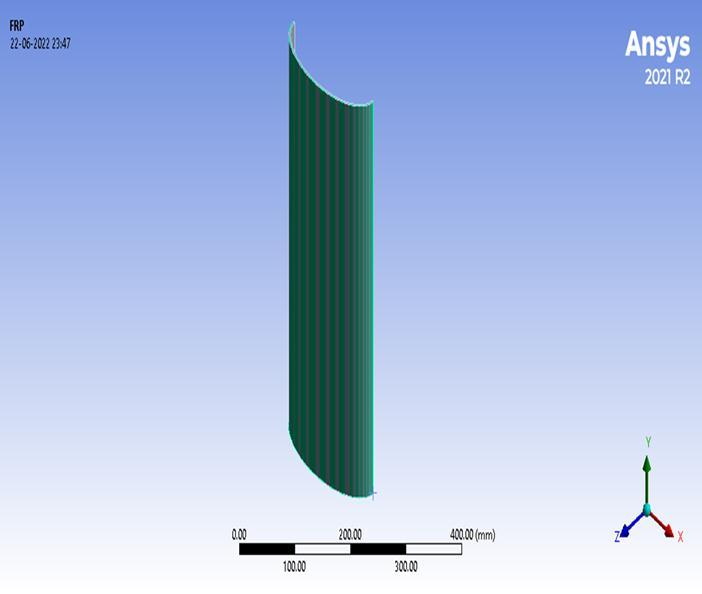

Fig 2: Crosssectionofspecimen

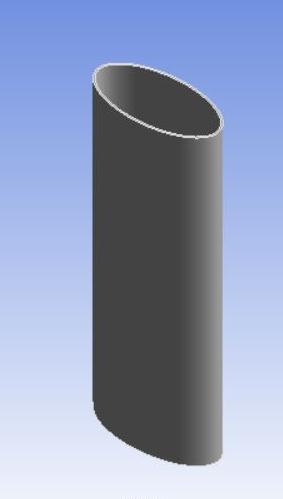

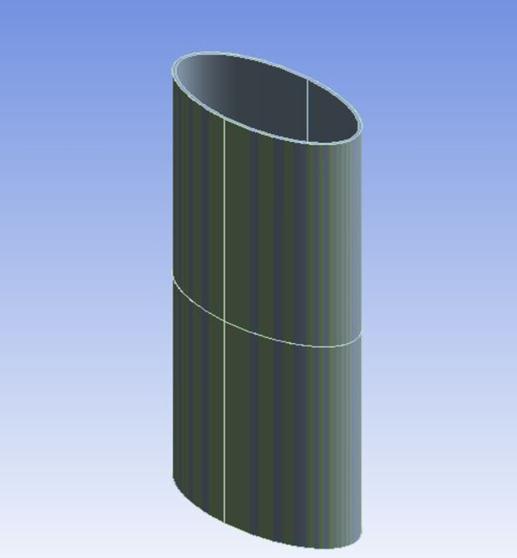

Fig- 3: ModellingofEllipticalsteeltubularsection

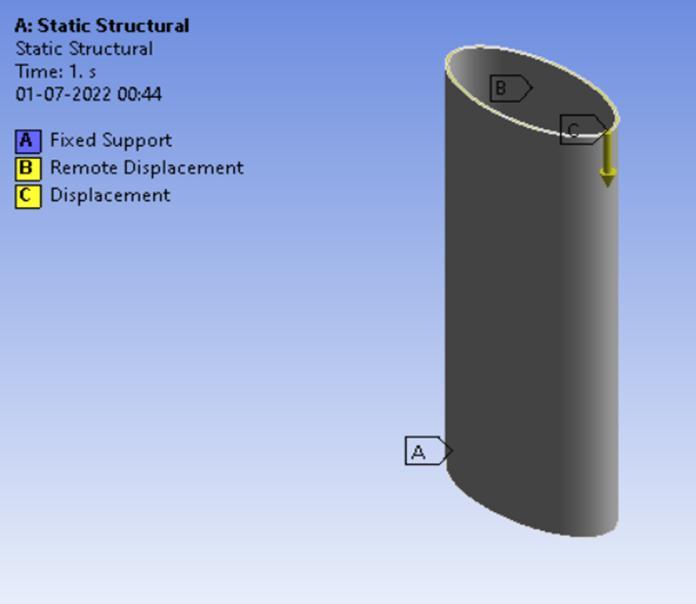

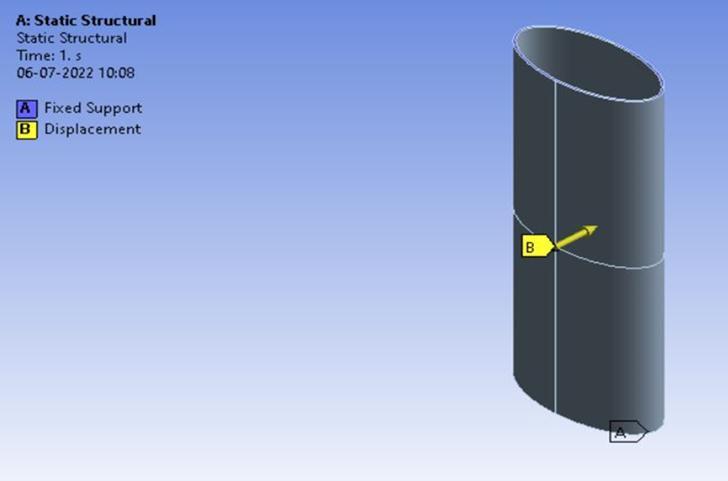

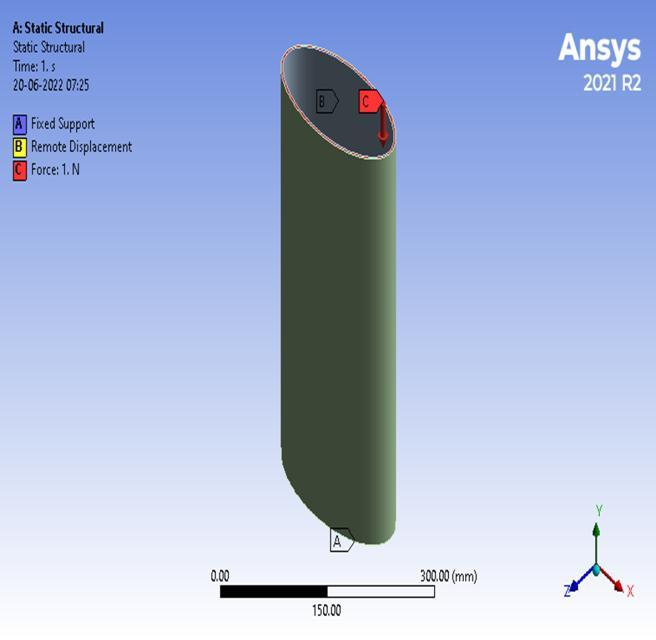

Fig - 4: Boundary condition of Elliptical steel tubularsection

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fixed support is given at the bottom face, Remote displacement is given at the top face in which x and z componentis0mm(ramped)andycomponentissetfree. Anditsbehavioriscoupled.

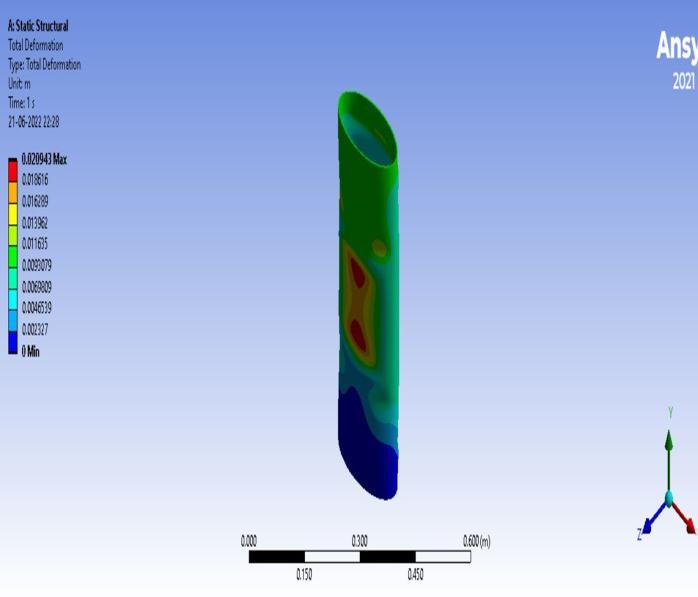

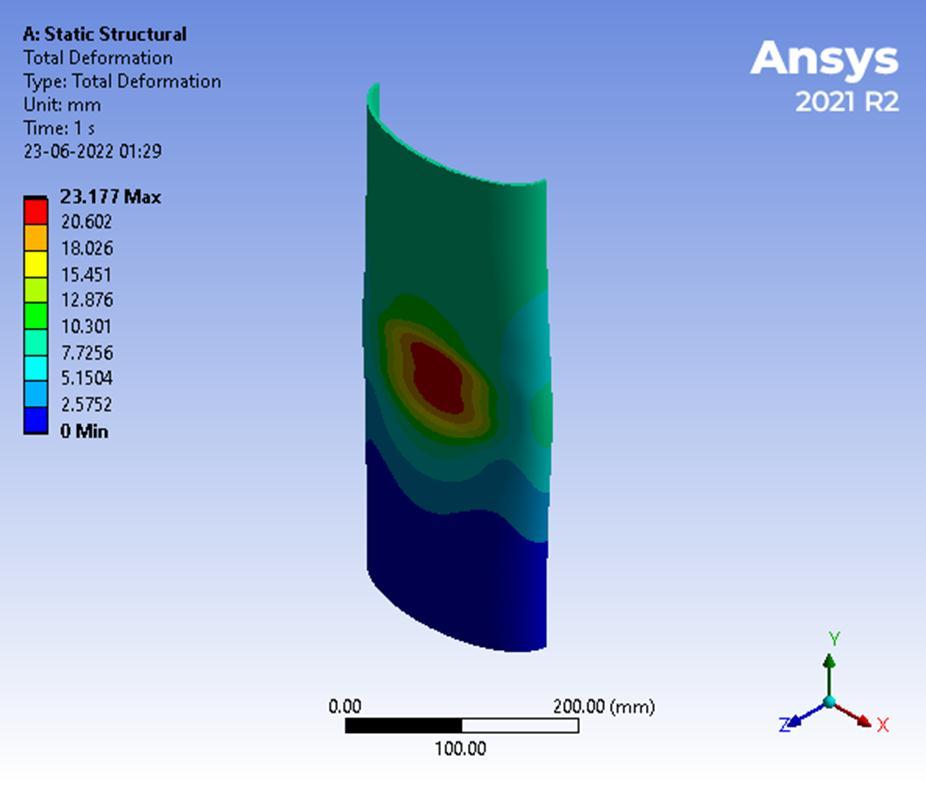

Maximumultimateloadobtainedfromloadvsdisplacement graphis467.74KNanditscorrespondingdisplacementis1 mm.

Anonlinearcompressionanalysiswasanalyzedfordifferent FRP. Here we use CFRP, AFRP and GFRP for wrapping around the steel tubular section. For the analysis we use symmetry model of the steel tubular section for the easy computationinFRPwrapping

FRP used for the study is orthotropic in nature. And the thickness used for frp sheet is 1mm. FRP is connected to specimenbytypebonded.

Ex=Modulusofelasticityinthexdirection

Ey=Modulusofelasticityintheydirection

Ez=Modulusofelasticityinthezdirection

Vxy=Poisson’sratiointhexyplane

Vxz=Poisson’sratiointhexzplane

Vyz=Poisson’sratiointheyzplane

Gxy=Shearmodulusinthexyplane

Gxz=Shearmodulusinthexzplane

Gyz=Shearmodulusintheyzplane

Fig 6: Symmetrymodelofspecimenwithfrp

Table -1: Propertiesoffrpsheets

PROPERTIES CFRP AFRP GFRP

Ex(Mpa) 165000 13600 21000

Ey(Mpa) 9650 1482.1 7000

Ez(Mpa) 9650 1482.1 7000

Gxy(Mpa) 5200 549.13 1520

Gyz(Mpa) 5200 547 2650

Gzx(Mpa) 3400 549.13 1520

Vxy 0.3 0.32 0.26

Vyz 0.3 0.35 0.3

Vzx 0.45 0.35 0.26

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Specimen without FRP has ultimate compression load 467.74KNanddisplacementatthatcorrespondingloadis1 mm. Specimen with CFRP has ultimate compression load 598.58KNanditscorrespondingdisplacement is5.2mm. SpecimenwithAFRPhasultimatecompressionload473.76 KN.Anditscorrespondingdisplacementis1.4mm.Specimen withGFRPhasultimatecompressionload498.98KNandits correspondingdisplacementis4.6mm. Specimenswrapped with FRP sheet shows improvement in compression load carrying capacity than specimen without FRP sheet wrapping. In which steel tubular specimen wrapped with CFRPhasmaximumloadcarryingcapacitythanotherFRPs.

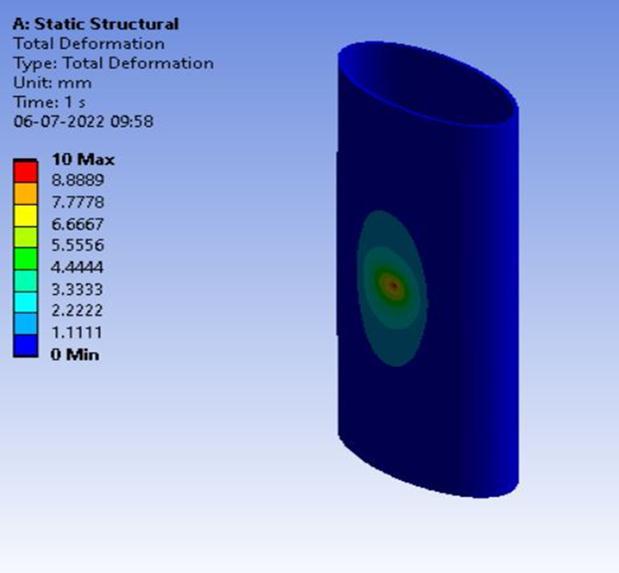

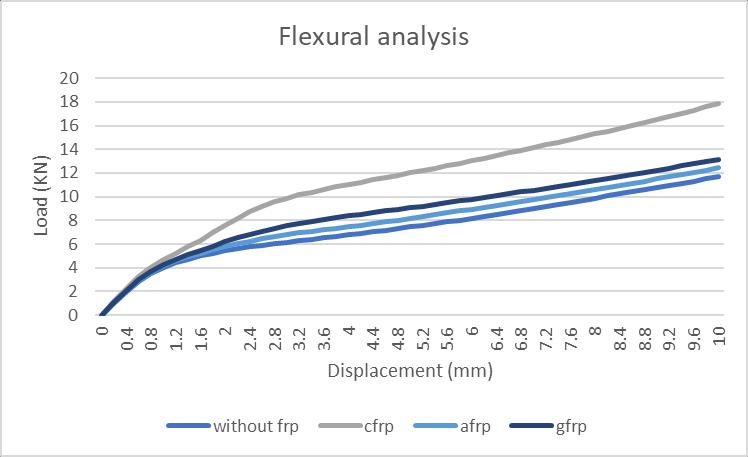

AnonlinearflexuralanalysiswasanalyzedfordifferentFRP. HereweuseCFRP,AFRPandGFRPforwrappingaroundthe steeltubularsection.Andcompareitwithspecimenwithout FRP.Propertiesusedforspecimenandfrpissameasusedin compressionanalysis.Meshingsize10mmisgiven.

Fixed support is given at the top and bottom face of specimen.Displacementloadanalysisisdone.Displacement isgivenatthecenterpointofthespecimen.

Fig -9: Boundaryconditionofflexuralspecimen

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Alinearstaticbucklinganalysiswasanalyzedfordifferent FRP. Here we use different FRP such as CFRP, AFRP and GFRPforwrappingaroundthesteeltubularsection.Anditis comparedwithspecimenwithoutFRPwrapping.

Boundaryconditions-Fixed supportisgivenatthebottom face,Remotedisplacementisgivenatthetopfaceinwhichx andzcomponentis0mm(ramped)andycomponentisset free.Aforceof1Nisappliedattopfaceofsection

Graph shown in fig 11 shows the comparison of flexural analysis of specimen with and without FRP wrapping. Specimenwithoutfrpwrappinghasflexuralloadof11.676 KN.CFRPwrappinggives17.849KN,AFRPwrappinggives 12.425KN,GFRPwrappinggives13.173KN.

Specimens with FRP wrapping has more flexural load capacity than specimen without FRP wrapping. And CFRP wrappedspecimengivesbetterresultthanAFRPandGFRP. Displacementiscontrolledat10mm.

Fig - 11: ModelwithFRPforstaticbuckling

Chart -1: Flexuralanalysisgraph

Fig 12: Boundaryconditionoflinearstaticbuckling

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

WithoutFRP 1 2.4193e+006 2 2.4202e+006

CFRP 1 2.9176e+006 2 2.9184e+006

AFRP 1 2.4721e+006 2 2.473e+006

GFRP 1 2.5504e+006 2 2.5515e+006

Most of the researchers use FRP sheet in concrete structures,anduseofFRPsheet insteel structural isvery rare. FRP laminates are commonly used for retrofitting works, but frp sheets have low weight and high strength than FRP laminates. In this study, we use elliptical steel tubularsection,sincenowadayspeoplearealsofocusingon aestheticalappearanceofstructural.DifferentFRPssuchas CFRP,AFRPandGFRPareusedinthestudy.

Wrapping of FRP increase the load carrying capacity, delays buckling and also prevent steel structuresfromcorrosion.

SteeltubularsectionwithdifferentFRPwrapping wasstudied.

SteeltubularwithFRPwrappinggivesbetterresults thanspecimenwithoutFRPs.

SpecimenwithCFRPhasultimatecompressionload 598.58KNincompressionanalysisanditisbetter thanotherfrpthatisAFRPandGFRP.Ittakesmore compressionloadthanotherFRPs

Among all fibers AFRP has lowest compressive strengththereforeitisnotwidelyused.

FlexuralanalysiswithCFRPwrappinghasflexural load17.849KNinflexuralanalysisanditisbetter thanAFRPandGFRP.

InthecaseoflinearstaticbucklingCFRPshowsthe bestresultwhencomparedwithAFRPandGFRP. From all the analysis CFRP shows a better result duetoitshighstrengthandresistancetofatigue.

[1] R. Al-Rousan and R. Haddad, (2013) “NLFEA sulfatedamagereinforcedconcretebeamsstrengthenedwith FRPcomposites”,CompositeStructures96,433 445.

[2] Meyyada Y. Alabdulhady, Lesley H. Sneed, Christian Carloni, (2017) “Torsional behavior of RC beams strengthened with PBO-FRCM composite An experimentalstudy”EngineeringStructures136,393 405

[3] FaqiLiu,YuyinWang,Tak-mingChan(2017)“Behavior ofconcrete-filledcold-formedellipticalhollowsections withvaryingaspectratios”,Thin–WalledStructures110 (2017)47 61.

[4] Sachin B. Kandekar, Rajshekhar S. Talikoti, (2018) “Torsional behaviour of reinforced concrete beam wrapped with aramid fiber”, Journal of King Saud University EngineeringSciences.

[5] Farid Bouziadia, Bensaid Boulekbachea, Abdelkader Haddib,MostefaHamrata,ChafikaDjelalb,(2019)“Finite elementmodelingofcreepbehaviorofFRP-externally strengthenedreinforcedconcretebeams”,Engineering Structures.

[6] Abderrahim Djerrada, Feng Fana, Xudong Zhia, Qijian Wu, (2019) “Experimental and FEM analysis of AFRP strengthened short and long steel tube under axial, compression”,Thin-WalledStructures139,9 23

[7] AnwarBadawyBadawyAbu-Sena,MohamedSaid,M.A. Zaki, Mohamed Dokmak, (2019) “Behavior of hollow steel sections strengthened with CFRP” , Construction andBuildingMaterials205,306 320

[8] S.SivasankarL.PonrajSankar,A.PraveenKumarc,M. Shunmugasundaram,(2019)“Compressionbehaviorof cylinder reinforced with aramid fiber reinforced polymer”MaterialsToday:Proceedings. externallybondedstrengtheningofRCbeams:Natural FRP”,CompositeStructures241,112081.

[9] ChengChen,YancaiYang,JinboYu,JinmingYu,Haizheng Tan, Lili Sui, Yingwu Zhou, (2020) “Eco-friendly and mechanically reliable alternative to synthetic FRP in

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

[10] Chittaranjan B. Nayak, Giridhar N. Narule, Harshwardhan R. Surwase, (2021) “Structural and cracking behaviour of RC T beams strengthened with BFRP sheets by experimental and analytical investigation” , Journal of King Saud University EngineeringSciences

[11] Chittaranjan B. Nayak, (2021) “Experimental and numerical investigation on compressive and flexural behaviorofstructuralsteeltubularbeamsstrengthened withAFRPcomposites”,JournalofKingSaudUniversity EngineeringSciences33,88 94

[12] A Kheyroddin, H. Arshadi a, M.R. Ahadi, G. Taban, M. Kioumarsi, (2021) “The impact resistance of FiberReinforced concrete with polypropylene fibers and GFRPwrapping”MaterialsToday:Proceedings

[13] Sachin B. Kandekar, Rajshekhar S. Talikoti, (2018) “Torsional behaviour of reinforced concrete beam wrappedwitharamidfiber”EngineeringSciences.

[14] AmirrezaBastania,SreekantaDasb,SaraKennoc,(2019) “Rehabilitationof thin walled steel beamsusingCFRP fabric”Thin WalledStructures143,106215

[15] MeyyadaY.Alabdulhady,KhalidAljabery,andLesleyH. Sneed, (2019) “Analytical Study on the Torsional Behavior of Reinforced Concrete Beams Strengthened with FRCM Composite” J. Compos. Constr, 23(2): 04019006 DOI: 10.1061/(ASCE) CC.1943 5614.0000927. © 2019 American Society of Civil Engineers.

[16] NabajyotiModak,S.Sivasankar,V.M.Sounthararajan,S. Gunaselvi, (2020) “Behavior of hollow circular steel columns in compression retrofitted with aramid fibre reinforced polymer composites”. Materials Today: Proceedings.

[17] ValarmathiT.N,SangeethaM.,GouthamGedelaVenkata, Dhanesh Muppala, Siva R, (2021) “Hygro thermal degradation studies on E glass woven rovings and aramidfibercomposites” ,MaterialsToday:Proceedings 44,3823 3828

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal