International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Abstract - Concrete is the back bone of the construction industry. The growth in population has placed an enormous need for more and more infrastructure and it keeps growing. The outcome of this demand is the increaseinproductionofcement.Theglobalproductionof cement is about 4.1 billion metric tons and is expected to increase to 4.83 billion metric tons in 2030. The quantity of plastics of all types consumed annually all over the world has increased substantially. The manufacturing processes, municipal solid wastes (MSW) and service industries generate a large amount of waste plastic materials.Thewastesthatareofeconomicimportanceare bagasse, molasses, and filter press mud. Bagasse is the fibrous residue remaining after the extraction of the cane juice from sugarcane. Sugarcane bagasse consists of approximately50%ofcellulose,25%ofhemicellulose,and 25% of lignin. The research work here deals with the partial replacement of cement by mass with Sugarcane bagasseashwithadditionofcoatedPETfibersinconcrete. Aftermixing,castingandcuringthecharacteristicstrength ofthisnewconcretearecomparedwithstandardconcrete of M35 grade. The experimental investigations are administered for compressive strength Split Strength and flexural strength for curing period of 7, 14 and 28 days. The experimental results show that the for a combined replacementpercentageof21%SBAand4%PET,isshow positive results. Workability reduces with increasing % ageofSugarcane bagasseashwithaddition ofcoatedPET fibers in concrete. The maximum proportion of replacement has been found by conducting the following strength tests: Compressive strength test, Flexural strengthtestandSplitTensileStrengthTest.

Keywords: Sugarcane Bagasse ash (SBA), polyethylene terephthalate (PET), Pozzolanic material, Compressive strength,FlexuralstrengthandSplittensilestrength

Today Ordinary Portland cement (OPC) is considered as foremost construction material across the globe. Portland cementistheconformistmaterialusedinbuildingsthatin fact is accountable for roughly about 5% 8% of carbon dioxide emissions globally. As there is exponential increase in the demand of cement, this environmental

effect of it might increase considerably. Investigators thoughtouttheglobetodayareconcentratingondifferent ways fortheuseofeitherindustrial oragricultural waste, askeymaterialsforindustry.Beingnotonlycosteffective but may help us in environmental pollution control. The Portland cement industry are examining substitutes to produce green building materials. Industrial wastes, such as blast furnace slag, fly ash and silica fumes are being usedasadditionalcementreplacementmaterials.

In comparing with restrained shrinkage cracking, the mix reinforced with1%byvolumeof 50 mm long deformed fibers exhibited the best performance as no cracks were observedafter28days. Including it use in the form of grids acquiredinamanualandverysimplewayofcuttingstrips from traditional mineral bottles has produced excellent resultsintermsofadhesion,ductility,andstrengthintest conducted onconcreteplateofsmallthickness,reinforced and subjected to dynamic loading. Mix of aggregates and PET fragments in mortar is effective in terms of the physical structure and strength of concrete. In addition, this mixture changes the behaviour of concrete against appliedstress.

The wastes that are of economic importance are bagasse, molasses, and filter press mud. Bagasse is the fibrous residue remaining after the extraction of the cane juice from sugarcane. Sugarcane bagasse consists of approximately50%ofcellulose,25%ofhemicellulose,and 25%oflignin.Inalotofsugarcaneindustries,thebagasse generated is usually used as fuel while also reducing its volume for disposal. This residual ash generated from burning or incineration is called bagasse ash inclusive of both bottom and fly ashes. In most modern plants, the bottom ash gets mixed with fly ash in the water channel that comes from the gas washer. This waste is typically disposed of into pits and is also applied on land as soil amendmentinsomeareas

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Jayminkumar A. Patel1, Dr. D. B. Raijiwala 2015 There in this analysis the ecological and environmental effect of cement is considered as of much concernas it generates a lot of carbon dioxide also on the other hand sugarcane baggaseashisseriousissueoflandfills.InthisstudySCBA isusedinM25gradeofconcretebyreplacingcement5%by weightandcomparewithnormalM25gradeofconcreteto squared the possibility of SCBA in concrete. This analysis reveals that SCBA can be used as partial replacement of cement”.

R.Srinivasan 2010 “In this paper, Bagasse ash has been partiallyreplacedintheratioof0%,5%,15%and25%by weight of cement in concrete. Fresh concrete tests slump cone test were done also test on the hardened state concretelikecompressivestrength,,flexuralstrengthand modulusofelasticitysplittensilestrengthat7and28days wasobtained.Therewasanincreaseinthestrengthofthe concreterevealsthestudy.

Satish Rao (2018): Theaimofthisresearchwastostudy thefireresistanceofconcreteusingthePET(Polyethylene Terephthalate)coatedwithsilicafumeintheformofshort fibers poured into concrete to improve the durability characteristicsofconcreteaswellastemperatureresisting endurance.Theexperimentalstudywasperformedontwo aspect ratios i.e. AR25, AR50 with varying fiber dose or fiber ratio 0.5%, 1%, 1.5% of PET fibers. The partial replacementofcementisdonewithfibers.Thesizeofthe fiber for AR25 is 50mm×2mm, for AR50 is 100mm×2mm .The purpose of the investigation was to determine or compare the difference in the properties of the concrete with containing no PET, and containing PET coated with silicafume(SF).Thisinvestigationascarriedoutbyusing several tests, which include compression test and major firetest(Mufflefurnacefiretest).Onotherhandweknow thattheplasticisaharmfulwasteanditslifeasawasteis veryhighascomparetoitsusefullife.

Pradhan & Dutta D (2003): Studied the effects of silica fume on conventional concrete, concluded the optimum compressive strength was obtained at 20% cement replacementbysilicafumeat24hours,7daysand28days. Higher compressive strength resembles that the concrete incorporatedwithsilicafumewashighstrengthconcrete.

Sajjad Ali Mangi (2017) SCBA when used in concrete produces compressive strength which is much more compared to the normal concrete, hence optimal results were found at the 5% replacement of cement with SCBA, the workability of fresh concrte increased to to the replacement of cement; future recommendation to determine several more properties for the use of SCBA in concrete. Modulus of elasticity, flexure test, split tensile test, drying shrinkage was observed through the experimental work that the study reveals that

compressive strength increases with incorporating SCBA in concrete. Outcomes showed that with use of 5% increased SCBA in M20 concrete the increase in compressive strength by 12% as related to the normal concrete.

3.1 CEMENT: Cement is a binding material in concrete thatdevelopsstrongbondingpropertieswhenmixedwith waterandprovidesstrengthtotheconcrete.Thechemical composition of cement mainly contains lime. There are manytypesofcementavailableinthemarketaccordingto the need and strength desired. The cement we will use in thisresearchwork is43GradeOrdinaryPortlandCement conforming to IS: 8112 with brand name Ambuja Cement and the physical properties related to cement is provided bytheconcernedlab.

3.2 FINE AGGREGATES: Fine aggregate consists of crushed sand particles or natural river sand passing througha4.75mmsieve.Ingeneral,riversandisusedasa fine aggregate having a particle size of 0.07mm. The extraction is done from rivers, lakes or sea beds. Sieve analysiswouldbedonetofindoutthezoneconformingIS: 383 1970. The physical properties of sand were provided bytheconcernedlab.

3.3 COARSE AGGREGATE: The particles retained on a 4.75mm sieve are termed coarse aggregate. For making a goodconcretemix,coarseaggregatedmustbehard,clean, andfreefromanychemicalcoatingofclayanddustonthe surface. Crushed stone makes the majority of the particle of coarse aggregate. Coarse aggregates angular in shape are used in this research work that is obtained from the local crusher. Grading of coarse aggregate was done according to IS:383 1970. Aggregates of Nominal size 20mm & 10mm to form a graded aggregate. The concerned lab provided the properties of coarse aggregate.

. The quantity of fibre applied to the concrete mix is expressed as a proportion of the total volume of the composition (concrete and fibres) , called “volume fraction”Vftypicallyrangei.e.,0.5,1and1.5percentage.In theproductionofPETfibres,thetopicofthemostconcern hasalwaysbeenalkaliresistance,butaftercarefulstudyit was found noticed that there was no problem in traditional concrete. In comparing with restrained shrinkagecracking,themixreinforcedwith1%byvolumeof 50 mm long deformed fibers exhibited the best performance as no cracks were observedafter28days. Including it use in the form of grids acquired in a manual and very simple way of cutting strips from traditional mineral bottleshasproducedexcellent resultsin terms of

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

adhesion, ductility, and strength in test conducted on concreteplateofsmallthickness,reinforcedandsubjected to dynamic loading. Mix of aggregates and PET fragments inmortariseffectiveintermsofthephysicalstructureand strengthofconcrete.Inaddition,thismixture changesthe behaviorofconcreteagainstappliedstress.

COMPONENT VALUE

Color White Lusture Briht Elasticmodulus 90 Specificgravity 1.38 SolubilityinWater Insoluble

Table 1: Physical properties of PET

3.2.5 BAGGASE ASH Bagasse ash is a fibrous material obtained from sugar cane plant after the extraction of sugar cane juice. Sugar factory waste bagasse is used as bio fuel and in manufacturing of paper. Sugar industry produces 30% bagasse for each of crushed sugar cane, when this bagasse is burnt the resultant ash is known as bagasse ash. Bagasse shows the presence of amorphous silica, which is an indication of pozzolonic properties, responsible in holding the soil grains together for better shearstrength.

Constituent Baggase ash Cement

Sio2 71.0 81.42 Al2O3 1.9 10.41 Fe2O3 7.8 1.54 CaO 3.4 3.35 MgO 0.3 0.76 NA2 3.4 1.36 K2O 8.2 1.31

Table 2 Chemical composition of bagasse ash

4.1 BATCHING: All the materials are collected and appropriately weighted. The measurement of the materials to be replaced is done, and then materials are adequatelymixed.Thewaterisaddedinaproperamount, andthenthemixtureisplacedinarespectivemould.

4.2 CASTING: The mixture is tested for workability via slumptest and then placed in a mould. The mould to be used is greased or appropriately oiled before use. After

placing the mixture in the mould, it is adequately compacted. The exact process is carried on for all specimens to be tested. Three samples are prepared for eachmix.

4.3 CURING:Beforeremovingthemould,itisdriedfor24 hours, and then specimens are placed in a water tank made to cure specimens. The specimens must be marked foridentificationso thatthere must not be any error.The specimens are removed from the tank and dried before putting in the testing machine. The specimens are kept in thetankfor7,14,28days.

4.4 SLUMP CONE TEST Itcanbeusedinsiteaswellasin lab. This test is not applicable for very low and very high workability concrete. It consists of a mould that is in the form of frustum having top diameter of 10cm, bottom diameter of 20cm and height of 30cm. The concrete to be tested if fitted in the mould in four layers. The each is compacted 25 times with the help of tamping rod. After themouldiscompletelyfilleditisliftedimmediatelyinthe vertically upward direction which causes the concrete to subside

4.5 COMPRESSIVE STRENGTH TEST Thenfreshconcrete is filled in mould in 4 layers and after filling each layer tamping should be done 35 times in case of cube and 25 times in case of cylinder by using standard tamping rod. Once the mould is filled then leveled top surface of concrete with trowel. After the day the mould will removed and specimen are dropped in the curing tank under standard temperature of 27±2° c. After 7,14 days and28daysinthisresearch.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The specimen used for this test is cylindrical and its dimension is 150 mm in diameter and 300mm in length. The instrument used for this testing is universal testing machine. The fresh concrete is prepared in according to the required grades and respective mix proportion. The freshconcreteisfilledinmouldinlayersandeachlayeris tamping with standard tamping rod with 25 blows for each layer. After the day the mould is removed and specimenisplacedinthecuringtankfor7,14daysand28 days in this research at the temperature 27+ 2°c. Then drawthelineonthespecimen

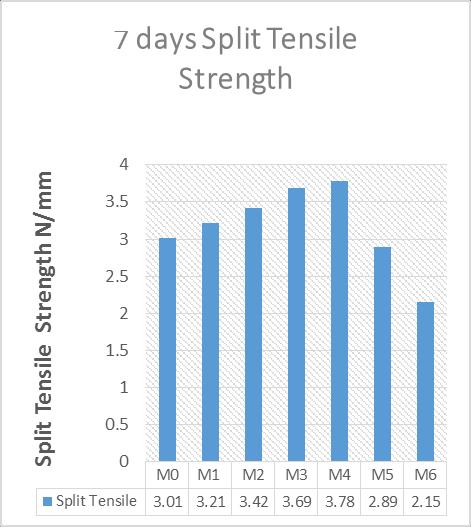

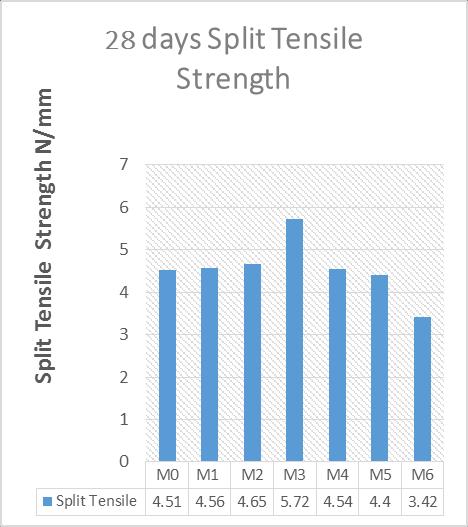

Fig 5 SPLIT TENSILE STRENGTH 7 DAYS Fig 6 SPLIT TENSILE STRENGTH 14 DAYS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Theconcreteispreparedatrequiredrateofmasselement the mould is filled with concrete in layers and blows 25 times with standardtampingrod. After the dayor wecan say 24 hours the mould is removed and specimen placed in the water tank for curing at a temperature of 27 + 2 C. Depending upon the requirement the test specimen is removedfromthewatertankandwipeitproperlyfor7,14 and28daysfortesting.

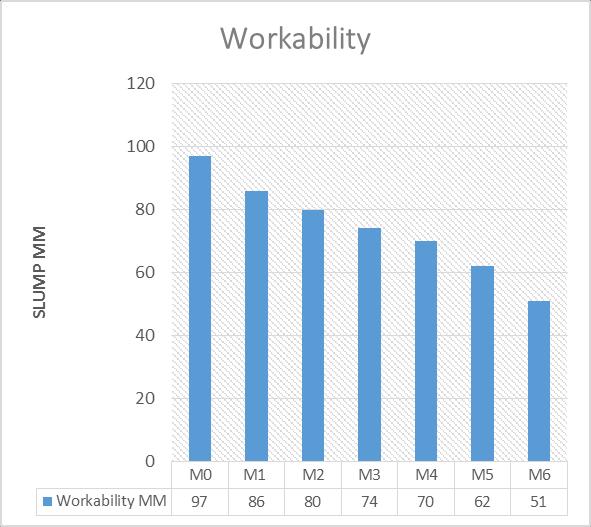

•Workabilityresultsshowthatifwereplacecementwith 21% replacement of Bagasse powder and 4% Addition of coatedPETfibers,however,afterafurtherincreaseinthe replacement, there is a minor decrease in workability. All the concrete mix containing Bagasse Ash and PET shows enoughworkabilitytobeeasilycompactedandfinished.It must be noted that the material used as a replacement must be adequately grounded. Otherwise, the water absorptionwillincrease,whichwillreducetheworkability oftheconcretemix.

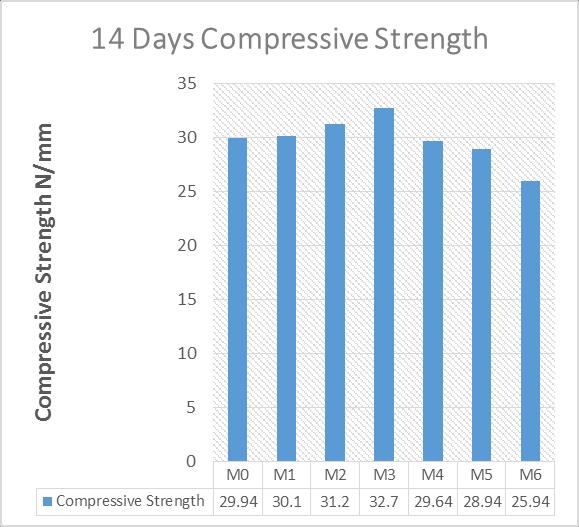

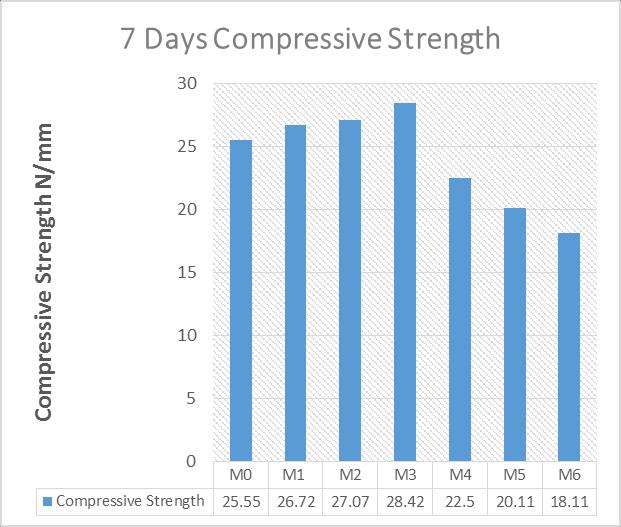

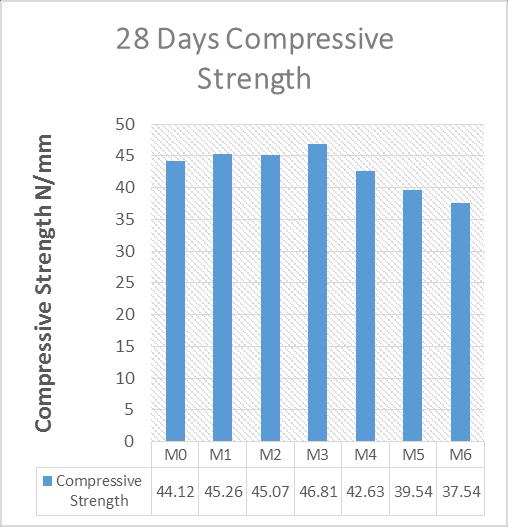

• The compressive strength results show that as we replace cement with Bagasse ash and with Addition of coatedPETfibers, there isanincrease in thecompressive strength, but at higher replacements, there is a decline in thecompressivestrengthofconcrete.

• The max compressive strength is achieved by replacing cement with 21% replacement of Bagasse Ash and 4%

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Addition of coated PET fibers on 28th day as 46.81 Mpa comparedto44.12Mpaasofstandardconcrete.

• The split tensile strength is optimum at 21% replacement of Bagasse Ash and 4% Addition of coated PET fibers. After a further increase in replacement, it keepsondecreasing.28thdaysplittensilestrengthatthis replacement is 5.72 Mpa compared to 4.51 Mpa as of standardconcrete.

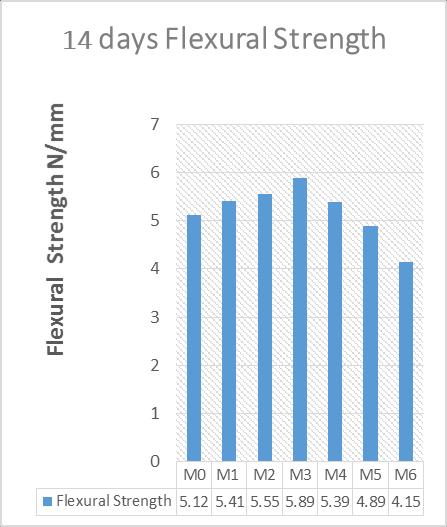

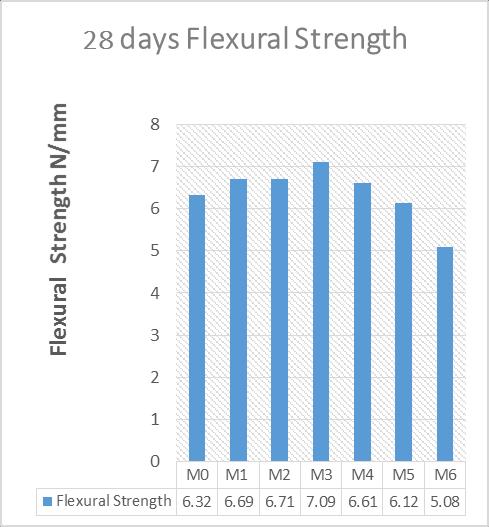

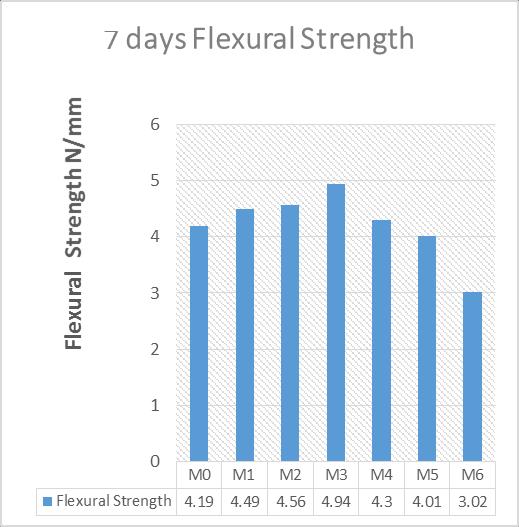

• The flexure strength is optimum at 21% replacement of Bagasse powder and 4% Addition of coated PET fibers. After a further increase in replacement, it keeps on decreasing.28daysflexuralstrengthatthisreplacementis 7.09Mpacomparedto6.32Mpaasofstandardconcrete.

• Hencefrom thisresearch work,itcanbeconcludedthat the optimum value of strength for different tests performed on concrete observed at 21% replacement of Bagassepowderand4%AdditionofcoatedPETfibers.

1.MohamedAnsarietal.,Studyonreplacementofcement using Bagasse powder, SSRG International Journal of Civil Engineering,Volume3,Issue3,March2016.

2 Amudhavalli, N. K. & Mathew, J. (2012). Effect of silica fume on strength and durability parameters of concrete. International Journal of Engineering Sciences & Emerging Technologies.

3. Perumal, K., Sundararajan, R. (2004). Effect of partial replacement of cement with silica fume on the strength and durability characteristics of High performance concrete. 29th Conference on OUR WORLD IN CONCRETE & STRUCTURES: 25 26 August 2004, Singapore.9. IS: 2386 1963,MethodofTestsofAggregatesforConcrete.

4 IS:516 1999,MethodsofTestsforStrengthofConcrete.

5 TextBook:M.S.Shetty,ConcreteTechnologyTheoryand Practice,S.ChandandCompanyLtd.Publication.

6.FernandoFraternali,VincenzoCiancia,RosariaChechile, Luciano Feo GianvittorioRizzano, Loredana Incarnato, Experimentalstudyofthethermomechanicalpropertiesof recycledPETfiber reinforcedconcrete.

7IS 10262 (2009), Indian standard Concrete Mix

Proportiong: Guidelines, Bureau of Indian standards, New Delhi , India IS 456 (2000), Indian standard Plain and Reinforced Concrete Code of Practice (fourth revision) , BureauofIndianstandards,NewDelhi,India

8 IS 5816, Indian Standard Splitting Tensile Strength Method Of Test (First Revision), Bureau of Indian standards,NewDelhi,India,2004.

9 IS 1199, Indian Standard Method of Sampling And Analysis Of Concrete, Bureau of Indian Standards, New Delhi,India,1999.

10.IS516,IndianStandardMethod ofTestsofStrengthof Concrete, Bureau of Indian standards, New Delhi, India, 1999?

11 R.N. Nibudey, P.B. Nagarnaik, D.K. Parbat, A.M. Pande, Strengths prediction of plastic fiber reinforced concrete (M30),Int.J.Eng.Res.Appl.(IJERA)3(2013)1818 1825.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |