International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1

, Er. Sonia2 , Er. Adnan Malik31M.tech civil (T.E) student,Desh Bhagat University, Gobindgarh Punjab India 2Professor, dept. of civil engineering, Desh Bhagat University, Gobindgarh Punjab India 3M.tech civil T.E) student, Desh Bhagat University, Gobindgarh Punjab India ***

Abstract Upgrade the physical and mechanical properties of cement are an expected area of exploration. Fiber supported concrete is one among those best in class which offers helpful, down to earth and prudent techniques for conquering miniature breaks and comparative sort of lacks. Since the substantial is powerless in pressure, fiber assists with defeating this lack. There are various fiber types accessible for business and trial use. The basic fibre used in construction is steel, glass, synthetic and natural fibre materials. Human hair is generally strong in tension, hence it can be used as a fiber reinforcement material. Hair fiber shall be an alternate and low cost material for remote locations of Jammu and Kashmir were Fiber Reinforcement Concrete are hardly practiced. Experiments were conducted on concrete with addition of human hair fiber i.e., 0%, 0.5%, 1%, 1.5%, 2%, and 3% by weight of cement and results are compared with those of plain cement concrete of grade M20. There is an augmentation in the strength of cement by the expansion of human hair as fiber support which makes it appropriate for an elective added substance for cement to upgrade its mechanical properties. Hair fiber concrete can be used for construction in Jammu and Kashmir were use of fiber in concrete is less cited due to lack of local vendors and higher market rates.

Key Words: Fiber Reinforced Concrete, Human Hair Fibre, Compressive Strength, Flexural Strength, Crack Resistance.

Definition and history of cement is a material utilized in building development, comprising of a hard, synthetically latent particulate substance, known as a total (normally produced using various sorts of sand and rock), that is fortified together by concrete and water. In 1756, British specialist, John Smeaton made the primary present day concrete(pressuredrivenconcrete)byaddingstonesasa coarse total and blending controlled block into the concrete.In1824,Englishcreator,JosephAspdindesigned Portland concrete, which has stayed the prevailing concrete utilized in substantial creation. Joseph Aspdin made the main genuine fake concrete by consuming ground limestone and dirt together. The burning process changed the chemical properties of the materials and

Joseph Aspdin created stronger cement than what using plaincrushedlimestonewouldproduce.

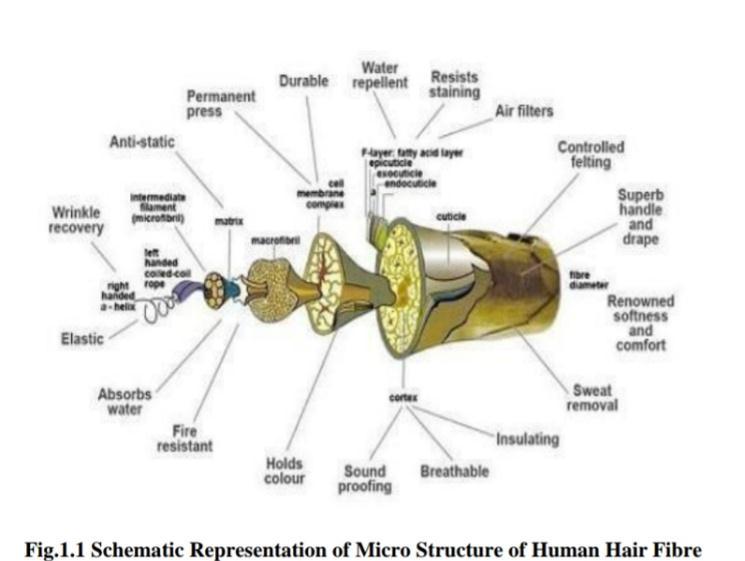

Fake filaments are artificial strands in which essential substance units produced by synthetic amalgamation. Regular strands are named hair like material which is acquired from trimming creature hair and plants. Synthetic fibres can be produced at very low cost and in huge quantities as compared to natural fibres. Fibres which are commonly used in construction industry are steel fibres, glass fibres, synthetic fibres, and natural fibres. Filaments having short length are blended in plain cement for working on its weak way of behaving and granting the pliability. This new kind of cement having shortdiscretestrandsspreadtowardallpathisalludedas fibersupportedconcrete(FRC).

Fiber Reinforced Concrete will be concrete containing stringy material which increments as primary and is acquiring significance. It contains short discrete filaments that are consistently appropriated and haphazardly situated. The idea of involving filaments as support isn’t new. Filaments have been utilized as built up since old times. All things considered, horsehair was utilized in mortar and straw in mud blocks. In the mid 1900s, asbestos filaments were utilized in concrete, and during the 1950s the idea of composite materials appeared and fiber supported concrete was one of the subjects of interest. Afterward, the utilization of asbestos for substantial support was deterred because of the related wellbeing chances. New materials like steel, glass, and manufacturedstrandstradedasbestosforsupport.

Fibres can be reduced permeability of concrete as well as bledingofconcrete.Fibresinterlinkandentraparoundthe aggregateparticlesandmixingofthesearemorecohesive so that reduce the workability. Fibresin concrete control cracksduetoplasticshrinkageanddryingshrinkage.

Human hair is a waste material which is found in abundant amount in everyday life. It is a very common constituent in muncipal waste streams and causes environmental problems as it is anon degradable waste. Also,humanhairisverystongintension.Asplainconcrete is weak in tension number of techniques are being developed to overcome this deficieney.Sustainable

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

concrete involves use of such materials which fulfill both requirements i.e. improve srenghth and materials should be available in local market at affordable amount.Hence haircanbeusedasfibresinconcrete.

Hairisusedasa fibre reinforcing material in concrete for thefollowingreasons:

1.Ithasa hightensilestrengthwhich is equal to that of a copperwirewithsimilardiameter.

2. Hair a non degradable matter is creating an environmental problem so its use as a fibre reinforcing materialcanminimizetheproblem.

3.Itiseasilyavailableinhugeamount.

4.Verycheapcost.

5. Increment in various properties of concrete and the strength of concrete by addition of hair fibre as an additionalreinforcement.

6.Crackingcontroltoeconomizeconcrete.

7. Very fine human hair fibres can be used for partial replacementofcementinConcrete.

Incorporated into concrete at content of 0.5, 1, 1.5, 2, 2.5 and 3% by weight of cement. 3D squares and barrel shapedexamplesarecastedandrelievedappropriatelyfor assessing different properties. These examples made of human hair fiber built up concrete are tried at 3, 7 and 28daysandtheadjustmentofpropertieswhencontrasted withplainconcretecementisnoticed

● Rohini B. Borkar.et.al (2018), RTMNU University published a paper on "Experimental Analysis and Application of Human Hair as a Fibre ReinforcementinConcrete"tostudytheeffectsof humanhaironplaincementconcreteonthebasis of its compressive strength, flexural strength etc. Experiments were conducted on concrete beams andcubeswithvariouspercentagesofhumanhair fibre i.e. 0%, 19%, 1.5%,2%, 2.5%, 3%, 3.5%, 4%,4.5%, 5% by weight of cement. For each gathering of extents of cement footer and solid shapes of standard sizes are tried for their mechanical properties at relieving times of 7, 14 and28days.Bytestingofshapesandshaftsthere is a raise in the different properties and strength ofcementbytheexpansionofhumanhairasfiber substantiationinconcrete.

● G. Sreevani, and Smt. B. Ajitha (2017), JNT University, published a paper on "Human Hair as Fibre Reinforcement in Concrete" to enhance the physical and mechanical properties of concrete. Experiments were conducted onconcrete cubes, cylinders and beams of standard sizes with addition of various percentages of human hair fiber i.e., 0%, 0.5%, 1% and 1.5% by weight of cement, fine & coarse aggregate and results were compared with those of plain cement concrete of M 20 grade. For each percentage of human hair addedinconcrete,fourcubes,threecylindersand three beams were tested for their respective mechanical properties at curing periods of 3 ,7 and 28 days. Optimum hair fiber content was obtainedas1.5%byweightofcement.

This chapter includes the background information to be consideredintheprojectwork.

● S. Aiswarya.et.al (2017), Dr. B. R. Ambedkar Institute of Technology, published a paper on "Experimental Investigation of Hair Fibre Concrete as an Alternative Low cost Building Material" to study the possibility of using humanhair as fibrein concrete. Tests were conducted on concrete with addition of HHF in various percentages i.e., 0%, 1%, 1.5%, 2%, 2.5% and 3% by weight of cement and results were compared with those of plain cement concrete of grade M20. There is an augmentation in the strength of cement by the expansion of human hair as fiber support which makes it appropriate for an elective added substance for cement to upgrade its mechanical properties. Hair fibre concretecanbeusedforconstructioninAndaman and Nicobar Islands were use of fibre in concrete is less cited due to lack of local vendors and highermarketrates.

● S. Ahmed, F. Ghani and Md. Mahmudul Hasan (2011), published a paper on the use of Waste Human Hair as a Fibre Reinforcement in

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Concrete" by addition of different percentage of human hair in concrete. There has been a significant increase in compressive strength. According to the test performed it is observed that there is remarkable increment in properties of concrete according to the percentages of hairs by weight of concrete. There was a general incrementof1 12%inthecompressivestrength of concrete and up to 5% in the flexural strength of substantial test examples by the expansion of hair strands in various amounts. Break arrangement and spread are a lot of decreased showing that HHF built up cement can have its applicationsinseismicsafedevelopments.

Thestufftobeuseinthisstudyare

● Ordinary Portland cement( OPC) 53grade ACC Cement

● Mortal hair fibre mortal hair fibre collected from thetaproomshopintheSrinagarquarter.

● These fibres are chapped into3.5 cm length and washedthesefibresintheacetoneforwashingor polishingpurposes.

● Water Collected from the original fresh water sources.

● Fine total Swash beach passing through4.75 mm sievesize.

● CoarsetotalAggregatesizesof20mm.

Cement acts as a binding agent in concrete. Cement imparts strength to concrete. Ordinary Portland cement( OPC)of53gradesconformingtoIS8112 1989isusedfor disquisition.

Differenttestwascarriedouttodeterminetheirparcelsas per Indian standard similar as specific graveness, normal thickness,originalsetting,finalsetting,finenessetc.

Fine aggregate is a material such as sand, crushed stones, or crushed gravel passing through sieve 4.75 mm size. In Pampore Jammu and Kashmir locally available crushed stonedustisusedasfineaggregateinthevariousconcrete mixes due to non availability of river sand at material testing lab. The properties of sand were determined by

conducting tests as per IS: 2386. The result indicates that thesandconformstoZone IIasperIS:383 1970.

The material whose particles are of size as retained on 4.75mm IS sieve is termed as coarse aggregate. Coarse aggregate of 20 mm size were used. Crushed granite stonestakenfrommaterialtestinglabwereusedascoarse aggregate. The properties of coarse aggregate were determinedbyconductingtestsasperIS:2386(part III).

The stuff used are Ordinary Portland Cement, Fine total, Coarsetotal,waterandmortalhairasfibre.Foreveryone of the accoutrements employed essential tests were directedbytheISdetails.

Thefollowingtestsaretobeconductedonfreshconcrete;

1. Slumpconetest

● Cement, sand and aggregate were mixed in dry stateintheratio1:1.66:2.87

● Adopted W/C ratio 0.5 calculated the quantity of water to be added. Water was added to dry ingredientsandtheyweremixedwell.

● Theslumpconeapparatuswascleanedanditwas heldfirmlyatthebase.

● The mould was filled in three layers and was given25blowsusingastandardtampingrod.

● Themouldwasliftedverticallyupcarefully.

● Afterthesubsidenceofconcrete.notedtheslump corresponding to highest part of slumped concreteinmm.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

● Theweightoftheemptycylinder,wlwasnoted.

● Fresh concrete of nominal mix with an initial W/Cratioequalto0.5wasprepared.

● The two hopper A and B and cylinder were cleaned well and the bottom doors of hoppers wereclosed.

● The freshly prepared concrete was placed gently into the upper hopper and the bottom door was released,allowingittofallintothelowerhopper.

● The bottom door of the second hopper was also released, allowing the concrete to fall into the cylinder.

● The excess concrete over the cylinder was struck off using a trowel and the outside surface was cleaned.

● Theweightofthecylinder,W2wasnoted.

● Concrete was filled in the cylindrical mould in three layers and compacted by giving 25 blows usingthestandardtampingrod.

● Theweightofthecylinder,W3wasnoted.

● Then compaction factor is calculated using the formula, Compaction factor = (W2 W1/ (W3 W1).

The following tests are to be conducted on hardened concrete;

Make specimens cubical in shape of size 150mm x 150mmx150mm.

● Placeitonthebearingsurfaceofthecompressive testingmachine.

● Applyauniformloadtillthespecimenfails.

● Note down the maximum load and calculate the compressivestrength.

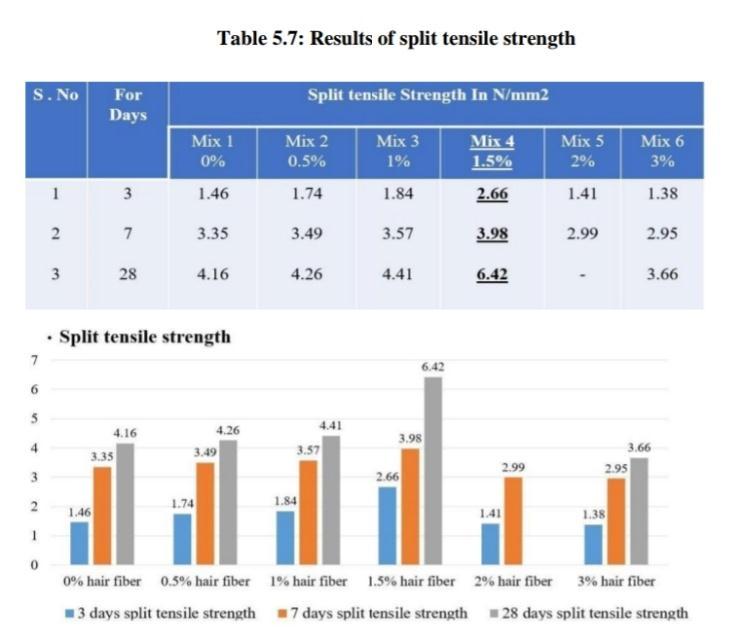

Cylinder specimen 150X300mm was prepared using concrete with w/c ratio 0.5. The test was done after 3 days, 7 days and 28 days of curing and immediately after removingofffromwater.Thesurfacewaterwaswipedoff. A diametric line on the two ends of the specimen was drawn so that they were in the same axial plane. One of the pressed wood strips was put along the focal point of thelowerplate.Theexamplewasputonthepressedwood stripandadjustedtosuchanextentthatthelinessetapart on the closures of the example were vertical and focused overthecompressedwoodstrips.Thesubsequentpressed wood strip was put longwise on the chamber. The load is appliedwithoutshockandgraduallyincreasedatasteady rate until the specimen failed by splitting at the vertical axialplane.Notetheload.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

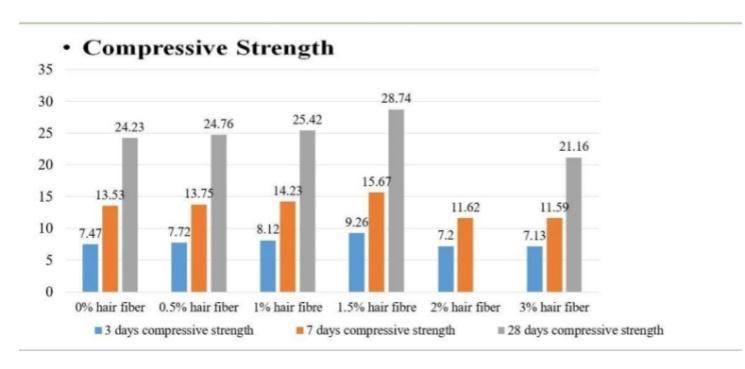

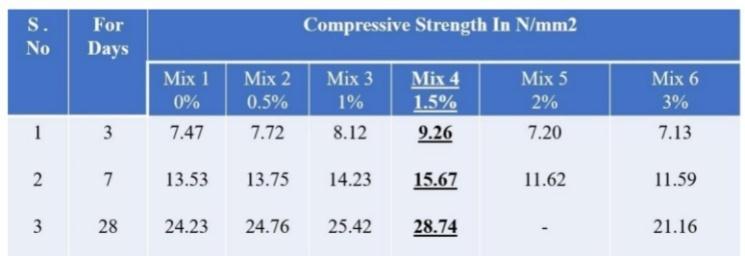

The compressive strength of concrete is determined by testingthecubesundercompressivetestingmachine.The results of compressive strength are shown in the maximum compressive strength occurred at (Mix 4: 1.5% hairfiber)anditisnearertothetargetstrength.

Thecompressivestrengthofconcreteisitsabilitytoresist a crushingforce.Itistheratioofloadatfailuretosurface area of concrete specimen. The results from the compressiontestareintheformofthemaximumloadthe cube can carry before it ultimately fails. The results of compressive strength test shows that the maximum compressive strength is obtained by adding 1.5% of humanhairbyweightofcement.

● Split tensile test was led for the chambers of 150mmdiaand300mmlength.Thegotvaluesare classified in Table 3, Compared to traditional substantialbreakwidthisforthisfibersupported concrete. Splitting of specimens into two pieces canbecontrolledcompletelywiththisfiber.

● Maximum split tensile strength occurred at (Mix 4: 1.5% hair fiber) and it is nearer to the target strength.

It is observed that the strength of concrete is increased accordingtothepercentagesofhairsbyweightofcement in concrete. Tests were carried out for 0%, 0.5%, 1%, 1.5%, 2% and 3%. It was found that M20 grade concrete with 1.5% HHF gives maximum compressive strength of 9.26,15.67and28.74N/mm2atcuringperiodsof3,7and 28 days respectively when compared with the plain cement concrete. Similarly there is an increase in split tensilestrengthalsofor1.5%HHF.Beyond1.5%thereisa reduction in strength. The cracks were also reduced in concrete specimens with hair fibre when compared with plainconcrete.

1. Natural hair waste can be effectively managed to be operatedinfibersupportedconcreteconstructions.

2. According to the test performed it's observed that there's remarkable addition in properties of concrete accordingtotheprobabilitiesofhairsbyweightofcement inconcrete.

3.Themortalhairfiberconcretehasthehighcompressive strengthvariedwiththeordinaryConcrete.

4. More disunited pliantness was fulfilled with the expansionofthemortalhairinconcrete.Thestrengthhas expanded when varied with that of the ordinary substantialillustration.

5.It'seacharoundsawthatthemostextremeproliferation is seen in the expansion ofl.5 hair fiber, by weight of concrete,ineveryoneofthecomposites.

6.Break arrangementand actualizingare a lotof lowered demonstratingthewaythatFRCcanhaveitsoperationsin seismicsafedevelopments.

7.Theexpansionofmortalhairstothesubstantialnotjust changes different parcels of substantial like severity, compressive strength yet also improves the limiting parcels,atomicbreakingcontrolandlikewisesupplements spallinginhibition.

1. ,B.B.,Prof. Kitey,M.S., andDr.Saklecha.,P.P.,( 2018). “ Experimental Analysis and operation of Mortal Hair as a Fibre Reinforced In Concrete. ” International Journal For Research In Emerging ScienceAndTechnology,5(6).

2. Aishwarya,S., Raj,J.S., and Narayan,N.,( 2017). “ Experimental disquisition of Hair Fibre Concrete As an Alternate Low Cost structure Material. ” International Journal of Engineering Technology, ManagementandAppliedlores,5(5),2349 4476.

3. AhmedS., GhaniF., and HasanM.,( 2011). “ Use of Waste Human Hair as Fibre underpinning in Concrete.”IEJJournal,Volume91FEB,

4. Sreevani,G.,andAjitha,B.,(2017).“mortalFibreas Fibre underpinning in Concrete ” International journal ofEngineering Scienceand Computing,7( 5), 11364.