International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Gigi 1 , Dalmiya Rajan2

1 Student, Dept. of Civil Engineering, St. Joseph’s College of Engineering & Technology, Kerala,India

2 Assistant professor, Dept.of Civil Engineering, St. Joseph’s College of Engineering & Technology, Kerala,India ***

Abstract Honeycomb sandwich structures are those structureswhicharemainlyintheshapeofahoneycomb. These structures are of high strength in addition to its weight therefore the applications of honeycomb structure plateareveryimportant.Duetoitshighstrengthtoweight ratio and high stiffness it can be used in automobile, aerospaceandspacestructures.Thehoneycombstructures mainlyconsistofthreepartstheyareoftwofaceplatesand acore.Byusingdifferentshapesofcoreandcombiningthem givesahybridcorewithspecialcharacteristics.Thispaper mainlyfocusesonthehybridsandwichplatestructuresand theirpropertiesandalsotocomparethein planeandout of planecompressionofhoneycombstructuresandtoconduct thebehaviourpredictionofhoneycombstructureandhybrid structure.Inthisstudybucklinganalysis,bendinganalysis anddynamicanalysisaredoneinthehybridsandwichplate structures and the analysis are done in the finite element analysissoftwareANSYS.

Key Words: Honeycomb structures , Hybrid structures, Corrugated sandwich structures, Cross supports.

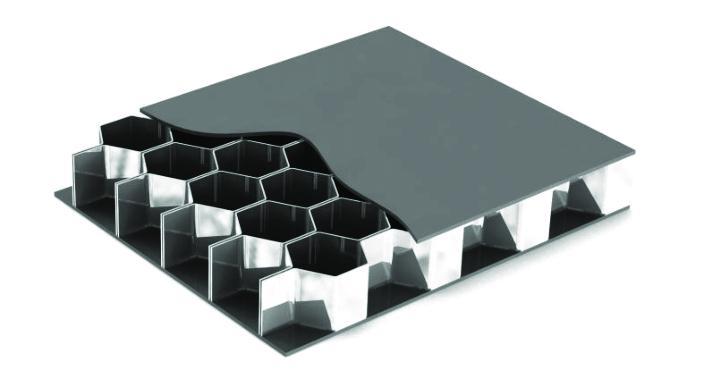

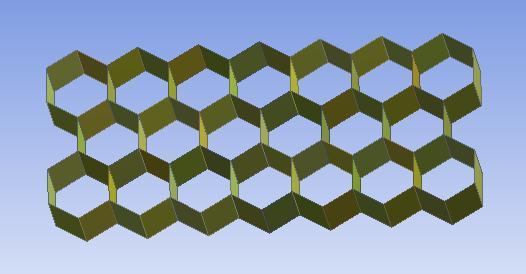

Ahoneycombsandwichplatestructureisformedbymainly ofthreememberstheyareoftwofaceplatesandacore.The face plates are made up of material like thin composite laminates of glass, aramid, carbon, aluminium and steel plates etc. and the core is made up of either metal or thin platelikematerials.Themostcommonlyusedcorematerial isaluminum[5][11].Thecoreisplacedinbetweenthetwo faceplatesinordertoachievehighstiffness to weightand strength to weightratios[1].Forimprovingtheproperities ofhoneycombsandwichstructuresthehybridstructuresare to be used. The hybrid structures give comprehensive thermal and mechanical advantages and also have high strength and specific energy absorption [13]. The unique character of honeycomb sandwich structure are of high stiffness to weight ratio, elimination of welding, superior insulationqualityanddesignversatility[11].Themainaim andobjectiveofthispaperistocomparethein planeand out of planecompressionofthestructureandtoconductthe behaviour prediction of honeycomb structure and hybrid structure.Thefig 1showsahoneycombsandwichstructure.

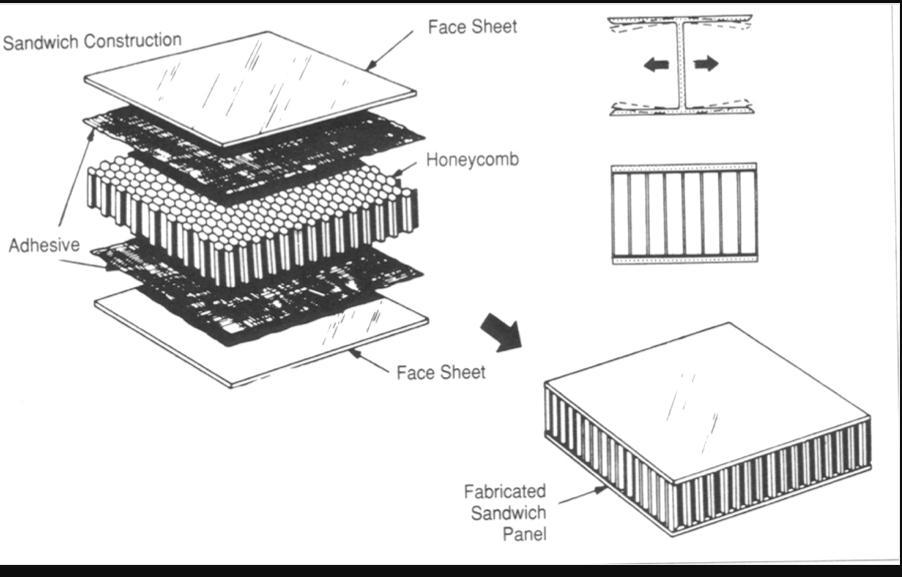

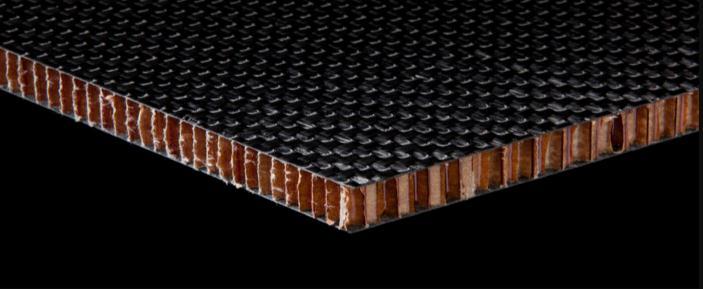

The honeycomb structures are mainly of natural or manmadestructureswhichareintheshapeofhoneycomb whichuseminimalmaterial toreducetheweightandcostof thematerial[1].Thearrangementofhoneycombsandwich structureisinsuchawaylikeasandwich.Thehoneycomb structure have of two face plates and a core. The core is mainly situated in between the two face plates like a sandwich. The commonly used face plates are of carbon fibre, glass fibre etc. and the most commonly used core material is aluminum [1][5][12][14]. The core gives high compressive strength. The compressive strength of sandwich panel is depends upon the foil thickness of honeycombcore,cellsize,thicknessofcoreandfacesheet thickness.Thecoreismadeupofdifferentcellsanditisof differentshapeslikehexagonalcells,squareandflexcore. Foradhesivelybondedhoneycombhexagonalcellshapeis commonly used and square cells are used mostly for resistance welded and brazed cores [11]. Typically a sandwichpaneliscomprisedofalowstiffness,lowdensity inner core enclosed by two stiff outer skins, as shown in Figure2 wherethewholeassemblyisheldtogetherbysome sort of structural adhesive (Figure 3). The outer skins are typically made from stiff carbon fibre or aerospace grade aluminium. The inner core is typically a Nomex or metal honeycomb, or an open or closed cell foam. Nomex is an aramidpolymersimilartoNylonthatisflame resistantand canbemanufacturedinpapersheetform.Nomexisagreat choice for the interior of aircraft cabins such as the floor panels due to its high safety in the event of fire. Multiple sheetsofNomexpapercanbeplacedontopofeachother andgluedtogetheratthenodelocationsbylinesofadhesive, whichareoffsetspatiallybetweendifferentlayers.Thislarge stack of Nomex can then be cut into smaller strips and expanded to form a sheet of Nomex honeycomb. Alternatively closed cell foams such as Rohacell® are commonly used for the core, which are denser then there

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

open cell counterparts but prevent moisture ingress in serviceandhavebettermechanicalproperties[4].

structuresthecoreisusedformakinghybridstructures.The cores used are of different shapes and by combining the differentshapedcoreitgivesahybridstructure.Byusingthe hybrid it give comprehensive thermal and mechanical advantagesandalsoithavehighstrengthandspecificenergy absorption[2][13]. There were different combination of hybrid structures one is of using the I type strut and the corrugated core by combining these two we get a hybrid core . The corrugated core is in the shape of ‘V’ then by combiningthiswith‘I’wegetaMtypeorNtypecore[2]The hybrid structures used in this study are of corrugated sandwich structure, I strut + hexagonal honeycomb, cross support + hexagonal honeycomb. Thr fig 5 shows an exampleofahybridstructure.

ThematerialsusedinthisstudyareofcarbonfibreUDand glassfibreUDasfacesheetsandthecorematerialusedisof Aluminium5052isshowninfig4

The honeycomb sandwich structure model is made up of mostlyofthreematerials.Theyaremainlyoftwofacesheets madeofcarbonfibreUDandglassfibreUDandthecoreis made up of Aluminium 5052. The face sheets are of unidirectional fibres and they have better compressive strength,modulusofelasticityandshearstrength.Thecore materialAluminium5052havegoodweldability.goodcold formabilityandmediumtohighfatiguestrength[1][4][8]. Thetable 1belowshowsthe materialproperties

Hybrid structures are those structures which are used to improvethepropertiesofhoneycombsandwichstructures. Thehybridstructuresarecommonlythecombinationoftwo structures. In the honeycomb sandwich composite

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page675

Fig 2: AhoneycombcarbonfibresandwichpanelInternational Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

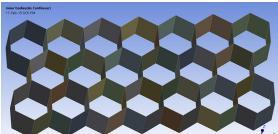

TheanalysisisdoneinfiniteelementmethodusingANSYS Firstly the model is created using solidworks and the thicknessofthesheetandmeshingisdoneinAnsys[1][3] [8][10][13].Thecoreandthesheetsweredesignedusing SOLIDWORKS..Thecellgeometryofthehoneycombcoreis giveninthefigurebelow.

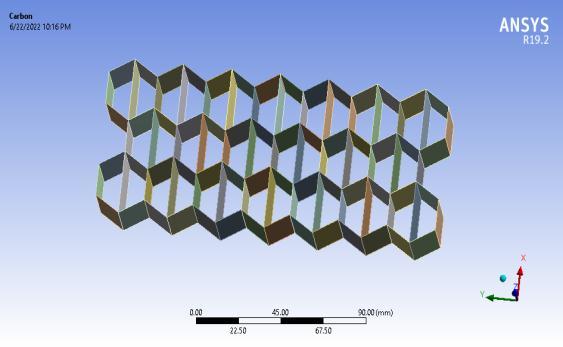

4.1. Modeling of hexagonal honeycomb sandwich structure and meshing

Fig -7:Modelof1,5mmthickness

Fig 6:Cellgeometryof hexagonalhoneycombcore

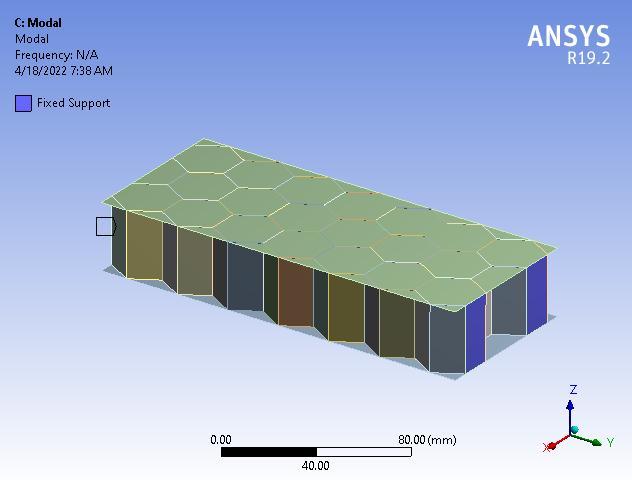

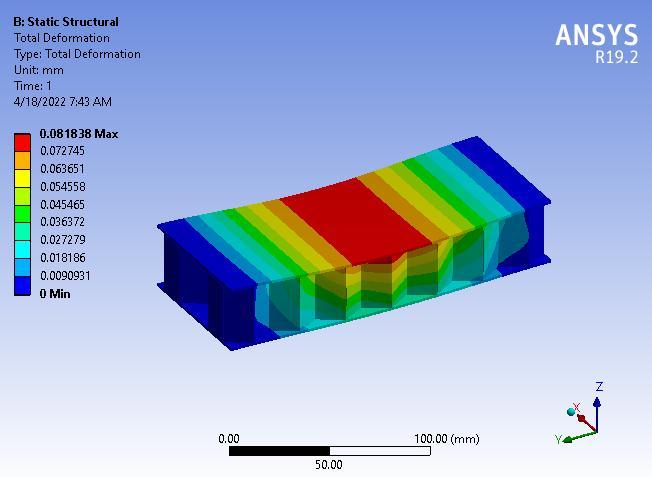

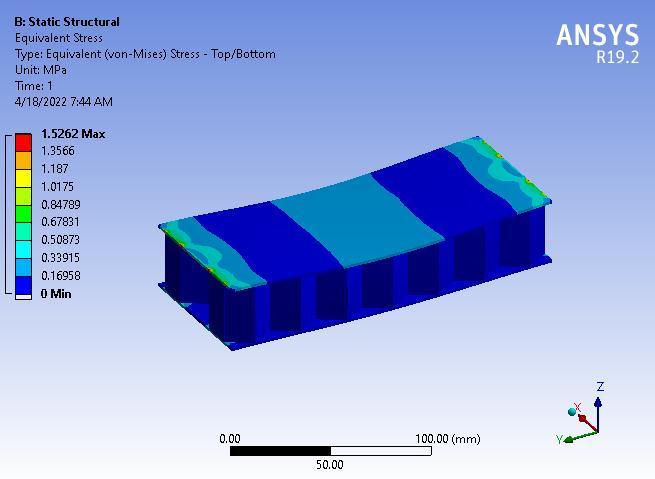

Themodalanalysis,bucklinganalysis,bendinganalysis & static structural analysis is done for the specimen under fixedendconditions.Herethevonmisesstressesandtotal deformationshouldbecalculated.Byapplyingvariousforces wecanstudy thebehaviourofthemodelandalsothefaces of the plates are in fixed condition. For commonly the varyingforcesarefrom100Pato700Pa[1][15]

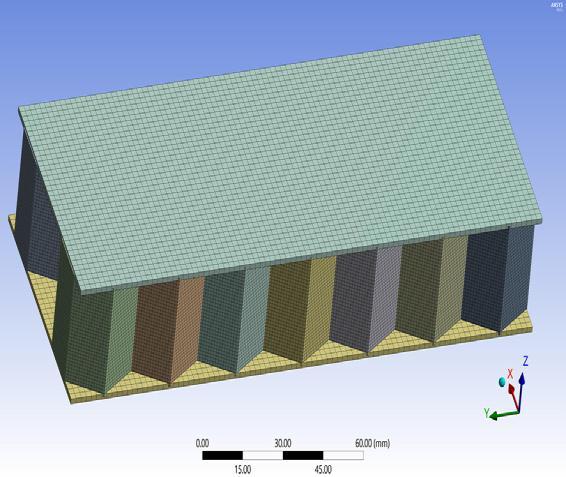

Themainpartofthehoneycombsandwichstructureisface sheetorfaceplatethefacesheetthicknessusedhereisof 1.5mm ,the edge length is 15mm, the height of the core is 32mmandthecorethicknessis0,5mmandtheelementsize usedisof2mm

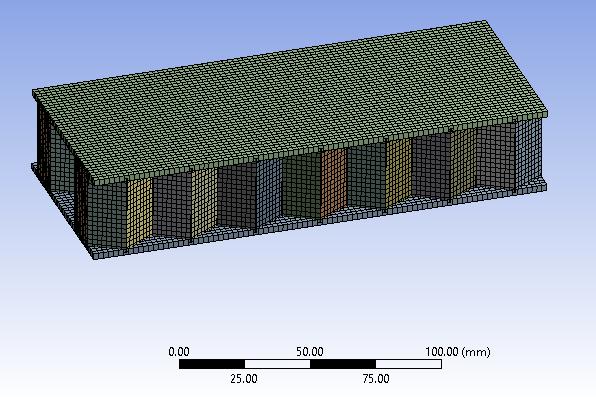

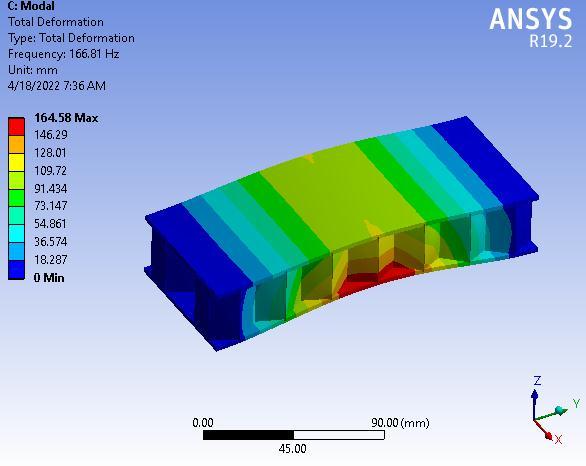

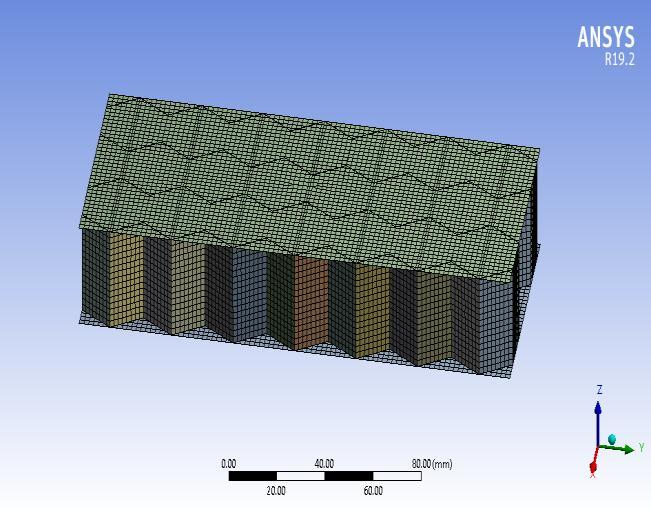

Thefiniteelementanalysisisusedforfindingtheanalytical valueofthehoneycombsandwichstructure.Thesoftware usedhere isofAnsys fortheanalysis[16] To makeother individual cells here first a unit cell is modelled and it is replicatedin X directionandY direction.Forassembling thehoneycombcoreofsandwichpaneltheindividualcells aremergedtogether.Tothehoneycombcoretodevelopthe fullpartofhoneycombsandwichpanelthefacesheetsare modeledandassembledonit[21].Thenthemeshigisdone. Aftermeshingthemodeltheboundaryconditionandload should be assigned. The result from the analyses are of deformationandstresses[1].TheanalysisinANSYSconfirms thenaturalfrequency.Theanalyzingprocessofeachmodein ANSYSisshowninbelowfigure.

Fig 8:Meshedmodelofhoneycombsandwichstructure

4.2. Modal Analysis

BoundaryConditions

(a) Firstmodeshape

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page676

Theparametricstudymeanschangingtheparameterslike changingtheloads,thickness,shapes,heights,lengthetc.and findingouttheeffectofeachparameter.Inthepresentstudy involves changing the loads, changing the face sheet thicknessandchangingthecoreshapesandatlastfindingthe effectofeachparameter.Thetable 2showstheeffectdueto load change. It mainly shows the total deformation and equivalentstressduetodifferentloads.Fromthetableitcan be understand that the total deformation and equivalent stressisincreasingwhentheloadismore.

Table 2: Resultsobtainedfordifferentloads

Loads Total deformation Equivalent stress 200 0.035796 1.8803 300 0.053694 2.8204 400 0.071592 3.7606 500 0.089489 4.7007 600 0.10739 5.6409 700 0.12529 6.581

Theeffectduetofacesheetthicknessisshowninthetable 3. Theeffectofdifferentfacesheetthicknessaffectsthenatural frequency. When the thickness of face sheet increases the naturalfrequencyalsoincreases.

Table 3: Resultsobtainedfordifferentfacesheet thickness

Face sheet thick ness

ωn1 (Hz) ωn2 (Hz) ωn3 (Hz) ωn4 (Hz) ωn5 (Hz) ωn6 (Hz)

0.5 73.16 4 124.6 3 168.6 3 173.9 9 179.6 4 183.2 4 1.0 123.4 0 167.0 4 179.6 4 183.2 4 184.9 6 185.5 5 1.5 166.8 1 180.4 8 183.2 3 184.9 6 188.6 7 188.9 1 2.0 179.6 4 183.2 4 184.9 6 188.6 7 188.9 1 194.5 2 2.5 179.6 4 183.2 4 184.9 6 188.6 7 188.9 1 194.5 2

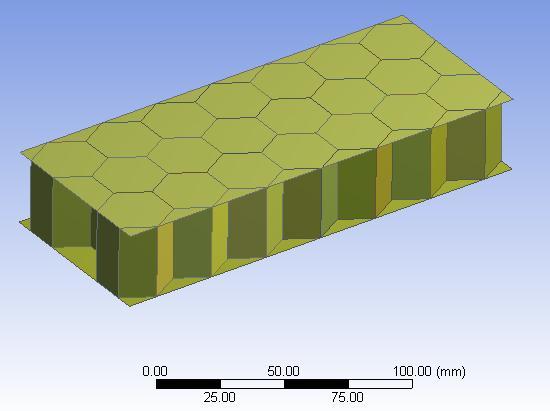

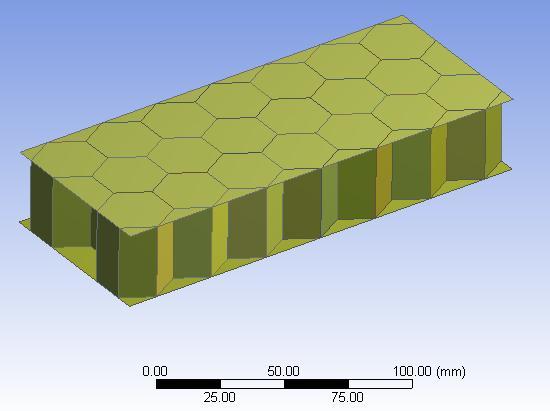

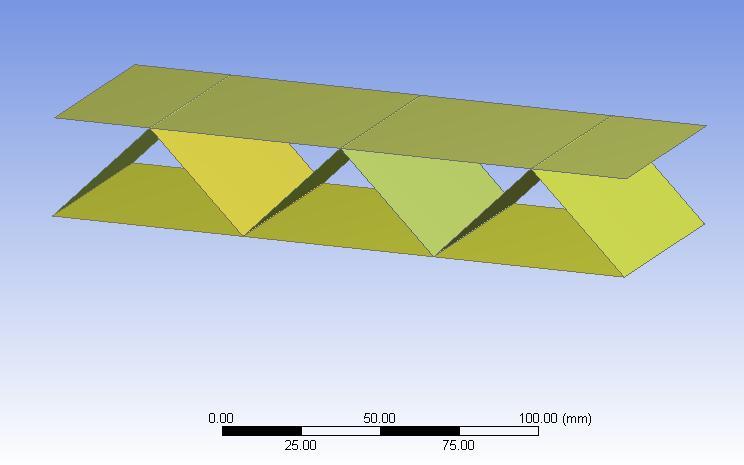

The different core shapes that are used are of hexagonal, corrugated etc . The fig below shows the different core shapesofahoneycombsandwichplatestructure.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Fig 10:Hexagonalhoneycombsandwichplatestructure

Fig 11:Corrugatedhoneycombsandwichplatestructure

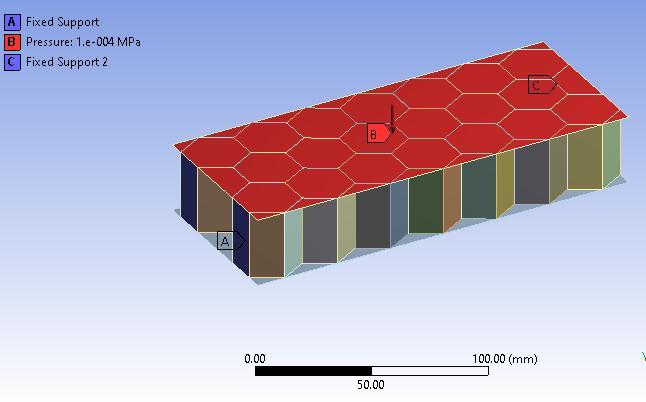

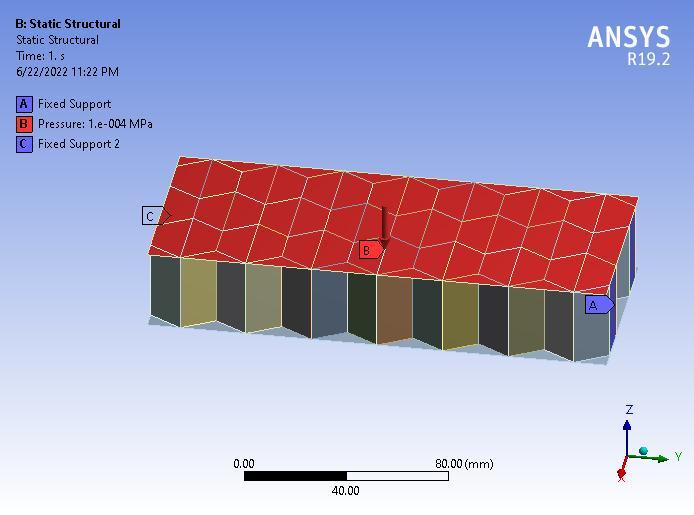

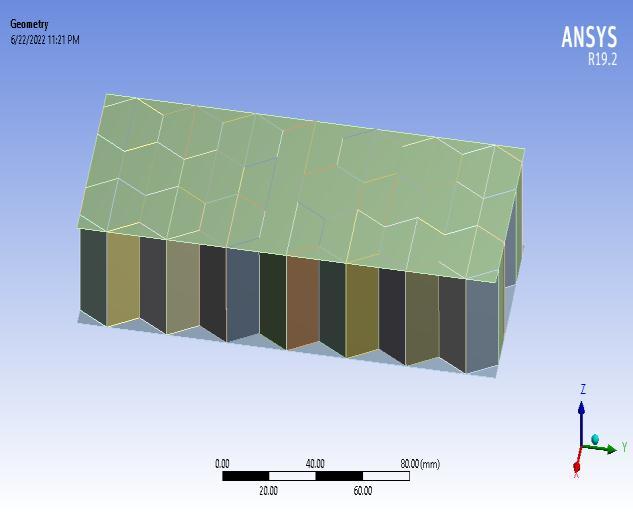

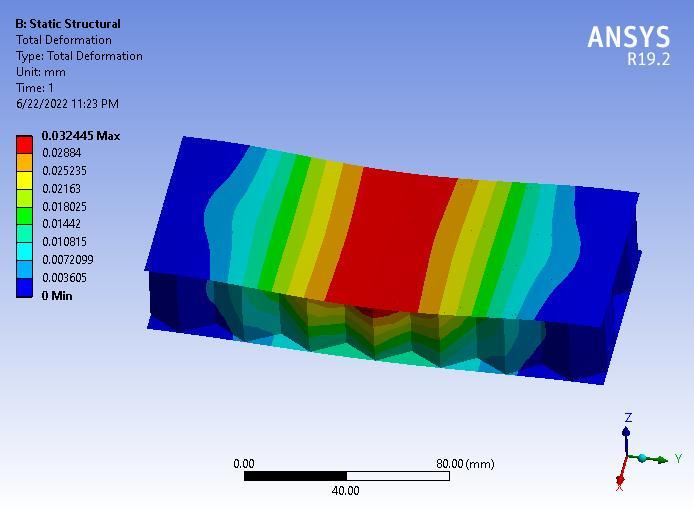

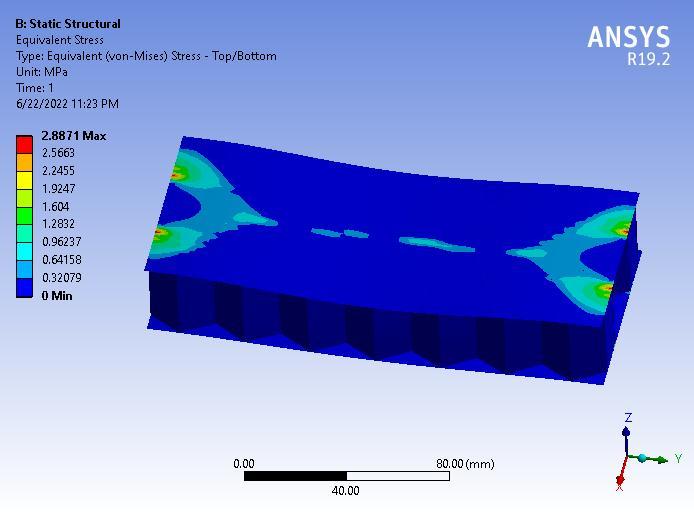

Thehybridstructuresareacombinationoftwocoreshape whichhasmanypropertieslikecomprehensivethermaland mechanical advantages and also it have high strength and specificenergyabsorption.Thehybridstructureusedinthis studyareofIstrut+hexagonalhoneycombandtheanalysis isdoneinfiniteelementmethodsoftwareANSYS. Thefig 12 showsthegeometryofthemodelinthisthefacesheetsare carbonandglassfibreandthecoreisofaluminium.Thefig 13showsthemeshedmodelandthemeshingisdoneatan elementsizeof2mm.Thefig 14showsthefixedboundary condition and the load given is of 100 Pa .The total deformation and equivalent von mises stress are to be get fromtheanalysisanditisgiveninthefig 15.

Fig 12:Geometricalmodelofthehybridstructure

Fig 13:Meshedmodelofthehybridstructure

Fig 14:Boundaryconditionandloadapplicationofthe hybridstructure

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[1]ShubhamUpreti,VishalK.Singh,SusheelK.Kamal, Arpit Jain, Anurag Dixit ; (2019) “Modelling and analysis of honeycombsandwichstructureusingfiniteelementmethod” MaterialsToday:Proceedings(ELSEVIER)

[2]ShanyoumingSun,DanLiu,YinglongSheng,Shangsheng Feng, Hongbin Zhu,Tian Jian Lu (2021) “Out of plane compression of a novel hybrid corrugated core sandwich panel”CompositeStructures(ELSEVIER)

[3] M Kamel, A F Nemnem and M Kassem (2020) “Experimental modal testing of a honeycomb sandwich plate” IOP Conference Series: Materials Science and Engineering(973)

[4] Clément Audibert,, Anne Sophie Andréani, Éric Lainé, Jean ClaudeGrandidier(2019)“Discrete modellingof low velocityimpactonNomex®honeycombsandwichstructures withCFRPskins”CompositeStructures(ELSEVIER)

[5]MeifengHe, WenbinHu (2008)“Astudyoncomposite honeycombsandwichpanelstructure”MaterialsandDesign vol.29

Fig 15:Totaldeformationandvonmisesstressesofthe hybridstructure

This study mainly focuses on the behavior prediction of honeycombsandwichstructureandthehybridstructure.For findingoutthenaturalfrequencyduetodifferentloadingin the honeycomb structure the finite element modeling software ANSYS is used. In the honeycomb sandwich structurehomogeneousshapedmaterialisusedasthecore andinthehybridstructurethecombinationofdifferenttype cores are to be seen. In this paper different type of parametricstudyshouldbedoneandtheeffectofdifferent parameteronthestructurecanbeidentified.Fromthe FEM analysisthetotaldeformationandtheequivalentvonmises stresses of the honeycomb structure and the hybrid structurecanbeobtained.Bycomparingthetwostructures thehybridstructurewillundergolessdefomationthanthe honeycomb structure because the hybrid structure have comprehensivethermalandmechanicaladvantagesandalso ithavehighstrengthandspecificenergyabsorption.Sothe hybrid structure is most efficient than the honeycomb structure. .

[6]QianchengZhang,XiaohuYang,PengLi,GuoyouHuang (2015)“Bioinspiredengineeringofhoneycombstructure Using nature to inspire human innovation” Progress in MaterialsScience vol.74

[7]Junhua Zhang,XiufangZhu,XiaodongYang,WeiZhang (2019) “Transient Nonlinear Responses of an Auxetic Honeycomb Sandwich Plate under Impact Loads” InternationalJournalofImpactEngineering.

[8]MahammadMuzeebBaig,SureshArjula(2019)“Bending Analysis of Honeycomb Sandwich Panels with Different combinationsofMaterialsforCoreandFacePlates”Journal ofengineeringsciencesVol10,Issue12

[9] Recep Gunes, Kemal Arslan, M Kemal Apalak and JN Reddy (2017) “Ballistic performance of honeycomb sandwichstructuresreinforcedbyfunctionallygradedface plates”JournalofSandwichStructuresandMaterials.

[10] K.Kantha Rao, K. Jayathirtha Rao (2012) “THERMOSTRUCTURAL ANALYSIS OF HONEYCOMB SANDWICH PANELS” INTERNATIONAL JOURNAL OF ENGINEERINGSCIENCE&ADVANCEDTECHNOLOGY Volume 2,Issue 5.

[11]ShubhamV.Rupani,ShivangS.Jani, G.D.Acharya(2017) “ Design, Modelling and Manufacturing aspects of HoneycombSandwichStructures:AReview”International JournalofScientificDevelopmentandResearch(IJSDR)Vol 2,Issue4

[12]OndrejFlasar,VaclavTriska,andMilanJunas(2017)” Experimental study of impact properties of aluminiumhoneycombsandwichstructure”MATECWebof Conferences(133)

[13] Zhi jia Zhang , Bin Han, Qian cheng Zhang, Feng Jin (2017) “Free vibration analysis of sandwich beams with honeycomb corrugationhybridcores”CompositeStructures ((ELSEVIER)

[14]SPZaoutsos(2017)“Mechanicalbehaviorofaluminum honeycomb sandwich structures under extreme low temperatureconditions”IOPConf.Series:MaterialsScience andEngineering.

[15]MohsinAbdullahAL Shammari&MuhannadAL Waily (2018) “Analytical Investigation of Buckling Behavior of Honeycombs Sandwich Combined Plate Structure” International Journal of Mechanical and Production EngineeringResearchandDevelopment(IJMPERD) Vol.8, Issue4,

[16] Anil Kumar1, Arindam Kumar Chanda, Surjit Angra(2021)“NumericalModellingofaCompositeSandwich Structure Having Non Metallic Honeycomb Core” EVERGREEN Joint Journal of Novel Carbon Resource Sciences&GreenAsiaStrategy,Vol.08,Issue04,pp759 767,

[17]Md.JabihullaShariff,Dr.R.SatyaMeher(2014)“Design Modulation of Composite Material Sandwich Panels with DifferentInnerPolyethyleneCoreStructures”International JournalofEngineeringResearch&Technology(IJERT)Vol.3 Issue11,

[18]Y.KiranKumarReddy,N.VenkatramanaReddy(2019) “DesignandAnalysisofSandwichHoneyCombStructures” InternationalJournalofResearchinEngineering,Scienceand Management Vol.2,Issue 1,

[19] A. Bonanno, V. Crupi, G. Epasto , E. Guglielmino, G. Palomba(2017) “Aluminium Honey Comb Sandwich for ProtectiveStructuresofEarthMovingMachines” Procedia StructuralIntegrityVol.8

[20]SaiafBinRayhan,MahtabUddinChowdhury,XuePu (2022)“Ballisticimpactresponseofreinforcedhoneycomb sandwich panels” IOP Conf. Series: Materials Science and Engineering

[21] A Florence, M Arockia Jaswin (2019) “Vibration and flexuralcharacterizationofhybridhoneycombcoresandwich panels filled with different energy absorbing materials” MaterialsResearchExpress

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page680