International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1Assistant Professor, Dept. of Mechanical Engg., Pimpri Chinchwad College of Engineering, Pune, Maharashtra 2,3,4 Undergraduate Student, Dept. of Mechanical Engg., Pimpri Chinchwad College of Engineering, Pune, Maharashtra ***

Abstract Electric vehicles use a motor, battery, and a controller to run instead of an engine. As the cost of fuels is increasing, there is a necessity for a substitute for IC engines. Electric vehicles are considered Green Transportation as it is environmentally friendly. The electric vehicle consists of various components like a battery, motor, and controller. We get power fa from a battery pack instead of fuel used in an IC engine. This saves money as well as the environment. One disadvantage of the current marketed EV is they are very costly and unaffordable to the common man. The modification of a conventional IC scooter into an electric scooter will provide the best alternative for the EVs currently on the market. They may be a replacement for the engine scooter but they give a drive performance approximately similar to them and is also cost efficient. In our project, we have designed and modified a conventional IC engine scooter into an electric scooter by giving power from battery to motor to chain & sprocket then the gearbox of the vehicle, and then finally to the wheel. The concepts of reducing, reuse, and recycling were used in our project as the vehicle, as well as in it, were reused and recycled according to our requirement. The principles and components of electric vehicle systems will be shown and the process of design and modification from an internal combustion vehicle to an electric vehicle will be described in detail. This report demonstrates that creating a running EV is a financially, environmentally, and intellectually rewarding endeavor.

Key Words:BLDCmotor,EVscooter,Battery,controller

TodesignandmodifyconventionalICenginescooterswithanequalperformanceproducingelectricscootertoreduceair pollutionproducedduetoconventionalICenginevehicles.Thefactorsareresponsiblefortheproblem. Climate:Theincrease inglobaltemperaturehascreatedtheneedtoreducetheuseoffossilfuels.IndiahasdecidedtocutitsGHG(Greenhousegas) emissionsby35%by2030. Renewable energy:Overtheyears,theeasyavailabilityofsolarelectricityhasimmenselyreduced itscostandmadeitpossibletohaveclean,low costenergyforconsumption.Indiaissettoadd190GWofrenewableenergy capacityby2024andtoachieve40%ofthegenerationofelectricityfromnonfossilfuelsbythesameyear. Urbanization: Economicdevelopmentiscreatingasenseofurbanizationasruralpeoplecometourbancitiesinsearchofjobs.Urbanization alsoincreasestheenergyandtransportinfrastructureleadingtotrafficandpollution.AccordingtoresearchbyWHO,Indiahas themostpollutedcitiescomparedtoothercountrieswhichifEVsareusedcandecreaseuptoacertainamount. Data capture: With the increase in GPS enabled smartphones and numerous mobility applications, mobility has gone under a digital revolution.Ithascreatedtheuseofexistingtransportationassets.ForEVs,whichhavefewervariablecoststocompensatefor relativelyhighfixedcosts,thisincreasedutilizationisanimportantelementtoachievetotalcostsofownershipcomparedtoIC enginevehicles. Battery:Researchinbatterytechnologyhasledtoincreasedenergydensities,lesstimeforcharging,and increasedbatterylife,thisiscombinedwiththedevelopmentofmotorswithincreasedreliability.Theseimprovementsin batterieshavereducedthecostsandhaveimprovedtheperformanceandefficiencyofEVs.

Inthispaper,wearegoingtostudytheperceptionandexpectationsofthepotentialforalternativetechnologyinautomobiles suchasEVs,bymodifyingaconventionalICenginescooterintoanelectricscooterbyusingaLi ionbatteryandaBLDCmotor. AlsotohaveastudycomparingcharacteristicsofEVandICenginescooterssuchasmaxspeed,acceleration,operatingcostper km,etc.

InsensewiththegrowinginnovationinEVs,it’simportanttodefinecriteriathatmeetourrequirementsfortheelectricmotor. ThemostusedmotorsareinductionmotorsandPMbrushlessmotors.Inductionmotorsarevery cheap. WhiletheBLDC motors are very efficient. DC motors are the most developed as an immense amount of innovation is done on them. The induction motors and the SRMs have solid advancements. The conversion of an IC engine scooter with a chain drive is

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

explainedbelow.TheideaofconvertinganICenginescooterwithapositivechaindriveisthefirstofitskind.Theauthor explainsthedrawbacksfacedduringtheirprojectduetothepoorselectionofcomponentsandsuggestsremediestoavoid them.Thefirstcomponenttobeselectedistheelectricmotor.Animportantcriterionofanelectricmotorispowerratingbased ontheloadrequired.Toselectamotorofrequiredpowerrating,vehicledynamicslikerollingresistance,gradientresistance, aerodynamicdrag,etc.areconsidered.Calculationsforthesamearegivenbelow.ThestepsforselectingamotorforanEV alongwithproperforceanalysisandloaddistributionareexplained.EVhasbeenchosenasaremedyforrisingairpollution andpowerconsumption.EVI(ElectricVehicleInitiative)isamulti governmentpolicythatadoptsandencouragestheuseof EVsworldwide. EVIconsistsofmanycountriesfromvariouscontinents.Wefoundthecurrentaswellasmarketscenarioall scenariosworld.

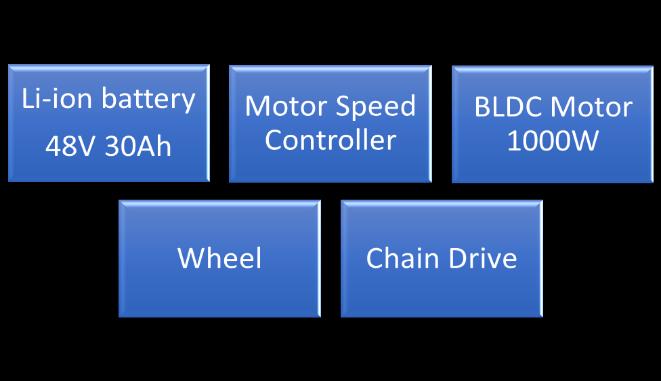

Theelectricvehiclehasmanycomponentslikechargingmodule,converters,controllers,batteries,electricmotorandtheblock diagramofpowerflowinanelectricvehicleisshowninFig 1.

FromtheFig 1,thepowersupplycanbeobtainedexternallybyusingsolarpanelstogenerateelectricityorfromdomesticAC supply.Thispoweristhenrectifiedusingconverterandismadeavailabletothebatterythroughchargingmodule.Thebattery supplieselectricpowertothemotorthroughamotorcontroller,whichhelpsincontrollingtheinputandoutputparametersof themotor.Theoutputmechanicalpowerfromthemotorisgiventothewheelthroughadriveshaft.Inthisway,electricpower flowsthroughvariouscomponentsinanelectricvehicleandgetsconvertedintomechanicalpower.

Anelectricmotordeterminestheoutputcharacteristicsofvehicleasawholeintermsofpower,torque,speed,etc.Theelectric motorselectedfordrivingavehiclemusthavetheabilitytoprovidesufficientpowerandtorquetoovercometheforcedueto loadandotheropposingforcesactingonthevehicle.

Fordecidingthepowerratingofavehicle,thevehicledynamicslikerollingresistance,gradientresistance,aerodynamicdrag, etc.hastobeconsidered.Forillustrationprocedureforselectingmotorratingforanelectricscooterofgrossweight200kgis considered.

Theforcerequiredfordrivingavehicleiscalculatedbelow[1] [4]:

Ftotal=Frolling+Fgradient+Faerodynamicdrag …(1)

Where,Ftotal=Totalforce

Frolling =forceduetoRollingResistance

Fgradient =forceduetoGradientResistance

Faerodynamicdrag =forceduetoaerodynamicdrag

Ftotal isthetotaltractiveforcethattheoutputofmotormustovercome,inordertomovethevehicle.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

TheresistanceofferedtothevehicleduetothecontactoftireswithroadiscalledasRollingresistance.Theformula forcalculatingforceduetorollingresistanceisgivenbyequation(2): Frolling=Crr*M*g

…(2)

Where,Crr=coefficientofrollingresistance M=massinkg g=accelerationduetogravity=9.81m/s2 Fortheapplicationofscooter,Crr=0.012 M=200kg Therefore, Frolling=0.012*200*9.81=23.544N

Theresistanceofferedtothevehiclewhileclimbingahillor flyoverorwhiletravellinginadownwardslopeiscalledas Gradientresistanceofthevehicle.Theanglebetweenthe groundandslopeofthepathisrepresentedasα,whichis showninFig 2.

Theformulaforcalculatingthegradientresistanceisgiven byequation(4):

Fgradientresistance=+M*g*sinα …(3)

Inthisillustration,letusconsidertheelectricscooterruns onaflatroad.Therefore,theangleα=0:

Fgradient= 200*9.81*sin 0: = 0 N. (4)

Fig 2:Anglebetweenthegroundandslopeofa path

Aerodynamicdragistheresistiveforceofferedduetoviscousforceactingonthevehicle.Itislargelydeterminedby the shapeofthevehicle.

Theformulaforcalculatingtheaerodynamicdragisgivenbyequation(5): Faerodynamicdrag=0.5*CA*Af*ρ*(V) 2

WhereAF =Frontsurfaceareaofvehicleincludingrider=0.42*1.7=0.714m2 ���������� =0.5*1.23*0.714*0.88*(11.11)2

Faero =47.696N

Therefore,TractiveForce������ =23.544+47.696

Ftr=71.24N

•Power=Ftr ×V=71.24*11.11

Power=791.47W

Efficiency=791.47/0.85Power=931.14W

ButasMotoroftheabovepowerratingisnotavailableinthemarket,ThereforePower=1000W

Step1:Findoutcurrent(inamp)consumedbymotortorun ��=���� 1000=48*I I=20.833amp(theoretically)

Step2:FindoutWatthrofbattery

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page658

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Torun1000Wattmotorfor1hr=1000Watthr

Takeefficiencyofbatteryas80%i.e.1000/0.8=1250Watthr Step3:ConvertWatthrofbatteryintoamphr ��=����

Watthr=V×Amphr

1250=48*amphr Amphr=26.06

Hence,wetakeamphrofbatteryas30Amphr Andhence,48V30Amphrwillgivearangeof50kmfora1000WBLDCmotor.

•Forselectingtheappropriateelectricvehiclemotors,onehastofirstlistdowntherequirementsoftheperformancethat thevehiclehastomeet,theoperatingconditionsandthecostassociatedwithit.•WehaveeliminatedbrushedDCmotor becauseoftheinconveniencecausedbybrushesthatistheyneedhighmaintenancebecauseofbrushesandcommutators.We haveeliminatedsteppermotorbecausewedonotneedasteppedoutput.Wehaveeliminatedservomotorbecausewedonot needaclosedloopmotor.•Forhighpowerapplicationslikeperformancetwo wheelers,cars,buses,truckstheidealmotor choicewouldbePMSMorInductionmotors.Oncethesynchronousreluctancemotorandswitchedreluctancemotoraremade costeffectiveasPMSMorInductionmotors,thenonecanhavemoreoptionsofmotortypesforelectricvehicleapplication.• Fortwo wheelerapplicationswhichrequireslessperformance(mostlylessthan3kW)atalowcost,itisgoodtogowithBLDC HubmotorsorBLDCExternalMotors[1].

ExternalBLDCMotororBLDCHUBMotor?ExternalmotorwouldnotcauseanyunsprungweightinthewheelasofHUB motor.NonhubmotorsaremoreefficientthanHubmotors.Hubmotorsdisruptthebalanceofabiketowardsthefrontorback. Theexternalmotorsuseachainorbelttoconveypowertotherearwheel.Thisofferstheopportunitytousedifferentsized pulleys/sprocketswhichallowsustoachievetherequiredRPMatthewheel.HencewehaveselectedtheExternalBLDCMotor

•Alithium ionbatteryorLi ionbatteryisatypeofrechargeablebattery.Lithium ionbatteriesarecommonlyusedforportable electronicsandelectricvehicles.•Inthebatteries,lithiumionsmovefromthenegativeelectrodethroughanelectrolytetothe positiveelectrodeduringdischarge,andbackwhencharging.Li ionbatteriesuseanintercalatedlithiumcompoundasthe materialatthepositiveelectrodeandtypicallygraphiteatthenegativeelectrode.•They'regenerallymuchlighterthanother typesofrechargeablebatteriesofthesamesize.Theelectrodesofalithium ionbatteryaremadeoflightweightlithiumand carbon. • Lithium is also a highly reactive element, meaning that a lot of energy can be stored in its atomic bonds. This translatesintoaveryhighenergydensityforlithium ionbatteries.Hereisawaytogetaperspectiveontheenergydensity.A typicallithium ionbatterycanstore150watt hoursofelectricityin1kilogramofbattery.ANiMH(nickel metalhydride) batterypackcanstoreperhaps100watt hoursperkilogram,although60to70watt hoursmightbemoretypical.Alead acid batterycanstoreonly25watt hoursperkilogram.Usinglead acidtechnology,ittakes6kilogramstostorethesameamountof energythata1kilogramlithium ionbatterycanhandle.•Nowadays,Li Ionbatterieshavethebiggestmarketsegmentin equippingelectricvehicles.Moderateenergyconsumption(14.7kWh/100km),continuousdeclineofthecostprice,advanced manufacturingtechnology,increasedcyclelife,lowweightandhighenergystoragepotentialmakeLi Ionbatteriesanoptimal choiceinthisfield.Theirdisadvantageisrepresentedbyhighfunctioningtemperatures,whichmayhavenegativeeffectson theirenergeticperformancesandlifecycle.Alltheserepresentrisksregardingsafeexploitationofthevehicle.Hence,wehave selectedLithiumIonBattery

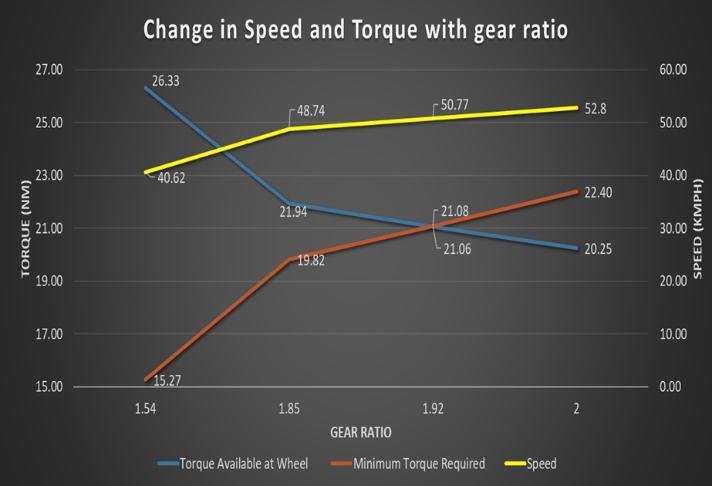

Speedandtorqueareinverselyproportionaltoeachotheri.e.asspeedincreasestorquedecreases.Speedisafunctionofgear ratioandthustoselectthegearratiowhereoptimumtorqueandadequatespeedcanbeobtained,weperformedanalysisof characteristicsofspeedandtorquev/sthegearratio.Asshowninthefigure,thethreelinesrepresentTorqueAvailableat wheel,minimumtorquerequiredandSpeedofthevehicle.Torqueavailableatthewheelistheactualtorquedeliveredbythe transmissiontothewheel whereasminimumtorquerequiredistorquerequiredtoovercomealltheforcesactingonthe vehicle and make it run on plain road. For gear ratio 1.92, the minimum torque required line coincides with the torque availableline implyingthatthegearratiocannotbefurtherincreased.Forgearratio1.54,theTorqueavailableissufficiently largethantheminimumtorquerequiredandspeedatthethatgearratioiscloseto41kmph.Hence,gearratio1.54was selectedforinitialtestingandvalidationofthedesignandbasedonresultsfurtherchangeswillbemadeingearratio.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

RunningCost:

ThecostofoperatinganelectricvehiclecanbedirectlycomparedtotheequivalentoperatingcostsofaICEvehicle.Aliterof petrolcontainsabout8.9kW·hofenergy.Tocalculatethecostoftheelectricalequivalentofaliterofpetrol,wemultiplythe utilitycostperkW·hby8.9.Becauseautomotiveinternalcombustionenginesareonlyabout20%efficient,thenatmost20%of thetotalenergyinthatliterofpetrolisused. Now,letusconsideravehiclepoweredbyaninternalcombustionengineat20% efficiencyand2.5L/100km[6].Tosimplymovethevehicle,itrequires: 8.9× 25�� 100���� ×20%��������������������= 445����ℎ 100����

Atacostof₹90/L,themileageof2.5L/100kmequatesto: ₹90 �� × 25�� 100���� = ₹225 100���� Anelectricversionofthesamecarwithacharge/dischargeefficiencyof81%andchargedatacostof₹9perkW·hwouldcost:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

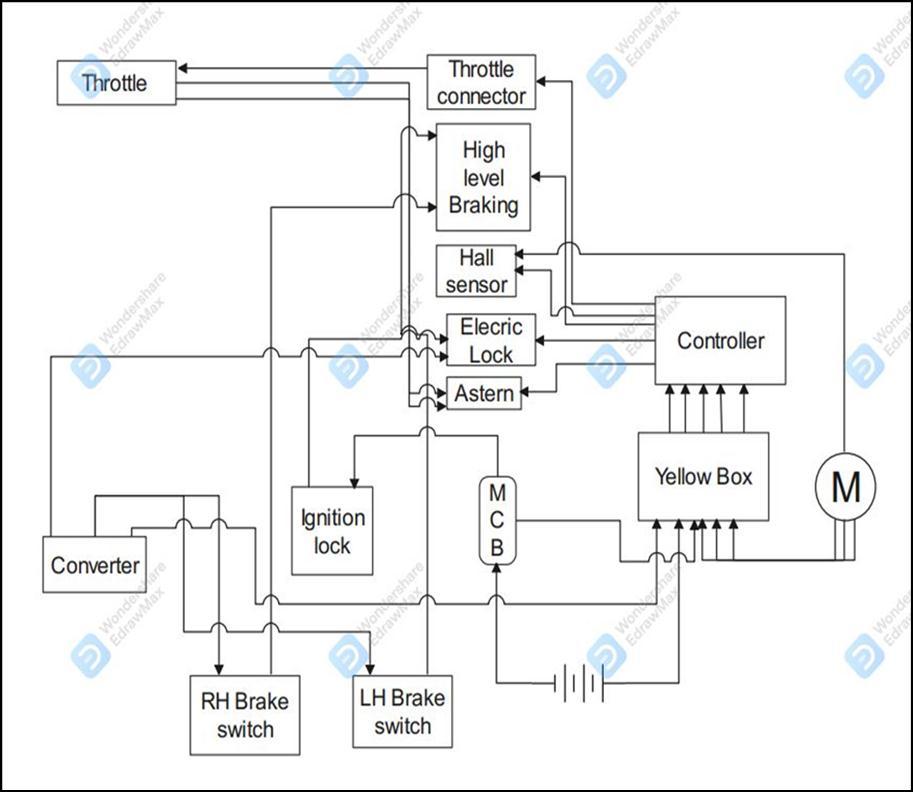

Thecircuitdiagramofalltheelectricalconnectionsofdifferentcomponentsisshowninfigure9.Themajorcomponentsshown in the circuit are Motor, Controller, Battery, Convertor, Yellow connection box, Ignition lock, Brake Switches, Brake light, Throttle, MCB, etc. All these components are connected such that all the components work properly for their respective specifiedpurpose.

DesignandManufacturingofanelectricvehiclewerepresentedthatiscapableoftravelingalmost35kmsinasinglecharge withatopspeedof60kmph.•Basedonthecalculationsdoneforthepowerratingofanelectricmotor,a1000WBrushlessDC Motorwasselectedforthemopedscooterapplication.•Fora1000Wmotor,a48V30Amphrlithiumionbatterywasselected basedonthecalculationsdone.•For100kmdistancetherunningcostforICEnginevehicleisRs225whereasforElectric vehicleisRs50.•PerformedcomparisonofvariousparametersbetweenICEnginevehicleandElectricvehicle.•Performedthe evaluationofthecompetencyofpiezoelectricmaterialintyres.Piezoelectricmaterialsarecapableofproducingsignificant amountofenergyundercertaincircumstances.But,theamountofenergyproducedbyPZTmodulesisnotsufficienttopower ElectricVehiclesandneitherisitefficientinincreasingtherangeofthevehicles

Theworldisquicklyadoptingtoelectricvehiclesandinthenextcoupleofdecades,EVsaregoingtobemoremainstream thaninternalcombustionvehicles.PeopleinUS,EUwouldnotmindspendingaround$35,000onanewcar.Thatfigureis about$15,000forpeoplewhobuyanewcarinChina.ButIndia,theaveragepriceofacarislessthan$10,000.Andtherefore, peoplewillbelookingtobuyanelectricvehicleonlywhenthepricesofEVswillfallinthatrange.ConvertingtheoldICengine vehicletoelectricischeapcomparedtobuyinganewoneandasthepricesfallintherangeofcustomer,itwillhelpthemin makingthetransactionfromICenginetoEV

19.

•Jeena Joy,Anusha,Joel George,RomyGeorg,Conversionofa GearlessScooterintoanElectricScooter,Vol.4,Issue4, InternationalJournalofAdvancedResearchinElectrical,ElectronicsandInstrumentationEngineering,April2015,pg.2417 2422.

•T.Porselvi,Srihariharan.M.K,Ashok.J,AjithKumar.S,SelectionofPowerRatingofanElectricMotorforElectricVehicles, Volume7,Issue4,InternationalJournalofEngineeringScienceandComputing,April20,pg.6469 6472.

•XiangdongXie,QuanWang,Amathematicalmodelforpiezoelectricringenergyharvestingtechnologyfromvehicletires, InternationalJournalofEngineeringScienceElsevier,2015,pg.113 127.

•RishabhJain,TheProgressOfElectricVehicle,Volume05,Issue10,InternationalResearchJournalofEngineeringand Technology,Oct2018,pg.1613 1618.

• Ali Eydgahi, Edward Lee Long IV , AC 2011 1048, CONVERTING AN INTERNAL COMBUSTION ENGINE VEHICLETOANELECTRICVEHICLE•AmitKhaire,AdinathLondhe,SaurabhPundle,SaurabhDesai,ConversionofConventional Scooter into an Electric Scooter, Volume 7, Issue III, International Journal for Research in Applied Science & Engineering Technology,Mar2019,pg.1295 1299.

•AyanBhattacharya,“PiezoelectricEnergyHarvestinginAutomobileWheel”,IJTRE,Vol.5,Issue11,July2018.•Aditya Pandey, Tejas Bansal, Amey Konde, Rushikesh Giri, Sarvesh Gandhi, “Energy Generation in Tyres using Piezoelectric Material”,Vol.9Issue07,July 202

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |