International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

***

Abstract Particle boards are one of the primary products used in buildings and furniture sectors. These materials are manufactured under pressure, by combining wood particles and other lignocellulosic fibrous materials by using an adhesive. The extensive use of particle boards can increase the economic advantage of low cost wood staple, inexpensive agents and, simple processing. For the manufacturing of particle boards based on renewable resources, the search for lignocellulosic substitutes for wood is one of the biggest challengesthat the wood industry is facing. In this project, particle boards were made using hair waste and waste fibre cloth, as a substitute for wood. Hair has high tensile strength which is equal to that of copper wire with similar diameter. Hair, a non degradable matter is creating an environmental problem so it used as fibro reinforcing material can minimize the problem. It also available in abundance and at a very low cost. Polyethylene terephthalate (PET) is a widely used thermoplastic polymer which is from non renewable petroleum resource needs to be reused or recycled. PET is extensively used to produce textile fibers and containers. About 74% of the PET used in textile industry was used to make staple fibers.

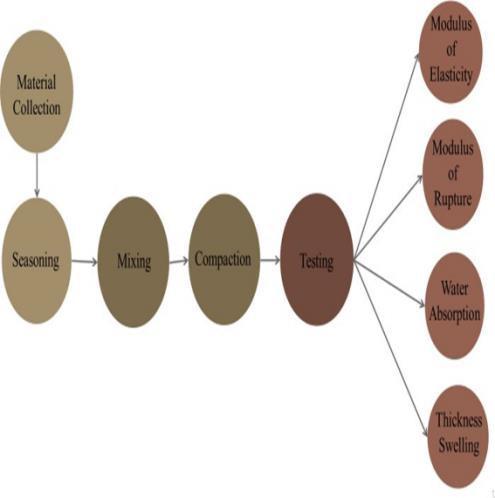

These staple fibers were mostly used to mix together with cotton fibers to produce cotton/PET blend fabrics.2,3 These blended fabrics are frequently disposed after use which ends in landfills. Boards of different mix proportions are to be casted and tested to know the properties. Water Absorption (WA), Thickness Swelling (TS), Modulus of Rupture (MOR) and Modulus of Elasticity (MOE) are to be analyzed.

Key Words: Hair fibre, particle board, waste material, rubber powder

Approximately95%ofthelignocellulosicmaterialusedforparticleboardproductioniswood.Thedemandforwoodinthe forest industry has been growing, but the production of industrialwood from thenaturalforestscontinuestodecline.The declineinforestresourcesindevelopingcountriesisduetothedepletionofresourcesandindevelopedcountriesduetothe withdrawalofforestareasfromindustrialproductionforotherusessuchasrecreationalareas.Also,thereisasignificant pressure onstanding forest resources as a result of higher demand for wood in forest industry due to the increasing population and new application areas. Consequently, there is a need for alternative resources to substitute wood raw material.However,atthepresenttime,environmentalconcerns have increased, the interest in manufacturing sustainable materialsbasedonrenewableresourcesotherthanwood,likeagriculturalwastes.

Theuseofthisrenewablesourceforindustrialapplicationsintheproductionoflightboardscanhelptoreducetheimpact ontheenvironment,providingeconomicdividends.Hairisusedforthefollowingreasons:i.Ithasa hightensile strength whichisequaltothatofacopperwirewithsimilardiameter.ii.Hair,anon degradablematteriscreatinganenvironmental problemsoitsusagecanminimizetheproblem.iii.Itisalsoavailableinabundanceandataverylowcost.

The foundation and development of new and emerging construction materials based on both degradable and non degradablewastecanleadtoadrasticchangeintheconstructionandwastemanagementfields.Theobjectiveofpresent researchistodevelopacompositefromwastematerialsthatareabundant,nondegradableand inexpensiveandimproves theneweraofwastemanagement.

Human Hair as Fibre Reinforcement in Concrete G.Sreevani1 etal(2017)Fiberreinforcedconcreteis one among those advancementswhichoffersaconvenient,practicaland economicalmethodforovercomingmicrocracksandsimilartype of deficiencies. Since concrete is weak in tension hence some measures must be adopted to overcome this deficiency. Humanhairisgenerallystrongintension;henceitcanbeusedasafiberreinforcementmaterial.Humanhair.Experiments were conducted on concretecubes,cylindersandbeamsofstandardsizes with addition of various percentages of human

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

hairfiberi.e.,0%,0.5%,1%and1.5%byweightofcement,fine&coarseaggregateandresultswerecomparedwiththose ofplaincementconcreteofM 20grade.Foreachpercentageofhumanhairaddedinconcrete,fourcubes,threecylinders andthreebeamsweretestedfortheirrespectivemechanicalpropertiesatcuringperiodsof3,7and28days.Optimumhair fibercontentwasobtainedas1.5%byweightofcement.Humanhairwastecanbeeffectivelymanagedtobeutilizedinfiber reinforcedconcreteconstructions.

HairFibreReinforcedConcreteJainD.andKothariA.(2012)Fibrereinforcedconcretecanofferaconvenient,practicaland economical method for overcoming micro cracks and similar type of deficiencies.Sinceconcreteisweakintensionhence some measures must be adopted to overcome this deficiency. Humanhairis strongin tension; hence it can be used as a fibrereinforcementmaterial.HairFibre(HF)analternatenon degradablematterisavailableinabundanceand atavery cheapcost.Presentstudieshasbeenundertakentostudytheeffectofhumanhaironplaincementconcreteonthebasisof itscompressive, crushing, flexural strength and cracking control to economise concrete and to reduce environmental problems. By testing of cubes and beams we found that there is an increment in the various properties and strength of concretebytheadditionofhumanhairasfibrereinforcement.Accordingtothetestperformeditisobservedthatthereis remarkableincrementinpropertiesofconcreteaccordingtothepercentagesofhairsbyweightofinconcrete.

Experimental Analysis and Application of Human Hair as a Fibre Reinforced In Concrete Rohini B. Borkar et al ( 2018 ) Fibre reinforced concrete offer a convenient, practical and economical technique for overcoming micro cracks. Since, concreteisweakintension hencesome proceduresmustbeadoptedtoovercomethis deficiency.Humanhairisstrongin tension; hence it can be used asa fibre reinforcement material. Hair Fibre (HF) an alternate non degradable matter is availableinabundanceandataveryeconomycost.Italsocreatesenvironmentalproblemforitsdecompositions.Present studies has been undertakentostudytheeffectofhumanhaironplain cement concrete on the basis of its compressive, flexural strength and cracking control to economies concrete and to moderate environmental problems. By testing of cubes and beams we initiate that there is an raise in the various properties and strength of concrete by the addition of humanhairasfibre corroborationinconcrete.Usedofhairfiberfortifiedcementdiminishesthedevelopment ofmoment breakswhichcanlimitthespillageissues,makingitappropriateforwaterverificationdevelopments.•Itstrengthensthe mortar and shields it from spalling. Established an inventive substance procedure of enhancing the dirtfruitfulness by utilizing human hair filaments. • .Adding of both cement and human hair toasphalt mixture increases the load bearing capacityofthemixture.

An Experimental Study of Human Hair in Concrete as Fibre Reinforcement & also used of the plasticizers/super plasticizers.RaghavRoshanetal(2020)Sincethetraditionaltimes,severalresearchesandadvancementswerecarriedto reinforce the physicalandmechanicalpropertiesofconcrete.Fiberconcreteis oneinallthose advancements thatoffers a convenient,sensibleandeconomicaltechniqueforovercomingsmallcracksandsimilarsortofdeficiencies.Sinceconcrete is weak in tension therefore somemeasures should be adopted to beat this deficiency. Human hair is usually sturdy in tension;thereforeitareoftenusedasafiberreinforcementmaterial.HumanhairFiberisanothernon degradablematter obtainableinabundanceandatvalue|low cost}cost.Itadditionallyreduces environmentalissues.additionallyadditionof human hair fibers enhances the binding properties, small cracking management, Imparts plasticity and additionally will increaseswellingresistance.Theexperimentalfindingsinourstudieswouldencouragefutureanalysiswithinthedirection for future performance toextendingthis valueofeffectivesort offiberstobeusedinstructuralapplications.Human hair wastecanbeeffectivelymanagedtobeutilizedinfiberreinforcedconcreteconstructions.Accordingtothetestperformed itisobservedthatthereisremarkableincrementinpropertiesofconcreteaccordingtothepercentagesofhairsbyweight ofcementinconcrete.ThehumanhairfiberconcretehasthehighcompressivestrengthcomparedtothenormalConcrete.

TheEffectofBananaLeavesLaminationontheMechanicalPropertiesofParticleBoardPanel.Nongman. A.Fetal (2015) Laminated composites weremadebylaminatingthebinderlessbananastem particleboardswithbananaleaftapesusing adhesiveintheformofadouble sidedtape.Theeffectofthelaminationonthetensileandflexuralpropertiesoftheparticle boardpanelwasinvestigated.Resultsobtainedshowedthatincreasingthenumberoflayersofbananaleaftapesalteredthe mechanical properties of the particle board. Particle board with four layers gave the highest flexural strength. Flexural modulusalsoincreasedwiththeincreaseinthenumberoflayerofbananaleaftapes.Thereisalsoanimprovementintensile strength with the number of layers of banana leaf tapes. Particle board panel laminated with four layers ofbananaleaf tapes showed the highest tensile strength. The tensile modulus, on the other hand, decreased with increasing layer of bananaleaftapes.Thefibreorientationinthe banana leaftapesalsoinfluencedthe mechanical propertiesoftheparticle board.Particleboardwiththebananaleaffibreorientationparalleltothetestdirectionshowedhighertensilestrength.The effect of banana leaf tape fibre orientation on the flexural strength was not significant.Particle board panel with banana stem fibre orientation parallel to the test direction have higher tensile strength than those with the crisscross fibre orientation.Whileforflexuralstrength,fibreorientationhasnosignificanteffect.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Composite materials made of waste tyers and polyurethane resin Carlos F Revels et al (2021) Presents a case study of flexible tile rubber powders from tyre waste. Provides a sustainable solution for reducing pollution due to rubber tyre waste. The composite material obtained can be used for several applications due to improved properties. This research presents a case study of producing flexible tiles from rubber powders obtained from automobile tire waste using a polyurethaneresinasabindermatrix.TheprocesswasmadeincollaborationwithacompanylocatedinColombia,where the manufacturing of these materials has been optimized. The material is a green solution to an increasing worldwide problem, rubber car tires mostly put in landfills or burned to extract their reinforced steel wires instead of properly recycled.Theflexiblecharacteristicsofbothresinandrubberenablethesecompositestobeusedinmultipleapplications. The tensile tests showed the composite can work very well for structural applications of low solicitations, such as wall covers,softfloorsandbarriers.Theprojectisasuccessfulexampleofasmall mediumenterprisecompanythatcontributes tothecirculareconomyofthesehighlypollutantmaterials.

Sustainable hybrid composites reinforced with textile waste for construction and building applications. Bijoya Kumar Behru et al(2021) The textile waste fibre reinforced composites are environment friendly and economically beneficial. However, textile waste reinforced composites have not gained the attention ofcomposite manufacturers due to limited reported studies, a variation in the waste fibre’s physical and mechanical properties that affect the resulting composite properties.Inthisresearch,newtypesofhybridcompositesreinforced witha cardedwebofcottonfibresextractedfrom waste cotton textiles were developed by laminating with unidirectional glass fibre perform and needle punched jute nonwovenfabric.Thedevelopedcompositesarethermallystableenough.Thedevelopedcompositescanreplacelowand medium cost timber in furniture items, construction, and building materials. Textile waste reinforced composites are environmentally and economically beneficial. Textile waste based hybrid composites have higher strength and modulus thanwood.Textilewaste basedhybridcompositesarethermallystableenough..

EmilianoManuelCiannameaetal(2017)Inthe development of materials based on renewable resources, the search for lignocellulosic substitutes for wood is one of the biggest challenges that academia and the particleboard and wood industries are facing. In this article, particleboards were processed using rice husk, an agricultural waste, as a substitute forwood.Ricehuskwithoutanyfurthertreatmentwasprocessedintoparticleboardsusingphenol formaldehyderesinas binder.Theeffectoftheprocessingparameters,pressureandbindercontent(BC)onthedensity,waterabsorption(WA), thicknessswelling(TS),modulusofrupture(MOR)andmodulusofelasticity(MOE)wasanalyzed.Theperformanceofthe obtainedpanelswasevaluatedincomparisonwiththeUSStandardANSI/A208.1.Particleboardswith11%ofBCmetthe minimum requirements of MOR and MOE recommended by the ANSI specifications for commercial use, while particleboardswithhighBC(14%)alsoaccomplishedtherequirementsforindustrialuse,findingaresourcefuluseforthis agriculturalwaste.Thebasiccomponentsofricehusk are thesameas wood butindifferentproportions.Themaingoalof thisstudywastoproducericehusk basedparticleboardsforexternalapplications, using phenol formaldehyde resin as binder. Limited studies have explored the combined effect of process ing parameters, such as pressure and binder content,onthepropertiesoftheseboards.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1. HairfibreandrubberarelocallysourcedfromPalabarbershopandAonecolorsKottayam.

2. Rawmaterialsareundergoneacleaningprocessbydetergent.

3. Hairfibresarecutintolengthsofaboutof2cm 4cm.

4. Rubber powder are grinded and particles passingthrough350μmstandardsievewerecollected.

5. Mouldismadeofmildsteelmaterialofdimension250mmx250mmx10mm.

6. For the fabrication of board, the mould is waxed for easy removal and fabrication is done by mixing the fibres with unsaturatedPUresin.

7. Theboardisthencompressedunderaconstantloadof100kNbyUniversalTestingMachine(UTM).

8. Curing processisdonebyovendryingatatemperatureof 85 °C for 2 hours and left under room temperature for 24 hours.

9. Repeatthesteps6to8fordifferenthairfibrecontent(15%,20%and25%)andcorrespondingrubberpowdercontent 35%,30%and25%).

10. Based on the mix proportions, the physical properties (Water Absorption, Thickness Swelling) and mechanical properties(ModulusofElasticity,ModulusofRupture)oftheparticleboardareanalyzed.

Hair,animportantpartofourbody,notonlypossessesaestheticsignificanceinourculture,butalsooffersprotection.This fiber reinforced nanocomposite plays a key role as an outer covering in many vertebrates. Hair fibers have a typical hierarchicalstructuresimilartootherα keratinmaterials,suchaswool,nails,claws,andhornspresentinmammals.The keratininreptilesandbirdsisprimarilyintheformofβ sheets.Keratinousmaterialsarecategorizedasα keratinifthey exhibitahelicalsecondarystructureorasβ keratiniftheyareintheshapeofsheets.Atypicalhairfiberhasadiameterof 50 100μmandiscoveredbyanoutermostlayer,thecuticle.Thecuticleconsistsofthinoverlappingscales.Eachscalehas an average length of 60 μm and a thickness of about 0.5 μm. Furthermore, 5 10 such scales overlap to create a total thicknessof~5μm.Themorphologyofthecuticleedgesisthoughttobeaffectedbyweathering,combing,and brushing, withmoreseveredamageseenonlonghairfibers.

Hairfibershave65 95wt%ofproteinsdependingonthehumidityandupto32%ofwater,withtherestaslipidpigments and other components. Therefore, chemically the properties of human hair are dominated by the α keratin. It has been demonstratedthatthetensilepropertiesofhairaremostlyproducedbythecortex,notthecuticle.RobbinsandCrawford damagedthecuticlewithchemicalsandfoundnoapparentdifferenceinthetensilepropertieswith

originalhairfibers.RelaxationtestsbyBarnesandRobertsandRobinsonandRigbyshowedthatthemoduliaredependent onthetimeaswellasstrainandthatthethiolcontentaffectsthemechanicalproperties.Itwasalsodemonstratedthatthe tensilepropertiesarehighlydependentontheinfluencesofvariousfactors:ahighrelativehumiditydecreasestheYoung's modulus and increases the extensibility; an increase in temperature leads to a decrease in Young's modulus and an increase in extensibility; twistingcreates damage tothe hair fibers and this effect leads to the decrease in the breaking stress, breaking strain and Young's modulus. Ethnicities and age also affect the properties of human hair. It has been shownthathairspecimensfromdifferentethnicitiesexhibitdifferentstrainsatcuticleliftof.

Rubber dust is the finest product after waste solid tires recycling. The name ‘powder’ clearly specifies its size which is between 0,1 and 1 millimetre. Rubber powder we produce and sell is completely clean from any iron and textile impurities.Thisisveryimportantforthemanufacturingofnewobjects.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Rubberdustfromwastesolidtiresrecyclinghasvariousapplications,inindustrialproductsmanufacturingaboveall.The maintiresmanufacturersuseitinnewtirescompounds.Also,rubberpowderisusedinthemakingofinsulatingboards, sealsandantivibrationpanels.Theultimateuseismixedwithbitumentoobtainrubberasphalt.

Utilizationofwastetirerubberinthemanufactureofparticleboardwasinvestigated,usingthesamemethodasthatused in the wood based panel industry. The manufacturing parameters were: a specific gravity of 0.65 andwastetirerubber content (10/90, 20/80, and 30/70 by wt% of waste tire rubber/wood particle). Two resin types, melamine/urea formaldehyde (MUF) and polyisocyanate, were used in the experiments. Average modulus of rupture values of MUF bonded particleboards with rubber crumbs were between 13 58% lower than the average of the control samples while polyisocyanatebondedparticleboardswere12 51%.Waterresistanceoftheboardsimprovedwiththeincreaseinrubber crumb/wood particle ratio. Thickness swelling values ofthe MUF bonded particleboards decreased from 14 53% while polyisocyanatebondedparticleboardswere9 48%ascomparedtocontrolsamples.

Themouldismadeofmildsteelplateandangleirons.Angleironhavingsize31.75mmX31.75mmX3mmwerescrewedtoa steelplateofdimension300mmX300mmX6.35mmtoobtainaninsidedimensionof250mmX250mm.Acoveringplate of mild steel having dimension 250mm X 250mm X 6.35mmwereusedtotransformtheloaduniformlyforthecompactionofboard.

Treatmentofhairwasteor washingofhairwasteisdone withdetergent. Detergentisusedtoremovethedirtsfromthe hair.Adetergentisasurfactantoramixtureofsurfactantswith cleansingpropertieswhenindilutesolutions.Therearea largevarietyofdetergents;oftentheyarethesodiumsaltsoflongchainalkylhydrogensulphateoralongchainofbenzene sulphonic acid. The most commonly found detergents arealkylbenzene sulfonates: a family of soap like compounds that are more soluble in hard water, because the polar sulfonate (of detergents) is less likely than the polar carboxylate (of soap) to bind to calcium and other ions found in hard water. The treatment removes the waxy substances on the fiber surfacetherebyimprovingtheclosecontactofthefiber matrix.

Polyurethanes are probably the most widely used type of casting resins and are used in applications ranging from miniatures and figurines, to rapid prototypes, through to structural components like skateboard wheels and engine mounts Polyurethane resins consist of soft and hard segments and have excellent elasticity and toughness. Various performance requirements (hydrophilicity, moisture permeability, abrasion resistance, heat resistance, chemical resistance,etc.)canbemetbychangingtheformulationandmoldingmethod.Itisalsopossible toaddmorefunctionsby denaturation.Numerous issues have arisen, such as stricter VOC reduction regulationsinvariouscountriesandreducing the weight of parts due to the spread of EV. Urethane resins are one of the most promising materials for meeting the performance requirements of the increasingly diverse and complex market in these days. In broad terms, Polyurethanes are plastics or synthetic resins that are a product of a polyaddition reaction involving polyisocyanates, dialcohols or polyols.PolyurethaneCastingResincomprisesabroadspectrumofcharacteristicsthatdifferfromoperationto operation andspansalargerangeofoptions.Polyurethaneresinsarecopolymersthatformwhenanalcoholcalledpolyol(eachofits moleculescontains3ormorereactivehydroxylgroups)reactswithanisocyanate (dualorpolymeric)whenappropriate additives and catalysts are introduced. A wide range of diisocyanates and polyols can be made to react for polyurethane resinproduction,andtherefore,polyurethaneresinusesaremanyandwide,andcutacrossavastrangeofindustries.

In general, the casting resin consists of a two component system of resin and hardener, which hardens after mixing through a chemical reaction. PU casting resins can, just like epoxy resin and polyester resin, be combined with various additivesaswellasfillingmaterialsorcolorants.Thisgivesthemthedesiredproperties.Forexample,theusercanaddan inhibitortotheresintoincreasetheso calledpotlife,i.e.,theprocessingtime.Asaresult,thiscanbemadeveryvariableto suitanyapplication.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

TheunsaturatedPUresinwasweighedbygentlypouringitintoaplasticcontainerplacedonadigitalweighingbalanceuntil theweightneededforthatparticularformulationwasachieve.Thecorrespondinghardenerwasalsoweightedandadded tothetesttubewherethePUresinwaspouredTheweightofhardenerdeterminedbytheweightofunsaturatedPUresin. Inthisproject,differentboardsarefabricatedbykeepingthebindercontentconstantandvaryingthefibercontent.

Duringblending,themassofhairfibreandtyrepowderwasvariedwiththatoftheunsaturatedPUresintogiveatotalof 400g.Theparticleboardshavingdifferentfibrecontentwerepreparedbyvaryingthehairfibreweightfractionfrom15% to 25%. The cleaned fibres, were weighed according to the percentages needed (Hair fibre: 15%.20% and 25%, Tyre powder: 35%,30% and 25%). After weighing, the hair fibre and tyre powder were mixed together. Following that, the unsaturated PU resin was taken with 1:2 weight percentage to the fibre used. 1% weight of hardener was added to the unsaturatedPUresin.Themixturewasthenstirreduntilitbecamehomogenicmixture.Thenthefibremixtureisaddedto the resin and mixed uniformly using a spatula. Then the mixture was transferred carefully into the mould and flattened appropriatelybyusingtheroller.Thecoveringplatewereplacedoverthemixtureandkeptunderthecompressiontesting machine.Particleboardsarepreparedwith3differentfibrecontents.Thedetailedcompositionandmixproportionofthe particle board are presented in table 1. The castofeachparticleboardwaspreservedunderaload ofabout 100kN for 1 hour.Thenthiscastiskeptforcuring.

Table1mixproportion

Material Board 1 Board 2 Board 3

Tyrepowder 35% 30% 25% Hairfibre 15% 20% 25% Resin 50% 50% 50%

Afterloading,theparticleboardwasovendriedattemperatureof85°Cfor2hours.Thenthiscastwaspostcuredinroom temperatureforanother24hours,afterwhich the board is then removed from the mould.

Specimensofappropriatedimensionswerecutforphysicalandmechanicaltests.

ParticleboardshavingdifferenthairfibrecontentweretestedtoanalyzeandcomparephysicalpropertiessuchasWater Absorption,ThicknessSwellingandmechanicalpropertieslikeModulusofElasticityandModulusofRupture.

The water absorption increases with increase in the hair fibre weightfraction.Thisisduetothepresenceofvoidsin the natural fibre reinforced particle board. These voids form because ofthepooradhesionbetweenthematrixand the fibre, which in this case was the hair fibre. When the natural fibre reinforced particle boards are exposed to moisture, the hydrophilic fibre swell, which leads to the micro cracking of the brittle thermosetting resin. As the board crack, the capillarity becomes active and hence, the water molecules are actively attracted to the interface, which in turn results in thede bondingofthefibreandmatrix.

Thepercentagethicknessswellingoftheparticleboardincreaseswithincreaseinthehairfibreweightfraction.Whenthe boardsareexposedtomoisture,thehighcelluloseofthefibrecontributetotheadditionalwaterpenetrationintothefibre matrixinterfacethrough micro cracks,whichleadstotheswellingof the particle boardwhich inturncreatesstressand ultimatelyleadstofailureoftheparticleboard

Itisclearthat,thevaluesofmodulusofelasticity(MOE)andmodulusofrupture(MOR)decreasesasthehairfibreweight fraction of the board increases. The increase in hair fibre content from 15 to 25 weight percentage results in fibre agglomerationanddecreasesthefibre matrixadhesion,resultinginlowerflexuralstrengthvalues.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Physicalandchemicalpropertiesofhairfibreandtyrepowder werestudied.Attheinitialstage,thehairfibreandrubber powder were washed in order to remove the wax and impurities that cover the outer surface of the fibres. This leads to improvethesurfaceroughnessofthefibresandthusfacilitatesthemechanicalinterlockingbetweenthefibre matrixand finallyincreasesthemechanicalproperties.

This study investigated the physical and mechanical properties of particle board made from hair fibre, rubber powder and unsaturated PU resin to investigate thepotentialfortheuseofhairfibreandrubberpowderasrawmaterialsfor non wood bio based particle board. Boards having 3 different hair fibre weight fraction (15%, 20% and 25%) and corresponding rubber powder content (35%, 30% and 25%) were casted and tested for physical (Water absorption, Thicknessswelling)andmechanical(Modulusofelasticityandmodulusofrupture)properties.

From the results obtained, the water absorption and thickness swelling of the board are found to be increasing with increase in the hair fibre weight fraction which is due to the decrease in adhesion between the fiber and resin. The minimum values of water absorption and thickness swelling were obtained as 1.803% and 1% respectively. As the hair fibreweightfractionincreasedfrom15%to25%,thevaluesmodulusofelasticityandmodulusofruptureweredecreased whichisduetothefibreagglomerationthatleadstothedecreaseinfibre matrixadhesion.Tyrepowder,whichisusedas the filler material, increases linearly with decrease in hair fiber content and thus the filler resin bonding increases and hence improves the mechanical properties. The maximum values of modulus of elasticity and modulus of rupture were obtainedas1600N/mm2and8.4N/mm2respectively.

Fromthestudiescarriedout,theoptimumvaluesofphysicalandmechanicalpropertieswereobtainedfromthefirsttype ofboardhavingthemixproportionas,tyrepowder35%,hairfibre15%andunsaturatedPUresin50%.

1. Carlos F Revelo et al (2021) “ Composite materials made of waste tyers and polyurethane resin” : A case study of flexibletilessuccessfullyappliedinindustry.

2. Bijoya Kumar Behera et al (2021) “ sustainable hybrid composites reinforced with textile waste for construction and buildingapplications”

3. RaghavRoshanel at(2020) “anexperimental studyof humanhairinconcreteasfibrereinforcementandalsouseof plasticizers”

4. GSreevanietal(2017) “Humanhairasfibrereinforcementinconcrete”

5. NogmanAFetal(2016) “Effectofbananaleafslaminationonthemechanicalpropertiesofparticleboard”

6. EmilianoManuelCiannameaetal(2017) “Particleborad basedon rice husk: Effect of binder content and processing conditions”

7. RJeyakumaretal(2019) “Investigationonmechanicalpropertiescoconutfibrereinforcedpolyestercomposite”

8. JainDetal(2012) “Hairfibrereinforcedconcrete”