International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Abstract - Concrete is a vital part of the construction industry.Theexpansioninpopulationhasplacedamassive wantformoreandmoreinfrastructureanditkeepsgrowing. Theresultofthisdemandisthattheincreaseinproduction ofcement.Theworldwideproductionofcementisaround 4.1billionmetrictonsandispredictedtoriseto4.83billion metrictonsin2030.Thishasinturnledtoexploitationof naturalresourcesinadditionasemissionofpollutantsthat causedamagetoourenvironment.Hugequantityofwaste materials and by products are made by manufacturing enterpriseslikericehuskash,silicafumesandmineralslag and so on. As a result, waste management has become an enormousproblemforourenvironment.Groundnuthastap root system which has many nodules, present in root and lateral roots. Granite powder which are the by product createdwhilecuttinglargegraniterocksingranitefactories totheirdesiredshapes.Thewastegeneratedbytheindustry has accumulated over the years, and it's been dumped immorallyleadingtoenvironmentalproblem.Theresearch workheredealswiththepartialreplacementofcementby mass with GSA and Fine aggregate with Granite Powder together.Aftermixing,castingandcuringthecharacteristic strengthofthisnewconcretearecomparedwithstandard concreteofM30grade.Theexperimentalinvestigationsare administered for compressive strength Split Strength and flexuralstrengthforcuringperiodof3,14and28days.The experimental results show that the for a combined replacementpercentageof32%GSAand24%GP,isshow positiveresults.Workabilityreduceswithincreasing%age of GSA and Granite Powder. The maximum proportion of replacement has been found by conducting the following strengthtests:Compressivestrengthtest,Flexuralstrength testandSplitTensileStrengthTest.

Keywords: Groundnut shell ash (GSA), Granite Powder (GP), Pozzolanic material, Compressive strength, Flexural strengthandSplittensilestrength

Globalconsumptionofconcreteissecondsolelytowater.As thedemandforconcreteincreases,thuswillthedemandfor Portland cement. Cement has been in use since the nineteenth century to make concrete. The demand for

concrete is growing with the growing demand for infrastructure, energy and resources. However, there are someproblemswithcementproduction,thatisn'tjustoneof the most powerful materials employed in construction, however it's additionally accountable for some carbon dioxide (CO2) emissions, which are common in global warming.AdditionalgasCarbondioxideaccountsfor65%of globalwarming.InIndia,marbleandgranitestoneprocessis one in all the most rising effects of changing marble dust contentonrecentandup to datephysicalandmechanical properties. Concrete technology will scale back the utilization of natural and energy resources to pollute the burdenontheenvironment.Asweallknowthatnowadays thepriceofconstructionmaterialsisrising.Wastedisposal will increase massively, quickly reduce dumping sites, increase rapidly in transportation and dumping cost will result on} the environment, preventing property development.

Granite belongs to the igneous rock family. The granite Density is between 2.65 to 2.75 g / cm3 also the compression strength is greater than 200MPa. Granite powder obtained from cooling units and structures was found.Sincegranitepowderwasgood,hydrometeranalysis wasperformedtodeterminetheparticlesizedistributionof granite powder. From the hydrometer analysis it was establishedthatthecoefficientofcurvaturewas1.95while the coefficient of uniformity was 7.82. The gravitational strengthofgranitepowderwasfoundtobe2.5.

Utilization of these agro wastes for formulation of white warebodywillbringaboutreductionintheuseofnatural rawmaterials,reducesproductioncost,energyconsumption aswellasservingasameansofsafedisposaloftheseagro wastes. White wares are usually manufactured by using different raw materials such as sodium or potassium feldspar,ceramicsfritstogetherwithclay,kaolinandsilica sand. Inspiteofthefactthatgroundnutshellsareproduced in large quantity in Nigeria and other parts of the world, insufficientattentionhasbeendevotedtocharacterizingthis

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

wastematerial asalternativerawmaterial for whiteware bodies.

K. Chiranjeevi Reddy et. al. 2015 Inthispaperentitledas “Experimental Study on Concrete with Waste Granite PowderasanAdmixture”Granitefinesareusedasafiller material within the concrete, replacing the fine aggregate whichcanhelpinfillingup theporeswithintheconcrete. Granitefinesresultedinanincreaseincompressionstrength inboth7&28daysto33.14&43.40N/mm2comparedto 23.26 & 39.41 N / mm2 of ordinary concrete. Tensile strengthalsofollowsthesamepatternwitha7.5%rotation andgranitefinesthatincreasethegripstrengthfor7&28 daysto2.87&4.19N/mm2comparedto2.4&3.4N/mm2 ofstandardconcrete.Howevertheflexiblestrengthatagood gradient conversion of 7.5% showed a significant improvementintheflexibilityfor28daysto6.34N/mm2 comparedto3.35N/mm2ofconventionalconcrete.

B.A. Alabadan 2015 Pozzolanic materials have long demonstrated their effectiveness in producing high performance Concrete. Artificial pozzolanas such as rice husk ash have gained acceptance as supplementary cementingmaterialsinmanypartsoftheworld.Thiswork evaluatesthe potentialsofgroundnutshell ash(GSA) asa partialreplacementforordinaryPortlandcement(OPC)in concrete. Chemical analysis of the ash was carried out to ascertain whether it possesses pozzolanic or cementing propertiesandthepartialreplacementofOPCby GSAwas varied from 0% to 70% in the concrete. The compressive strengths of the control and those of other combinations increased with curing age but decreased with increased ashPercentage. Though, the strength of the control was higher,replacementofcementwithashupto30%wouldbe moresuitablethanothers.

H. Mahmoud et. al. 2012 InThisresearchpaperentitledas “Theproductionofsandcreteblocksusinggroundnutshell ash (GSA) as cement replacement was investigated. The resultsshowthatthecompressivestrengthrangesfrom4.50 N/mm2to0.26N/mm2.Theoptimumreplacementlevelwas achieved at 20% with a corresponding strength of 3.58 N/mm2.Thestrengthattheoptimumlevelwaswithinthe recommendedlimitoftheNigerianIndustrialStandard(NIS) 87:2000. The results also showed that the strength decreaseswithincreaseofcementabove20%replacement.

Any variation in their quantity affects the compressive strength of the concrete mix. Portland cement (Ordinary PortlandCement)isaveryimportanttypeofcementanda finepowderproducedtogrindPortlandcementclinker.The

value:

OPCisdividedintothreephases,namelyGrade33,Grade43 andGrade53dependingonthestrengthof28days.OPCof grade53conformingtoIS12269fromasinglelotwasused throughoutthecourseoftheinvestigation.Itwasfreshand withoutanylumps.

According to size, the fine aggregate may be described as coarse,mediumandfinesands.IS:383 1970hasdividedfine aggregate into 4 grading’s which become gradually finer from grading zone I to IV. The fine aggregate used in this research wasclean riversandcollected. Whose maximum sizewas4.75mm,conformingtoIS3831987gradingzone II.

Theparticlesretainedona4.75mmsievearetermedcoarse aggregate. For making a good concrete mix, coarse aggregatedmustbehard,clean,andfreefromanychemical coatingofclayanddustonthesurface.Crushedstonemakes the majority of the particle of coarse aggregate. Coarse aggregatesangularinshapeareusedinthisresearchwork that is obtained from the local crusher. Grading of coarse aggregatewasdoneaccordingtoIS:383 1970.Aggregatesof Nominal size 20mm & 10mm to form a graded aggregate. The concerned lab provided the properties of coarse aggregate.

Thorough mixing of the materials is essential to produce uniform concrete. The mixing should make sure that the mass become homogeneous, uniform in consistency and colour.Therearetwomethodsadoptingformixingconcrete oneishandmixingandotherismachinemixing.

Beforeremovingthemould,itisdriedfor24hours,andthen specimens are placed in a water tank made to cure specimens.Thespecimensmustbemarkedforidentification so that there must not be any error. The specimens are removed from the tank and dried before putting in the testing machine. The specimens are kept in the tank for 3,7,28days.

It can be used in site as well as in lab. This test is not applicableforverylowandveryhighworkabilityconcrete.It consistsofamouldthatisintheformoffrustumhavingtop diameterof10cm,bottomdiameterof20cmandheightof 30cm.Theconcretetobetestediffittedinthemouldinfour layers. The each is compacted 25 times with the help of tampingrod.Afterthemouldiscompletelyfilleditislifted immediatelyintheverticallyupwarddirectionwhichcauses theconcretetosubside

Thenfreshconcreteisfilledinmouldin4layersandafter fillingeachlayertampingshouldbedone35timesincaseof cube and 25 times in case of cylinder by using standard tamping rod. Once the mould is filled then leveled top surfaceofconcretewithtrowel.Afterthedaythemouldwill removedandspecimenaredroppedinthecuringtankunder standard temperature of 27±2° c. After 3,14 days and 28 daysinthisresearch.

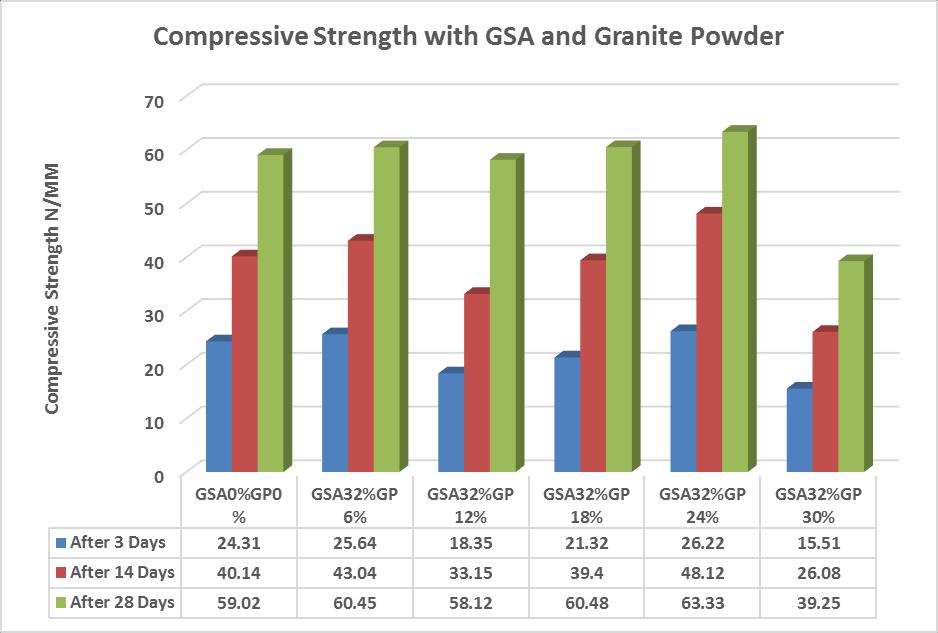

Fig 2: COMPRESSIVE STRENGTH

3, 14, 28 DAYS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The specimen used for this test is cylindrical and its dimensionis150mmindiameterand300mminlength.The instrumentusedforthistestingisuniversaltestingmachine. Thefreshconcreteispreparedinaccordingtotherequired gradesandrespectivemixproportion.Thefreshconcreteis filled in mould in layers and each layer is tamping with standardtampingrodwith25blowsforeachlayer.Afterthe day the mould is removed and specimen is placed in the curingtankfor3,14daysand28daysinthisresearchatthe temperature27+2°c.Thendrawthelineonthespecimen.

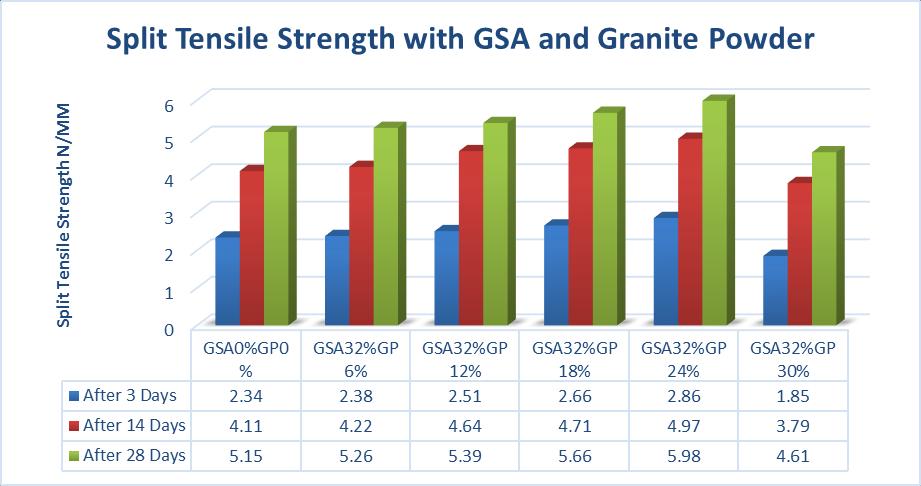

Fig 3 SPLIT TENSILE STRENGTH 3, 14, 28 DAYS

Theconcreteispreparedatrequiredrateofmasselement the mould is filled with concrete in layers and blows 25 timeswithstandardtampingrod.Afterthedayorwecansay 24hoursthemouldisremovedandspecimenplacedinthe water tank for curing at a temperature of 27 + 2 C. Depending upon the requirement the test specimen is removedfromthewatertankandwipeitproperlyfor3,14 and28daysfortesting.

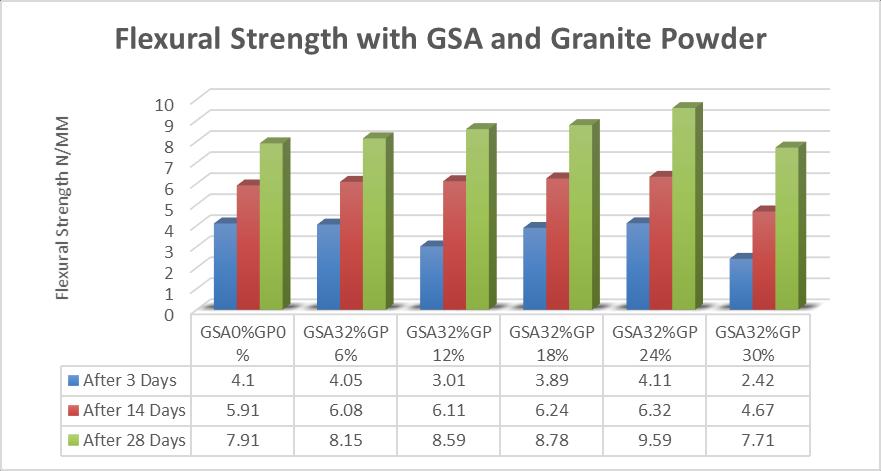

Fig -4 FLEXURAL STRENGTH 7,14,28 DAYS

• The use of Groundnut shell ash and Granite powder as partial replacement of cement and Fine Aggregate respectively should be taken up for acceptable and environmentallyfriendlyconstruction.

•Byusingtheseeasilyavailableleftoversandagricultural wastematerialsinconstruction,wecangreatlydecreasethe cost of construction up to a certain level and also not compromisingmuchonthequalitywhilealsoovercoming theenvironmentalhazards.

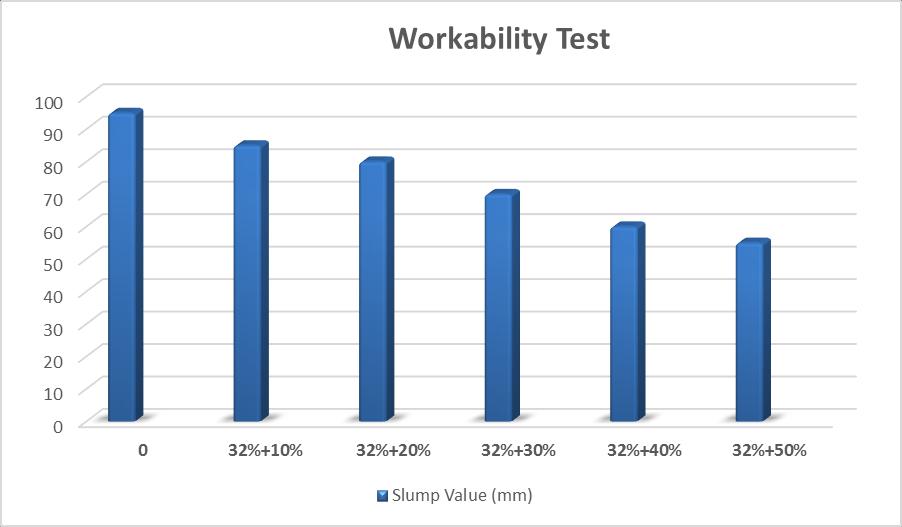

•Ingeneral,itwasalsoobservedintheexperimentthatthe workabilityofconcretedecreaseswiththeincreaseinthe percentageofGroundnutshellashandGranitePowderthe concretewaslessworkable.

• This investigation has also established that the use of Groundnut shell ash and Granite Powder by a certain percentagecanproducepositiveresultswhencementand fineaggregate.Thuscanbeusedinconstructionpurpose.

• It is observed that by replacement of cement with Groundnutshellashupto32%byweightofcement,thereis anincreaseincompressivestrength,Flexuralstrengthand Split tensile strength of concrete after which there is a drasticdeclineinthestrengthofconcrete.

•Themaxcompressivestrengthisachievedbyreplacement offineaggregatewithGranitepowderandreplacementof Cement with Groundnut shell ash in combination on 28th dayas63.33Mpa.

•InthecaseofreplacementoffineaggregatewithGranite powder and replacement of Cement with Groundnut shell

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

ashincombination,itisfoundoutthatthereisanincreasein allthethreestrengthscompressive,splittensileandflexural. Theincreaseis uptoa percentage replacement of32% of Groundnut shell ash and 24% of Granite Powder in combination by weight of cement and fine aggregate respectively.

•Themaxsplittensilestrengthisachievedbyreplacement offineaggregatewithGranitepowderandreplacementof Cement with Groundnut shell ash in combination on 28th dayas5.43Mpa.

•AsitwasobservedthatGroundnutshellashoverallgains strengthinthelaterdaysduetoitspozzolanicactivityand henceisagoodenoughmaterialasthereplacementmaterial ofcement.

• Themaxflexural strength isachievedby replacement of fine aggregate with Granite powder and replacement of Cement with Groundnut shell ash in combination on 28th dayas9.59Mpa.

• Theinvestigationalsoshowedthatgranitepowderisan excellentmaterialforreplacementinconcreteforriversand thus can help save the environment and also reduce the expenses.

1. Pi Jie Ying, Fu Sheng Liu, Shu Xia Ren, Gang Gang Dong“TheResearchontheEffectofGranitePowder onConcretePerformance”(Volumes204 208)

2. Experimentalstudyonconcreteusingglasspowder andgranitepowderMrs.G.Lavanya,R.Karuppasamy (2016)

3. EffectofGranitePowderonStrengthPropertiesof ConcreteDr.T.FelixKala2013

4. P. Asha, A. Salman, R. Arun Kumar “Experimental StudyonConcretewithBambooLeafAsh”

5. Alaneme KK, Fatile BO and Borode JO. (2014). Mechanical and Corrosion Behaviour of Stir Cast Zn 27al Alloy Matrix Composites Reinforced with GroundnutShellAshandSiliconCarbide.Tribology inIndustry,36(2),195 203.

6. IS10086(1982):Specificationformouldsforusein testsofcementandconcrete.

7. IS456 2000,IndianStandard,PlainandReinforced Concrete codeofpractice.

8. IS 383 1970, Indian Standard Specification for CoarseandFineAggregatesfromNatural Sources forConcrete.

9. IS 10262 2009, Indian Standard Recommended GuidelinesforConcreteMixDesign

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal