International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

VELUCHAMY M1 , SURENDRAN R 2 , SEKAR T3

1PG Scholar, Department of Manufacturing Engineering, Government College of Technology, Coimbatore, India

2 Assistant Professor, Department of Manufacturing Engineering, Government College of Technology, Coimbatore, India

3 Professor and Head, Department of Manufacturing Engineering, Government College of Technology, Coimbatore, India ***

Abstract Demand for aluminum hybrid metal matrix composites has recently increased due to improved mechanical properties to meet the needs of advanced engineeringapplications.Theperformanceofthesematerials is greatly influenced by the choice of the right combination of reinforcement materials. Alumina is the most common reinforcementusedinthemanufactureofthesecomposites.In this publication, an attempt was made to produce an Al7085 Nano composite fortified with particles of different weight fractions of Al2O3 by a stir casting process. Experimental studies were performed on the composites prepared to study the mechanical properties of the addition of some reinforcements. Compare the mechanical properties of the proposedcompositesUltimatetensilestrength,yieldstrength, impact strength, hardness with those of the unreinforced Al7085. The experimental study also aims to observe changes in properties with changes in the weight fraction of the Al2O3 reinforcement

Key Words: 7085Al alloy; Al2O3; Composite; Fabrication; AMMCs; Stir Casting; Micro analysis

A material is a substance that makes up a product or a combination of two or more substances. In all industries, materials are the primary input for manufacturing final products. Due to the current competitive situation in the market,almostallindustriesplantoimprovethequalityof theirproductswithminimaleffort.Therefore,allindustries adopt the principles of materials science to select or manufacturematerialsthatimprovethequalityofthefinal products manufactured. It is based on atomic bonds, structures, physical, chemical, thermal and electrical properties. This classification facilitates the selection of materialsfora varietyofindustrial applications.Recently, the use of composites in the technical field has increased significantlyduetotheirimprovedpropertiescomparedto

existingmaterials.Stressfractureisthenetcross sectional fracture of a part or deterioration of the composite on a microscalewhenoneormorelayersofthecompositeare disruptedbythestressofthematrixorthefractureofthe bond between the matrix and the fibre. It may be some composites. Composites are made up of two or more different materials that are chemically and physically different from each other. Composites are completely different from alloys. In alloys the two elements form a homogeneoussolidsolution,whereasincompositesthetwo elementsareseparateanddistinctinthefinishedstructure. In general, composites are made up of two main components:matrixandreinforcement.Reinforcingmaterial is a material that is added to the matrix to increase its strength. A metal matrix composite material (MMC) is a compositematerialoftwoormoreconstituentmaterials,the matrixmaterialmustnecessarilybeametalorametalalloy, andtheothermaterialsarealsometalsorceramicsorany organiccompound.Whentherearethreeormorematerials in a composite, it is called a hybrid composite. The liquid manufacturingprocessisthemostwidelyusedmethodfor manufacturing metal matrix composites due to its cost effectiveness.Inthisprocess,themetalmatrixismeltedby heatingitinafurnace,thenthemoltenmatrixispouredover the reinforcement or the reinforcement is added to the molten matrix. Various techniques in the liquid state manufacturing process are stir casting, die casting, compositecasting,infiltration,andin situmanufacturing.

Literature reviews provided insights into alloy research work and the gaps found there, allowing them to identify problem areas and find solutions to achieve their goals through experimental methodologies. The first step is to select the material for the casting and focus on the application of the material. Then proceed to the stirring

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

casting process. This process requires the material to be preparedbycalculatingtheweightandweightPrecentofthe composite.Afterthestirringcastingprocessiscomplete,the ingots are collected and moved to the machining process according to Compare the mechanical properties of the proposed composites Ultimate tensile strength, yield strength, impact strength, hardness with those of the unreinforcedAl7085

In this project, Al7085 Aluminium alloy is chosen as matrix material. It has high strength to weight ratio, better hardness and good yield strength. Table 1 representsthecompositionofAl7085alloy.

Table 1: CompositionofAl7085alloy

Composition percentage

Zn 7.0 8.0 Si 0.06 Fe 0.08 Ti 0.06 Cu 1.3 2.0 Mn 0.04 Mg 1.2 1.8 Cr 0.04 Others 0.65 Balance Al

Aluminaisanimportantmaterialwidelyused inceramics, electrical devices, metallurgy and composites. The most common methods are milling machines, chemical vapour deposition, vapour deposition, hot water and incinerator processes.Al2O3 isimportantforuseinthemanufactureof aluminium metals, as an abrasive for hardness, and as a refractory for its high melting point (2072 °C). Table 2 showsthecharacteristicsofthealuminapowderAPS20 30 nmaluminaNanopowderpurchasedfromthemarket.

Table 2:PropertiesofAluminaNanopowder

Engineering Property values

Density(g/cc) 3.72 ElasticModulus (GPa) 370

Meltingpoint(0C) 2015 Poissionratio 0.26

Hardness(kg/mm2) 1500

Compressive Strength(MPa) 2560

TheAl7085aluminiumalloyplatewascuttotherequired mass and placed in a graphite crucible. The crucible was placedinaninductionfurnacetogetherwiththebasemetal and heated to a temperature of 650 ° C. Once the base materialhadmelted,adegassedtabletwasaddedtoremove impurities and gaseous inclusions present in the base material.Afterthat,impuritiesgeneratedonthesurfaceof themoltenmetalwereremoved.Toincreasethewettability between the Al7085 and Al2O3 reinforcements, 1% magnesium(Mg)powder[2]wasaddedtothemoltenmetal and the alumina Nano powder was preheated to 700 ° C. After adding 1% magnesium powder, preheated Al2O3 powderwasaddedtothemoltenmetal.Thestirringblade wasslowlyinsertedintothemoltenmetalandstirredata rate of 235 rpm for 15 minutes until the temperature droppedto520°C.,duringwhichtimethemixturereacheda slurrystate.Afterstirringagainfor15minutes,themixture washeatedagainto680°C.toreachamoltenstate.Finally, themoltenmetalwaspouredintoamouldhavingalengthof 10 cm, a width of 10 cm, and a thickness of 15 mm. The Al7085 / Al2O3 Nano composites were manufactured by varying the fortification rates by 0.5%, 1%, and 1.5% in a stirringcastingsetup,asshowninFigure 1.

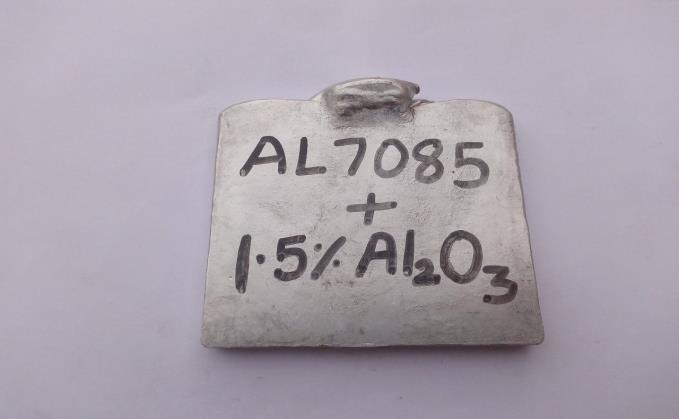

Materials used in engineering applications are typically selectedbasedonpropertiessuchas tensilestrength,yield strength, and modulus of elasticity. Tensile testing is the most common method for determining these mechanical properties.Inthisstudy,tensiletestswereconductedona universaltestingmachine(UTM),andthedevelopedhybrid composite material samples A, B, and C were prepared accordingtoASTMstandards.Theaverage tensilestrength and yieldstrengthvaluesmeasuredforsamplesA,BandC were 247 MPa, 256 MPa and 268 MPa, respectively, in Figures4and5.

Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

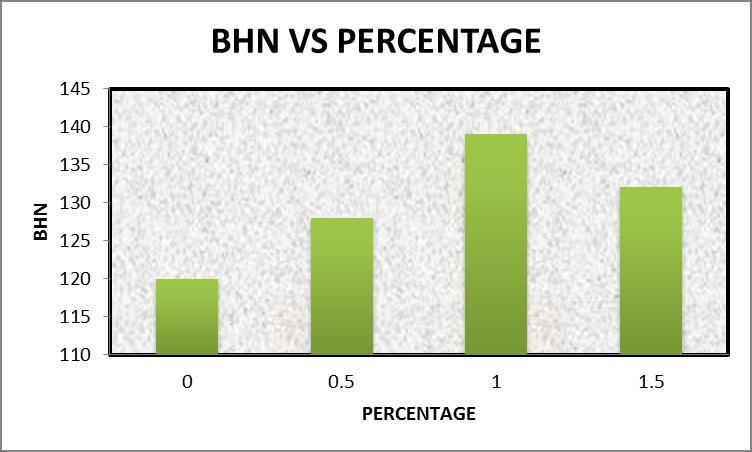

In this study, the hardness of samples A, B, and C of the Alumina nano composite was measured using a Brinell hardnesstesterwithanindenterdiameterof5mm.Aloadof 5kNwasappliedtoeachsamplefor30seconds.TheBHN valuesobtainedforsamplesA,BandCwere128,139and 132,respectively.

TheimpactstrengthsobtainedforSamplesA,BandCwere 1.83J / mm², 1.85J / mm² and 1.80J / mm², respectively. Performedonapendulumtesterusingacantilevertestpiece withalengthof75mm,acrosssectionof10mmx10mm,a standard notch of 45 °, and a depth of 2 mm. The impact strengthsobtainedforSamplesA,BandCwere1.83J/mm², 1.85J/mm²and1.80J/mm²,respectively.

The composites were prepared using stir casting techniques with two different compositions of 0.5 wt%, 1 wt%, and 1.5 wt% reinforced alumina nanoparticles, respectively,asshowninFigures2andFigure3

ThevaluesofmechanicalpropertiesofAl7085aluminanano particlesgiveninthetable. 3

Table 3: Mechanical properties of the proposed Alumina NanoMMCfordifferentspecimens

MATERIAL Pure Al7085 AL7085 +0.5% Al2O3

AL708 5+1% Al2O3

AL7085 +1.5% Al2O3

TheultimatetensilestrengthofNanocompositesdepends ontheamountofreinforcement.ThisisshowninFigure4 andfigure5.TheextremetensilestrengthvaluesforSamples A, B, and C shown in Table 6.1 indicate that the ultimate tensile strengths for Samples B and C are significantly increasedcomparedtothebasemetal.Thetearstrengthsof Samples A, B and C are increased by 7.39%, 11.30% and 16.52%,respectively,comparedtothebasemetal.Theslight improvement in the strength of sample A may be due to inadequateadhesionbetweenthereinforcedparticlesand the matrix compared to the other two samples of the aluminumNanocomposite.Inthegraphvariationoftensile strengthindifferentpercentagesisshownin Chart 1.

Fig 4:BeforeTestingofspecimensA,BandC

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

ThehardnessofSamplesAandCincreasedby6.6%and10%, respectively,comparedtothenon reinforcedmetalmatrix (base material). However, for Sample B, the hardness was dramatically improved by 15.8% compared to the unreinforcedmetalmatrix.Chart 2showsthattheBHNvalue ofhybridcompositesishigherwith1%reinforcement.Italso showsthatincreasingtheamountofreinforcementreduces theBHNvalue.

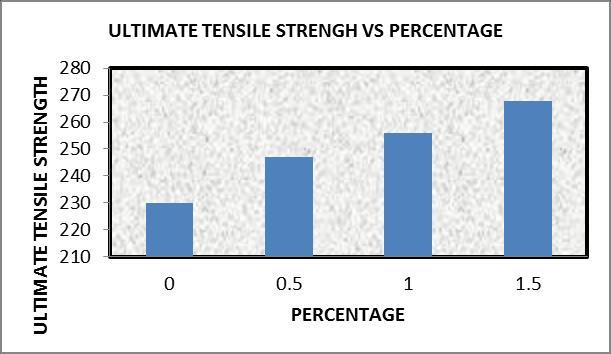

Theyieldstrengthofahybrid compositedepends onthe amount of reinforcement. This is shown in Chart 3 The yieldstrengthvaluesforSamplesA,B,andCshowninTable 6.1indicateasignificantincreaseintheyieldstrengthfor SamplesBandCcomparedtothebasematerial.Theyield strengths of Samples A, B, and C are increased by 9.2%, 21.5%, and 15.38%, respectively, compared to the base metal.

Chart 2:Hardness(BHN)vs Percentage

Chart 3: YieldStrengthvsPercentage

Thisexperimentalstudyaimstoproducenon metalceramic reinforced materials Al2O3 and Al7085 Nano metal matrix composites using stirring casting techniques and to investigate theirmechanical properties. Thedensityof the proposedcompositewasreduced,andmechanicalproperties suchashardness,tensilestrength,andyieldstrengthwere slightly reduced compared to those of the Al7085 NMMC reinforcedwithasingleceramicreinforcement.Madewith equalamountsofAl2O3 (0.5wt%,1wt%,1.5wt%),NMMC hasatensilestrengthof247MPa,ayieldstrengthof142MPa andahardnessof128BHN.Thisstudyislimitedtoobserving changesinmechanicalpropertieswhileincreasingtheweight fraction ofAl2O3 in three steps (0.5 wt%, 1 wt%, 1.5 wt%, respectively). The following remarks are possible. SEM images showed that the Al2O3 reinforced particles were completely wet with the Al7085 matrix material. Brinell hardnesstestshaveshownthatthehardnessincreasedfrom 128BHN to132BHN andthecompositestrengtheningrate increased by 0.5% to 1.5%. The results of the tensile test show that the tensile strength increased from 247MPa to 268MPa and the reinforcement ratio of the composite increasedfrom0.5%to1.5%.Theresultsoftheyieldstrength test showed that as the composite reinforcement rate increased from 0.5% to1.5%, the yieldstrengthincreased from 142MPa to 150MPa. Compared to the base material Al7085,theproposedcompositeshowsgoodimprovements

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

intensilestrength,yieldstrength,andhardness.sothebest compositionoccursAl7085+1%Al2O3 ofHowever,thereis nosignificantchangeinimpactstrength.

ThisresearchwassupportedbytheMechanicalengineering Department in Government College of technology, Coimbatore. It is our privilege to express whole hearted gratitude and thanks to our Project Guide Professor R. Surendran for his valuable guidance and constant encouragement behind the successful completion of this projectwork.

[1] ShunmugasundaramM,PraveenKumar,PonrajSankar, Sivasankar, ‘Experimental investigation and process parameters optimization of stircast aluminium metal matrix composites to improve material removal rate’MaterialsToday:Proceedings,Volume2pp.1 6J.

[2] Suresh, HarinathGowd and Deva Kumar (2019), ‘Experimentalinvestigationonmechanicalpropertiesof Al7075/Al2O3/Mg NMMC’s by stir casting method’, Indianacademyofscience,Volume54

[3] Arun Kumar, S.; Hari Vignesh, J.; Paul Joshua, S. (2020). Investigating the effect of porosity on aluminium 7075 alloy reinforced with silicon nitride (Si3N4)metalmatrixcompositesthroughSTIRcasting process. Materials Today: Proceedings, (), S2214785320358168doi:10.1016/j.matpr.2020.07.690

[4] Gudipudi, Suresh; Nagamuthu, Selvaraj; Subbian, Kanmani Subbu; Chilakalapalli, Surya Prakasa Rao (2020). Enhanced mechanical properties of AA6061 B4C composites developed by a novel ultra sonic assisted stir casting. Engineering Science and Technology, an International Journal, (), S221509861932350X doi:10.1016/j.jestch.2020.01.010

[5] Negi, A. S., & Shanmugasundaram, T. (2020). Hybrid particles dispersion strengthened aluminum metal matrix composite processed by stir casting.Materials Today:Proceedings.doi:10.1016/j.matpr.2020.03.717

[6] Ramadoss,N.;Pazhanivel,K.;Anbuchezhiyan, G.(2020). Synthesis of B4C and BN reinforced Al7075 hybrid composites using stir casting method. Journal of MaterialsResearchandTechnology,9(3),6297 6304. doi:10.1016/j.jmrt.2020.03.043Volume9,Issue3,May June2020,Pages6297 6304

[7] M C, Gowrishankar; Hiremath, Pavan; Shettar, Manjunath; Sharma, Sathyashankara; Rao U, Satish (2020). Experimental validity on the casting characteristics of stir cast aluminium composites. JournalofMaterialsResearchandTechnology,Volume 9,Issue3,May June2020,Pages3340 3347

[8] Akbar, Hammar Ilham; Surojo, Eko; Ariawan, Dody; Putra, Galang Ariyanto; Wibowo, Reyhan Tri (2020). Effect of Reinforcement Material on Properties of Manufactured Aluminum Matrix Composite Using Stir

CastingRoute.ProcediaStructuralIntegrity,Volume27, 2020,Pages62 68

[9] Shashi Prakash Dwivedi, Ajay Kumar (2020), ‘Development of graphite and alumina reinforced aluminiumbasedcompositematerial’,MaterialsToday: Proceedings,pp.1 5

[10] S.Sivananthan, K.Ravi, C.Samson Jerold Samuel (Elsevier) Effect of SiC particles reinforcement on mechanical properties of aluminium 6061 alloy processedusingstircastingroute.2019.

[11] Nagendra kumar, Maurya, Manish maurya, Ashish kumar Srivastava,shashi Prakash dwivedi, Abdhesh kumar,Sandeep Chauhan (Elsevier) Investigation of mechanical properties of Al6061/SiC composite preparedthroughstircastingtechnique.2019

[12] Ankit singh negi,T.Shanmuga sundaram, (Elsevier) Hybrid particles dispersion strengthened aluminium metalmatrixcompositeprocessedbystircasting2020.

[13] Hammariihamakbar,ekosurojo,Dodyariawangalang ariyanto putra,rayhan tri wibowo,(Elsevier) Effect of reinforcementmaterialonpropertiesofmanufactured aluminium matrix composite using stir casting route.2020.

[14] Mahmood khan,Abdul rehman,Taha Aziz,Kashif naveed,Tayyab subhani. (Elsevier) Cold formability of frictionstirprocessedaluminiumcompositescontaining carbonnanotubesandboroncarbideparticles.2017

[15] V.Balaji,N.Sateesh,M.Manzoor,Hussain, (Elsevier) Manufacture of Aluminium Metal Matrix Composite (Al7075 SiC)byStirCastingTechnique,2015.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page27

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

VELUCHAMY M isaPGScholarof M.E (2022) in Manufacturing Engineering of Government CollegeofTechnology,Coimbatore HeholdsaBachelorofEngineering (2018)inMechanicalEngineering from the Government College of Engineering Bodinayakkanur. He presented International Conferences (02) and National Conferences(01)

SURENDARN R is a Assistant Professor (S.G) of Manufacturing Engineering Department, GovernmentCollegeofTechnology Coimbatore He obtained his B.E (1999)inProductionEngineering from Madras University, Chennai and M.E (2008) in Engineering Design from College of Engineering, Guindy (Anna University), Chennai. He also Doing the research Ph.D. in Tribological Behaviour of Nano Composites. He Presented more than 150 lecture delivered as a resource personinFDP & Special Lectures

SEKAR T isaProfessorand Head ofPG ManufacturingEngineering, Mechanical Department, GovernmentCollegeofTechnology Coimbatore He obtained his B.E (1997)inMechanicalEngineering from PSG College of Technology, Coimbatore and M.E (1999) in Production Engineering from Annamalai University, Annamalai Nagar He obtained also the Ph.D. (2009) from Anna University, Chennai. He has published more than 50 Research papers in reputed peer reviewed International Journals and organized one National level conferenceatGCE,Dharmapurias a Convener and also he has published two books and four Book chapters Currently he is Supervisor of Two PhD scholars andfivealreadycompletedunder hisGuidance