International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Student, Civil Department, St. Joseph’s College of Engineering and Technology, Palai, Kerala, India Student, Civil Department, St. Joseph’s College of Engineering and Technology, Palai, Kerala, India Student, Civil Department, St. Joseph’s College of Engineering and Technology, Palai, Kerala, India Asst.Professor, Civil Department, St. Joseph’s College of Engineering and Technology, Palai ***

Abstract Concrete is a most widely used construction material around the world. This concrete based materials are very effective and easy to handle in all the ways. Concrete has excellent bonding property with coarse andfiner aggregate. Due to the excellent setting property of concrete, the strength of concrete can be achieved even in under water also. When compared to its compressive strength, the tensile strength of concrete is very low. Due to less tensile strength concrete fails in very less tensile loads. This problem of concrete can be overcome by reinforcing suitable materials. Steel rod is one of the commonly used reinforcing material in concrete technology. Reinforced rods in the concrete helps to improve the tensile strength of concrete. However, concrete is extremely brittle, rigid and very stiff, due to this character of concrete it allows the formation of cracks on it. The main weakness of the concrete is their crack formation. The cracks generally propagated on the concrete when it subjected to loads and stress. The cracking behavior of the concrete needs to be overcome.

Fibre reinforced concrete is a best way to reduce the formation of cracks in concrete. Fibres in the concrete help to prevent the cracks and enhance the mechanical properties of concrete. This project discusses about the effects of adding glass and bamboo fibres in the concrete. The glass and bamboo fibres has high strength and higher potential to control the cracks. The certain percentage of fibres in the concrete greatly improves the strength parameters of the concrete, but excess of fibres in the concrete may cause adverse effects. Bamboo fibre is used to replace the usage of synthetic and glass fibres. Bamboo fibres are easily available, bio degradable and renewable. The combination of glass and bamboo fibres in the concrete improves the concrete property and reduce the overall cost of the construction.

In this study, the concrete of M30 grade with mix proportion of 1: 2 .037: 3.44 is used. The compressive, split tensile and flexural strength tests are conductedto analyze the performance of pure concrete and concrete with glass and bamboo fibres. The volume of fibre is used as 1% to the weight of cement. All the bamboo fibres treated with suitable chemical to prevent the decay and to improve the strength.

The cube, cylindrical and beam specimens are casted to conduct the compressive, split tensile and flexural strength tests respectively. All the structures are tested after 28 days of curing.

The experimental result clearly indicates that the strength of fibre reinforced concrete is better than the pure concrete. The maximum strength of concrete is gained in 1% fibre weight content with the mix proportion of 75% glass and 25% bamboo fibres, therefore 1% fibre weight and 75 25 mix proportion of glass and bamboo fibre is taken as optimal. Taguchi optimization method is used to find the optimal variable influence the result. Performance analysis of concrete using Etabs is also conducted.

Key Words: FRC, Taguchi method, Bamboo fibre reinforced concrete, Glass fibre reinforced concrete, Comparison of PCC and FRC

Concrete is one of the most widely used construction material in the world. Now a day’s the Concrete is used widely as construction material for the various types of buildingandstructuresduetoitswelldurability.Foralong span it was considered to be a durable and sustainable material which requires less maintenance during its life span.Concreteplaysaveryimportantroleforachievinghigh strengthatearlyageoftimetofulfilltherequirementofthe structures. The less and endurable life of conventional concrete under the different types of climatic conditions conventionalconcretepossessesmajordeficiencieslikelow bond strength, low tensile strength high permeability and also develop more cracks. Concrete is an adaptable constructionmaterialusedallaroundtheworld.

Fibres are commercially available and it is manufactured from steel, plastic, glass, cores and other natural materials. Steel fibres can be defined as discrete, shortlengthofsteelhavingratioofitslengthtodiameteris calledaspectratiointherangeof20to100withanyofthe severalcross sections,andthataresufficientlysmalltobe easilyandrandomlydispersedinfreshconcretemixusing

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

conventional mixing procedure. The random distribution resultsin a loss ofefficiency ascompared toconventional rebars,butthecloselyspacedfibresimprovetoughnessand tensilepropertiesofconcreteandhelptocontrolcracking. FibreReinforcedConcrete(FRC)isdefinedasacomposite material essentially consisting of steel fibres, cement, aggregates and water in conventional concrete or mortar. Althoughreinforcingbrittlematerialswithfibresisanold concept,moderndayuseoffibres inconcreteisonlystarted in the early 1960s onwards. Realizing the improved propertiesofthefiberreinforcedconcreteproducts,further research,developmentandinnovationsonfiberreinforced concretehasbeeninitiatedsincethelastthreedecades.

Bambooisoneoftheoldestbuildingmaterialsused bymankind.Thebambooculmsorstemhasbeenmadeinto an extended diversity of products ranging from domestic house hold products to industrial applications. In Asia bambooisquiteforbridgesscaffoldingandhousing,butitis usually temporary exterior structural material. In many overly populated regions of the tropics certain bamboo supplies,theonesuitablemateriali.e.sufficientlycheapand plentiful. In response to global warming issues and sustainable society, the manufacturing using natural material has become actively in developing countries. Bambooislowcost,fastgrowingandbroaddistributionof growthisexpectedtocontributesignificantlyinearthquake resistantconstructionandseismicretrofittechnology.

These fibres will provides the various mechanical properties and design applications. Different parameters such as water cement ratio, porosity, composite density, inter filler content, orientation and length, type of cure influence properties and behaviour of FRC as well as accuracyofproductionmethod.TheuseoffibreintheHigh Performance Concrete (HPC) class, being a class with extremely high mechanical performance, durability, workabilityandaesthetics,hasgainedmomentuminrecent years.

Glassfibrereinforcedconcrete(GFRC)isamaterial thatismakingasignificantcontributiontotheeconomics, technology and aesthetics of the construction industry worldwide for over 40 years. GFRC is one of the most versatile building materials available to architects and engineers.Comparedtotraditionalconcrete,ithascomplex properties because of its special structure. Different parameterssuchaswater cementratio,porosity,composite density, inter filler content, fibre content, orientation and length, type ofcure influencepropertiesand behaviour of GFRCaswellasaccuracyofproductionmethod[2 4].GFRC can be produced as thin as 6 mm so their İskender, M., Karasu,B.ECJSE2018(1)136 162137weightismuchless thantraditionalpre castconcreteproducts.Progressingof 3D printingtechnologywithglassfibrereinforcedinkcan buildawholebuildingandcomplexarchitectureformswith highreliabilityaswellastheuseofpremix,spray up,hybrid methods of GFRC. Self cleaning environmentally friendly panelsforindustrialconstructionhavebeencontributingto the GFRC both in terms of cost and popularity. The use of glass fibre in the High Performance Concrete (HPC) class, beingaclasswithextremelyhighmechanicalperformance, durability, workability and aesthetics, has gained momentuminrecentyears.Thedesignandmanufactureof GFRCproductsiscoveredbyinternationalstandards,which have been developed in Europe, America, Asia and Australasia.GFRCismanufacturedinover100countries.

Tostudytheeffectofglassfibreandbamboofibre inconcrete.

To analyse the comparative performance of Fibre Reinforced Concrete (FRC) using experimental methodandTaguchimethod.

QualityimprovementofFRC.

1.4.

Experimentalstudieshavetobeconductedfor developingnewertypeofconcretewhichishaving

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

desirableproperties,sustainableaswellascost effective.

BambooandGlassFibreimprovetoughnessand tensilepropertiesofconcreteandhelptocontrol cracking

AdditionofmineraladmixtureslikeNaOHmakesthe concretemoredurableandalsoimprovesthe mechanicalpropertiesofhardenedconcrete.

Fibre reinforced concrete hasmore tensile strength whencomparedtonon reinforcedconcrete.Itincreasesthe concrete'sdurability.Itreducescrackgrowthandincreases impact strength. Fibre reinforced concrete improves resistanceagainstfreezingandthawing.Fibresareusually used in concrete to control plastic shrinkage crackingand dryingshrinkagecracking.Theyalsolowerthepermeability of concrete and thus reduce the bleeding of water. Some typesoffibresproducegreaterimpact,abrasionandshatter resistance in concrete. Reinforced concrete itself is a composite material, where the reinforcement acts as the strengthening fibre and the concrete as the matrix. It is therefore imperative that the behaviour under thermal stresses for the two materials be similar so that the differentialdeformationsofconcreteandthereinforcement areminimized.Theuniformdispersionoffibresthroughout theconcretemixprovidesisotropicpropertiesnotcommon to conventionally reinforced concrete. The applications of fibres in concrete industries depend on the designer and builder in taking advantage of the static and dynamic characteristicsofthisnewmaterial.Themainarea ofFRC applications are runway, aircraft parking and pavements, tunnel lining and slope stabilization, dams hydraulic structuresetc.

fireside treated with Noah (Khan et al 2017) to improve basic properties and limits their action with other substances. To attain high tensile property weak, amorphous, Hemi cellulose components are eliminated. Glassfibersarecreatedwiththecombinationofmaterials suchasSiO,ALLO,CaO.B,O,etc.Theseglassfibreshavehigh density and cost than bamboo fibers. These materials are non recyclableandnon renewable.

Concrete mix is created by utilizing ordinary Portland cement with 53grade and designation of M30 grade. Maximum size of 20mm stone chips is used as coarse aggregate and local sand materials are used as the fine aggregate.Watercementratioofconcretemixis0.40and mix proportion is 1:2.037:3.44 by volume the glass and bamboofiberratioof75:25with1%fibercontentbyweight of cement fraction were used. Usage of water reduced by addingthesuperplasticizermaterials.Theseconcretemixes are casted in various molds for developing the concrete structures.Cylindrical,cubicandbeamshapedstructuresare created for testing. The ratio between water, cement, fine aggregate,andcoarseaggregatestakenare0.4:1:2.037:3.44. The cement and water are taken as 350,140 Kg/m respectively.Differentstructureshapesaremoldedusingthe preparedconcretemix.

The cylindrical shaped specimens are mainly created for split tensile testing. The concrete mix poured in to a cylindricalmoldsof150mmdiameterand500mmheight. Themoldedcylindricalconcretestructuresarekeptinwet place and de molded after 24 hours. These concrete structuresaresubmergedinopenwatertankforcuringup to28days.

The concrete mix poured in to a cubical mold of 150mmxI50mmx150mm. After the creation process, the concretestructuresarede moldedat24hoursofcuring.The cubic specimensarethensubmergedintothe waterfor a curingof28days.

Thepreparationofconcreteandpreparationofvariousfiber materials are discussed in the experimental design phase. The bamboo fibers are extracted from bamboo and glass fibers from glass. After collecting the bamboo fibers this

Theconcretemixispouredintoabeamshapedmold.After thecreationprocess.Theconcretestructuresarede molded at24hoursofcuring.Inthisexperimentation,mainlythree dimensionsofconcretebeamsarecreated.ThebeamBI,B2, B3arecastedwiththedimensionsof230mmx300mx1200 mm,230mmx350mx1200mmand230mmx400mmx1200 mm respectively. The beam shaped structures are mainly createdforflexuralstrengthtest.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page17

Fig2.1CrackingofNon ReinforcedConcreteFig

After24hoursofcasting,thesampleswere demouldedandplacedinthecuringtankfor28days. Figureshowscuringtankanddemouldedspecimensfor 28daycuring.

4.1.

Compression strengthis the capacity of a material or structure to withstand loads tending to reduce size, as opposedtotensilestrength.Thetestwasconductedtofind compressivestrengthofconcreteasperIS516:1959.The curing specimen were taken out and surface was cleaned anddryfor6hours. ThestrengthisexpressedinN/mm2 The specimen (150X150X150) were tested by using compression testing machine of 2000KN capacity. The testing of cubes in the compression testing machine are shown in fig 4.5. The compressive strength at failure is calculatedusingthefollowingequation.

Compressive strength N/mm2 =

Fig4.5Compressiontestingmachine

Thesplittingtensilestrengthtestareconductedto determine Splitting tensile strength of concrete as per IS 516:1959.Fordifferentpercentagereplacementsofclinker bricksof 10% .15% and 20%concretesofthreecylinders werecastedandsplittingtensilestrengthtestwascarried out.

Thecylinderofsize150X300mmwascastedand cured for 14 days and specimen was tested after surface drying.Thespecimenwereplacedinthecompressiontesting machineandplacepackingstripsmadeupofplywoodalong withspecimenonbothtopandbottom.Theloadwasapplied andincreasecontinuously,tillthespecimenbreakswithout shock.Untilfailuretheappliedloadwasnoted.

Thesplittingtensilestrengthofthespecimenwas calculatedusingthefollowingformula: T= Where,

T=Splittingtensilestrength

P=maximumappliedload

D=Diameterofcylinder

L=LengthofCylinder

The standard size of beams used here was 150X150X500mm.Thespecimenswascastedandcuredfor 28daysandswipeoutwaterbeforetesting.Thespecimen wereplacedinthemachinesuchawaythattheloadapplied along two lines spaced 200 mm apart. The beams are supportedoveraneffectivespanof400mmandtested in load testing machine by applying two point load along its length.Theloadwasappliedandincreasecontinuouslyuntil failure and the maximum load applied to the specimen duringthetestwerenoted.Thefollowingequationisusedto calculatetheflexuralstrengthofthespecimen:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

F=

F=Modulusofrupture

P=Maximumloadapplied

L=Lengthofspecimen

B=Widthofspecimen

D=Depthofspecimen

Fig4.6Flexuralstrengthtestmachinesetup

The compressive tests are carried out for all specimenswithatotaloftwenty eightdaysandwhichare givenintable4.1and2.Inthecompleteconcrete,thefibre contents are added as 1% . In this, the fibre reinforced concrete cubes are designed for glass to bamboo ratio of 75:25 . For pure concrete (without reinforcement), the maximumcompressivestrengthof34.08N/mm2isattained after28days.Besides,thecompressivestrengthisminimum forthewithoutreinforcementinconcrete.Whenusing1%of fibre content in the overall concrete the maximum compressivestrengthisgainedwitharateof42.08N/mm2 .

Specimens Weight (Kg) Compressive Strength(N/mm^2)

Cube 1 7.56 32.57

Cube 2 8.10 34.08

Cube 3 8.2 32.16

Table4.1

Specimens Weight (Kg) Strength(N/mm^2)

Cube 1 8.59 40.36

Cube 2 8.7 42.08

Cube 3 8.46 41.01

Table4.2

TheresultsofSplitTensileStrengtharegivenin Table 4.3 and 4.4 . In this, the fibre reinforced concrete cylinders are casted with glass to bamboo ratio of 75:25 with 1 % of fibre content. Besides, the tensile strength is minimumforthewithoutreinforcementinconcrete.When using 0% of fibre content (pure concrete) in the overall concrete the split tensile strength is gained with a rate of 3.41N/mm2.Themaximumtensilerateisgainedfor75%of glassand25%ofbambooas4.13N/mm2

Specimens Weight (Kg) Compressive Strength(N/mm^2)

Cylinder 1 12.89 3.36

Cylinder 2 12.98 3.41 Cylinder 3 13.01 3.45

Table4.3

Specimens Weight (Kg) Tensile Strength(N/mm^2)

Cylinder 1 13.27 4.26

Cylinder 2 13.66 4.13 Cylinder 3 13.17 4.19

Table4.4

Table4.5and4.6showstheFlexuralStrengthof M30GradeHFRCprisms.Theanalysisofflexuralstrength,a concretebeamwiththeabsenceofreinforcementprovides theminimal valueofflexural strength whencomparedto the glass and bamboo fibre reinforced concrete. The maximum flexural strength achieved from the concrete without reinforcement is 6.7. At the same time, 7.28 of flexuralstrengthisgainedfromthereinforcedconcretewith 75% of glass fibres and 25% of bamboo fibres at 1% by weightofcement.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Specimens Flexural Strength(N/mm^2)

Beam 1 6.4

Beam 2 6.7 Beam 3 6.6 Table4.5

Specimens Flexural Strength(N/mm^2)

Beam 1 7.22

Beam 2 7.28 Beam 3 7.26 Table4.6

It has been noticed from the above laboratory experiments that the highest compressive intensity is achievedwith1percentglassfibrecontent:75:25%bamboo fibre.Theintensityisobservedtodecreasemoreinthefibre material. And the optimal quality of fibres is found as 1 percentamongwhich75percentofglassand25percentof bamboo are contained. Since glass and bamboo hybridization(75 25percent),theblendgivesanimproved solution to arrest micro and macro fractures, thereby increasingtheconcrete'scompressivestrengthrelativeto pure concrete and every other variation of hybridization ratio.

Theaveragesplittensilestrengthisachievedbyweight of1%cementmaterial,inwhich75%glassfibreand25% bamboofibreareproduced.Thesplittensilestrengthofthe managed experiment is observed to be smaller than for strengthenedconcreteconstructedfromsyntheticmaterial. Theimprovementinresistancetobreaktensileduetoglass fibre integration is higher than bamboo fibre. Large glass fibre elasticity module renders concrete more ductile. Ductile content friction strength is stronger than brittle substances.

Concreteflexuralpowerimproveswiththeapplication of fibre to material. The flexural intensity of all managed experimentsofhybridizedconcretewasfoundtobesmaller thanthat.

TaguchimethodwasdevelopedbyDr.Taguchiof NipponTelephonesandTelegraphCompany,Japanbasedon orthogonalarraywhichgivesmuchreducedvarianceforthe experiment with optimum setting of control parameters. Taguchiexperimentminimizethevariationsinoutputeven thoughnoiseispresent.ThroughtheTaguchioptimization

methods,theoptimumfactorsareaffectingtheperformance can be easily determined. Taguchi method treats optimizationproblemsintwocategories.

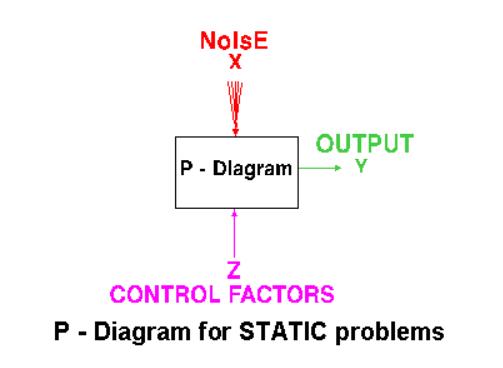

Generally, a process to be optimized has several control factorswhichdirectlydecidethetargetordesiredvalueof theoutput.Theoptimizationtheninvolvesdeterminingthe bestcontrolfactorlevelssothattheoutputisatthetarget value.Suchaproblemiscalledasa"STATICPROBLEM".

ThisisbestexplainedusingaP Diagramwhichisshown("P" standsforProcessorProduct).Noiseisshowntobepresent intheprocessbutshouldhavenoeffectontheoutput!This istheprimaryaimoftheTaguchiexperiments tominimize variations in output even though noise is present in the process.TheprocessisthensaidtohavebecomeROBUST.

There are 3 Signal to Noise ratios of common interest for optimizationofStaticProblems:

(I)SMALLER THE BETTER: n= 10Log10 [meanofsumofsquaresofmeasureddata]

(II)LARGER THE BETTER: n = 10 Log10 [mean of sum squares of reciprocal of measureddata]

(III)NOMINAL THE BEST: squareofmean n=10Log10 variance

Figure 5.1: DiagramforStaticProblems

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

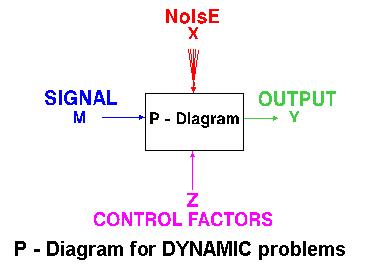

Intheseproblemssignalinputdirectlydecidesthe output.Thedesiredvalueisobtainedbyinput/outputratio. SuchaproblemiscalledDynamicproblem.

The application of Taguchi is extended in various designs such as tolerance design, parameter design, and system design.TheTaguchioptimizationisperformedbymeansof theSNratio,whichprovidestheoptimalcontrolpoints.The SNratioisknownasSignaltoNoiseratio.TheSNratiocan becalculatedusingthreeformulas,whichareselectedbased ontheobjective.Theformulasusedonthreecharacteristics likesmallerisbetter(12),largerisbetter(13)andnominal thebest(14)(Pradhan et al 2019).

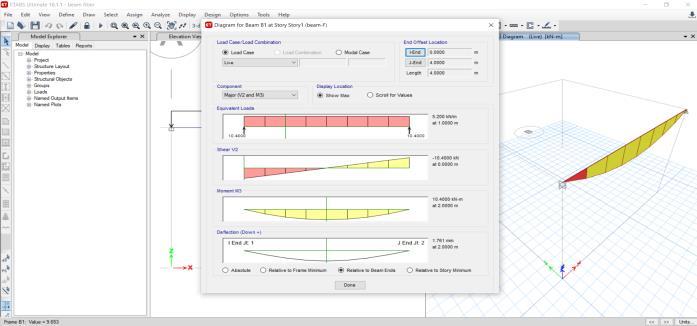

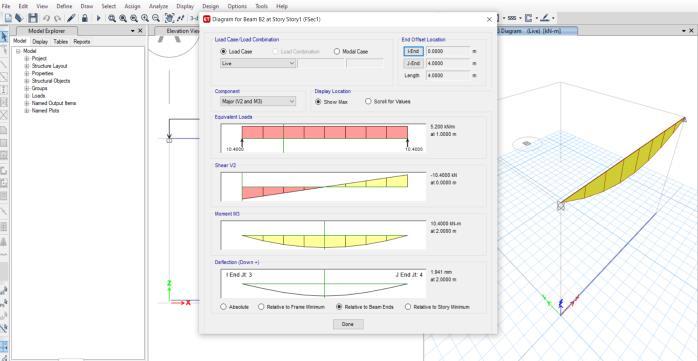

ETABS is an engineering software product that caterstomulti storybuildinganalysisanddesign.Modeling toolsandtemplates,code basedloadprescriptions,analysis methods and solution techniques, all coordinate with the grid likegeometryuniquetothisclassofstructure.Basicor advancedsystemsunderstaticordynamicconditionsmay beevaluatedusingETABS.

ETABS software is used for the analysis of beams andcolumns.Itishighlyacclaimedforstaticanddynamic analysisofmulti storeyframeandshearwallbuildings.

6.1. PCC

Figure 5.2: DiagramforDynamicProblems

SN ratio for Compressive Strength of concrete with 7 days curing

SN ratio for Compressive Strength of concrete with 28 days curing

Split Tensile Strength

Level Glass Bamboo Glass Bamboo Glass Bamboo

1 25.93 25.93 34.08 34.08 34.10 34.10

2 26.15 26.53 36.93 42.08 36.60 41.30 3 25.71 25.39 34.30 41.21 38.30 38.30 4 25.92 25.95 35.10 38.64 41.30 36.60 5 26.14 25.95 39.67 37.10

6 26.14 25.58 36.40 36.40 7 25.39 25.71 41.21 34.40 8 25.58 25.53 39.20 32.12 Delta 0.76 1.14 7.13 996 0.720 0.720 Rank 2 1 2 1 15 15

6.2.FRC

1. S.NRamaswamyandAnceMathew. Propertiesof Concrete Incorporating Bamboo and Glass Fiber. International Journal of Civil Engineering and Technology,8(7),2017,pp.613 619.

2. Durgesh Kumar Gupta and R. C. Singh. An ExperimentalEvaluationofCompressiveStrength andFlexuralStrengthofBambooFiberReinforced Concrete. International Research Journal of EngineeringandTechnology(IRJET),Volume:05 Issue:09|2018.

3. M. Muthukannan, Ance Mathew. ApplicationsOf Fibre Reinforced Concrete .Palarch’s Journal Of

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

ArchaeologyOfEgypt/Egyptology17(9).ISSN1567 214x,(2020).

4. J.D.Chaitanya kumar, G.V.S. Abhilash, P.Khasim Khan, G.Manikanta sai , V.Taraka ram. Experimental Studies on Glass Fiber Concrete. AmericanJournalofEngineeringResearch(AJER). Volume 5,Issue 5,pp 100 104,2017.

5. Hector Archila . Sebastian Kaminski . David Trujillo . Edwin Zea Escamilla . Kent A. Harries. Bamboo reinforced concrete: a critical review. MaterialsandStructures(2018)51:102

6. Tarun Kumar. Glass Fibre Reinforced Concrete: Design&Analysis.IJRDO JournalOfMechanicalAnd Civil Engineering, Volume 2 | Issue 5 | 2019 | Paper 5.

7. Chandramouli K., Srinivasa Rao P. , Pannirselvam N. , Seshadri Sekhar T. and Sravana P. Strength Properties of Glass Fiber Concrete.ARPNJournalofEngineeringandApplied Sciences.Vol.5,No.4,April2017.

8. Shadheer Ahamed M, Ravichandran.P , Krishnaraja.A.R. Natural Fibers in Concrete A Review.IOPPublishing.1055(2021).

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal