International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Kavya. B1 , Dr. D. Ramesh2

1Student, Department of Industrial Engineering and Management, SSIT, Tumakuru, Karnataka, 2Dr. D. Ramesh, Professor, Dept. of IEM, SSIT, Tumakuru, Karnataka, ***

Abstract – Metal Matrix composites based on aluminum were developed for light weight applications particularly in aerospace and automobiles sector. The present work deals with the development and characterizationofAluminumalloy 7050 matrix composite reinforced with Titanium Oxideof6%. Stir casting process were adopted for fabricating the composite. The mechanicalpropertiessuchashardness, tensile strength, compression strength and microstructure will be studied and compared with those of base alloy.

Key Words: MetalMatrixComposite,Aluminiumalloy7050, Titanium Dioxide, Stir Casting, Hardness, Compression Strength,TensileStrength,MicrostructureBehaviour.

MetalMatrixComposite(MMC)iswidelyusedinindustryto make appropriate changes in the properties of the base metal. Metal matrix composites have a high application potential in automotive engineering in braking systems, pistonrods,pistonpins,pistons,frames,valvespringcaps, brakediscs,discbrakecaliper,brakepads,cardashaftetc. They have also found application in military and civil aviationintheareaofaxletubes,reinforcements,bladeand gearboxcasing,turbine,fan,andcompressorblades.Inthe aerospace industry MMCs have been applied in frames, reinforcements,aerials,joiningelementsetc.Al basedmetal matrixcomposites(MMCs)arewell known for theirhigh specific strength, hardness, and attractive tribological properties.

Aluminum metal matrix composites significantly enhanced the mechanical properties compared to the unreinforcedaluminumalloys.Thereasonforpreferringthe aluminumcompositebecauseofitsavailability,ithashigh toughness, strong mechanical strength, and good stress corrosion cracking resistance. AMMC’s strength can be reduced at high temperatures. Aluminiummetal matrix compositeshave potential demand in various structural applicationssuchasaerospace,construction,automobiledue to their remarkable characteristics in comparison with conventionalalloys.Al7050iswidelyusedandsuitablealloy among the Al 7xxx series for transportation applications. The physical, mechanical, tribological and microstructure characteristicsofAl7050metalmatrixcanstillbeimproved with the addition of suitable reinforcing materials.

Aluminum used in mainly in automotive and aerospace industriessotheyneedlessweightmorestrength.

Various reinforcements are used in aluminum compositematerialssuchassiliconcarbide,aluminumoxide, boroncarbide,graphene,graphiteetc.,Titaniumoxidewas found to be most effective in enhancing the strength properties of Aluminum when incorporated via ingot metallurgy process. Titanium Oxide has the excellent mechanical characteristics cause a great potential in strengthening elements in polymer, ceramic and metal matrixcompositesforfunctionalandstructuralapplications. To alter the mechanical properties of aluminum such as tensile,hardnessetc.byaddingreinforcementsuchthatdue tothataddedmaterialwegetthedesiredproperties.

Al 7050 is selected as the base material because of its availabilityandmechanicalproperties.Thecompositionand thepropertiesareexplainedinthefollowingtable.

Table 1: Chemical Composition of Al 7050

Element Content %

Aluminium,Al 89 Copper,Cu 2.3 Magnesium,Mg 2.3 Zinc,Zn 6.2 Zirconium,Zr 0.12

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page544

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Properties Metric

Density 2.6 2.8g/cm3

Meltingpoint 494℃

Tensilestrength 515MPa Yieldstrength 455MPa

Fatiguestrength 240MPa Elasticmodulus 70 80GPa Elongation 11% Thermalconductivity 180W/mK

TitaniumDioxide,alsoknownastitaniumoxideorTitania,it is the naturally occurring oxide of titanium, chemical formulaTiO2 Whenusedasapigment,itiscalledtitanium white,PigmentWhiteorCI77891.Titaniumdioxidehasthe grainsizeof25µm.thevariousapplicationsoftitaniumoxide areitexhibitsgoodphotocatalyticproperties,henceusedin antiseptic and antibacterial compositions. It is used for manufacturing of printing ink, self cleaning ceramics and glass, coating etc. Making of cosmetic products such as sunscreencream,morningandnightcream,skinmilks,etc. used in the paper industry for improving the capacity of paper. Thepropertiesareexplainedinthefollowingtable.

andstartsmeltingatthetemperatureupto800℃where the Al 7050 is in liquid molten state.

TheAl70503hoursformeltingwhilethetitanium oxideisweighedaccordingtotheAl7050billetweights.The temperature of crucible is maintained around 950℃ , the speedismaintainedaround380 400rpm.TheDe gassing tabletisaddedtominimizetheoxideformationduringthe process.Thepreheatedreinforcement(6%wtTiO2)upto 450℃is added by pouring slowly into the crucible and stirred for 15 20 mins. The stirred is removed and the temperatureisincreased. Thepreheatedmoldiskeptready forpouringthemoltencomposition,themoltencomposition is stirred for 5 10 mins then poured into the mold and allowedtosolidify.Thenthemoldisdisassembledtoobtain theAluminiumMetalMatrixComposite.

3.1 Tensile Strength: Tensile strength, maximum load that a material can support without fracture when being stretched,dividedbytheoriginalcross sectionalareaofthe material. When stresses less than the tensile strength are removed,amaterialreturnseithercompletelyorpartiallyto itsoriginalshapeandsize.ThetensilespecimenofAMMC’s is machined as per ASTM E8 16a standards and tested throughUniversaltestingMachine(UTMTUE C 600)

ThestircastingmethodwasusedforMMCofAl7050alloy andthereinforcementparticle.Thematerialsarepreheated to a temperature near to that of the main process temperature. The purpose of preheating is to remove the water vapor and other contaminants present in the metal powders.

Thefurnacetemperatureismaintainedaround700 750℃andthepreheatedAl7050around600 800℃.Atthis temperaturetheAl7050alloyisplacedinsidethecrucible

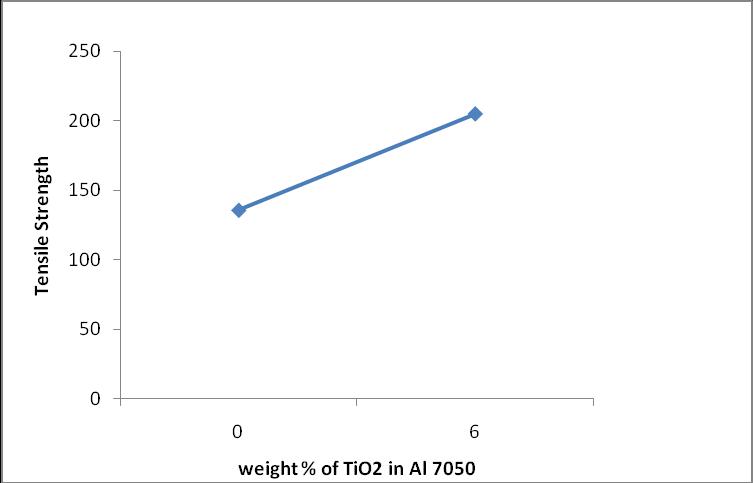

Fig-1 Ultimate tensile strength of Al 7050 reinforced with 0 and 6 % TiO2

ThetensilestrengthofAl7050andcompositewith0and6 wt%TiO2areillustratedinFig 1.Fromthefigitisseenthat theAl7050 6%TiO2 compositehasincreaseinthetensile strengthas204.90N/mm2.Thecompositematerialhasthe highertensilestrengththanAlalloy7050.

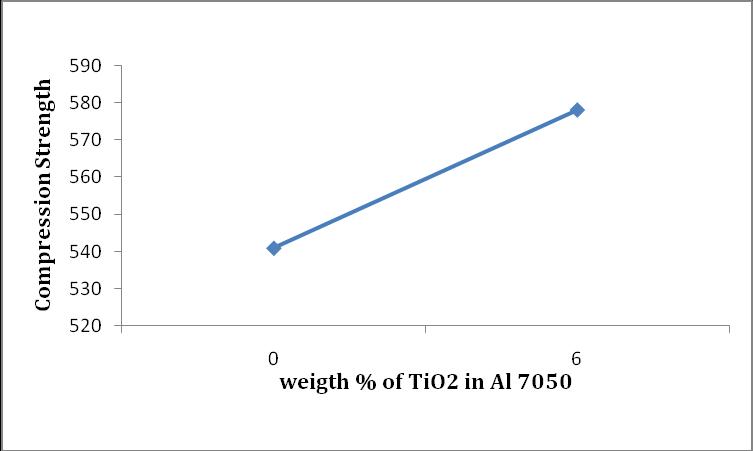

3.2 Compression strength: Compressiontestsarealso used to determine themodulus of elasticity, proportional limit,compressiveyieldpoint,compressiveyieldstrength,

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page545

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

andcompressivestrength.Thesepropertiesareimportantto determineifthematerialissuitedforspecificapplications.

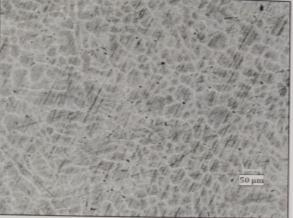

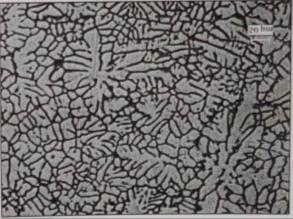

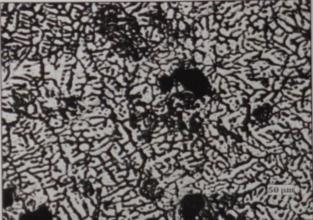

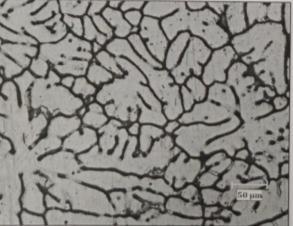

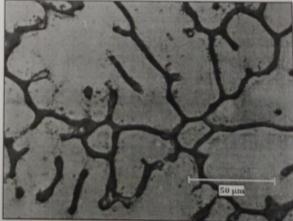

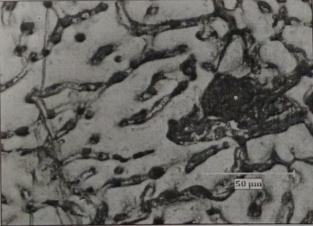

3.4 Microstructure: Microstructuretestarecarriedoutto investigate of distribution of the titanium oxide in the development of AMMC’s. Samples having different weight percentageofreinforcementsareexamined.Thesmallpieces ofcutspecimensasperstandardmetallographweretaken andgrindingthroughgrind wheelsandtogetfinesurface finish.Aseriesofemerypaperswithgritsizesvaryingfrom 400mto1500mwereused.

Fig 2 Compression strength of Al 7050 reinforced with 0 and 6 % TiO2

TheCompressionstrengthofAl7050andcompositewith0 and 6 wt% TiO2 are illustrated in Fig 2. The test result showedthatthematerialcanwithstandthehigherloadand has578.08N/mm2 valueofcompressionstrengththanthe baseAlalloy.

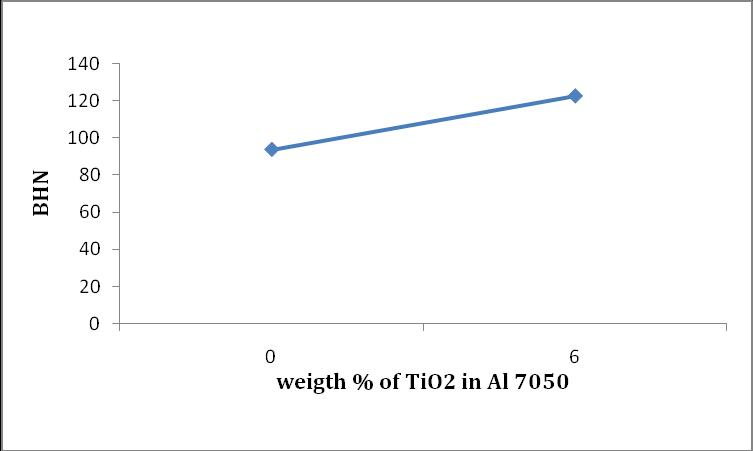

3.3 Hardness: Hardnessistheabilityofamaterialtoresist deformation. The specimen is prepared as per ASTM E10 standards, HBW 250 Brinell was used for testing of specimens.Aloadof250Kgfwasappliedwiththesteelball indenter of 5mm diameter. The test was carried out at different locations to know the effect of indenter on the harderparticles.Hardnesswasdeterminedbymeasuringthe indentationsdiameterproduced.

The Fig 3 shows the Hardness of Al 7050 and composite with 0 and 6 wt% of TiO2 . The hardness value increased comparedtothebaseAlalloy,threeindentationsisdonethe material and higher value i.e.122.6 is considered as the hardnessvalueofthecomposite.

Fig 3 Hardness of Al 7050 reinforced with 0 and 6 % TiO2

Fig microstructure behavior of Al alloy 7050 With 6% of TiO2

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page546

Themicrostructureimagesfor0and6wt%ofcompositions composite material are taken with 100X and 500 X magnifications. It is clearlyknown from the above images that there is an improvement in its structure and the reinforcement causes close bonding and uniform distributionofTiO2 particlescanalsobeseeninthismicro structuralview.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

ThemechanicalpropertiesoftheAMMC’srevealsthatthere isincreaseinpropertieslikehardnessandtensilestrength andincompressionstrength.Microstructuregraphreveals uniformdistributionofTiO2 particles. ItisconcludedthatcompositeAl 7050 and6%wtof TiO2 indicatesbetterTensilestrengthandHardnesscomparedto 0%wt

1. T.Sathish,S.Karthick,“WearBehaviorAnalysison Aluminium Alloy 7050 with Reinforcement SiC Through Taguchi Approach” Journal of Materials Research and Technology, vol 9 issue 3, 2020, pp 3481 3487.

2. A.Brotzu,G.Delellis,F.FelliandD.Pilone“Studyof DefectFormationinAl7050Alloys” ElsevierB.V, Volume3,2017,pp246 252.

3. A. Chennakeshava Reddy “Stir Casting Process on Porosity Development and Micromechanical Properties of AA 5050 / Titanium Oxide Metal Matrix Composites”, 5th National Confress on MaterialsandManufacturingProcesses,Hyderabad, 2006,pp144 148.

4. Palukuri. Veerendra, M.Deepak, M “Evaluation of MechanicalPropertiesandMicroStructuralstudyof AA 7050 Reinforced with SiC Metal Matrix Composite”InternationalJournalofResearchISSN: Vol6,No13(2019)pp514 530

5. G.S. Kataiah, Dr.D.P.Girish “The Mechanical PropertiesofAluminium6061 TiO2Composites” International Journal of Innovative Research and Development(SpecialIssue)volumeno.5,2016.

6. Himanshu Kala, K.K.S Mer, Sandeep Kumar, “A ReviewonMechanicalandTribologicalBehaviorsof Stir Cast Aluminium Matrix Composites”, Science direct,2014,pp.1951 1960.

7. G.SivakarunaandDr.P.SureshBabu,“ASurveyon Effects of Reinforcement on Aluminium Metal Matrix Composites”, International Journal of Mechanical Engineering and Technology (IJMET), volumeno.8,2017pp.112 131.

8. S.Das,S.Das,K.Das,“RETRACTED:AbrasiveWear ofZirconSandandAluminaReinforcedAl 4.5Wt% CuAlloyMatrixComposites AComparativeStudy”, CompositesScienceandTechnology.2007,pp746 751.

9. A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Benedictus,andW.Miller,“RecentDevelopmentIn Aluminium Alloys For Aerospace Applications”, Mater.Sci.Eng.A,280(1),2000,pp.102 107.

10.V.KavimaniK.SooryaPrakashTitusThankachan R. Udayakumar “Synergistic Improvement of Epoxy Derived Polymer Composites Reinforced with GrapheneOxide(GO)PlusTitaniumdiOxide(TiO2)” Sciencedirect,Volume191,15June2020.

11.M. Asif, K. Chandra, P.S. Misra. “Development of AluminiumBasedHybridMetalMatrixComposites forHeavyDutyApplications”JournalofMinerals& MaterialsCharacterization&Engineering,Vol.10, No.14,2011,pp.1337 1344.

12.SharifiEM,KarimzadehF,EnayatiMH.“Fabrication and Evaluation of Mechanical and Tribological PropertiesofBoronCarbideReinforcedAluminium MatrixNanoComposites”MaterDes,Vol.32,2011, pp:3263 71.

13.B.VijayaRamnath,C.Elanchezhian,M.Jaivignesh,S. Rajesh, C. Parswajinan, “Evaluation of Mechanical Properties of Aluminium Alloy Alumina Boron Carbide Metal Matrix Composites”, Materials and Design”Vol.58,pp:332 338,2014

14.Abhishek Kumar, Shyam Lal, Sudhir Kumar, “Fabrication and Characterization of A359/Al2O3 MetalMatrixCompositeUsingElectromagneticStir CastingMethod”,Journalofmaterialsresearchand technology2(3)(2013)25 254.

15.M.MahendraBoopathi,K.Arulshri,NandIyandurai, “EvaluationOfMechanicalPropertiesOfAluminium Alloy2024ReinforcedWithSiliconCarbideAndFly AshHybridMetalMatrixComposites”,Am.J.Appl. Sci.,10(3),2013pp.219 229.

16.Jenix Rino J., Chandramohan D., Sucitharan K.S. (2012) “An Overview on Development of Aluminium Metal Matrix Composites with Hybrid Reinforcement”, International Journal of Science andResearch(IJSR).

17.Mohit Kumar Sahu., Raj Kumar Sahu (2018) “FabricationofAluminumMatrixCompositesbyStir CastingTechniqueandStirringProcessParameters Optimization”,Selectionofourbooksindexedinthe Book Citation Index in Web of Science™ Core Collection(BKCI).

18.Arun Kumar Sharma, Rakesh Bhandari, Amit Aherwar , Camelia Pinca Bretotean (2020) “A study of fabrication methods of aluminum based

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page547

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

composites focused on stir casting process” MaterialsToday:Proceedings.

19.C.S.Ramesh,A.R.AnwarKhan,N.Ravikumar,P.Sa vanprabhu, “Prediction of Wear Coefficient of Al6061 TiO2 Composites”, Wear 259 (2005), pp 602 608.

20.C. M. Ward Close, L. Chandrasekaran, J. G. Robertson, S. P. Godfrey and D. P. Murgatroyde, “Advances in the Fabrication of Titanium Metal Matrix Composite”, Materials Science and EngineeringA,Vol.263,No.2,1999,pp.314 318

Kavya. B currently pursuing Master degree in Product Design and manufacturing from SSIT, Tumakuru.

Dr.D.RameshworkingasProfessor inDeptofIEM,SSIT,Tumkuru.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page548