International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

2

3

Abstract The use of Nano silica as an additive material in manufacturing concreteisanewtechnology. Testshaveshown that this material enhances the mechanical properties of hardened concrete. The addition of this material increases density, reduces porosity and bleeding, and improvesthebond between cement matrix and aggregates. Thus, some concrete with high compressive strengths can be produced when using Nano silica. Pertaining to the shear failure of concrete members, it is well known that when principal tensile stresses exceed the tensile strength of concrete, diagonal cracks occur in the shear span. Some of the existing reinforced concrete structures may require strengthening or repairingtoincrease their structural performance. It has been reinforced using an internal epoxy injection, where epoxy is used as a strong material with high pressure strength and high cohesion with concrete. This study presents shear behavior of reinforced concrete beams contained nano silica and strengthening by epoxy injection. Different concrete mixtures were using nano silica (0,2, 4, 6%) and different cement content to obtain concrete compressive strength of 30, 45, 60 Mpa. Eight mixes were used to inspect concrete beams. Beams were strengthening by internally injected epoxy in shear zone. Through this study, it is found that beams with 4% nanosilica, showed the best results in terms of ultimate load and ductility. The use of injected kemapoxy103 increased the ultimate load and absorbed energy significant in most case. The results showed that the injection of Kemapoxy 103 increased the ultimate load and absorbed energy up to 7.4% and 38.6%, respectively.

***

inappropriate design, construction faults, or extreme environmentalconditions.Cracksmayrepresenttheentire extent of damage, or they may suggest larger difficulties. Theymayindicatejust,ortheymaysignifyseriousstructural distressorlackofdurability.Itssignificanceisdetermined onthetypeofstructureandthenatureofthecrack.Various methodsforadjustingcracksinreinforcedconcretebeams. [1]Topatchholesinastructure,youwillneedafixthatis bothelastomericandchemicallyresistant.Thegoalofthis projectistostrengthenthegirderbymodifyingreinforced concretebeamsandimprovingtheirstrength.

Shear failure in concrete is known to be brittle and disastrous.Inusualstructuraldesign,shearisaccountedfor byprovidingshearreinforcementsuchasstirrupsinbeams, Sometimes the shear reinforcement may be less than sufficient if the loading configuration were different from thatpredictedduringdesign,suchasduringearthquakeorat critical section reinforcement conjunctions. Fibers are effectiveshearreinforcement,itsincreasedshearstrength andultimatelyresultsinductileflexurefailures.Pertaining totheshearfailureofconcretemembers,itiswell known that when principal tensile stresses exceed the tensile strengthofconcrete,diagonalcracksoccurintheshearspan. Theuseofdiscontinuous,randomlyorientedfibershaslong beenrecognizedtoprovidepost crackingtensilestrengthto concrete.[2]

Words: Nano silica; Epoxy injection; Shear strengthening;Ductility

Manyexistingconcretestructuresaroundtheworldarein desperateneedofrehabilitation,rebuilding,andrepairdue todeteriorationcausedbyvariousfactorssuchascorrosion, failure of bonding between joints of girder columns, increasedserviceloads,andsoon.Whichleadstocracking, andthelossofstrength,skew,andsoon,thattheneedfor effectiverehabilitationandtechniquesofexistingconcrete structures led to structural strength research and development. Although most concrete structures have performedwellinrecentyears,severalissueshaveemerged becauseofpoormaterialquality,inaccuratespecifications,

Nanomaterials are fundamental to both nanoscience and nanotechnology.Nanostructurescienceandtechnologyisa broad and interdisciplinary field of research and developmentthathasexplodedinpopularityoverthelast fewyearsallovertheworld.Ithasthepotentialtotransform the way materials and products are made, as well as the varietyandkindoffunctionsavailable.Italreadyhasalarge commercialinfluence,whichwillundoubtedlygrowingthe future.[3]

Nano silicahasagreatimpactonthemechanicalproperties ofconcrete.Theadditionofthismaterialincreasesdensity, reduces porosity and bleeding, and improves the bond betweencementmatrixandaggregates.Thus,someconcrete with high compressive and flexural strengths can be producedwhenusingNano silica.[4]

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

AlGhabbanetal,conductedateston13prismstotestthe effectofusingNanosilicaonthemechanicalpropertiesand flowability of concrete. The main parameters were the changeincementcontentandtheNanosilicacontent(0%, 1%,2%,3%,and4%)intheconcretemix.Thetestresults concludedthattheoptimumpercentageofNanosilicainthe concretemixwas4%toachieveabetterperformance.[5]

Tavakoli et al, conducted a test on nine cubic molds and studiedtheeffectofNanosilicaonconcreteproperties,the test results also concluded that the best behavior was obtainedwiththeuseof4%Nanosilica,thenthemechanical propertiesloweredasthepercentageofNanosilicawasmore than4%.[6].Repairistheprocessofrestoringsomethingto itsoriginalstateafterithasbeendamaged,deteriorated,or broken. Damaged buildings are repaired to restore their strengthafteracalamity.[7]

The act or process of faithfully representing the form, characteristics,andcharacterofapropertyasitappearedat aspecificmomentinitshistorybyremovingfeaturesfrom previousperiodsandreconstructingmissingfeaturesfrom the restoration period. [8] H. Nikopour and M. Nehdi conductedatestonsixRCgirderstoseeifthereisaneffect, inject the FRP hybrid shear installation and the external epoxyintotheRCbeams.Thetestresultsconcludedthatthe Crack injection with low viscosity epoxy increased the stiffnessofallrepairedRCbeams.[9]

M. Venkata Rao et al, tested the reliability of concrete containing Nanolsilica. It was found that the use of 3% Nanosilica in concrete mix significantly increased the concrete resistance to cracks and permeability. However, increasingtheamountofNanosilicaaboveacertainlevelcan negativelyaffecttheconcreteperformance.[10].Rahuland Minipreparedafiniteelementmodeltotestepoxy,acrylic resinmodifiedmortar,hydrauliccement,andpolyurethane in crack controlling. The results exhibited that epoxy injected specimens can resist a considerably higher load thanothermaterials,howeverthespecimenshadabrittle behaviourinfailure.Unlikethepolyurethanewiththemost ductilebehavior.[11]

OrdinaryPortlandcementwasutilizedwiththegradeof42.5 N/mm2. The employed cement’s chemical and physical propertiesmeetEgyptianStandardSpecification(E.S.S.4756 1/2009)(CEMI42.5N).Finesandwithaspecificgravityof 2.55 t/m3 was used. Crushed gravel with a maximum nominal size of 10 mm, specific gravity 2.64, and volume weight1.567t/m3wereusedascoarseaggregates.In this study,SuperPlasticizers(AddicreteBVF)wasusedashigh rangewaterreducer.

Nano silica used in this study is a white powder with the properties,whichpresentedinTable1

Table 1: Nano silicaproperties

Diameter of particles (nm) Density (g/cm3) Specific Surface (m2/g) Purity Percentage 19 2.12 160 99.9

Kemapoxy103isaninjectionepoxyresinforconcretecracks thatcanfillthepathofcrackseveninthefurthestpoints.It consistsoftwopartsAandBwithamixingratioof2:1for partsA:B.Theinjectionoperationwasdonethroughspecial pipes(pipeline)carryingtheEPOXYfromthepumptothe concretespecimens.

Inthisexperimentalwork,eightmixeswereusedtoinspect concretebeams.Themixdesignandtestingprogramwere conductedin accordance withECP.Therequiredconcrete compressivestrengthinthisresearchwas30Mpa,45Mpa, and 60 Mpa. Mix proportion by weight (kg/m3) of fresh concreteisgiveninTable2

Table -2: Nano silicaproperties

Mix Cement Water Fine Agg Coarse Agg Silica Fume (7.5%)

Super Plasticizer (3%) Nano Silica Kg/m3

300 0% 270 135 657.4 1314.8 20.3 8.1 0

300 2% 270 135 656.1 1312.1 20.3 8.1 5.4

300 4% 270 135 654.7 1309.5 20.3 8.1 10.8

300 6% 270 135 653.4 1306.8 20.3 8.1 16.2

450 0% 369 140 625.2 1250.3 27.7 11.1 0

450 4% 369 140 621.6 1243.2 27.7 11.1 14.8

600 0% 467 150 593.2 1186.5 35.0 14.0 0.0

600 4% 467 150 588.6 1177.2 35.0 14.0 18.7

Experimental program was carried out to investigate the influenceandtheeffectofusingNano Silicaontheconcrete compressive strength to obtain the optimum percentage with respect to the 7 and 28 day compressive strength. Experimental tests were carried out on a total number of

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

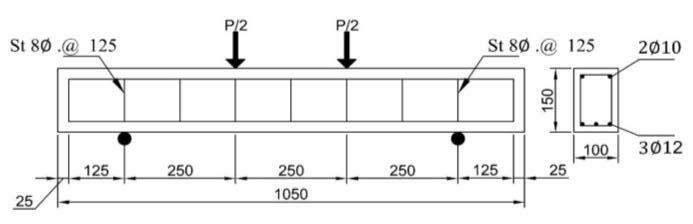

fourteenreinforcedconcretebeamsunderstaticloadingup tofailure.Thereinforcementofthetestedbeamswas3Φ12 atthebottomand2Φ10atthetopwithstirrupsofΦ8mm @125mmasshowninfigure1,andfigure2,table3

Fig 1:TestSpecimensofGroups(1,2,3) (Reinforcedconcretebeam)

otherhalfofthesuperplasticizerwasaddedtothemixfor1 minute,oruntiltheconcretemixturehasreachedthedesired consistency,thentheconcretemixwascastedinawooden formwork.Toobtainthepropertiesofhardenedconcrete,the samples were left for 24 hours before being covered with soakedcanvasandcuredfor28days.

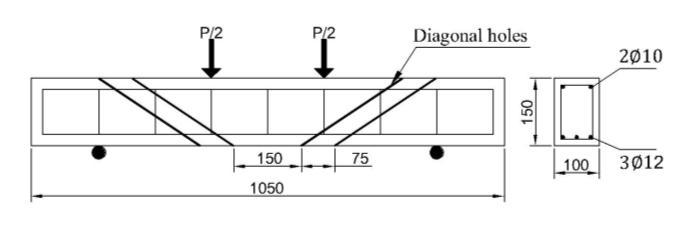

Fig -2:TestSpecimensofGroups(4and5) (Reinforcedconcretebeaminternallyinjectedbyepoxy)

Table -3: StrengtheningandRepairingScheme

Group no. Beam ID Nano Silica (%) Fcu MPa Epoxy

G1 B1 0 300 0 30 B2 0 450 45 B3 0 600 60 G2 B4 2 300 2 30 B5 4 300 4 B6 6 300 6 G3 B7 4 450 4 45 B8 4 600 60 G4 B9 0 300I 0 30 2Hole B10 0 450I 45 2Hole B11 0 600I 60 2Hole G5 B12 4 300I 4 30 2Hole B13 4 450I 45 2Hole B14 4 600I 60 2Hole

Prior to casting the beams, the reinforcement cages were assembledaccordingtotherequireddetails;Priortomixing theconcretemix,thegravelwaswettedandallowedtodry for2hours,afterwhichthecoarseandfineaggregateswere added to the mixer and mixed for 2 minutes. The cement, silicafumeandnanosilicawereaddedtothemixandmixed foranother2minutes,andthewatercontentwasaddedby dissolvinghalfofthesuperplasticizerinhalfofthewaterand adding half of the water tothe mix for 1 minute. Then the

Thegrooves,wheretheKemapoxy103wasinjected,were cleanedfromanyhardenedconcreteresiduebyusingwater pressure to ensure the total injection of the whole groove along the beam span. The beams were tested under four pointloadtesttoachievehalfofultimateloadachievedbythe corresponding reference beam, then the grooves were injectedwithKemapoxy103andwaslefttohardenfor24 hours.After24hoursofinjectingtheEpoxy,thebeamswere testeduntiltheultimatefailureloadwasachievedasshown infigure3 Fig 3:TestSampleduringandafterInjection 3. EXPERIMENTAL

Slumptest is used to measure the workability of the fresh concrete.Table4showstheresultsobtainedfromtheslump testconductedonfreshconcrete.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Thecompressiontestwasconductedon15×15×15cm,for each concrete mix three cubes were cast to obtain the averagevalueofthecompressionstrength.Table5showsthe resultsofthecompressiontestafter7and28days.

Table 5: ConcreteCompressiveStrengthafter7and28 days

Concrete Mix Compressive Strength (MPa) 7 Days 28 Days

300 0% 22.17 31.31 300 2% 24.22 33.21 300 4% 25.04 36.83 300 6% 23.23 32.14 450 0% 32.60 46.24 450-4% 35.28 49.62 600 0% 43.05 61.41 600 4% 47.13 66.43

Table 6 shows the test results of concrete splitting tensile strengthafter28days.Itcanbefoundthatusing4%nano silica showed the best results in tensile strength with increaseupto42.6%comparedto0%nanosilica

Table 6: ConcretesplittingTensileStrengthafter7and 28days

Concrete Mix

Tensile Strength (MPa) 28 Days 300 0% 3.52 300 2% 4.34 300 4% 5.02 300 6% 4.41 450 0% 6.27 450 4% 6.55 600 0% 6.79 600 4% 7.81

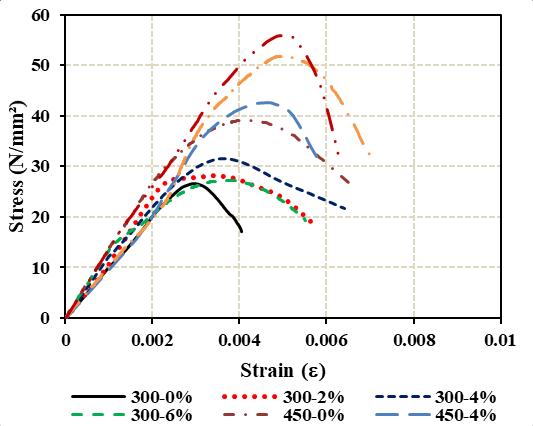

TheStress straincurvesofthetestedcylindersareshownin figure 4 and the results are tabulated in table 7. From the results, it can be inferred that the use of 4% nano silica providedthebestresultsintermsofcompressivestrength.

Table 7: ConcreteModulusofElasticity

Concrete Mix F’c (MPa) Modulus of Elasticity (MPa)

300 0% 26.51 10105.75 300 2% 28.08 10541.2 300 4% 31.57 12365.75 300 6% 27.23 13361.6 450 0% 39.13 9622.547 450 4% 42.54 13437.68 600 0% 51.8 10117.87 600 4% 55.84 13816.88

Fig 4:Concretestress straincurve

Table8showstheresultsofbeamsasfollows:

Theultimateload(Pu)

Firstcrackload(Pcr)

Ultimateshearforce(Vu)calculatedfromEq.(1).

Ultimateshearstress(τ)calculatedfromEq.(2)according totheEgyptianCodeofConcreteECP203 2017.[12]

Crackmoment(Mcr)calculatedfromEq.(3).

Ultimatemoment(Mu)calculatedfromEq.(4).

Ultimateflexuralstress(Fru)calculatedfromEq.(5).

Vu=Pu/2

……………………..Eq.(1)

Mu=(Pu ×l)/6 ……………………..Eq.(2)

Mcr=(Pcr ×l)/6 ……………………..Eq.(3)

τ=Pu /(b.d) ……………………..Eq.(4)

Fru=(Mu ×y)/Ig ……………………..Eq.(5)

WhereIg=(b×h3)/12

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Table 8: TestResultsofthe

Beams

G1 B1 0 300 65.67 121.60 60.80 9.73 8.21 15.200 40.53 B2-0-450 83.95 135.41 67.71 10.83 10.49 16.926 45.14 B3 0 600 88.04 157.21 78.61 12.58 11.00 19.651 52.40 G2 B4 2 300 66.95 119.12 59.56 9.53 8.37 14.890 39.71 B5 4 300 78.94 128.36 64.18 10.27 9.87 16.045 42.79 B6 6 300 77.74 109.33 54.67 8.75 9.72 13.667 36.44 G3 B7 4 450 84.55 153.16 76.58 12.25 10.57 19.146 51.05 B8 4 600 112.56 170.29 85.15 13.62 14.07 21.286 56.76

G4 B9 0 300I 73.77 122.96 61.48 9.84 9.22 15.370 40.99

B10-0-450I 79.12 145.43 72.72 11.63 9.89 18.179 48.48 B11 0 600I 111.46 164.63 82.32 13.17 13.93 20.579 54.88 G5 B12 4 300I 67.71 130.20 65.10 10.42 8.46 16.275 43.40 B13 4 450I 105.02 154.44 77.22 12.36 13.13 19.305 51.48 B14 4 600I 116.58 174.00 87.00 13.92 14.57 21.750 58.00

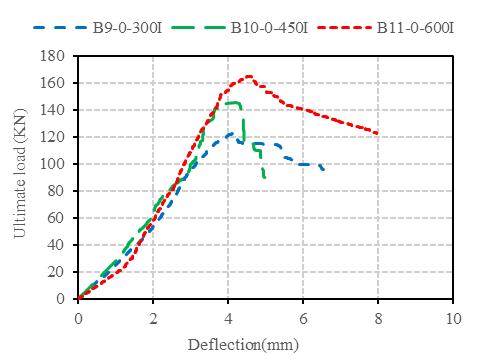

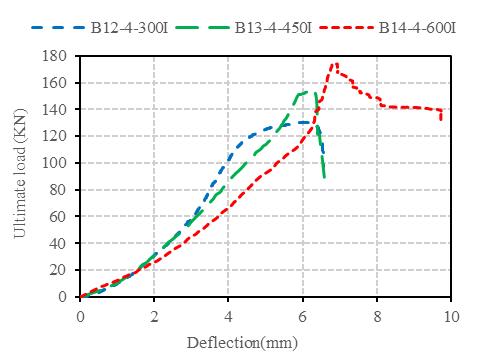

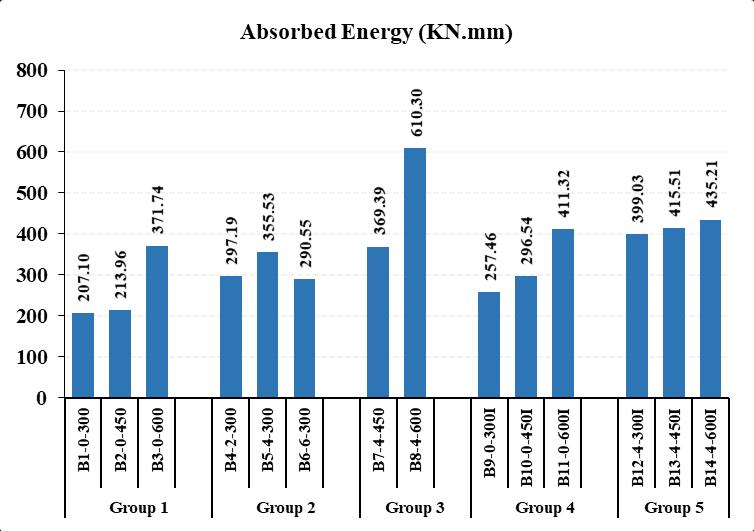

Table9andfigure5areshowntheultimatedeflectionand absorbedenergy(AE)oftestedbeamsandfailuremode.

Table 9: UltimateDeflectionandAbsorbedEnergyof TestedBeamsandFailureMode

Beam ID u (mm) AE (KN mm) % Increase in Pu

% Increase in AE Failure Mode

B1 0 300 4.115 207.102 Shear

B2 0 450 2.812 213.964 Shear

B3 0 600 4.724 371.738 Shear

B4 2 300 5.16 297.192 2539% 4350% Shear

B5 4 300 5.685 355.531 3815% 7167% Shear

B6 6 300 5.877 290.553 4282% 4029% Shear

B7 4 450 5.897 369.39 109.71% 7264% Shear

B8 4 600 6.114 610.296 2942% 6417% Shear

B9 0 300I 4.186 257.459 1.11% 2432% Shear

B10 0 450I 4.212 296.537 7.40% 3859% Shear

B11 0 600I 4.524 411.318 4.72% 1065% Shear

B12 4 300I 6.094 399.026 1.44% 1223% Shear/ Flexural

B13 4 450I 6.288 415.513 0.84% 1249% Flexural

B14 4 600I 6.785 435.207 2.18% 0.00% Shear/ Flexural

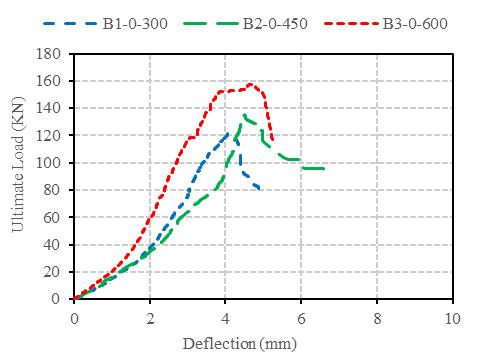

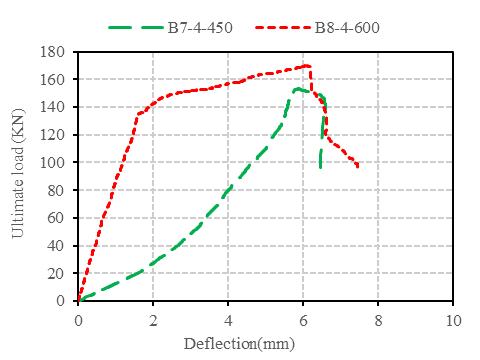

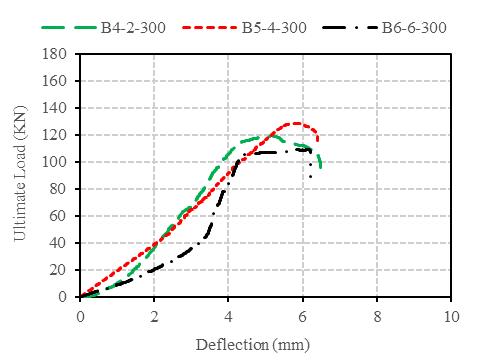

Allthebeamsweretestedbyfour pointloadtest,fromthe figures for all groups it is noted that the behavior of the curveinitiatedlinearlyandchangedtononlinearbehavior whenthecrackstookplace.

Group 1 does not contain nano silica (control) and compressivestrength(300,450and600kg/cm2).Notethat thehigherthestrength,thehighertheductility,andthe600 kg/cm2strength,thebettertheresults.Thepercentagesof NanosilicainGroup2were(2%,4%,and6%)(Control)and compressivestrength(300kg/cm2).Notethatthehigherthe strength, the higher the ductility, and the 600 kg/cm2 strength,thebettertheresults.Notethatwiththestabilityof thestrength,andtheincreaseofthenanosilica,itwasfound thatat4%,theductilityincreased.ThepercentagesofNano silica in Group 3 were 4% (control) and compressive strength(450,and600kg/cm2).Itwasdiscoveredthatas thenanosilicaratiostabilisedandthestrengthincreased,the ductilityincreased.Group4doesnotcontainnanosilicaand compressive strength (300,450 and 600 kg/cm2) and all beams are reinforced with internal epoxy injection. The higherthestrength,thegreatertheductility,andthehigher thestrength(600kg/cm2),thebettertheoutcomes.

The percentages of Nano silica in Group 5 were 4% and compressive strength (300,450 and 600 kg/cm2) and all beamsarereinforcedwithinternalepoxyinjection.Notethat withthestabilityofthenanosilicaratio,andtheincreasein the strength, it was found that when the strength 600 kg/cm2increases,theductilityincreases.Itshouldbenoted that with the stability of the nano silica ratio and the increase in strength, it was discovered that the ductility increasedasthestrength600kg/cm2increasedasshownin figure6.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

3.3.3.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

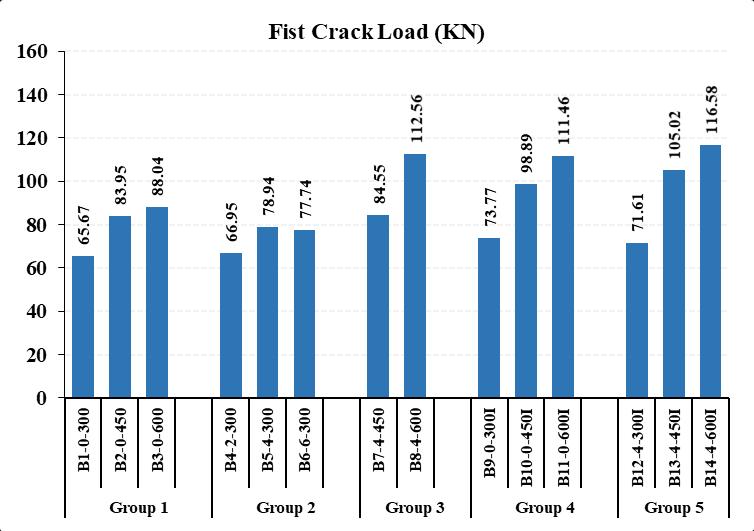

comparedto2%and6%. Group3Theresultsshowthatas compressivestrengthincrease,firstcrackloadincreaseas well. Group 4 The results show that when compressive strengthincreases,firstcrackloadincreases,wheretherate ofincreasewas12.35%,17.80%and26.60%inB9,B10and B11, respectively. Group 5 It is clear from the results that firstcrackloadincreasesascompressivestrengthincreases, Wheretherateofincrease was0%,24.22%and3.57% in B12,B13andB14,respectively,asshowninfigure8

Fig 6:Load DeflectionCurvesforGroups(1 5)

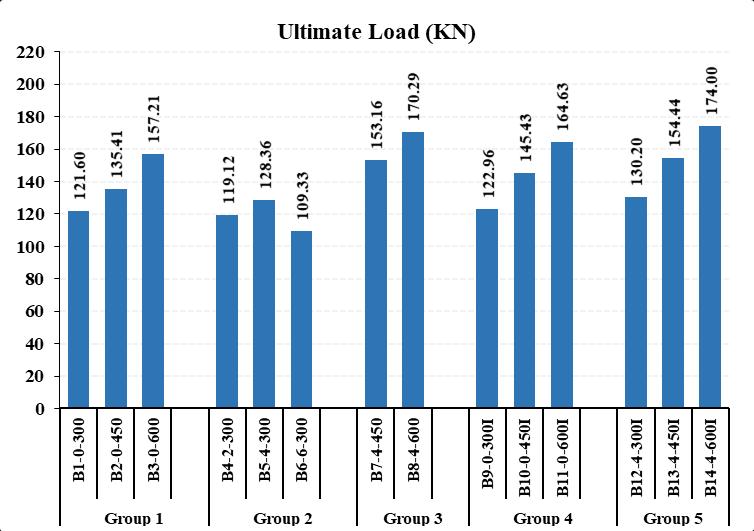

TheultimateloadsofGroup1Itareclearfrom theresults that ultimate load increases as compressive strength increases.Group2itcanbeseenfromtheresultsthatboth the ultimate load and the first crack load significantly increased using 4% nano silica compared to 2% and 6%. Group 3 The results show that as compressive strength increase,ultimateloadincreaseaswell.Group4Theresults show that when compressive strength increases, ultimate loadincreases,wheretherateofincreasewas1.11%,7.40% and 4.72% in B9, B10 and B11, respectively. Group 5 It is clear from the results that ultimate load increases as compressivestrengthincreases,Wheretherateofincrease was 1.44%, 0.84% and 2.18% in B12, B13 and B14, respectively,asshowninfigure7

Fig 8:FirstCrackLoadforGroups(1 5)

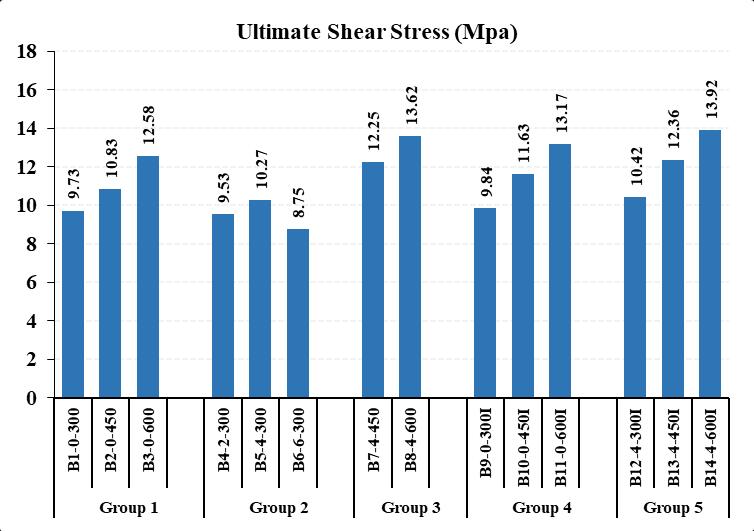

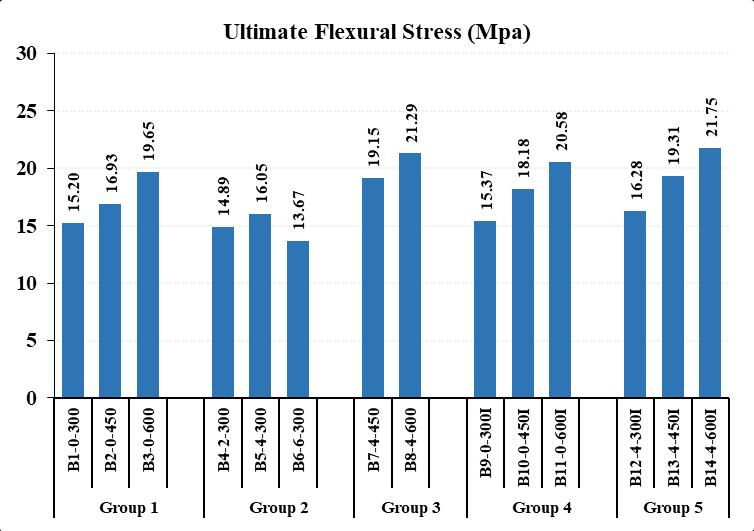

TheultimateShearandFlexuralStressofthecontrolbeams andtheultimateShearandFlexuralStressofGroups1 5are shown in figures 9 and 10. The percentage of increase in themisthesameastheincreasethatoccurredinultimate loadcomparedtothecorrespondingcontrolbeam.

3.3.4.

Fig -7:UltimateLoadforGroups(1 5)

ThefirstcrackloadsofGroup1Itisclearfromtheresults that first crack load increases as compressive strength increases. Group2itcanbeseenfromtheresultsthatfirst crack load significantly increased using 4% nano silica

Fig 9:UltimateShearStressforGroups(1 5)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

3 Theuseofinjectedkemapoxy103increasedtheultimate loadandabsorbedenergysignificantinmostcases.

4 Theuseofinjectedkemapoxy103increasedtheultimate loadby(0.84 7.4)%andincreasedtheabsorbedenergyup to38.6%comparedtothecontrolbeams.

5 The increase in concrete compressive strength did not resultsinanyincreaseinabsorbedenergyontheotherhand theultimateloadincreasedsignificantly.

6 The increase in shear capacity was not signific, which couldbeduetotheincrease intheamountstirrupsinthe tested beams, and that is coincident with the research conductedbyMofidiandChaallal.[13]

Fig 10:UltimateFlexuralStressforGroups(1 5)

The ductility of the control beams of Groups 1 3 and the ductility of Groups 4 5 are shown in figure 11. Where the rate of increase in Group 4 was 24.32%, 38.59%, and 10.65% in B9, B10 and B11, respectively. Group 5 was 12.23%,12.49%,and0%inB12,B13andB14,respectively.

Fromtheexperimentalresults,itwasfoundthatpre loading andinjectionofKemapoxy103providesabetterbehavior.

[1] R.J.Detwiler,“Construction,repair,andrehabilitation,” PCIJ.,vol.58,no.1,p.7,2013.

[2] C.DonnellyandS.Rigbey,“Conceptsofshearresistance and practical applications,” Dam Eng., no. April 2014, 1998.

[3] Arti,“IntroductiontoNanomaterials,”Nanotechnology, pp.1 10,2020.

[4] S.Gopinath,P.C.Mouli,A.R.Murthy,N.R.Iyer,andS. Maheswaran, “Effect of nano silica on mechanical propertiesanddurabilityofnormalstrengthconcrete,” Arch.Civ.Eng.,vol.58,no.4,pp.433 444,2012.

[5] A.AlGhabban,A.B.AlZubaidi,M.Jafar,andZ.Fakhri, “EffectofNanoSiO2andNanoCaCO3ontheMechanical Properties,DurabilityandflowabilityofConcrete,”IOP Conf.Ser.Mater.Sci.Eng.,vol.454,no.1,2018.

Fig 11:AbsorbedEnergyforGroups(1 5)

Theobjectiveofthisexperimentistoreachthebestnano silica ratio in increasing the strength and to examine the effectofusingepoxyinjectiontostrengthentheshearofRC beams.Themainconclusionremarksareasthefollowing:

1 For Beam, with no nano silica, the increase in the compressivestrengthresultedsignificantincreasein both ultimateloadandabsorbedenergy(ductility).

2 Beams with 4% nano silica, showed the best results in termsofultimateloadandductility.Whichagreeswiththe resultsconcludedbyAlGhabbanet.el.[5]

[6] “Prediction of combined effects of fibers and nano silicaonthemechanicalpropertiesofself compacting concreteusingartificialneuralnetwork,”vol.1988,no. 1989,pp.1906 1923,1997.

[7] G.Sundhar,V.S.Raj,F.M.Usman,K.Tamilmaran,andG. A. Vijay, “Repair and Rehabilitation of RCC Structures UsingNDTTechniques,”vol.16,no.3,pp.3 5,2020.

[8] I.C.R.Institute,“PreparedbytheInternationalConcrete RepairInstitute,”no.June,2015.

[9] H. Nikopour and M. Nehdi, “Shear repair of RC beams usingepoxyinjectionandhybridexternalFRP,”Mater. Struct.Constr.,vol.44,no.10,pp.1865 1877,2011.

[10] M.V.Rao,R.Sivagamasundari,andA.S.Raju,“Studyon reliability of concrete nano mixture containing nano

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

silica,” Mater. Today Proc., 2022, doi: 10.1016/j.matpr.2021.12.518.

[11] R. Goushis and K. M. Mini, “Finite element analysis of polymericandcementitiousmaterialstosecurecracks inconcrete,”Mater.TodayProc.,vol.49,pp.1599 1606, 2022,doi:10.1016/j.matpr.2021.07.418.

[12] “EgyptianReinforcedConcreteCode2017.pdf.”.

[13] A. Mofidi and O. Chaallal, “Shear Strengthening of RC BeamswithExternallyBondedFRPComposites:Effect of Strip Width to Strip Spacing Ratio,” J. Compos. Constr.,vol.15,no.5,pp.732 742,2011

Dina A. Adly

TeachingAssistant,Civil EngineeringDept FacultyofEngineering,Nahda UniversityBenisuef,Egypt

Ahmed Abd El Azim A.

AssistantProfessor,Civil EngineeringDept. FacultyofEngineering,Fayoum University,Fayoum,Egypt

Aly Abdel-Zaher Elsayed

AssistantProfessor,Civil EngineeringDept FacultyofEngineering,Assiut University,Assiut,Egypt

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page