International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

3

1 2Department of Mechanical Engineering, Dr.D.Y.Patil Institute of Engineering, Management & Research, Akurdi, Pune, Maharashtra, India

3Department of Mechanical Engineering, K.K. Wagh Institute of Engineering Education & Research, Nashik, Maharashtra, India ***

Abstract - Lithium ion batteries are used for their high energy efficiency and are frequently used by electric car manufacturers typically employ them (EVs). However, abrupt temperature changes cause these batteries to lose efficiency quickly. Liquid cooling, a majorly used thermal management approach that increases battery pack servicelife,isonewayto limit temperature rises (whether ambient or created by the battery itself). Because of their low rate of self discharge,high energy density, and long life cycle, lithium ionbatterieshavea wide range of applications. They have a high energy densityin relation to their weight. Choosingtherightcoolingmechanism for a lithium ion battery pack for electric vehicles and developing an appropriate cooling control plan to maintain the heat contained within a safe range of 15 to 40 degrees Celsius is critical to boosting safety, extending the pack durability, and lowering cost. The design and analysis of the battery pack are presented in this paper. The temperature difference between the battery cell and the cooling fluid is depicted in this paper.

Despitethefactthateachcoolingmethodhasprosandcons, studiesshowthatliquidcoolingisaviableoptionforLi ion battery packs in EVs due to its size, weight, and power requirements. Even though immediate liquid cooling requiresdrenchingthebatterycellsinthefluid,alow(orno) conductivity cooling liquid is essential. For indirect liquid cooling to work, the battery cells do not need to be in immediatecontactwiththecoolingmedium.

Alternatively, the liquid coolant can be circulated through the system's metal pipes, which necessitates the use of anticorrosion protection on the metal. Liquid cooling, an efficientthermalmanagementstrategythatextendsbattery pack service life, is one way to control temperature rises (whetherenvironmentalorgeneratedbythebatteryitself). Engineers can use Multiphysicssimulation to study liquid coolinginbatteriesandoptimizethermalmanagement.

Theindustryforelectricdrivevehicles(EDVs)isgrowing, andithasmuchmorepotentialifbatterieshavemorepower, can travel longer ranges, and are less costly. The battery thermalmanagementtechnologyinelectricvehicles(EVs) and hybrid electric vehicles (HEVs) should keep temperatures within a proper range of 15 0C to 40 0C to keep lithium ion (Li ion) battery packs functioning safely andextendingtheirlife.Thebatterypackgeneratesalarge amount of heat during vehicle operation, which must be dissipated. The removal of heat generated and having a constanttemperatureinEDVshasbecomeachallengedueto the higher demand for gravimetric and volume energy. A varietyofcoolingtechniquesareproposedandtested.

A battery in an electric vehicle is usually cooled in one of the following ways:

1.Aircooled

2.Liquid cooled

Heatmakeselectricvehiclebatteriesworkharder,anditisa major battery killer. Batteries will stop working, swell, bubble,causesparksandflames,harmyourdevice,orblow upiftheyareexposedtotoomuchheat.Extremeheatcan shortenthelifeofabatterybycausingcorrosion.

The components inside lithium ion batteries begin to degradewhentheyareoverchargedoroverheated,releasing oxygen,carbondioxide,andothergasesintheprocess.As pressurebuilds,theheatedbatteryexpandsfromarectangle to a pillow shape. For increasing safety, extending pack service life, and lowering costs, selecting the right cooling method for a lithium ion (Li ion) battery pack for electric drive vehicles (EDVs) and developing an optimal cooling controlstrategytokeepthetemperaturebetween15and40 degreesCelsiusiscritical.Prices,complexity,weight,cooling effects,temperatureuniformity,andparasiticpowerareall factorstoconsiderwhenchoosingacoolingtechnologyand developingstrategies.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

•Toefficientlylowerthebattery'stemperature.

•Lowerthecostofanelectricvehicle'scoolingsystem.

•Coolingsystemsmustbeworkingwithinasaferangeof15 to40degreesCelsiusforthebatterypack.

•UsingCATIAv5orSpace climesoftwaretocreatea3D conceptualmodal.

•UsingANSYSfluentR12020softtosolvetheFEMsolution totheintendedmodal.

•Changingtheworkingmedium

•Recordthetemperaturevariationfordifferent Workinthemedium.

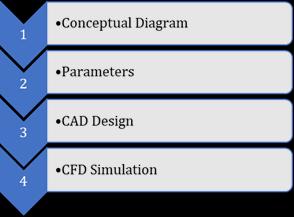

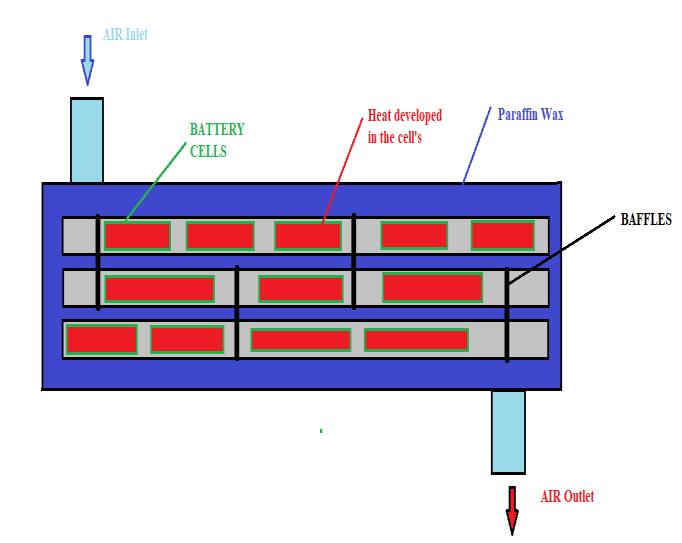

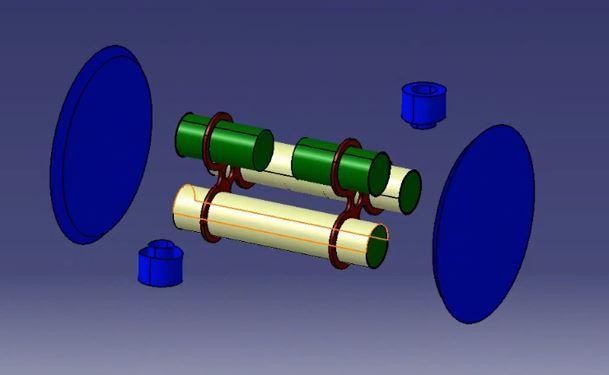

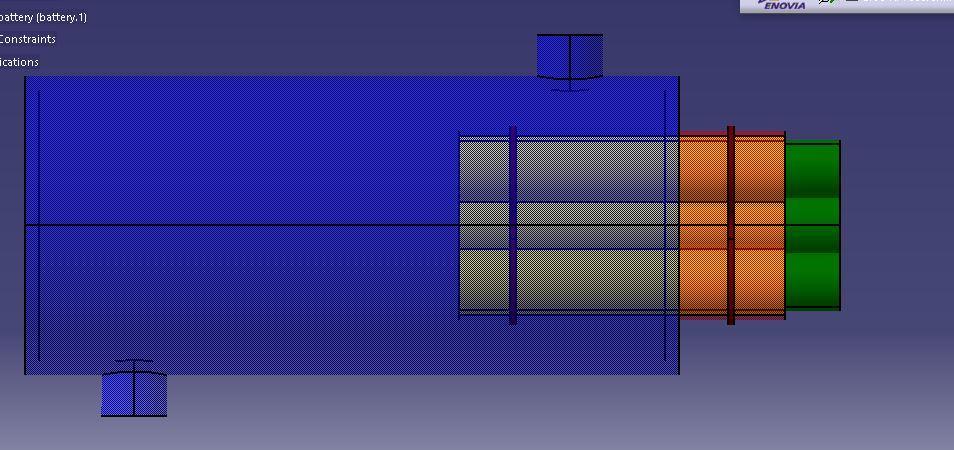

We got the idea for the design and development of the batterypackfromresearchpapers,andwecanincreasethe coolingefficiencybycombiningparaffinwaxwithwater.SoI wrappedparaffinwaxaroundthealuminumplate,andthere were battery cells inside the aluminum plate. We will investigateheattransferefficiencyaroundthebatterycells, aluminum tubes, and chamber using the ANSYS fluent systemandthetransientmethod

Forthepurposesofthisproject,thebatteryandshell parametersareassumed.

Solid shell for exchanging heat

Length=60cm Diameter=27.5cm Shellthickness=1.5cm

Shell inlet and outlet

OuterDiameter=6cm InnerDiameter=3.5cm

Aluminum tube

Thickness=0.1cm Length=30cm Outerdia=6cm Innerdia=5.8cm

Battery Cells

Diameter=5.8cm Length=12cm

Baffle Plate

Thickness=0.5cm OuterDiameter=8cm InnerDiameter=6cm

PCM Solid coating

Thickness=0.2cm Length=overallaluminumtube

The velocity of the water entering the tube

Velocity=pi*d*n/60

N=rpmofthewatermotorisconsideredas=1400 D=3.5cm

V=2.56approx

Temperature=normalroomtemperatureat240Celsius

Singlebatteryconditionwithseriesandparallelsetup

Volts=capacity/currentrate

Thecapacityofthebatterytoproduceamp/hour=14.2 Currentrate=0.3 Approx.4.26analytical

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Inthissystem,wearedevelopinga3DmodalusingCATIAv5 R20

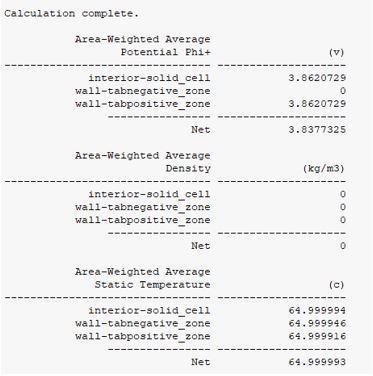

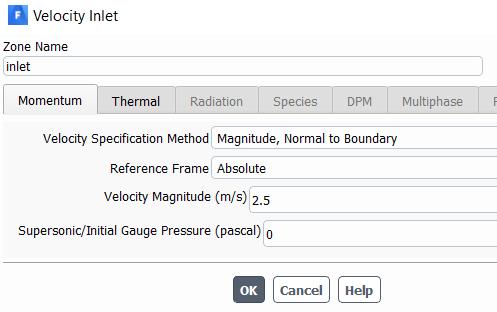

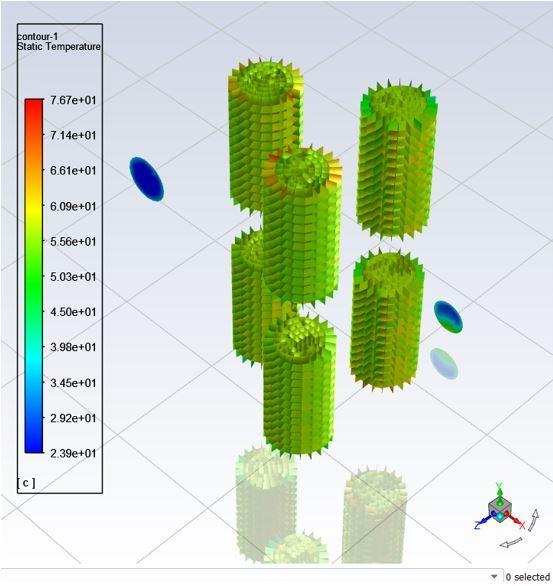

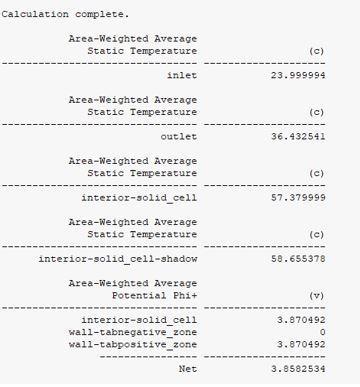

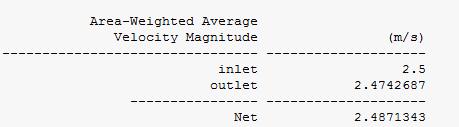

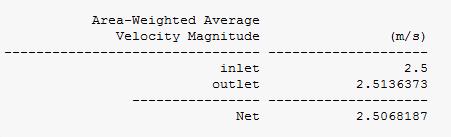

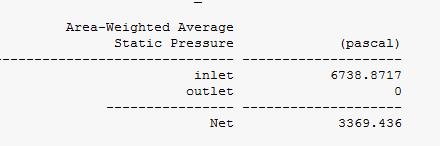

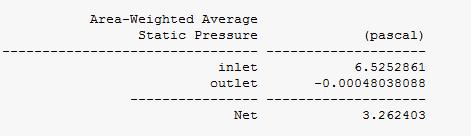

Theboundaryconditionforallcoolingmediumsisthesame. We consider laminar flow with velocity 2.5m/s and temperature23.999994 0c.

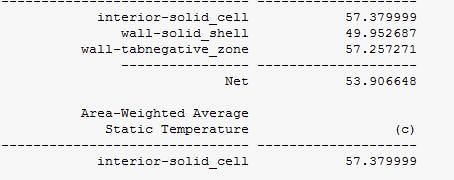

Iteration 1 Cooling with Water at a given boundary condition

Thetemperaturegot57.379999 0Cinthebatterycells.

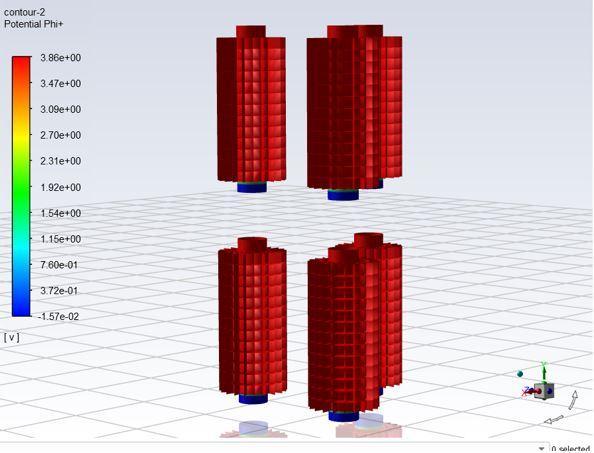

Potential volt generated for 1 hour. Potential Phi of the battery max 3.8 volts from positive to 0 at the negative terminalandwithoutusinganycoolingmedium64.999994 0Cgot

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

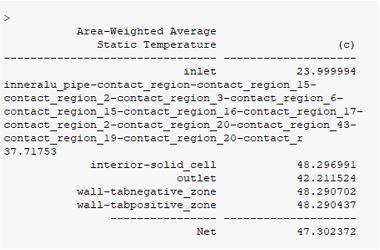

Iteration 4 Water with PCM of 0.2 cm thickness

Thetemperatureatthebatterycellis47.302372 0C.

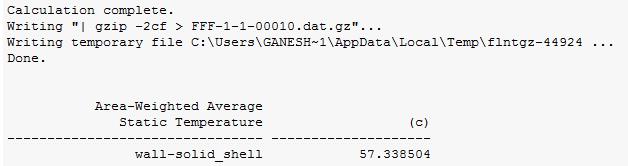

Iteration 2 Air Results

Thetemperaturegot57.338504 0Cinthebatterycells.

Thetemperaturegot57.379999 0Cinthecells.

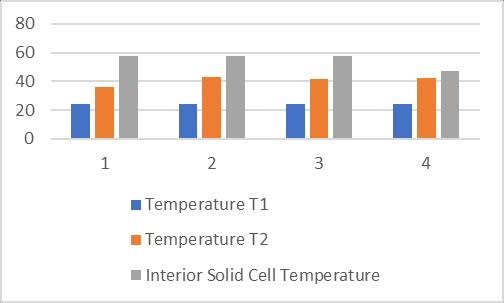

Materialsareexpensive,andobtainingcomponentsrequired forspecific ragesis difficult. With theseresearchfindings, other direct cooling methods have entered the market. However,thiswasourattempttoputthemodelintoaction. AwatercoolingsystemwithPCMcoatingoveraluminumis effective.We'vecreatedtablesandgraphstocompare the temperaturedifferencesbetweenvariouscoolingmediums.

Sr.No. Typeof Working Medium

Interior SolidCell 0C 1 Water 36.432541 57.379999 2 Air 42.884944 57.338504 3 Glycol 41.444251 57.379999 4 PCM 42.211524 47.302372

Outlet Temperature T2 0C

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

[1] Saw,L.H.,Tay,A.A.O.,&Zhang,L.W.(2015,March). Thermal management of lithium ion battery pack with liquid cooling. In 2015 31st thermal measurement, modeling & management symposium (SEMI THERM) (pp.298 302).IEEE.

[2] Chen,D.,Jiang,J.,Kim,G.H.,Yang,C.,&Pesaran,A. (2016).Comparisonofdifferentcoolingmethodsfor lithium ion battery cells. Applied Thermal Engineering, 94,846 854.

[3] Sun,H.,&Dixon,R.(2014).Developmentofcooling strategy for an air cooled lithium ion battery pack. Journal of Power Sources, 272, 404 414. K. Elissa,“Titleofpaperifknown,”unpublished.

[4] Behi, H., Karimi, D., Behi, M., Ghanbarpour, M., Jaguemont,J.,Sokkeh,M.A.,...&VanMierlo,J.(2020). AnewconceptofthermalmanagementsysteminLi ion battery using air cooling and heat pipe for electricvehicles. Applied Thermal Engineering, 174, 115280.

[5] Khateeb,S.A.,Amiruddin,S.,Farid,M.,Selman,J.R.,& Al Hallaj,S.(2005).ThermalmanagementofLi ion battery with phase change material for electric scooters:experimentalvalidation. Journal of power sources, 142(1 2),345 353.

[6] Lyu,Y.,Siddique,A.R.M.,Majid,S.H.,Biglarbegian, M., Gadsden, S. A., & Mahmud, S. (2019). Electric vehicle battery thermal management system with thermoelectriccooling. Energy Reports, 5,822 827.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified