International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN: 2395-0072

e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN: 2395-0072

Abhijith Shaji1 , Akhil P2 , Arjun B Lal3 , Cyril Babu4 , Assi. Prof. Abin Babu5

1,2,3,4 Btech students, Department of Mechanical Engineering, Mangalam College Of Engineering ,Kerala, India686631

5,Faculty, Department of Mechanical Engineering, Mangalam College Of Engineering ,Kerala, India 686631 ***

Abstract A heat exchanger is a system used to transfer heat between two or further fluids. Heat exchangers are used in both cooling and heating processes. They're extensively used in space heating, refrigeration, air exertion, power stations, chemical Shops, petrochemical shops, petroleum refineries, natural gas processing, and sewage treatment. With the ever decreasingly severe energy and terrain problems, there has been a swell of interest in largely effective energy conversion and operation in recent times. It's well given that convective heat transfer marvels are generally involved in the process of energy application, and perfecting the convective heat transfer performance by heat transfer

Improvement ways is significant for energy conservation and environmental protection.

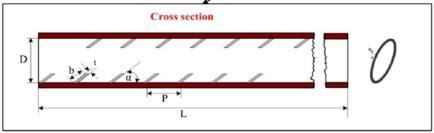

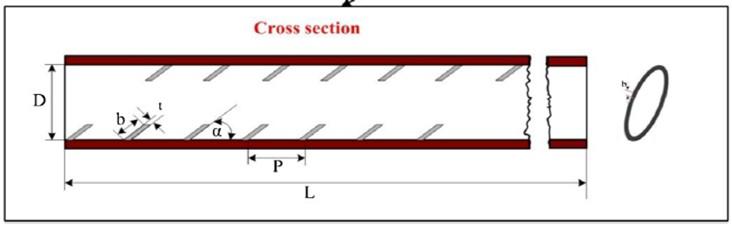

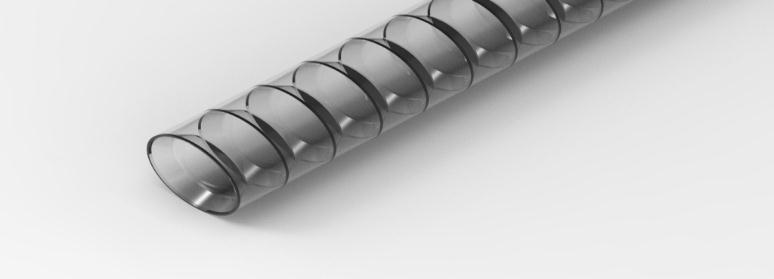

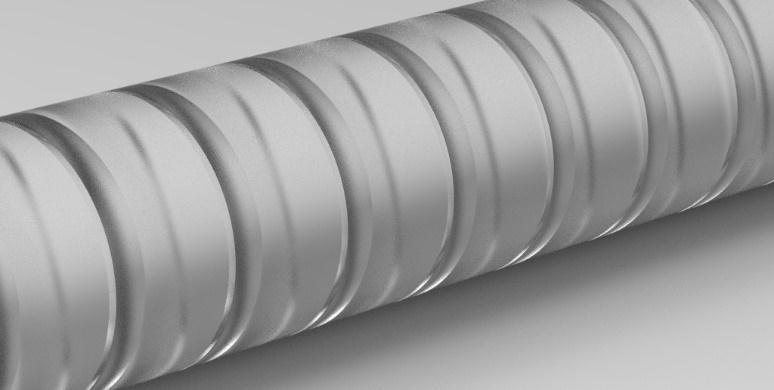

In the present design we employ windy heat exchanger with twisted internal flaps of tube of length of L = 2000 mm, with 50.8 mm inner periphery( D), 53 mm external periphery( Do), and mm consistence( t). The dimension of twisted whirlpool delirium is defined by its length = b and its angle α we design heat exchanger with α = 30 °, L/ D rate of0.1 and0.2 and pitch ( P/ D) of0.5, 1 and1.5. twisted whirlpool flaps would have minimal resistance to mass inflow rate. The end at using the whirlpool flaps is to produce counter rotating maelstroms inside the tube to help increase the turbulence intensity as well as to convey the colder fluid from the core governance to the heated wall region.

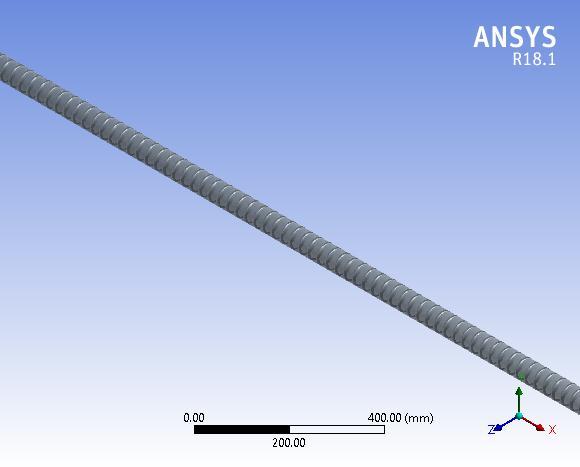

The proposed design is meant to ameliorate the heat transfer rate due to the enhanced curve and turbulence. Thetwistedwhirlpoolflapsarepreciselydesignedsoasto have minimal effect in mass Inflow rate. The numerical simulationswillcarriedoutusingANSYSfluent.

Heat transfer addition fashion is used to enhance heat transferrateandmelioratetheirthermalperformance.The fashion rate was divided into two active system which requires external power for illustration mechanical aid.

Another System was unresisting system which does not bear an external aid. Generally unresisting system was used generally. also the vortex/ wind flux in the thermal system.Insertionofvortex generatorsinacirculartubeis asimplefashionforenhancingtheconvectiveheattransfer measureonthetubesideofaheat exchangesduetotheir advantages of fabrication, operation and conservation. Performance of tabulators of vortex generators strongly depend on their figure. Different types of vortex Generators employed in the heat exchanger tubes are helical coiled line, circular/ crooked rings angle finned tapes. A heat exchanger is a system used to transfer heat betweentwoorfarther fluids.Heatexchangersareusedin both cooling and toast processes. They are considerably used in space heating, refrigeration, air exertion, power stations, chemical shops, petrochemical shops, petroleum refineries, natural gas processing, and sewage treatment. With the ever increasingly severe energy and Terrain problems, there has been a swell of interest in largely effective energy conversion. It's well known that convective heat transfer sensations are generally involved in the process of energy operation, and perfecting the convective heat transfer performance by heat transfer enhancement ways is significant for energy conservation and environmental protection. In the present design we design and stimulate the effect of vortex flaps in the innards of a heat exchanger. crooked vortex flaps would have minimum resistance to mass flux rate. The end at using the whirlpool flaps is to produce counter rotating vortices inside the tube for increasing the turbulence intensity toconveythecolder fluidfromcoregovernance to heated wallregion.The proposeddesignimprovesthe heat transfer rate due to the enhanced wind and turbulence. The numerical simulations are carried out usingANSYSfluent

2.1 convective heat transfer in a circular tube with short length twisted tape insert

S.Eiamsa ard,C.Thianponge,P.Eiamsa ard,P.Promvonge( 2009)presentsanexperimentalstudyonthemeanNusselt number, disunion factor and improvement effectiveness characteristics in a round tube with short length twisted tape recording insert under invariant wall heat flux boundaryconditions.Inthetrials,measureddataaretaken

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page497

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN: 2395-0072

atReynoldsfiguresinaturbulentregionwithairasthetest fluid. The full length twisted tape recording is fitted into the tested tube at a single twist rate of y/ w = 4.0. The short length tape recording is introduced as a swirling inflow device for generating a strong curve inflow at the tube entry before decaying alongthetube. The full length tape recording( LR = 1.0) is anticipated to produce a explosively swirling inflow over the whole tube. The variation of heat transfer and pressure loss in the form of Nusseltnumber(Nu)anddisunionfactor(f)independently is determined. The experimental result indicates that the short lengthvideotapesofLR=0.29,0.43and0.57perform lower heat transfer and disunion factor values than the full length tape recording around 14,9.5 and6.7; and 21,15.3and10.5,independently

P. Promvonge( 2008) Experimentally delved the goods of cables with square cross section forming a coil used as a turbulator on the heat transfer and turbulent inflow disunion characteristics in a invariant heat flux, indirect tube. In the present work. The trials are performed for overflows with Reynolds figures ranging from 5000 to. Two different spring curled line pitches are introduced. The results are also compared with those attained from using a typical curled indirect line, piecemeal from the smooth tube. The experimental results reveal that the use of curled square line turbulators leads to a considerable increase in heat transfer and disunion loss over those of a smooth wall tube. The Nusselt number increases with the rise of Reynolds number and the reduction of pitch for both indirect and square line coils. The curled square line provides advanced heat transfer than the indirect one under the same conditions. Also, performance evaluation criteriatoassessthereal benefitsinusing bothcoilcables oftheenhancedtubearedetermined.

K.Yakut,B.Sahin(2004)reportedtheeffectofconical ring turbulators on the heat transfer, pressure drop, inflow convinced vibration and maelstroms. In addition, the thermal performance for employing the turbulators at constant pumping and entropy generation was estimated. From the evaluation of entropy generation, the conical ringturbulatorsshowedthemeritasenergy savingdevice onlyatlowReynoldsnumbersincelowpressuredropwas generated in that inflow region. In the present work, inflow convinced vibration characteristics of conical ring turbulators used for heat transfer improvement in heat exchangers are delved experimentally. The conical rings, having 10, 20 and 30 mm pitches, are fitted in a model

pipe linethroughwhichairispassedastheworkingfluid. whirlpool slipping frequentness and breadth are determined and St Re, Prms Re variations are presented graphically. Flow aural coupling is also anatomized experimentally. It's observed that as the pitch increases, whirlpool slipping frequentness also increase and the maximumconfinesofthemaelstromsproducedbyconical ring turbulators do with small pitches. In addition, the goods of the promoters on the heat transfer and disunion factor are delved experimentally for all the arrangements. It's set up that the Nusselt number increases with the adding Reynolds number and the maximum heat transfer isattainedforthelowestpitcharrangement

P. Promvonge( 2008) studied the insertion effect of the conicalringarrangements,videlicet,clusteringconicalring, divergingconicalring,andclusteringdivergingconicalring on the heat transfer rate, disunion factor and thermal performance in a round tube. The study showed that the diverging conical ring offered advanced thermal performance than the clustering and clustering diverging bones . To increase convection heat transfer in a invariant heatfluxtubebyaunresistantsystem,severalconicalrings used as turbulators are mounted over the test tube. The goods of the conical ring turbulator inserts on the heat transferrateanddisunionfactorareexperimentallydelved in the present work. Conical rings with three different periphery rates of the ring to tube periphery( d/ D = 0.5,0.6,0.7) are introduced in the tests, and for each rate, the rings are placed with three different arrangements( clustering conical ring, appertained to as CR array, divergingconical ring, DR arrayand clustering diverging conical ring, CDR array). In the trial, cold air at ambient condition for Reynolds figures in a range of 6000 is passedthroughtheinvariantheatfluxindirecttube.It'sset upthatthering totube periphery rateand the ringarrays give a significant effect on the thermal performance of the test tube. The experimental results demonstrate that the useofconicalringinsertsleadstoaadvancedheattransfer ratethanthatoftheplainfacetube,andtheDRarrayyields a better heat transfer than the others. The results are also identified in the form of Nusselt number as a function of Reynolds number, Prandtl number and periphery rate. An additionofoverto197,333,and237inNusseltnumberis attained in the turbulent inflow for the CR, DR and CDR arrays, independently, although the effect of using the conical ring causes a substantial increase in disunion factor.

A. Durmus( 2004) excavated the effect of angle arrangement of the conical- ring type turbulators on the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN: 2395-0072

heat transfer and disunion loss. The excavated results revealed that heat transfer rate as well as disunion factor increased with the increase in the conical- ring angle. therefore,energysavingaspectsaretrulyimportantinthe design,constructionandoperation ofthe heat exchangers. For this reason, various active or unresistant styles have been sought to save energy by adding the heat transfer portions in the cold and warm fluid sidesintheheatexchangers.Inthisstudy,theeffectofcutout conical turbulators, placed in a heat exchanger tube at constant external face temperature, on the heat transfer rates was excavated. The air was passed through the exchanger tube, the external face of which was toast with logged water vapor. The trials were conducted for air flux ratesintherangeof⩽Re<.Heattransfer,pressurelossand exergy analyses were made for the conditions with and without turbulators and compared to each other. Some empirical correlations expressing the results were also derivedandmooted.

2.6 Heat transfer behaviors in a tube with combined conical ring and twisted tape insert

P. Promvonge,S. Eiamsa ard( 2007) examined the concerted effect of the conical ring and crooked tape recordingforheattransferimprovementinaindirecttube. As reported, the use of the conical ring in common with the crooked tape recording handed an average heat transfer rate up to 10 over that of the conical ring alone. Heat transfer, disunion factor and improvement effectiveness characteristics in a indirect tube fitted with conical ring turbulators and a crooked tape recording curve creator have been delved experimentally. The heat transfer test section is hotted electrically assessing axially and circumferentially constant wall heat flux boundary conditions. In the trials, two improvement heat transfer bias are applied. One is the conical ring used as a turbulator and placed in the tested tube and the other is the crooked tape recording curve creator placed at the core of the conical ring. Air as the tested fluid is passed both improvement bias in a Reynolds number range of 6000to.Twocrooked videotapesofdifferenttwistrates,Y = 3.75, and7.5, are introduced in each run. The experimental results reveal that the tube fitted with the conical ringandcrooked taperecordingprovidesNusselt number values of around 4 to 10 and improvement effectivenessof4to8advancedthanthatwiththeconical ring alone. A maximum heat transfer rate of 367 and improvement effectiveness of around1.96 is set up for usingtheconical ringandthecrooked taperecordingofY =3.75.Forallthebiasused,theimprovementeffectiveness tends to drop with the rise of Reynolds number and to be nearly livery for Reynolds number over. In addition, correlations for Nusselt number, disunion factor and performance evaluation criteria to assess the real benefits

in using the turbulator and curve creator of the enhanced tubearedetermined..

2.7 Heat transfer and friction behavior in rectangular channels with varying number of ribbed walls

P.R. Chandra,C.R. Alexander,J.C. Han( 2003) studied the heattransferbehavioursinasquarechannelwithnonstop caricatures on four walls where caricatures were placed superimposed on walls. They set up that the heat transfer increases with the proliferation in the number of ribbed walls and with reducing Reynolds number while the disunion factor increases with both cases. piecemeal from experimental examinations, the numerical studies on heat transfer improvement by means of the indirect ring turbulators were also reported. An experimental study of face heat transfer and disunion characteristics of a completely developed turbulent air inflow in a square channelwithtransversecaricaturesonone,two,three,and four wallsis reported. Tests were performed forReynolds figures ranging from to. The pitch to caricature height rate,P/e,waskeptat8andcaricature height to channel hydraulic periphery rate, e/ Dh was kept at0.0625. The channellength to hydraulicperipheryrate,L/Dh,was20. The heat transfer measure and disunion factor results were enhanced with the increase in the number of ribbed walls. The disunion roughness function, R( e), was nearly constantoverthe entirerangeoftestsperformedandwas within similar limits of the preliminarily published data. Theheattransferroughnessfunction,G(e),increasedwith roughness Reynolds number and compared well with former work in this area. Both correlations could be used to prognosticate the disunion factor and heat transfer measure in a blockish channel with varying number of ribbedwalls.The resultsof thisdisquisitioncould beused in colorful operations of turbulent internal channel flows involvingdifferentnumberofcaricatureplanedwalls.

SmithEiamsa ard,PongjetPromvonge(2004)Influenceof spiral videotapes fitted in a tube on heat transfer improvement is studied experimentally. A spiral tape recording recording recording is fitted in the tube with a viewtogeneratingwindfluxthathelpstoincreasetheheat transfer rate of the tube. The flux rate of the tube is considered in a range of Reynolds number between 2300 and8800.Theswirlingfluxbiasconformingof(1)thefull length spiral tape recording recording recording with or without a centered rod, and( 2) the regularly spaced spiral tape recording recording recording, are fitted in the inner tube of a concentric tube heat exchanger. The experimental data attained are compared with those attained from plain tubes of published data. Experimental resultsvindicatedthattheuseofspiralvideotapesleadsto aadvancedheattransferrateovertheplaintube.Thefull

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

length spiral tape recording recording recording with rod provides the topmost heat transfer rate about 10 better than that without rod but it increased the pressure drop. Toovercomethis,different free distancerate(s=Ls/Lh) of0, and2.0 were examined. It was set up that the space rate value should be about unity for Re< 4000. The regularlyspaced spiral tape recording recording recording insertsats=0.5yieldsthetopmostNusseltnumberwhich isabout50abovetheplaintube.

2.9 A review on single phase convective heat transfer enhancement based on multilongitudinal vortices in heat exchanger tubes

NianbenZheng,FangYan,KangZhang,TianZhou,Zhiqiang Sun( 2019) in this work, a review on single phase convective heat transfer improvement grounded onmulti longitudinal maelstroms is carried out. Theoretical examinations on convective heat transfer optimization from different principles similar as entropy generation minimization principle, field community principle, entransy dispersion extremum principle, power consumption minimization principle, and exergy destructionminimizationprincipleforthebettertrade off between heat transfer addition and inflow resistance reduction are originally estimated. It's set up that the optimal inflow fields are substantially characterized bymulti longitudinal maelstroms, inferring that heat transfer improvement ways which can induce the inflow patterns analogous to the optimal inflow fields may also enjoy the satisfactory balance between heat transfer improvement and inflow resistance reduction. also, colorful ways similar as artificial roughness, special structured tubes, multiple curve bias, and longitudinal whirlpool creators that can construct the inflow pattern ofmulti longitudinal maelstroms are epitomized. Results indicate that utmost of the ways show excellent thermal hydraulic performance, but some ways still suffer from high inflow resistance. Grounded on the discussion, some new perspectives on the being exploration gaps, grueling , and unborn exploration directions have been handed for the development of enhanced heat transfer ways by generating multi longitudinal maelstroms in heat exchangertubes.

S. Kwankaomeng,P. Promvonge,S. Sripattanapipat,S. Tamna, S,C. Thianpong( 2010) studied numerically the laminar periodic inflow over 30, and 45, angled baffles constantly mounted only on one wall of a square channel, independently. They noted that the heat transfer improvement for the 45, angledcocoon withBR ¼0.4 was about 2e3 fold advanced than that for the 90 ° cocoon whilethedisunionlosswassome10e25lower.Inaddition, theysetupthatasinglestreamwisemainwhirlpoolinflow

created by the angled baffles/ fins can help to induce smash overflows on the upper, lower and cocoon running end walls of the channel. The appearance of the whirlpool convincedsmash(VI)ledtodrasticincreaseinthethermal performance of the channel. In comparison, the 30 ° cocoon/finperformsbetterthanthe45°oneduetolower pressureloss

Literature review on performance enhancement of heatexchangers

Study of CFD tools required for the numerical analysis

Meshingofflow domain

Design and Modelling of conventional straight tube heat equation required forCFD

Designingvortex flaps with varying length andpitch

of Study governing Modellingofheat exchangers with vortexflaps

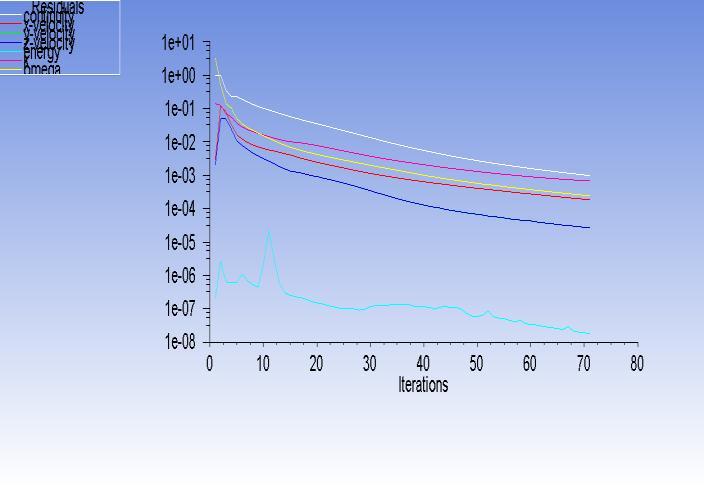

Simulation of Baseline model and newly design models using

Result and post processing, analyzing the performance

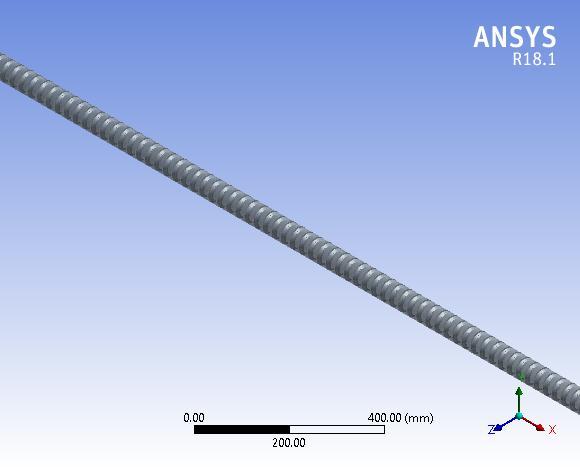

Weemployserpentineheatexchangerwithcurvedinternal flapsoftubeoflengthofL=2000mm,with50.8mminner diameter (D), 53 mm outer diameter (Do), and 1.5 mm thickness (t). The dimension of curved vortex flap is defined by its length = b and its angle α we design heat exchanger with α = 30°, b/D ratio of 0.1 and 0.2 and pitch (P/D)of0.5,1and1.5.

6.1 Case 1

Length,L=2000mm

InnerDiameter,D=50.8mm

OuterDiameter,Do=53mm Thicknessoftheflap,t=1.5mm Angle,α=30°

b/DRatio=0.1 P/DRatio=0.5

2.10 Numerical investigation of laminar heat transfer in a square channel with 30° & 45° inclined

We use CFD Post for result and post processing. Here we compare the result of low velocity flow through the heat exchanger tube without flaps & heat exchanger tube with flapsof0.1&0.2b/DRatio.

9.1 Result comparison of low velocity flow

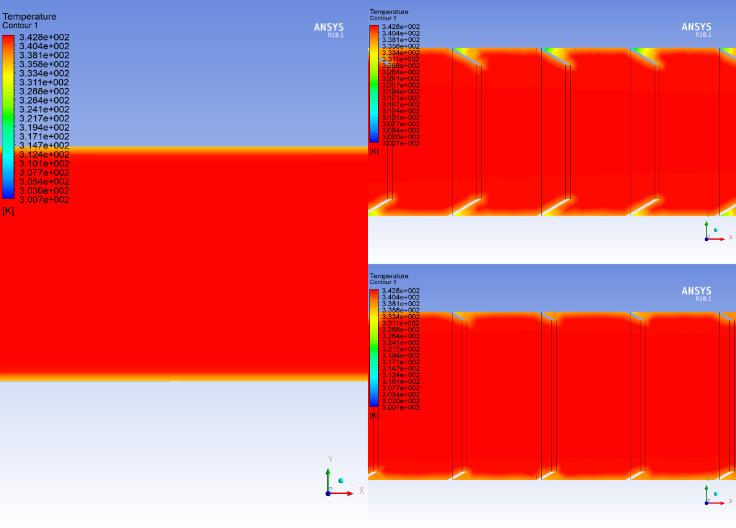

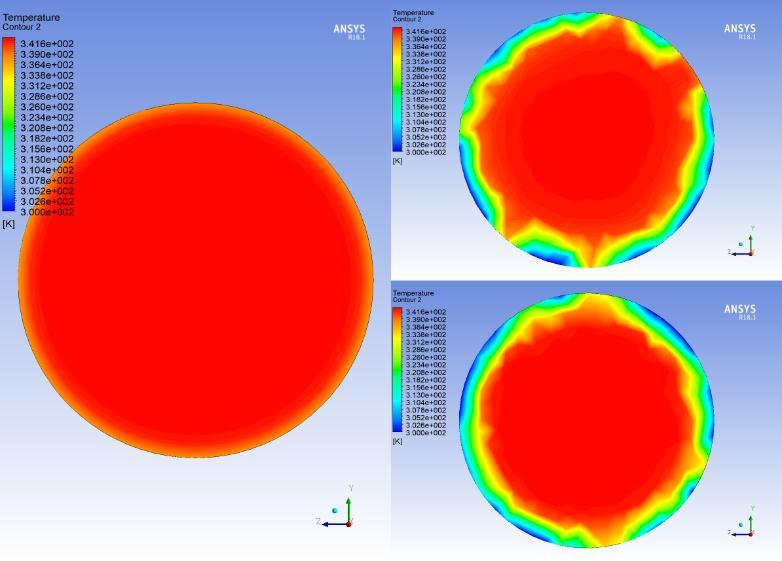

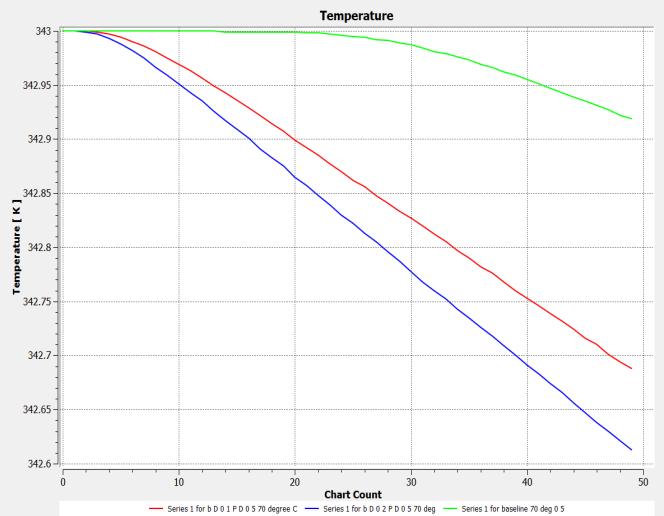

9.1.1 Temperature drop comparison

Fig9.1.1Figureshowingthetemperaturedropinsideheat exchangertubewith0.1&0.2b/DRatio

From this figure we can say that the heat exchanger tube withb/DRatioof0.2havethehighesttemperaturedrop

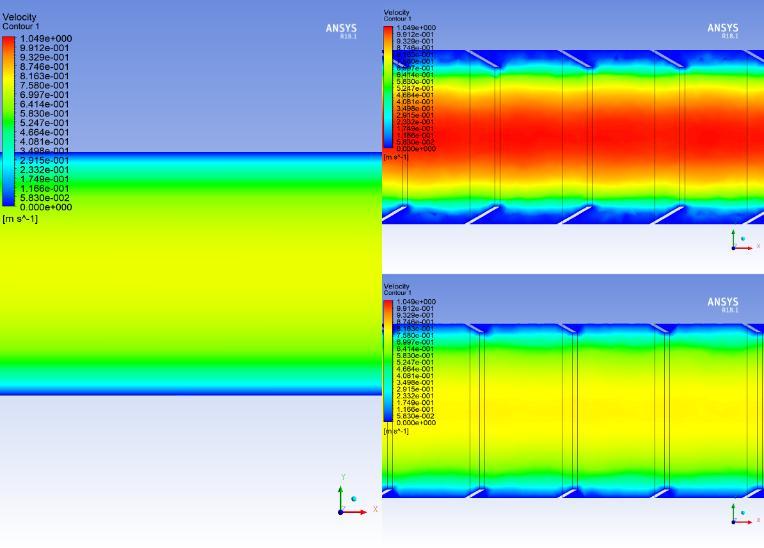

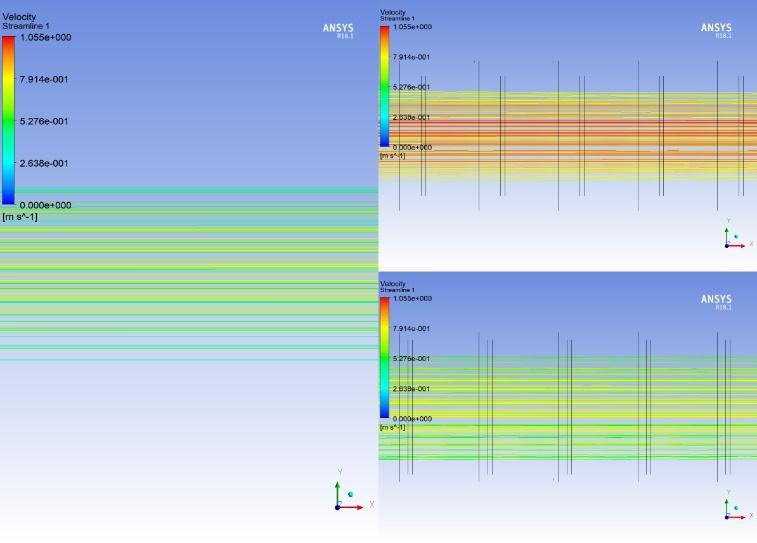

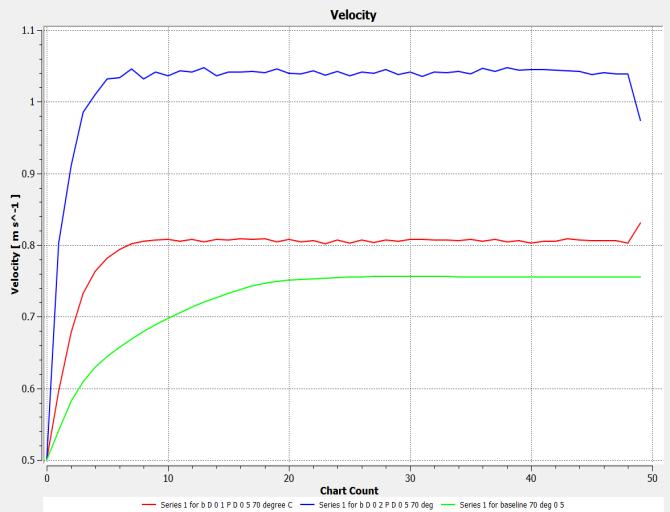

9.1.2 Velocity comparison

Fig9.1.2Figureshowingthevelocitydifferenceinflow insideheatexchangertubewith0.1&0.2b/DRatio

From this figure we can say that the heat exchanger tube withb/DRatioof0.2havethehighestflowvelocity

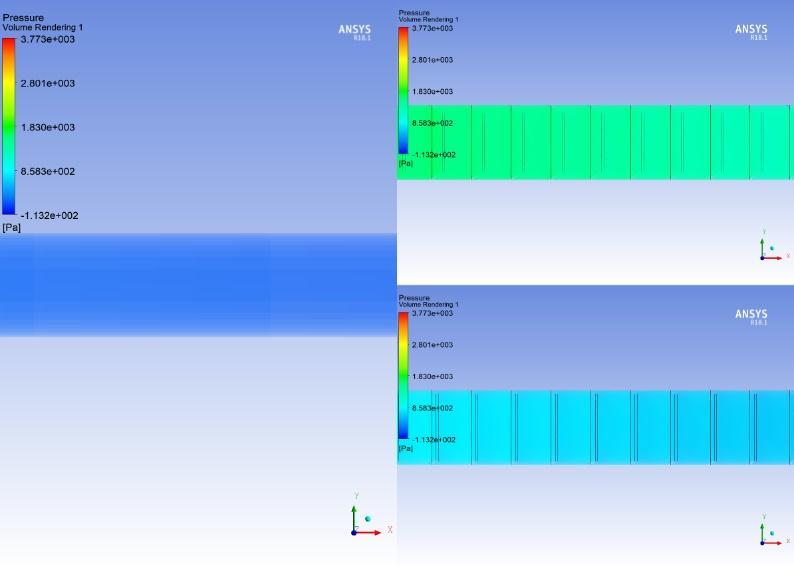

9.1.3 Pressure drop comparison

Fig9.1.3Figureshowingthepressuredropinsidetheheat exchangertubewith0.1&0.2b/DRatio

From this figure we can say that the heat exchanger tube withb/DRatioof0.2havethelowestpressuredrop

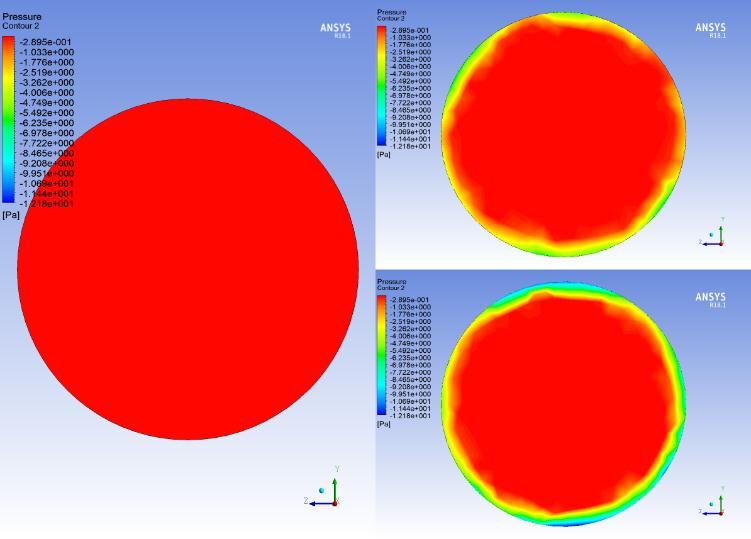

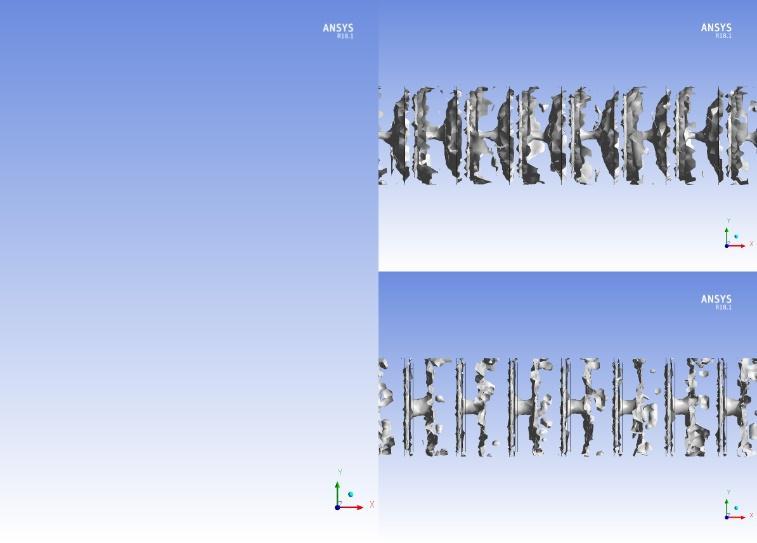

Fig9.1.1Figureshowingtheformationofvortexswirl insideheatexchangertubewith0.1&0.2b/DRatio

From this figure we can say that the heat exchanger tube with b/D Ratio of 0.2 have the highest turbulency due to vortexswirformation.

Fig9.1.1Figureshowingthetemperaturedropofheat exchangertubewith0.1&0.2b/DRatio

Fromthisfigureit’sclearthattheflowlinesareparallelto one another. So there is no flow disruption due to our design.Theheatexchangertubewithb/DRatioof1.2have thehighestflowvelocityatthecenterwhichisrepresented byredlines.

Fig9.1.6Figureshowingtheoutlettemperatureofheat exchangertubewith0.1&0.2b/DRatio

From this figure we can say that the heat exchanger tube with b/D Ratio of 0.2 have the highest Outlet temperature drop.

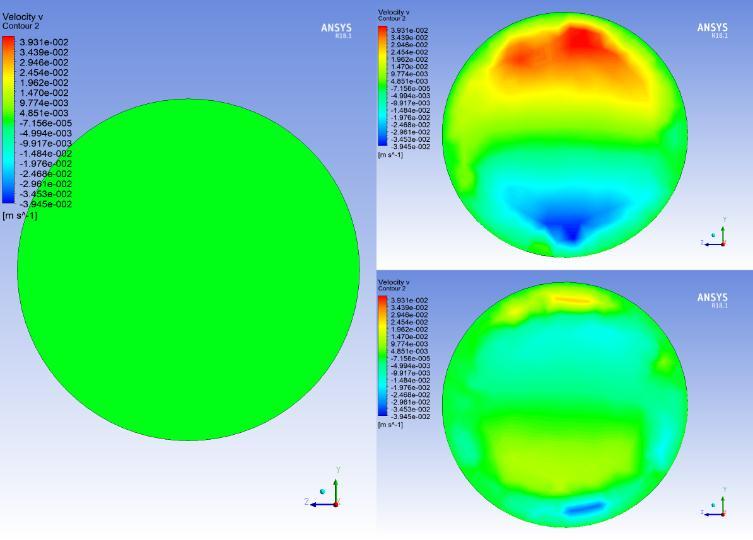

9.1.7 Outlet pressure drop

Fig9.1.1Figureshowingtheoutletpressuredropofheat exchangertubewith0.1&0.2b/DRatio

From this figure we can say that the heat exchanger tube withb/DRatioof0.2havethelowestOutletpressuredrop.

From this figure we can say that the heat exchanger tube with b/D Ratio of 0.2 have the highest Outlet velocity differencewhichcauseturbulency.

From graph 9.2.1 & 9.2.2 we can say that the heat exchanger tube with b/D Ratio of 0.2 have the highest velocityandtemperaturedrop

Aheatexchangerisasystemusedtotransferheatbetween two or further fluids. They are considerably used in space heating, refrigeration, air exertion, power stations, chemicalshops,petrochemicalshops,petroleumrefineries, natural gas processing, and sewage treatment. With the ever increasingly severe energy and terrain problems, there has been a swell of interest in largely effective energy conversion and operation in recent times. It's well known that convective heat transfer sensations are generally involved in the process of energy operation, and perfecting the convective heat transfer performance by heat transfer enhancement ways is significant for energy conservation and environmental protection. The end at using the vortex flaps is to producecounter rotating vortices inside the tube to help increase the turbulence intensityaswellastoconveythecolderfluidfromthecore governance to the heated wall region. The proposed design is meant to meliorate the heat transfer rate due to the enhanced wind and turbulence. The crooked vortex flaps are precisely designed so as to have minimum effect inmassfluxrate

[1] S. Eiamsa ard, P. Promvonge, Heat transfer characteristics in a tube fitted with helical screw tape with/without core rod inserts, Int. Commun. Heat Mass Transfer34(2)(2007)176e185.

[2] S. Eiamsa ard, S. Pethkool, C. Thianponge, P. Promvonge,Turbulentflowheattransferandpressureloss

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

inadoublepipeheatexchangerwithlouveredstripinserts, Int.Commun.HeatMassTransfer35(2008)120e129.

[3] S. Eiamsa ard, C. Thianponge, P. Eiamsa ard, P. Promvonge,Convectiveheattransferinacirculartubewith short length twisted tape insert, Int. Commun. Heat Mass Transfer36(2009)365e371.

[4] P. Promvonge, Thermal augmentation in circular tube with twisted tape and wire coil turbulators, Energy Convers.Manage.49(2008)2949e2955.

[5] P. Promvonge, Thermal performance in circular tube fitted with coiled square wires, Energy Convers. Manage. 49(5)(2008)980e987.

[6] P. Promvonge, Thermal enhancement in a round tube withsnailentryandcoiled wireinserts,Int.Commun.Heat MassTransfer35(2008)623e629.

[7] V. Kongkaitpaiboon, K. Nanan, S. Eiamsa ard, Experimental investigation of convective heattransfer and pressure loss in a round tube fitted with circularring turbulators, Int. Commun. Heat Mass Transfer 37 (2010) 568e574.

[8] C. Thianpong, K. Yongsiri, K. Nanan, S. Eiamsa ard, Thermal performance evaluation of heat exchangers fitted with twisted ring turbulators, Int. Commun. Heat Mass Transfer39(2012)861e868.

[9] P. Promvonge, S. Skullong, S. Kwankaomeng, C. Thiangpong, Heat transfer insquare duct fitted diagonally with angle finned tape e part 1: experimentalstudy, Int. Commun.HeatMassTransfer39(5)(2012)617e624.

[10] P. Promvonge, S. Skullong, S. Kwankaomeng, C. Thiangpong, Heat transfer insquare duct fitted diagonally with angle finned tape e part 2: numerical study, Int. Commun.HeatMassTransfer39(5)(2012)625e633.

[11] K. Yakut, B. Sahin, S. Canbazoglu, Performance and flow induced vibrationcharacteristics for conical ring turbulators,Appl.Energy79(2004)65e76.

[12] K. Yakut, B. Sahin, Flow induced vibration analysis of conical rings used of heat transfer enhancement in heat exchanger,Appl.Energy78(2004)273e288.

[13] P. Promvonge, Heat transfer behaviors in round tube with conical ring inserts, Energy Convers. Manage. 49 (2008)8e15.

[14] A. Durmus, Heat transfer and exergy loss in cut out conical turbulators, Energy Convers. Manage. 45 (2004) 785e796.

[15] P. Promvonge, S. Eiamsa ard, Heat transfer behaviors in a tube with combinedconical ring and twisted tape insert, Int. Commun. Heat Mass Transfer 34(2007) 849e859.

[16] M.E. Taslim, T. Li, D.M. Kercher, Experimental heat transferandfrictioninchannelsroughened withangled, V shaped, and discrete ribs on two opposite walls, ASME J. Turbomach.118(1996)20e28.

[17] P.R. Chandra, C.R. Alexander, J.C. Han, Heat transfer andfrictionbehaviourinrectangularchannelswithvarying number of ribbed walls, Int. J. Heat Mass Transfer 46 (2003)481e495.

[18]V.Ozceyhan,S.Gunes,O.Buyukalaca,N.Altuntop,Heat transfer enhancement in a tube using circular cross sectional rings separated from wall, Appl. Energy 85 (2008)988e1001.

[19] S.O. Akansu, Heat transfers and pressure drops for porous ring turbulators ina circularpipe, Appl. Energy 83 (2006)280e298.

[20]S.Kwankaomeng,P.Promvonge,Numericalprediction on laminar heattransfer in square duct with 30 angled baffle on one wall, Int. Commun. Heat Mass Transfer 37 (2010)857e866.

[21] P. Promvonge, S. Sripattanapipat, S. Tamna, S. Kwankaomeng, C. Thianpong,Numerical investigation of laminarheat transfer ina square channel with 45 inclined baffles, Int. Commun. Heat Mass Transfer 37 (2010) 170e177.

[22] P. Promvonge, W. Jedsadaratanachai, S. Kwankaomeng, Numerical study oflaminar flow and heat transfer in square channel with 30 inline angled baffleturbulators, Appl. Therm. Eng. 30 (11e12) (2010) 1292e1303.

[23] P. Promvonge, S. Sripattanapipat, S. Kwankaomeng, Laminar periodic flow andheat transfer in square channel with 45 inline baffles ontwo opposite walls,Int. J. Therm. Sci.49(2010)963e975.

[24] P. Promvonge, W. Changcharoen, S. Kwankaomeng, C. Thianpong, Numericalheat transfer study of turbulent square duct flow throughinline V shapeddiscrete ribs,Int. Commun.HeatMassTransfer38(10)(2011)1392e1399.

[25] P. Sriromreun, C. Thianpong, P. Promvonge, Experimental and numericalstudy on heat transfer enhancement in a channel with Z shaped baffles, Int. Commun.HeatMassTransfer39(2012)945e952.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

[26] ASME, Standard, Measurement of Fluid Flow in Pipes Using Orifice, Nozzle and Venturi. ASME MFC 3M 1984, UnitedEngineeringCenter,345East47th Street,NewYork, 1984,pp.1e56.

[27]ANSI/ASME,MeasurementUncertainty,1986.PTC19, 1e1985.PartI.

[28] F. Incropera, P.D. Dewitt, Introduction to Heat Transfer,fifthed.,JohnWiley&SonsInc,2006.

[29] W.Q. Tao, Y.L. He, A unified analysis on enhancing single phase convectiveheat transfer with field synergy principle,Int.J.HeatMassTransfer45(20024871e4879.

[30]J.M.Wu,W.Q.Tao,Investigationonlaminarconvection heat transfer in finand tube heat exchanger in aligned arrangement with longitudinal vortexgenerator from the view point of field synergy principle, Appl. Therm. Eng. 27(2007)2609e2617.

[31] W. Liu, Z.C. Liu, Physical quantity synergy in laminar flowfieldand itsapplication inheattransfer enhancement, Int.J.HeatMassTransfer52(2009)