International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1Masters in Construction Technology and Management, Department of Civil Engineering, Desh Bhagat University, Punjab India.

1Assistant Professor in the Department of Civil Engineering, Desh Bhagat University, Punjab India. ***

Abstract - Concrete is a construction chemical compound composed primarily of water, aggregate, and cement. Often, added constituents and reinforcements are incorporated in the mixture to accomplish the wanted functional characteristics properties) of the completed material. At point when these fix ups are mixed together, they frame a liquid mass that is formed into shape. After some time, the concrete structures a hard grid which ties whatever remains of the fixings together into a solid stone like material with numerous uses . Concrete is a to a great degree adaptable building material in light of the fact that, it can be designed for compressive strengths running from M 10, to 140 MPa or higher and workability going from 0 mm slump to 150mm slump or more. Concrete with a compressive strength under 50 MPa is viewed as ordinary strength. The basic elements of concrete in both of these occurrences are the same. However, the conclusion is its nearly equivalent proportioning. The exploratory system comprised of experimental work on concrete developed by ACI, DOE, USBR and BIS method mix design method to portray & think concerning its properties, for example, compressive strength, flexure strength, split tensile, abrasion strength. For this objective, the M35 examination of concrete cubes, frames and cylinder designed by ACI, BIS, USBR and BRITISH mix design processes or methods were thrown & tried for individual property after they've been cured for 7,28 and 56 days. For every stage curing an arrangement of different three specimens of every sort had been thrown. The effect of varying fine aggregates i.e. stone dust and sand on strength parameter discussed above, were studied and cost analysis was done on the basis of aggregates used as the cement constituents & water to cement ratio was kept constant.

Key Words: Stone Dust, Mix Design, Split Tensile Strength, Compressive Strength. Flexural Strength.

Concreteisacompositematerialmadeforthemostpartoutof water,aggregate,andcement.Often,addedconstituentsand reinforcementsareincorporatedinthemixturetoaccomplish thewantedphysicalpropertiesofthecompletedmaterial.At thepointwhenthesefixingsaremixedtogether,theyframea liquid mass that is formed into shape. After some time, the

concretestructuresahardgridwhichtieswhateverremainsof the fixings together into a solid stone like material with numerous uses . Concrete is a to a great degree adaptable buildingmaterialinlightofthefactthat,itcanbedesignedfor compressivestrengthsrunningfromM10to140MPaorhigher andworkabilitygoingfrom0mmslumpto150mmslumpor more.Concretewithacompressivestrengthunder50MPais viewedasordinarystrength.Ineveryoneofthesecasesthe fundamentalelementsofconcretearethesame;howeveritis theirrelativeproportioningthathastheeffect.

Mix design is a procedure of determining the blend of constituentsneededtomeetexpectedpropertiesoffreshand solidifiedconcrete.Concretemixdesignisthemethodofright proportioning of elements of concrete according to the site prerequisites,keepinginmindtheendgoaltogetattractive propertiesofconcreteinplasticaswellasinsolidifiedstage The prime target of proportioning a concrete mix is to get relativeamountsofelementsforthemostpracticalmixthat meetsthebasecriteriaofquality,workability,sturdiness,total attributes and economy. Reasonable proportioning of the elements of concrete is the fundamental nature of concrete mix design and its motivation is to guarantee most ideal extentsoftheconstituentmaterialstomeetthenecessitiesof thestructurebeingfabricated.Mixdesignisvitalindifferent ways.Basicconcretemustopposeexternalforces&internal stressesbecauseofdifferentsortsofloads.Soconcretemust showcertainbaseproperty,forexample,quality,consistency, sturdinessandsoon.

Consequentlysomesuitablematerialsoughttobechosen& theirrelativeamountsoughttoberesolved.Againconcrete oughttobecleaningspecialistinthemostfinancial procedure.

It should be made certain in mix design that, the concrete:

Agreestotheparticularofstructuralstrengthsetdown, whichistypicallyexpressedregardingthecompressive strengthofstandardtestsamples.

Becapableforbeingblended,transported,compacted andputasproductivelyaswouldbeprudent.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Maximum cement content to maintain a strategic distance from shrinkage cracking because of temperaturecycleinmass

Greatest water cement ratio and/or greatest cement contenttogivesatisfactorystrengthforthespecificsite conditions.

Variousstandardmixproportioningmethodsareaccessible for routine normal strength concrete (NSC). Numerous methodshavebeencreatedtotouchbaseattheseextentsin an investigative way. There are four entrenched mix plan techniques for planning normal strength concrete (NSC) mixes to be specific Indian, American, US Bureau of Reclamation(USBR)and BritishStandardmethods.These methods have some consistent ideas in touching base at extentshowevertheirstrategyforcomputationisdiverse

This section gives an itemized portrayal of the materials utilized as a part of the exploratory program and testing strategies utilized as a part of this study. The exploratory system comprised of research centre test on concrete designedbyACI,USBR,BISandBRITISHmixdesignmethodto portray and think about the properties, for example, compressivestrength,flexurestrength,splittensilestrength, abrasion.Forthisreasoncubes,beamsandcylindersofM35 andM40evaluationsofconcretedesignedbyACI,USBR,BIS andBRITISHmixdesignmethodswerethrownandtriedfor the individual properties after a curing time of 7,28 and 56 days. For every stage curing an arrangement of three specimensofeverysortwasthrown.

Thewaterutilizedformixingandcuringwasspotlessandfree fromdamagingamountsoforganicandnon organicharmful substancesanddifferentsubstancesthatmaybeinjuriousto totalsorconcrete.Consumablewaterwasutilizedasapartof concretebrickwork.ThepHestimationofwateroughttobeat least6.

Theprovinciallyaccessiblestonedustandsandwereutilized independentlyinthisanalysis.Itsvariousphysicalproperties weretestedasperIS:383 1970.20mmand12.5mmgraded aggregateswereusedinsucharatiothatitcombinestoform 20mm graded aggregates. Various properties of fine and coarseaggregatesarelistedbelow:

Finenessmodulus=2.8

Gradingzone=zone3 Specificgravity=2.65

For Sand:

Specificgravityofcoarseaggregates=2.72 Gradingratioof20mmaggregatesto12.5mm=1.5:1(60% 20mm&40%12.5mm)

UnitweightofCoarseaggregates=1450

The cement utilized as a part of this trial project is the PortlandPozolonabondofgrade43.Itwastestedaccordingto theimportantprocurementsofIScodeandresultsaregiven belowintable3.1

Table 1: - Properties of

Procurements of IS 8112 1989 Standard consistency(using Vicatapparatus) 33

Property VALUES

Initialsettingtime (min.) 65 >30mins Finalsettingtime (min.) 435 <10hrs Specificgravity 3.0 3.0 3.15

Mix design for M35 grade of concrete

Concretewithaparticularfinishedobjectivetogetcharming properties of concrete in plastic additionally in cemented stage the prime focus of proportioning a concrete mix is to securerelativemeasuresofcomponentsforthemildmixthat meets the base criteria of strength, workability, sturdiness, aggregatetraitsandeconomy.

3.2.1

Targetmeanstrength=43.25

Watercementratio=0.40

Cement=415 kg

Watercontent=415*0.40 =166Lt

Amountofplasticizeradded1%ofcementcontent= 1*415/100=4.15Lt

Volumeofcoarseaggregate correspondingtounit volumeoftotalaggregatefordifferentzonesoffine aggregate=0.66

Volumeoffineaggregates=(1 0.66)=0.34

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Absolutevolumeofcement=415/3.0*1/1000=0.138

Water=164/1000=0.166 Plasticizer=4.15/1.1*1/1000=0.0037

Totalaggregates=1 (0.138+0.166+0.0037)=0.692 Massofcoarseaggregate=0.692*0.66*2.72*1000= 1242.27 kg/m3 Mass of fine aggregate = 0.692*2.54*1000*0.32 = 623.49kg/m3 Finalratio

Table 2: Ratio of constituents of M35 grade concrete for BIS method Cement F.A C.A Water Plasticizer For1 m3 415 623.49 1242.27 166 4.15 3.2.2 MIX DESIGN OF M35 BY ACI METHOD.

Specificgravityofcoarseaggregates=2.72

Specificgravityoffineaggregates=2.65 Gradingratioof12.5mmand20mmaggregates=1:1.5

Specificgravityofcement(PPC)=3.0

Finenessmodulusoffineaggregates=2.8 UnitweightofC.A=1450

Specificgravityofcoarseaggregates=2.72

Specificgravityoffineaggregates=2.65 Gradingratioof12.5mmand20mmaggregates=1:1.5 Specificgravityofcement(PPC)=3.0 Finenessmodulusoffineaggregates=2.4

Targetmeanstrength=48.25 Water cementratio=0.40 Cement=430kg Watercontentaccordingtothetable4.

Max size of Air content Fine C.A Water Aggregate Aggregates

20mm 6% 42% 62% 156ltr.

Amountofplasticizeradded1%ofcementcontent= 1*430/100=4.3ltr.

Table 5. Adjustments for water content

Water Sand C.A

Targetmeanstrength=43.25 Watercementratio=0.40 Cement=415 kg Watercontent=415*0.40 =166Lt Amount of plasticizer added 1% of cement content = 1*415/100=4.15Lt FinenessmodulusofF.A=2.8 BulkvolumeofC.A=0.62 MassofC.A=0.62*1450=899kg Absolute volume of cement = 415/3.0*1/1000 =0.138 Water=166/1000=0.166. Plasticizer=4.15/1.1*1/1000=0.0038 C.A=899/2.72*1/1000=0.330 Fineaggregates=(1 0.330 0.166 0.138 0.0038)= 0.362

Massoffineaggregates=0.362*2.65*1000=959.3 Finalratioinkg

Table 3: Ratio of constituents of M35 grade concrete for ACI method

Cement F.A C.A Water Plasticizer

For1 m3 415 959.3 899 166 4.15

Fineness modulus 3.1% +6.2% (2.75 2.4) Slump 6% (25 50mm) Aircontent +18% +4.5% 6% Watercement ratio 0.4% 0.38 Sand +0.4% 0.8% +1%

Sowatercontent=+12.4%=175.34kg F.A=+0.4% =42.4%

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

C.A= +5.4%=67.4%

VolumeofF.A (1000 430/3 175.34)*0.424=290.79.

Weightofstonedust=290.79*2.65=290.79Kg

VolumeofC.A= 685.83 290.29=395.54

WeightofC.A=395.54*2.72=1052kg

Finalratioinkg

Table 6. mix proportions of M35 as per USBR method

Cement F.A C.A Water Plasticizer

For1 m3 430 290.79 1052 175.34 4.3

Specificgravityofcoarseaggregates=2.72

Specificgravityoffineaggregates=2.65

Gradingratioof12.5mmand20mmaggregates=1:1.5

Specificgravityofcement(PPC)=3.0

Finenessmodulusoffineaggregates=2.8 Wetdensityofconcrete=2400

Water cementratio=0.40

Cement=415 kg

Watercontent=415*0.40 =166Lt

Amountofplasticizeradded0.8%ofcementcontent= 0.8*415/100=3.32Lt

Volumeofcoarseaggregate correspondingtounit volumeoftotalaggregatefordifferentzonesoffine aggregate=0.66+0.02=0.68

Volumeoffineaggregates=(1 0.68)=0.32

Absolutevolumeofcement=415/3.0*1/1000=0.138 Water=164/1000=0.166 Plasticizer=3.32/1.1*1/1000=0.0033

Totalaggregates=1 (0.138+0.166+0.0033)=0.692

Massofcoarseaggregate=0.692*0.68*2.72*1000= 1281.21kg/m3

Mass of fine aggregate = 0.692*2.54*1000*0.32 = 562.45kg/m3

Finalratio

Table 8: Mix proportions of M35 as per BIS method

Cement F. A C. A Water Plasticizer For1 m3 415 562.45 1281.21 166 3.32

Test data required:

Targetmeanstrength=43.25 Water cementratio=0.40 Cement=415 kg Watercontent=415*0.40 =166Lt

Amountofplasticizeradded1%ofcementcontent= 1*415/100=4.15Lt

Totalaggregatecontent=2400(1 415/3000 0.166 0.0030)=1662.4kg

Percentageoffineaggregates=22%by1662.4= 22*1662.4/100=365kg

Specificgravityofcoarseaggregates=2.72

Specificgravityoffineaggregates=2.54 Gradingratioof12.5mmand20mmaggregates=1:2 Specificgravityofcement(PPC)=3.0 Finenessmodulusoffineaggregates=2.4 UnitweightofC.A=1450

Mix design:

Massofcoarseaggregates=1297kg Finalratioinkg

Table

Targetmeanstrength=43.25

Targetmeanstrength=43.25

Water cementratio=0.40

Cement=415 kg

Watercontent=415*0.40 =166Lt

Amount of plasticizer added 1% of cement content = 1*415/100=4.15Lt

FinenessmodulusofF.A=2.4

BulkvolumeofC.A=0.66

MassofC.A=0.66*1450=957kg

Absolutevolumeofcement=415/3.0*1/1000=0.138

Water=166/1000=0.166

Plasticizer=4.15/1.1*1/1000=0.0038

C.A=957/2.72*1/1000=0.351

Fineaggregates=(1 0.351 0.166 0.138 0.0038)= 0.341

Massoffineaggregates=0.341*2.54*1000=866.65

Finalratioinkg

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Table 9: Mix proportions of M35 as per ACI method

Cement F.A C.A Water Plasticizer For1 m3 415 866.65 957 166 4.15

3.3.3

Table12:

Cement F.A C.A Water Plastic izer For 1 m3 415 738.6 1075.86 175.34 4.15

Targetmeanstrength=43.25 Watercementratio=0.45 Cement=415kg Watercontentaccordingtothetablebelow:

Specificgravityofcoarseaggregates=2.72

Specificgravityoffineaggregates=2.54

Gradingratioof12.5mmand20mmaggregates=1:2

Specificgravityofcement(PPC)=3.0

Table 10. Water content table

Max size of Air content Fine C.A Water Aggregate aggregates 20mm 6% 42% 62% 156lt

Amountofplasticizeradded1%ofcementcontent= 1*415/100=4.15lt

Table 11. Adjustments for water content

Water Sand C.A Fineness modulus 3.10% 6.20% (2.75 2.4) Slump 6% (25 50mm) Aircontent 18% 4.50% 6% Water cement ratio 1% 0.4 Sand 0.40% 0.80% 0.40%

Finenessmodulusoffineaggregates=2.4 Wetdensityofconcrete=2400

Mix

Targetmeanstrength=43.25 Water cementratio=0.40 Cement=415 kg

Watercontent=415*0.40 =166Lt

Amount of plasticizer added 1% of cement content = 1*415/100=4.15Lt

Total aggregate content = 2400 (1 415/3000 0.166 0.0030)=1662.4kg

Percentageoffineaggregates=25%by1662.4 =25*1662.4/1=415.6kg Massofcoarseaggregates=1246.8kg Finalratioinkg

Table 13: mix proportions of M35 as per DOE method

Cement F.A C.A Water Plasticizer For 1 m3 415 415.6 1246.8 166 4.15

Panmixerwasutilizedformixingconstituents.Allcubes, beamsandcylinderswerethrowninthestandardmetallic forms and vibrated to get obliged example size. The moulds were tidied up dust and oil was applied on all sidesofmouldsbeforecementingthespecimen.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page467

F.A=+0.4% =42.4% C.A= +5.4%=67.4% VolumeofF.A (1000 415/3 175.34)*0.424 (685.83)*.43=290.79 Weightofsand=290.79*2.54=738.6 VolumeofC.A= 685.83 290.79=395.54 WeightofC.A=395.54*2.72=1075.86kg Finalratioinkg

Altogethermixedconcretewasfilledthemouldsinthree equivalent layers and the moulds were put on vibrating table for a little period. Over abundance concrete is uprootedwithatrowelandthetopsurfaceisdonewitha smoothsurface

Procedure:

Expelledthesamplefromwaterafterthepredetermined curing time and wipe out abundance water from the surface.

Cleanedthebearingsurfaceofthetestingmachine Putthesampleinthemachineinsuchaway,tothepoint thattheloadshallbeconnectedtotheoppositesidesof thecubecast.

Alignedthespecimencentrallyonthebaseplateofthe machine.

Rotated the movable portion gently by hand so that it touchesthetopsurfaceofthespecimen.

Applytheloadgradually,withoutshockandcontinuously attherateof140kg/cm2/minutetillthespecimenfails Recorded the maximum load and noted any unusual featuresinthetypeoffailure.

The moulds were demoulded after 24hrs and put in curing tankfortherespectiveperiodsof7,28and56days.Asetof3 sampleswaspreparedforeachstagecuring.Thetemperature ofcuringtankwaskeptat25°±2°cfor56days.

Theaccompanyingteststrategieswereledsoastoanalyzethe sought properties of concrete designed by distinctive methods.

The test specimens were cubical in shape (150 * 150 * 150 mm).Mouldswerefilledfortestingat7,28,56dayscuring.

Thecylindermouldshellisofmetal,3mmthick.Thecylinders usedtobewithdimensions20cmlengthand10cmDIA.Each mouldwascapableofbeingopenedlongitudinallytofacilitate theremovalofthespecimen

Concretecylinderwerefilledfortestingat7,28,56days.At least3mouldswerefilledfortestingateachstagecuring

Fig. 4: Gear for split tensile testing of cylindrical specimen

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Procedure:

Took thewetspecimenfromwaterafter curing

Wipeoutwaterfromthesurfaceofthespecimen.

Notedtheweightanddimensionofthespecimen.

Set the compression testing machine for the required range.

Placedthesampleinthesplittensiletestingassembly.

Placedtheassemblyinthecompressiontestingmachine.

Bringdowntheupperplatetotouchtheassembly.

Apply the load continuously without shock at a rate of approximately14MPa/min.

Notedownthebreakingload(P)

AsperIS456,splittensilestrengthofconcrete.=0.7Fck Thesplittingtensilestrengthiscalculatedusingtheformula

Tsp = 2P/ π DL

WhereP=appliedload

D=diameterofthespecimen

L=lengthofthespecimen

Testspecimenswerepreparedbymoldingsconcretetoa beam section, curing and storing in accordance with standard procedure. The section of the beam shall be (100*100*500)mm.

Mouldswillbefilledfortestingat7,28,56days.Atleast 3mouldswerefilledfortestingateachstagecuring

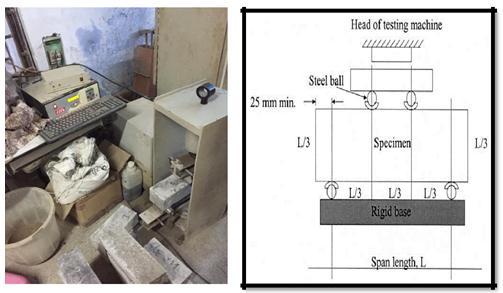

Afourpointbendingtestwasconductedtomeasurethe flexural strength of concrete beams. Circular rollers manufactured out of steel having cross section with diameter 38mm were used for providing support and loadingpointstothespecimens.Thelengthoftherollers was at least 10 mm more than the width of the test specimen.A total of four rollerswasused,threeoutof whichwerecapableofrotatingalongtheirownaxes.The distancebetweentheouterrollers(i.e.Span)was 3d and thedistancebetweentheinnerrollerswas d.Theinner rollers were equally spaced between the outer rollers, suchthattheentiresystemissystematic.

Thespecimensstoredinwaterweretestedimmediately on removal from water; while they were still wet. The test specimens were placed in the machine correctly centered with the longitudinal axis of the specimen at rightanglestotherollers.Themouldfillingdirectionwas normaltothedirectionofloading.

Theloadshallbeappliedslowlywithoutshockattherate 1.0MPa/mininallcases.

TheFlexuralStrengthisgivenby fb= pl/bd2 a>200.0mmfor15.0cmspecimenor>13.0cmfor100.0mm specimen. fb= 3pa/bd2 a<20.0cmbut>17.0for15.0cmspecimenor<133mm but>11.0cmfor100.0mmspecimen. b=widthofspecimen d=failurepointdepth l=supportedlength p=max.Load

The abrasion testing machine was utilized for this test as determined in IS 1237. Test size: square molded sample (71.0mm)wasutilizedastestfortesting.Thesampledriedto consistentmassatatemperatureof105degreec.Thesample wastriedfollowing7and28dayscuring.3samplesweretried ateverycuringstage.

The weight of specimen was noted nearest to 0.1 gm beforetestandaftereveryfourcycles. The grinding path was evenly strewn with 20 gm of abrasive powder. The specimen was fixed in holding devicesuchthatthetestsurfacefacesthegrindingdisc. Thespecimenwascentrallyloadedwith294N. Thegrindingdiscrunsataspeedof30RPM.Thediscwas stoppedafteracycleof22revolutions.

The test cycle was repeated 16 times, the specimen being turned90ˑintheclockwisedirectionandspreading20gmof abrasivepowderontestingtrackaftereachcycle.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Theabrasivewearofspecimenafter16cycleswillbe calculatedasthemeanlossinthethickness.

∆t = W − W ∗ V/W ∗ A

Δt = loss in thickness after 16 cycles

W1 = initial mass of the sample

W2 = final mass of the sample

Fig.

A=areaofsampleinmm2 V=volumeofsample. Theabrasivewearshallbereportedtothenearestwhole numberof1000mmper5000mmз.

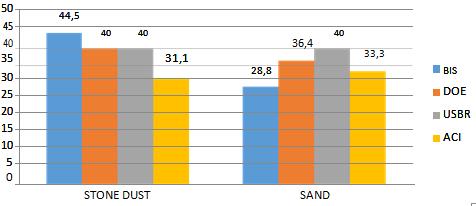

Thecompressivestrengthofdistinctivespecimenswastried following7,28and56daysofcuring.The150mmcubeswere triedoncompressiontestingmachineundermonotonicload @ 14Mpa/min. The crucial compressive load of the cubes obtainedfromdiversemixdesignmethodsissaidinthetable underneath

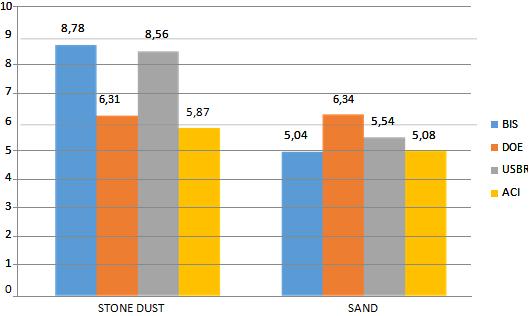

Chart 1: Compressive strength of M35 grade of concrete at 7 Days

Chart 2: Compressive strength of M35 grade of concrete at 28 Days.

Chart 3: Compressive strength of M35 grade of concrete at 56 Days.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table 14: Compressive strength of M35 grade of concrete at 7, 28 & 56 days for stone dust and sand

span length (mm) that is the distance between the line of fractureandthenearesqqtsupportmeasuredfromthecenter line of the tensile side of specimen, B is the width of the specimen(mm),disthedepthofspecimen(mm)

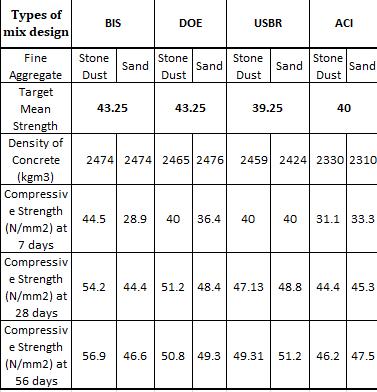

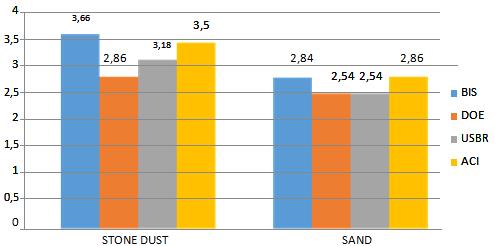

Chart4: Flexure strength of M35 grade of concrete at 7 days.

The comparison was carried out between compressive strength of concrete composed by IS, DOE, ACI and USBR methods for M35 evaluation utilizing stone dust and sand independentlyasfineaggregates.

For M35 concrete designed by BIS method, there was huge 50%raisein7Dayscompressivestrength,22%increasein28 daysand56dayscompressivestrengthofcubescastedusing stonedustascomparedtocubescastedusingsand.ForM35 concretedesignedbyDOEmethod,therewas9%increasein7 Days compressive strength, 4% increase in 28 Days and 56 dayscompressivestrengthofcubescastedusingstonedustas compared to cubes casted using sand. Taking into account M35concretedesignedbyUSBRmethod,itwasnotedthatthe cubes casted with sand achieved same (i.e. 40 N/mm2) compressive strength at 7 Days whereas there was slight increaseof3%incompressivestrengthatboth28and56days strength of cubes casted using sand as compared to compressive strength of cubes casted using stone dust. SimilarlyforM35concretedesignedbyACImethod,itwasthe cubes casted sand which achieved a slight increase in compressivestrengthat7,28and56days.

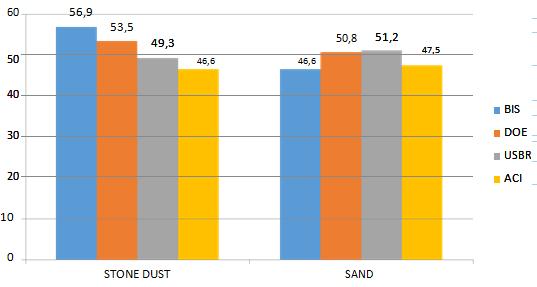

Thebeamsofdimensions(10*10*50cm)werepreparedand testedafter7,28and56daysofcuring.Beamsweretested undermonotonicincreasingloadingtodeterminetheflexural tensilestrength.Therateofloadapplicationwas1.0MPa/min in all cases. The flexural strength can be determined as PL/BD2 ,wherePisthemaximumnodeapplied (N),Listhe

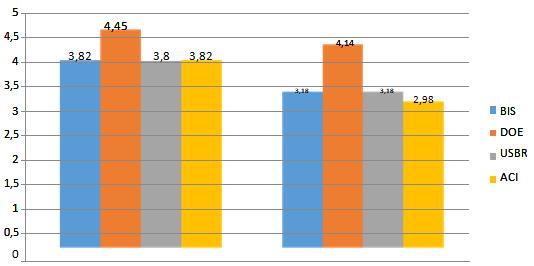

Chart5: Flexure strength of M35 grade of concrete at 28 days.

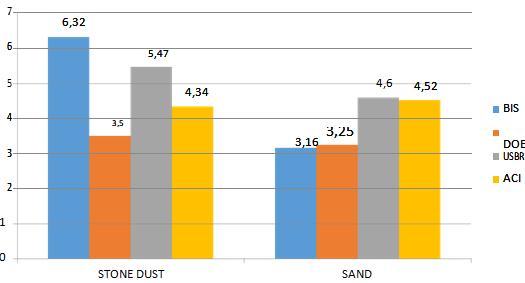

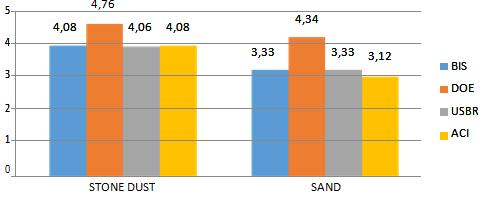

Chart 6: Flexure strength of M35 grade of concrete at 56 days.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

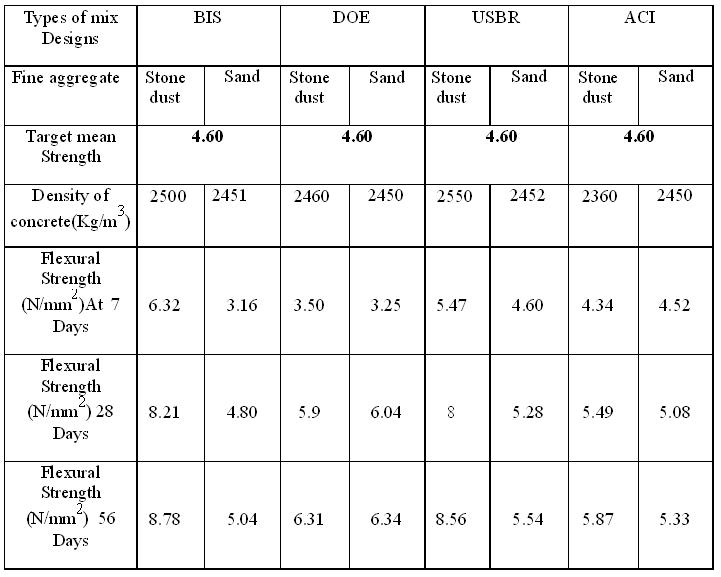

Table 15: Flexure strength of M35 grade of concrete at 7, 28 & 56 days for stone dust and sand

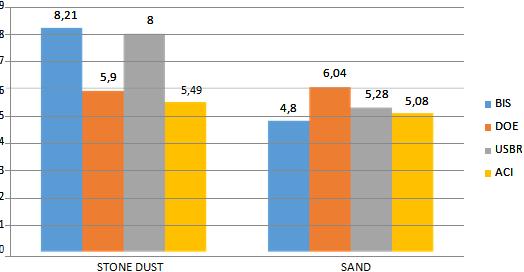

Chart 7: Split Tensile strength of M35 grade of concrete at 7 days.

The comparison was carried out between compressive strength of concrete designed by IS, DOE, ACI and USBR methods for M35 grade using stone dust and sand independentlyasfineaggregates. For M35 concretedesigned byBISmethod,therewashuge50%raisein7Daysflexural strength, 71% increase in 28 days and 74% increase in 56 days flexural strength of cubes casted using stone dust as compared to cubes casted using sand. For M35 concrete designed by DOE method, there was 7% increase in 7 Days flexuralstrength,2%decreasein28Daysandsimilar56days flexuralstrengthofcubescastedusingstonedustascompared tocubescastedusingsand.TakingintoaccountM35concrete designedbyUSBRmethod,itwasnotedthatthecubescasted with stone dust achieved higher (i.e. 5.41 N/mm2) flexural strengthat7Days,whereitwasanincreaseof51%inflexural strengthatboth28and56daysstrengthofcubescastedusing stonedustascomparedtoflexuralstrengthofcubescasted using sand. Whereas, for M35 concrete designed by ACI method,itwasthecubescastedsandwhichachievedaslight increaseinflexuralstrengthat7,28and56days.

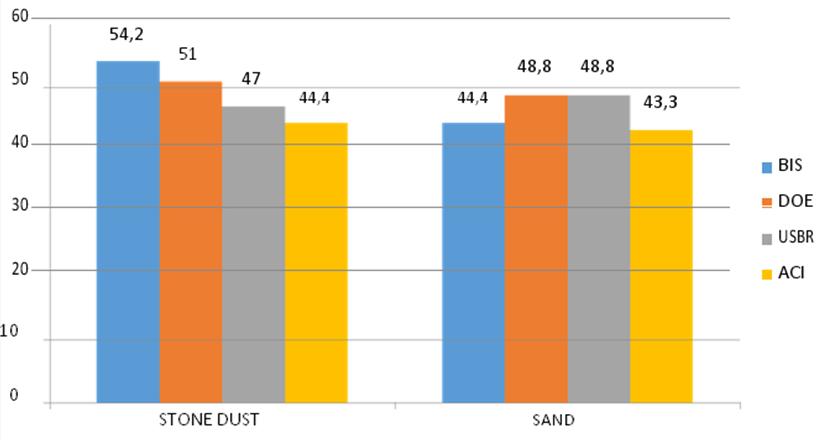

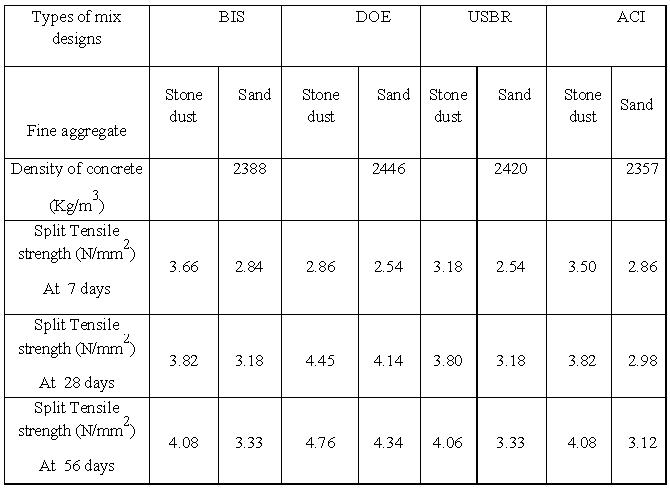

Cylindersof10cmdiameterand20cmlengthwereprepared and tested under increasing loading @14 MPa/min. Three cylindersweretestedat7,28and56daysofcuringforeach typeofmixdesign.TheSplitTensileStrengthisdeterminedby 2P/πLD WhereP=Loadatwhichsamplefails,L=lengthofthe specimencylinder,D=diameterofthespecimencylinder.

Chart 8: Split Tensile strength of M35 grade of concrete at 28 days.

Chart 9: Split Tensile strength of M35 grade of concrete at 56 days.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table 16: Split tensile strength of M35 grade of concrete at 7, 28 & 56 days for stone dust and sand

Ensuing to examination of the information acquired from outlinesforsplittensilestrengthforM35evaluationconcrete composedbyACI,USBR,DOEandBISmethodsutilizingstone dustandsandindependentlyasfineaggregates,takingafter certaintieswerewatched.

For M35 concrete designed by BIS method, there was 10% raisein7Dayssplittensilestrength,30%decreasein28days and56dayssplittensilestrengthofcubescastedusingstone dust as compared to cubes casted using sand. For M35 concretedesignedbyDOEmethod,therewas55%decreasein 7Dayssplittensilestrength,24%decreasein28Daysand56 dayssplittensilestrengthofcubescastedusingstonedustas comparedtocubescastedusingsand.TakingintoaccountM35 concrete designed by USBR method, it was noted that the cubescastedwithstonedustachieved25%moresplittensile strengthat7Days,alsotherewasanincreaseof19%insplit tensile strength at both 28 and 56 days strength of cubes casted using stone dust as compared to flexural strength of cubescastedusingsand.WhereasforM35concretedesigned byACImethod,itwasagainthecubescastedstonedustwhich achieveda22%increaseinsplittensilestrengthat7days,and 30%increasein28and56dayssplittensilestrength.

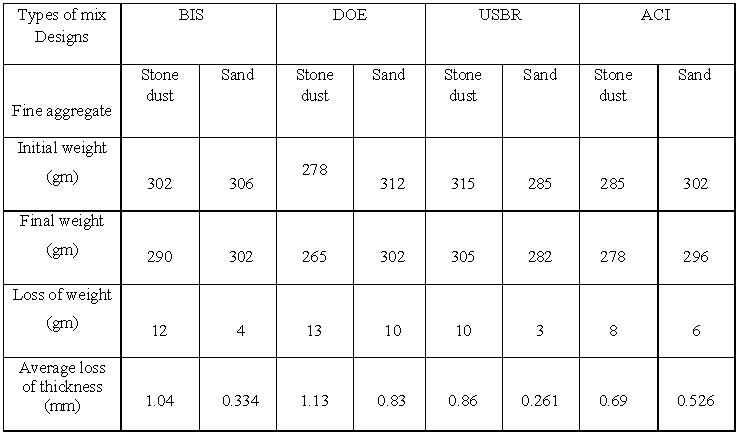

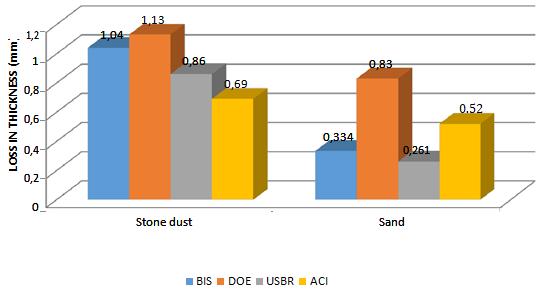

Abrasion test was performed on concrete samples measuring 70*70*25mm, to analyse the toughness of concretedesignedwithvariousmixdesignmethods.The

lossofthicknesswasobservedineachcase.Theresults obtainedareputintoatablebelow.

17: Abrasion values of M35 grade

The examination between the cement planned by different configurationtechniquespresumedthatfor M35 evaluation, testsofUSBRmethodsamplesutilizingstonedustbestowed leastmisfortuneinthickness,yetthehigherstrengthwasseen insamplesofUSBRmethodutilizingsand.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

The M35 grade of concrete were designed by different methods of mix design for fulfillment of objectives in this researchwork.Thecement contentandwatercementratio was fixed in this analysis. The fine aggregates and coarse aggregateswerevariedaccordingtomixdesigns.Tocompare theproportioningparameters ofdifferentmix design methods,theproportionsobtainedasperdesignfrom DOE,ACI,BISandUSBRarelistedbelow:

Table 18: Comparison of Mix proportions of M35 obtained as per different Mix Design Methods using stone dust

Type of mix design W/C Water Content Cement content Stone dust Coarse aggreg ates Plasticiz er

BIS 0. 4 166 415 623.5 1242 4.15

DOE 0. 4 166 415 365 1297 4.15

USBR 0. 4 176 415 855 1008 4.15

ACI 0. 4 166 415 959.3 899 4.15

Table 19: Comparison of Mix proportions of M35 obtained as per different Mix Design Methods using sand

Type of mix design W/C Water Content Cement content Stone dust Coarse aggrega tes Plasticiz er

BIS 0.4 166 415 562.5 1281 4.15

DOE 0.4 166 415 415.2 1246 4.15

USBR 0.42 174. 3 415 738.6 1075 .9 4.15

ACI 0.4 166 415 866.1 957 4.15

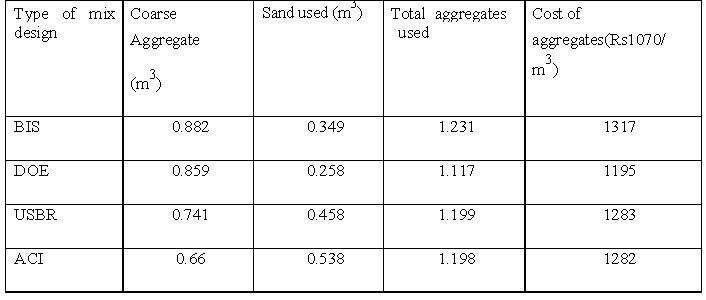

Incontextwiththetablesabove,followingobservationswere made. The amount of cement and water cement ratio were keptsimilarforallthemethodsi.e.cement=430andW/C= 0.38forM40concreteandcement=415,W/C=0.40forM35 concrete.ForM40andM35concrete,theminimumamountof sandwasobservedinDOEmethodwhereasmaximumamount ofsandwasfoundinACImethod.ForbothM35andM40if stonedustistakenintoconsideration,itwasmaximuminACI methodanditwasminimumforDOEmethod.

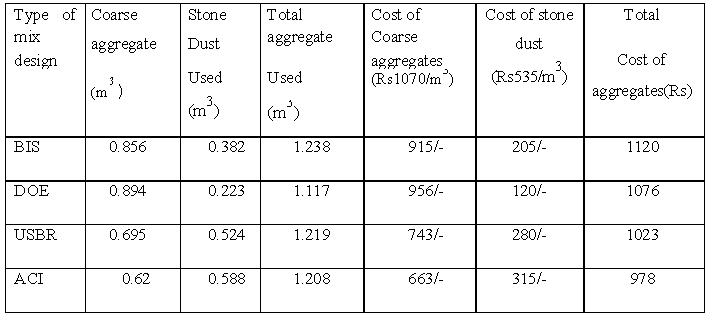

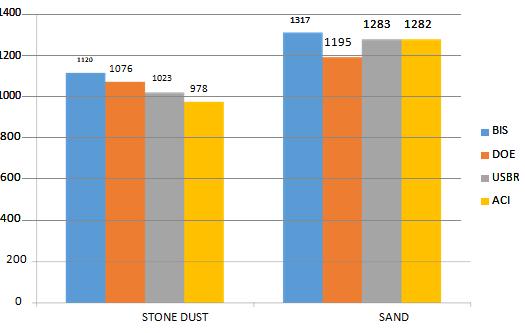

Theexpensecorrelationinthisexplorationisbaseduponthe amount of aggregates fine and coarse utilized as a part of different blend plan method, as the concrete substance is settledforallthemethods.Theexpenseofaggregatesusedto bearontheexaminationistakingintoaccounttheexpenseof by regional standards accessible aggregates without the transportationcost.Theexaminationisexecutedforonem3of concretecomposed.

Table 20: cost evaluation for M35 concrete using stone dust

Table 21: Cost Evaluation for M35 concrete using Sand

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Incaseofcompressivestrength,thetargetmeanstrength wasachievedbyallthesamplesofM35gradeofconcrete using stone dust. For M35 grade concrete while using stone dust, maximum compressive strength was achieved by BIS method (i.e. 54.2 N/mm2 for M35), whereastheleastcompressivestrengthwasimpartedby ACImethodforM35.

Considering for M35 grade, maximum compressive strength was accomplished by DOE and USBR with similarvalues(i.e.48.8N/mm2),thoughleaststrength was accomplished by BIS method (i.e. 43.3 N/mm2) Therefore it was reasoned that stone dust gave preferable compressive strength over that of compressivestrengthgivenbysand.

In the wake of evaluating above tables and outlines, the accompanyingthingshavebeenwatched.Thecementcontent wasfixedforallthemethodsandpriceofaggregatesisvarying ineachmethod.TherateofstonedustisRs.535/ percubic meterwhereasthecostofsandandcrushedcoarseaggregate isRs.1070/ percubicmeter.ForM35concrete,ACImethod usingstonedustprovedtobemosteconomicmethod,whereas BISmethodwithsandprovedtobemostexpensivemethod.

The exploratory system comprised of laboratory test on concretedesignedbyACI,USBR,BISandBRITISHmixdesign method to portray and think about the properties, for example,compressivestrength,flexurestrength,splittensile strength,abrasion.Forthisreasoncubes,beamsandcylinders ofM35evaluationsofconcretedesignedbyACI,USBR,BISand BRITISHmixdesignmethodswerethrownandtriedforthe individualpropertiesafteracuringtimeof7,28and56days. Foreverystagecuringanarrangementofthreespecimensof everysortwasthrown.Thereweretwoarrangementsoftests threw,oneutilizingstonedustandanothersetinvolvingsand, composedautonomouslywithACI,USBR,BISandBRITISHmix designmethodsforM35grade.Afterevaluatingthevaluesof variousstrengthparameters,lossduetoabrasion,varyingmix proportions and cost analysis , some conclusions discussed below were drawn for both M35 concrete designed by distinctivedesignmethodslikeACI,DOE,USBR,BISfurther broadlydifferentiatedwiththetypeofaggregatesi.e.sandand stonedust

Incomparisonwithsandandstonedustasfineaggregates,it wastheconcretecastedusingstonedustthatsubstantiated itselfbetterincompressive,flexural,splittensilestrengthand economy.However,theabrasionmisfortunes were morein stonedustwhencontrastedwithsand.Variousparametersare discussedindetailasfollows:

Takingintoaccounttheflexuralstrengthattainedusing stonedustasfineaggregateafter28dayscuring,same pattern of strength was observed for M35 grade of concretei.e.BISmethod(8.21N/mm2 forM35)wasat peak followed by USBR method (8 N/mm2 for M35), whereastheminimumflexuralstrengthwasattainedby ACImethod(5.49N/mm2 forM35).

The flexural strength achieved by samples using sand was less as compared to the strength achieved by samples casted using stone dust. For M35 grade using sand, the maximum flexural strength at 28 days was achieved by DOE (.i.e.6.04 N/mm2), whereas the minimum flexural strength was given by BIS (i.e. 4.8 N/mm2).

The split tensile strength of the cylinders casted with stone dust and sand offered a marginal difference. For cylinders of M35 grade casted using stone dust, the maximumSplittensileafter28dayswasachievedbyBIS method (i.e. 3.66 N/mm2) whereas the minimum was achievedbyDOEmethod(i.e.2.86N/mm2).

Incontrastwiththecylinderscastedusingsand,theM40 grade cylinders designed by BIS(i.e.5.41 N/mm2) achieved maximum split tensile strength, whereas the minimumwasachievedbyACImethod(i.e.2.99).Inthis regardcylinderswithstonedustachievedaslighthigher spilttensilestrengththanthatofcylinderscastedusing sand.

Theconcretemixdesignedusingstonedustgavemore abrasion losses than the concrete mix designed using sand. For M35 grade of concrete maximum loss in thicknesswasobservedinDOEmethodusingstonedust and minimum loss in thickness was observed in USBR usingsand.

Theanalysisofproportionsofaggregateswascarriedout fordifferentmixdesignmethods.Incaseofstonedust used as fine aggregate, minimum amount of coarse

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

aggregate for M35 was used by ACI method and the maximum amount was used by DOE method .The maximum amount of stone dust and was used by ACI methodandtheminimumwasusedbyDOEmethodfor bothM35. Whereasminimumamountofsandwasused byDOEinM35,whilethemaximumamountofsandwas usedbyACIinbothM35.

Cost analysis of various design mixes was carried out taking into account the variation in aggregates as the cementcontentwasfixedforeverymethod.Intermsof fineaggregates,stonedustwas50%cheaperthansand. Sothesamemixdesignswithsame gradesusingstone dustprovedtobeeconomicalascomparedtosandtobe used as fine aggregate. When stone dust was used the mosteconomicalmethodcameoutbeACIforbothM35 concrete (Rs.883 Rs.978 per cubic meter of concrete), while the most expensive was BIS method (Rs.1120 Rs.1153).WhereaswhenSandwasusedasfineaggregate themosteconomicalwasDOEmethod(Rs1195percubic meterofconcrete).

The overall conclusion of the study reveals that the concrete designed as per BIS method using stone dust achieved higher compressive flexural and split tensile strengthforboththegrades.AstheBISmethodismost expensiveincomparisonwithothermethodstherefore DOEfollowedbyUSBRandthenACIshouldbefavoured foreconomy,strengthparametersandtoughness.

Inthisstudystonedustasafineaggregatewasusedwith crushedaggregate.In future ,attemptscanbemadein usingstonedustwithroundedaggregate.

Thestrengthsachievedbypresentcementcontentgavea good rise in strengths, whereas it can be optimized to bring down the strength near to target strength for economy.

Thefineaggregateasstonedustcanbeusedforhigher compressivestrengthsmorethan40MPa.

Thisstudywouldnotbecomplete,haditnotbeenforalotof assistancefromalotofsources.Itakethisasanopportunityto extendmygratitudetoallofthosewhohavecontributedto thecompletionofthisreportinanymannerlargeorsmall. Iamespeciallygratefultomyguide ER. SHASHNAK YADAV whose remarkable enthusiasm and valuable words were instrumentalinmyperceivingthingsinalogicalmannerand formulatingadirectionforthisstudy.

[1] Amarjit Singh, Kamal Gautam, (University Of Hawaii At Manoa, USA; 30th Conference On OUR WORLD IN CONCRETE & STRUCTURES): 23 24 August 2005, Singapore On Comparison Of ISI And ACI Methods For AbsoluteVolumeConcreteMixDesign

[2] “Concrete Technology”, Gambhir M.L. ,Tata Mcgraw Hill,fifth edition 2013,

[3] “ Concrete mix proportioning as per IS 10262:2009 ComparisonwithIS10262:1982andACI211.1 91”, M.C. Nataraja and Lelin Das

[4] Codeofpracticeforplainandreinforcedconcrete(fourth edition), IS 456:2000, Bureau of India Standard, New Delhi.

[5] Dr.Deepa A. Sinha(Indian Journal Of Applied Sciences) Studied The Compressive Strength Of Concrete Using DifferentMixDesignMethods.Volume:4|Issue:7|July 2014.

[6] H. S. Sureshchandra, G. Sarangapani, and B. G. Naresh Kumar ; “Experimental Investigation on the Effect of Replacement of Sand by Quarry Dust in Hollow ConcreteBlock for Different Mix Proportions” ;International Journal of Environmental Science and Development,Vol.5,No.1,February2014.

[7] Indianstandardconcretemixproportioning Guidelines (Firstrevision)IS10262:2009,BureauofIndiaStandard, NewDelhi,India.

[8] Nataraja, M.C, Lelin Das and N. Richard Sandeep “Comparison of Indian StandardDraft Method and ACI Method of Concrete Mix Proportioning”, Second nationalseminaronadvancesinmaterialsandstructure, IIT,Chennai,India

[9] R.Ilangovana,N.MahendranaAndK.Nagamanib(Vol.3, No.2,May2014)StrengthAndDurabilityPropertiesOf ConcreteContainingQuarryRockDustAsFineAggregate.

[10] S. P. S. Rajput, M. S. Chauhan (International Journal of EmergingTechnologyandAdvancedEngineeringWebsite: www.ijetae.com(SSN2250 2459,ISO9001:2008Certified Journal,), Suitability of Crushed Stone Dust as Fine AggregateinMortars.Volume4,Issue3,March2014.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1Shahid Bin Bashir , Masters inConstructionTechnologyand Management,DepartmentofCivil Engineering,DeshBhagatUniversity, PunjabIndia.

2Shashnak Yadav AssistantProfessorin the DepartmentofCivilEngineering,Desh BhagatUniversity,PunjabIndia.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |