International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Mubeena T S1 , Bindu Sebastian2

1PG student, Dept. of Civil Engineering, KMEA Engineering College, Kerala, India

2Associate Professor, Dept. of Civil Engineering, KMEA Engineering College, Kerala, India ***

Abstract There is an increasing demand for jumbo shapes in the constructions of high rise buildings. Super jumbos are very heavy rolled wide flange sections with up to 140 mm flange thickness and weigh up to 1377 kg/m. An outstanding feature of jumbo sections is their lowcarbonequivalent values. However, there is a lack of knowledge of the behaviour ofthese types of construction, especially under seismic loading. As a part of the study, seismic analyses of jumbo sections with and without RBS connections was evaluated and analytically treated to lateral seismic load. The primarygoalofthe studyis to use the ANSYS WORKBENCH software to compare the performance of several types of RBS in order to reduce premature failure and plastic hinge relocation.

Key Words: Jumbo shapes, RBS Connections, ANSYS, Seismic analysis, Plastic hinge

ReducedBeamSection(RBS)momentresistingconnections are among the most economical and practical rigid steel connections developed in the aftermath of the 1994 Northridge and the 1995 Kobe earthquakes. Experience showsthatsteelstructuressubjectedtoearthquakesbehave well.Thismaybeexplainedbysomeofthespecificfeatures ofsteelstructures,suchas:highductileandstablehysteretic behaviour under cyclic loading. One of the most common solutionstoobtain aductilebehaviouristheutilisation of RBSmomentconnection,whichinvolvescuttingoffportions of the beam flange to limit the force at the critical welds betweenthebeamandcolumn.[1] Ifthissolutionisadopted, theinelasticdeformationsareforcedtohappeninthebeam and not in the column. This would lead to a more ductile behaviourreducingtheriskofcollapse

The "strong column weak beam" design concept was investigatedbytheSACJointVenture,whichwashiredby FEMA.Thisdesignideacanhelpshifttheplasticdeformation from the column to the beam during an earthquake, preventing the connection between the column and the beam from experiencing inelastic deformations. It is best used in conjunction with ArcelorMittal's RBS connection, whichwasreleasedfrompatentin1995.AISCsuccessfully evaluatedthetechnique,whichwasthenincorporatedinto theFEMA350and355documents.[3,4]

To study the behaviour of jumbo structures with and without implementing RBS in beam column connection.

Toinvestigatetheperformanceofdifferenttypesof RBS to optimise the plastic hinge relocation and prematurefailure.

The main objective of this study is to improve seismic performanceofjumbobeamsandcolumns Asapartofthe studytoexamineseismic behaviour,a jumbosection with andwithoutRBSisinvestigated.Afurtherstudyiscarried outtoanalysetheperformanceofdifferenttypesofRBSto optimisetheplastichingerelocationandprematurefailure

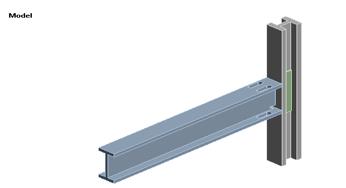

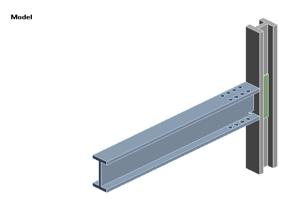

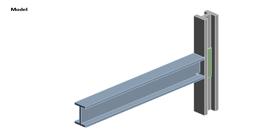

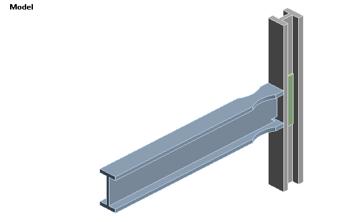

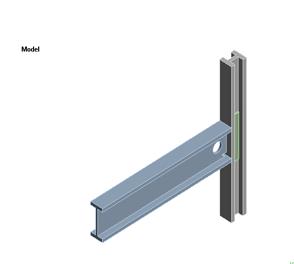

AnexteriorRBSmomentconnectionspecimenwasmodelled usingANSYSWorkbench. Ajumbosectionunderinelastic monotonicloadingisconsidered. BeamswereA992Grade 50steel(fy =345MPa)and hasYoung’sModulus200GPa and Poisson’s ratio as 0.3 Columns were A913 Grade 65 steel(fy =450MPa)andhasYoung’sModulus200GPaand Poisson’s ratio as 0.3. Plate material was A572 Grade 50 steel(fy =345MPa).Dimensional detailsofjumbosection areshowninTable1.FEMmodelofspecimensareshownin Fig1to5.

Table 1: Dimensionaldetailsof

Specimen Beam Beam RBS dimension (a,b,c)mm

SP3 W920×420×13 77 W360×410×1 299 236,710,99

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Fig -5: FCRBSslit

Theleftendofthecolumnwasrestrainedagainsttranslation inallthreedirectionswhiletheotherthreesupportsforthe column were stimulated by restraining translation in one directiononly.Amonotonicdisplacementwasappliedtothe beamtoachieveastorydriftangleupto4%.

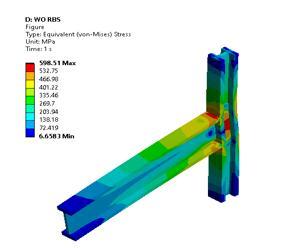

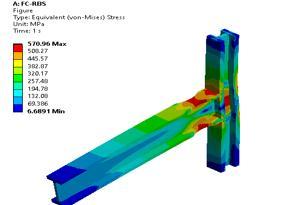

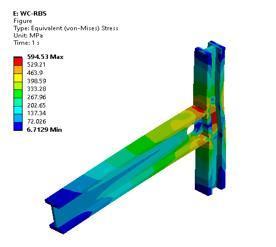

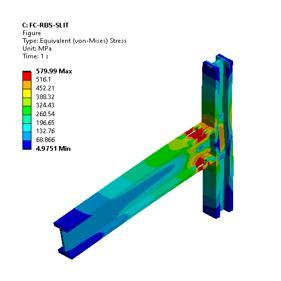

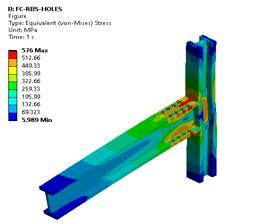

The model is subjected to nonlinear static analysis and Figure6to10representsthestraindistributionresultsof specimens.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

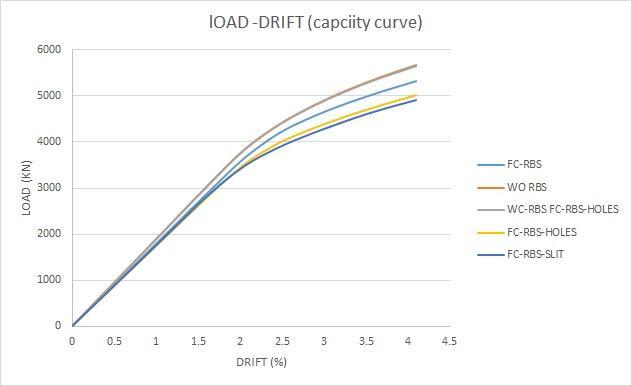

Chart1givesload driftcurveofdifferentRBSsection

Fig 8: WCRBS

Fig 9: FC RBS holes

Fig -10: FC RBS slit

Chart 1: Load driftcurve

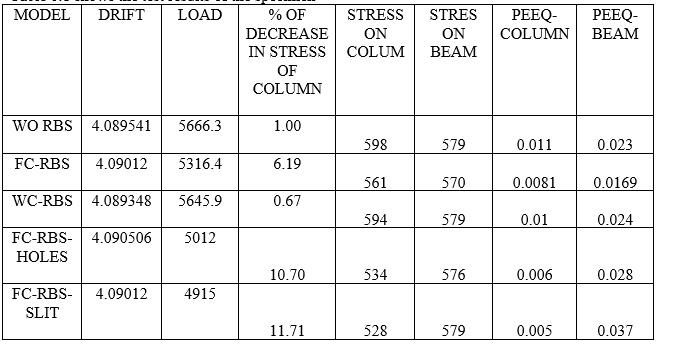

Table 2 displays the jumbo section's performance with variousRBSkinds.

Table -2: Performanceofjumbosectionwithdifferent typesofRBS

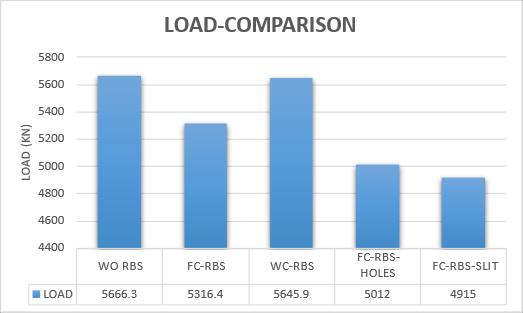

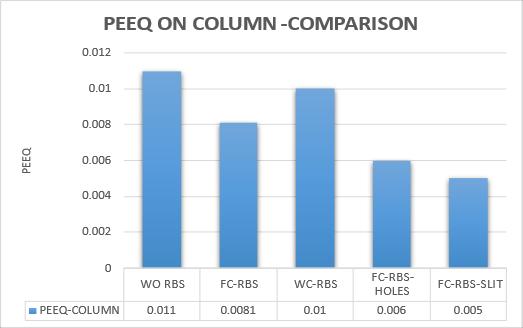

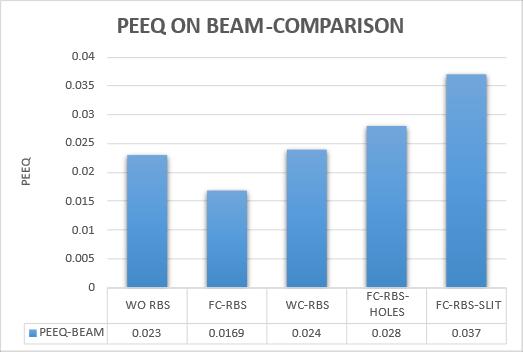

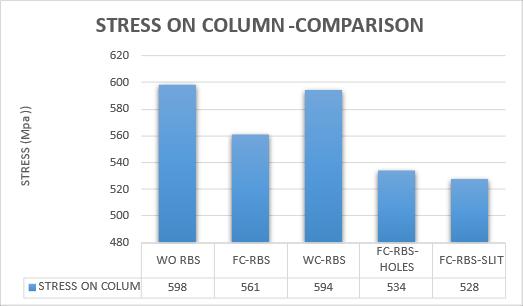

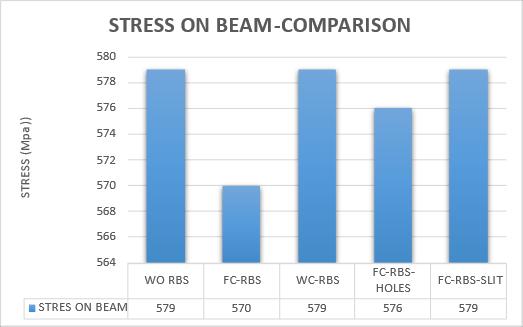

The results are compared and analysed. The comparison graphsareshowninchart2to6.

Chart 2: LoadcomparisonofdifferentRBSsection

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Numerical analysis is conducted to evaluate stress strain behaviourofjumbobeamsandcolumnswithdifferenttypes of RBS. After conducting the study, the following findings wereobtained:

The load carrying capacity can be increased with theintroductionofRBSinthejumbosection.

When RBS is used, jumbo section performance is moreeffective.

Whencompared,thestressonthecolumnforFC RBS SLIT increases by up to 11.71 percent, while the stress on the beam increases by up to 579 kN/m.

For FC RBS SLIT, the lowest PEEQ (Equivalent plasticstrain)columnandbeamvalueswerefound.

As a result, we may say that the FC RBS SLIT sectionistheidealRBSsection.

[1] Liangjie Qi, Roberto T. Leon, Matthew R. Eatherton, JonathanL.Paquetteb,‘‘Parametricinvestigationonthe designofRBSmomentconnectionswithjumbobeams and columns” J. Struct. Engg, vol.122, 2021, pp 1292 1299.

[2] P Cimagala, “Optimization of Reduced Beam Sections (RBS)forDuctileDetailingofSeismicJointConnections Using Finite Element Analysis (FEA)” J. Constr. Steel Res.,vol.42,pp49 69,2021.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

[3] FEMA,Recommendedseismicdesigncriteriaforsteel moment framesbuildings,FEMA350,2000(Washington, DC).

[4] FEMA, State of the art report on base metals and fracture,FEMA355A,2000,(Washington,DC)

[5] AISC, Prequalified connections for special and intermediate steel moment frames for seismic applications,AISC358 10.Chicago,IL,2016.

[6] J. Paquette, “Experimental Investigation of Reduced Beam Section Moment Connections for Jumbo Steel WideFlangeSections”VirginiaTech,2018.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |