International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

1B.Tech. Student, Department of Mechanical Engineering, Vishwakarma Institute of Technology (VIT), Pune, Maharashtra, India

2Assistant Professor, Department of Mechanical Engineering, Vishwakarma Institute of Technology (VIT), Pune, Maharashtra, India

3Chief Instructor, Diesel Training Centre, Diesel Loco Shed (IR), Pune, Maharashtra, India ***

Abstract - Indian Railways is the state owned railway company of India having more than 64000 Kilometres of track and 6909 stations. It has the world’s 4th largest railway network after that of United States, Russia, and China. It carries over 20 million passengers and 2 million tons of freight daily. It is one of the world’s largest commercial employerswithmorethan1.6millionemployees.Itownsover 200000 freight wagons, 50000 coaches and 10000+ locomotives.

Key Words: soft robots, pneumatically, finger, prosthetics

Indian Railways owns over 250000+ locomotives running all over India. When we were doing internship at Diesel loco Shed Pune, we came across one problem that wasFILLINGOFSANDINLOCO.OneLococonsistof8Sand box with each sand box weighing 50 kgs resulting in total weight of 400 kgs. So, while filling the sand box there was humanlabourinvolvedwhichresultedinlossofsandwhile filling the boxes. On an average for filling one sand box resulted in loss of approximately 10 kgs of sand. Mathematically if we calculate there is more than loss of 2500+ tons of sand resulting of Rs 3750000 as of 250000 engines.Dailymorethan2lackslocosaretobefilledthose resultsinlossofcrorestoIndianRailways

So,studyingthescenariowehavedesignedamachineon pneumaticmechanismcapableoffillingtheLocoof400kgs thatrequiresunskilledlabour,minimummaintenance,zero cost of operation. The machine is easy to manufacture and cost of manufacturing is quiet low. The main advantage of machine is that it has tank as a storage for compressed air as well input from loco can also be given which makes ita mobile machine fit for use. Hence this machine can be effectively implemented in Loco sheds which will increase theefficiencyaswellasreducethewastage.

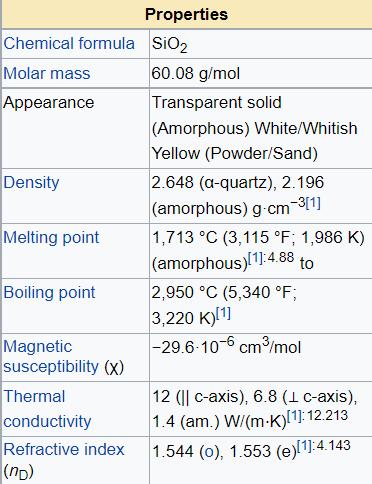

Silica or silicon dioxide (SiO2) is a chemical compound consisting of one silicon and two oxygen atoms. Quartz is a common mineral with the same chemical composition, but quartz and silica are not synonyms.Specificmineralsalwayshaveadefinitecrystal structure while chemical compounds have no such restriction just like every piece of carbon is not a diamond. Quartz is made of silica but so are also cristobalite, tridymite and few other minerals (polymorphsofsilica).Theyarecollectivelyreferredtoas silica minerals. Quartz is the most common sand forming mineral. However, it is not the most common mineral in thecrust. That honour goes tofeldspars. If the sand deposit contains almost nothing but quartz, we often call it a silica sand. Such sand deposits are said to be mature because other rock forming minerals are already broken down by the weathering process leaving only the super resistant quartz as a residue. Silica sand is a mineral resource. It is mined mostly for glassmaking. Another major use of sand is a concrete production but that does notneedsandtobeaspure.

Some beautiful beaches are made of silica sand. Beach of Siesta Key in Florida is especially famous for its white sand.Notallwhitesandsaremadeofsilica,though.White Sands National Monument in New Mexico is a dune field whichiscomposedofsandmadeofgypsum.Therearelots

Sarvesh Malakolikar1, Rishikesh Mishra1 , Prf Unmesh Chavan2 , Er Moolchand Nahariya3,Er Venu Gopal Rao3International Research Journal

Engineering

Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

of light coloured beach sands around the world but many of them (especially in low latitudes) are made of small pieces of corals and other sea creatures. This sand is calcareous (composed of calcium carbonate) but some biogenic grains are siliceous as well. For example, radiolarians (amoeboid protozoa) and diatoms (algae) havesiliceousshells.

In mostsilicates, the silicon atom showstetrahedral coordination, with four oxygen atoms surrounding a central Si atom (see 3 D Unit Cell). Thus, SiO2 forms 3 dimensional network solids in which each silicon atom is covalently bonded in a tetrahedral manner to 4 oxygen atoms. In contrast, CO2 is a linear molecule. The starkly different structures of the dioxides of carbon and silicon areamanifestationoftheDoublebondrule.

SiO2 has severaldistinct crystalline forms, but they almostalwayshavethesamelocalstructurearoundSiand O.In α quartz the Si O bond length is161 pm, whereas in α tridymite it is in the range 154 171 pm. The Si O Si angle also varies between a low value of 140° in α tridymite, up to 180° in β tridymite. In α quartz, the Si O Siangleis144°

to increase at a healthy growth rate because of the growing construction and foundry industry. The silica sand market is partially consolidated. Silica Sand is geologically available in particularly excellent quality inAndhra Pradesh, India. Our company is considered the most pioneer in Silica sand mining industry. Silica Sand is consumed in substantial number of industries in different forms

Fig - 3:SilicaSandPropertyTable

AccordingtoIndianMineralsYearbook,theproduction of silica sand in 2021 is estimated to around 8621.6 thousandmetricton.India’ssilicasandmarketisexpected

As locomotives run on a railway track, there is always friction which makes possible the movement of locomotives buttherearefewcaseswherethereisloss of friction and therefore to maintain friction and swift movementoflocomotives,thesilicasandisused.

ConditionsthatcauselossofFriction

1)HeavyLoadings

2)Unevenlandformsduetogeo graphicallocations

3)Low weight of Electric Locos, resulting in low tractive efforts

4)DemandingBreakingConditions

5)Humid&Rainyconditions.

The above mentioned conditions cause loss of friction andto counter suchchallengesSilica sandisusedandthe advantageofusingthislackofwearandtearofwheels.

Sand Filling Pneumatic Machine works on the principle oftheVenturiPump,Principlebehindtheoperationofthe Venturi flowmeter is the Bernoulli effect. The Venturi measuresafluid'sflowratebyreducingthecross sectional flow area in the flow path and generating a pressure difference.

Bernoulli's principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in staticpressureoradecreaseinthefluid'spotentialenergy A Venturi pump uses the kinetic energy in a fastmoving fluid to move another liquid or semi-liquid substance The standard Venturi pumps are part of a

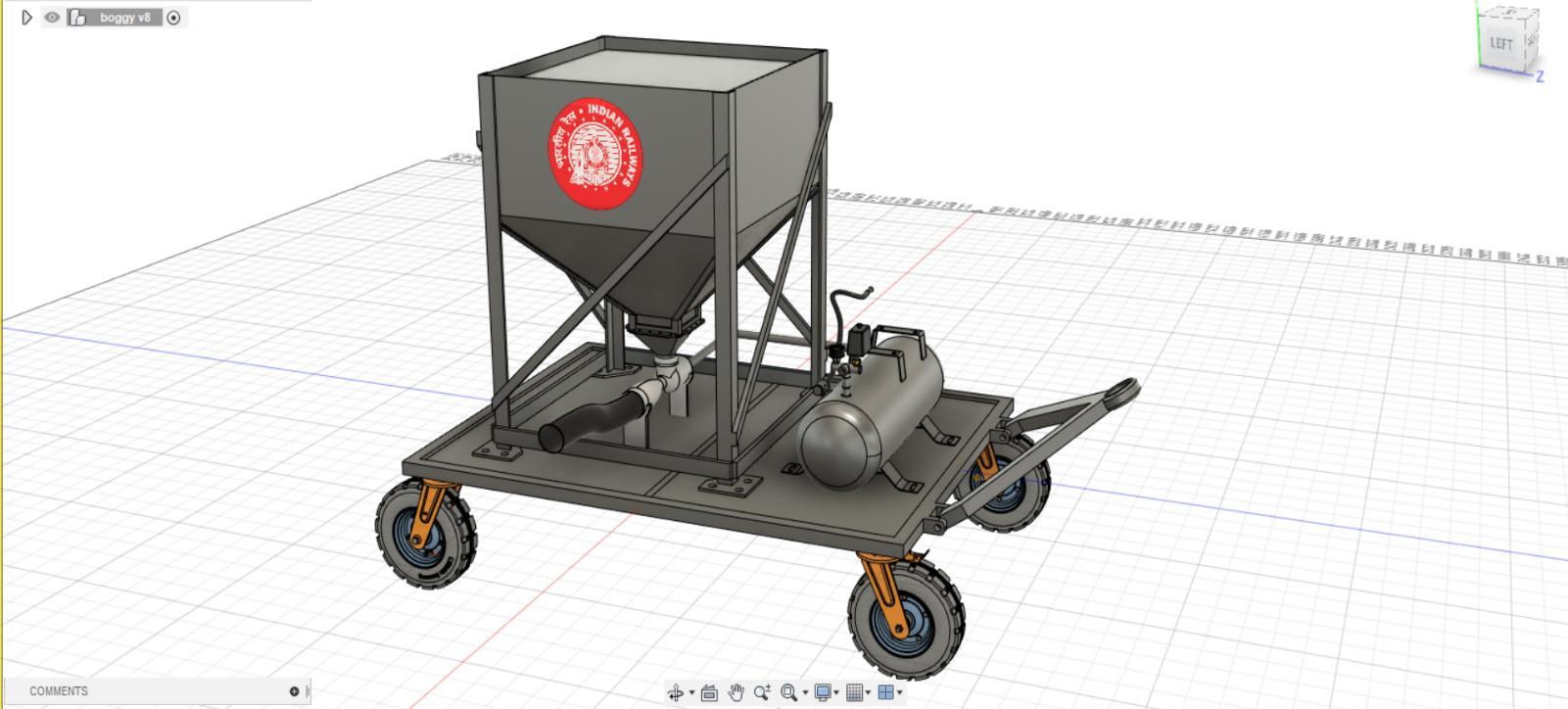

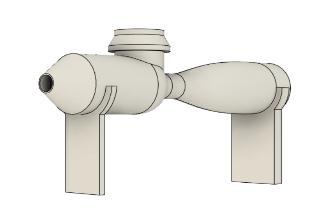

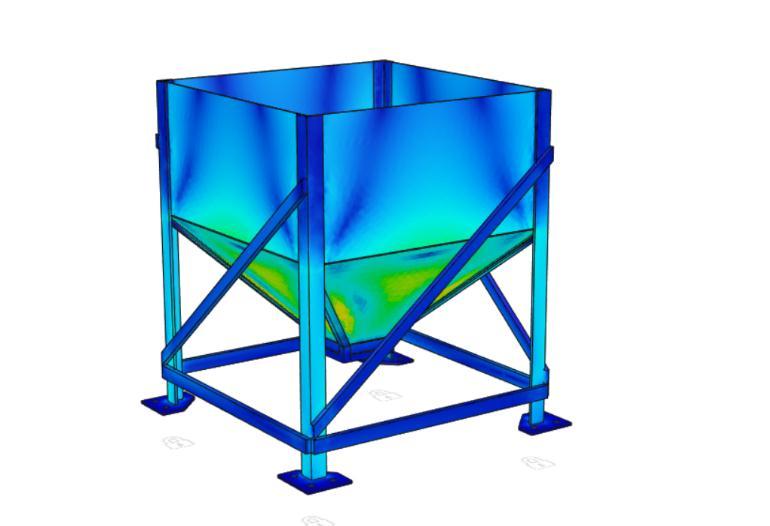

Fig 6:CADDesign(Fusion360)

liquid system with atmospheric pressure. A modified version called the Venturi vacuum pump uses the same principles in vacuum pressure conditions. These pumps require a compressed air source, but no electricity. Venturi vacuum pumps make a lot of noise. People workingnearVenturivacuumpumpsneedearprotection. These pumps are often installed at a distance to reduce noise pollution and to reduce additional power among workers in the area. Most Venturi vacuum pumps are small, and some are portable. These long lasting pumps are

In the design of this system, we tried to make it convenient to move it around and take it to blazes at feeling and can't be brought back to shade to be refilled. Thecompletesystemisfixeduponatrolleywhichcan be toured behind another vehicle. the trolley has 4 free spinningwheelswhichmakeiteasytohandle.

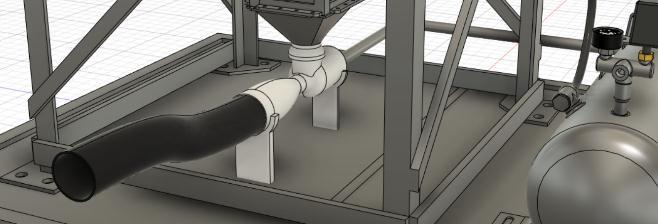

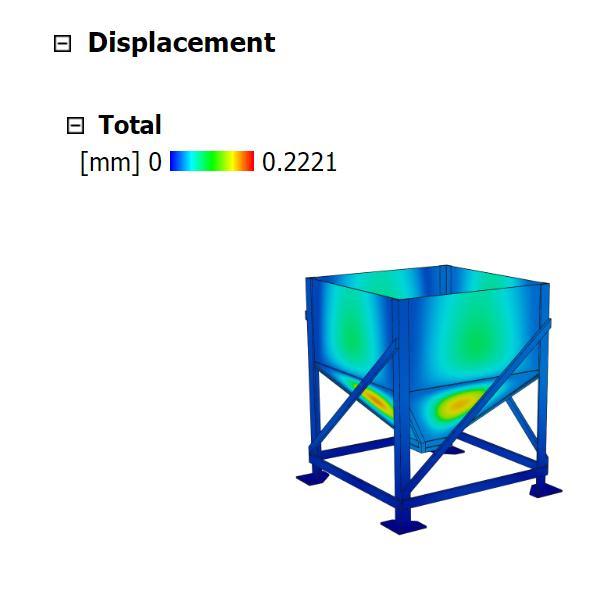

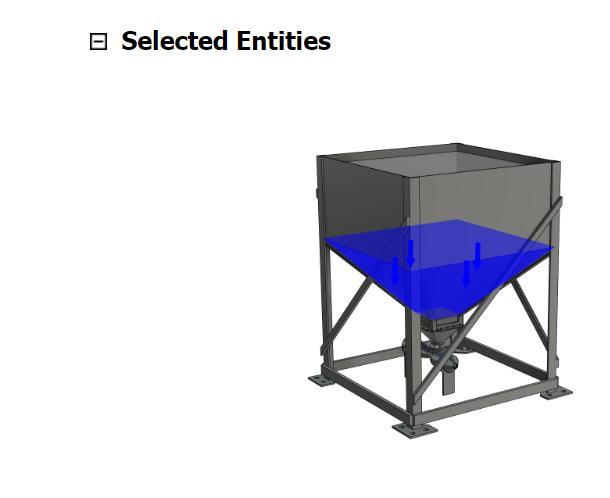

The hopper is attached on the trolley with venturi pumpatitsbasehopperhas2sectionsoneistheprimary hopper second is the secondary hopper. The primary hopper work as the storage for sand and the secondary hopper work as delivery mechanism for venturi pump. The the venturi pump is fixed at the bottom of the upper tothesecondaryhopperandattachedwith2pipesfirstis the intake pipe which comes from the pneumatic storage tankthesecondistheoutletpipewhichgoesthroughthe feelingnozzleforsand.Theintakepipeisconnectedtothe storage tank or compressor which will ideally provide a pressure of 15 to 20 PSI . The pressure can be generated

by compressor fixed on the trolley or can be taken from the pneumatic pipeline in the plant to fill the tank to decide pressure. The connecting pipe delivers the pressure from tank to venturi pump. The sand is slowly dischargefromthesecondaryhopperintothetopsection of venturi pump where in the chamber did it get mixed with pneumatic pressure and is pushed forward by the phenomena called pneumatic conveying or venturi conveying.Themixtureofsandandaircanwesendupto 10 meters in a pipeline diameter 10 centimetre. The pipe usedforoutletmustbeaflexiblepipe.

A hopper is a pyramidal or cone-shaped vessel used in industrial processes to hold particle or flowable material of any kind (such as dust, rocks, nuts or seeds) and extract this from the ground where necessary. In some special applications even small parts of metal or plastic can be loaded and unloaded by small hopper systems. In the case of dust collectors hoppers dust can be collected in blown air. Dust collectors are usually grouped to allow for a larger collection. Hoppers are used in many industries to hold goods until they are needed, suchas flour, sugar or nuts for food, animal feed pellets,milled ore for refining, etc. Dust hoppers are used inindustries that use air pollution control equipment.such as dust collectors, electrostatic precipitators, and baghouse / cloth filters. Most hoppers are madeofsteel.

Fig 6:CADDesign(Fusion360)

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the pressure application,andwilldependonthesizeofthevessel, thecontents,workingpressure,massconstraints,and the number of items required. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country. Design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using non destructive testing, suchasultrasonic testing, radiography, and pressure tests. Hydrostatic pressure tests usually use water, but pneumatic tests use air or another gas. Hydrostatic testing is preferred, because it is a safer method, as much less energy is released if a fracture occurs during the test (water does not greatly increase its volume when rapid depressurization occurs,unlikegases,whichexpandexplosively).Mass or batch production products will often have a representative sample tested to destruction in controlled conditions for quality assurance. Pressure reliefdevicesmaybefittediftheoverallsafetyofthe systemissufficientlyenhanced.

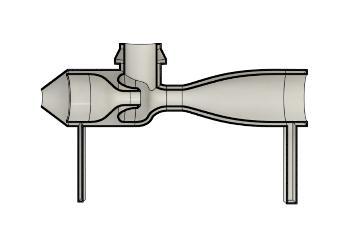

A vacuum ejector, or simply ejector is a type of vacuum pump, which produces vacuum by means of the Venturi effect. Here sand from Hopper is redirectedtoVenturipumpandtheairpressurefrom the tank acts as push which generates Venturi effect andthesandispushedaway

Fig 6:VenturipumpCrossSection

- 6:COMPRESSORCADDESIGN

Fig 6: Venturipump

Connecting pipes function as a linkage between compressor tank and Venturi pump which permits theflowofpneumaticpressurethatinitiatesthesand flow

It acts as a delivery pipe of the system work. The mixture of sand and air pressure paves its way throughthepipeintotheSandbag

Fig 6: Venturipump

Calculation of sand hopper and amount of sand required to fill sandbox of multiple engines in single

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Bulkdensity=1.22x103 Kg/m3

Densityofsilicasand=1538kg/m3

LOCOsandboxcapacity 1sandbox=14ft3

Total8sandboxinoneLOCO=112ft3 112ft3=3.17149m3

Volumeofsandrequired=3.17149m3

Massofsandrequired=3.17149x1538 =4877.75Kg

Total sand required for Filling of all sandboxes of oneLOCOis4877.75kg

Heating of sand before discharge to remove moisturecontentfromsand.Wetsandcannotbe allowed in sand box as well as it will clog the system. © 2022, IRJET | Impact Factor value: 6.529 | ISO 9001:2008 Certified Journal | Page

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

DevelopmentofQuickreleasesystemforsand delivery pipe for easy access and system maintenance

Venturi pump clog bypass and de clogging mechanism

IndianRailwaysiswitnessingProgresseveryyear andthephasehasarrivedwhereIndianRailwayshas taken initiative to electrify its Running Systems and will accomplish its goal by 2030. So we feel effective utilization of resources, reducing wastage of resources and money with proper utilization of manpower will give a boost a to progress. After studying the locomotives, we have come across a designofmachinewhichiscapableofmeeting future needsmachinei.eSandfillingPneumaticMachine.

MobileMachine

Saves Sand by effectively delivering it to sandbox

HasaCompressorandstorageTank

Canhaveenergyinput(AirPressure)from Loco & Workshop Pneumatic Pipes as well.

RequiresminimumMaintenance

Demandsnotrainedmanpower

Bedfordshire Silica Sand Study, 2006/2007. CuestaConsultingLimited.

Silica Sand: Geology and mineral planning fact sheets for Scotland. BGS 2007 Proposed Extension to existing silica sand operations with progressive restoration, Massingham Quarry, North Lincolnshire. Planning Statements.Sibelco2009.

Extensiontosilicasandextractionoperations withprogressiverestoration: WBB Minerals. Report by Director of planningandtransportation.5May2006.