International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Abstract Plastic concrete is susceptible to develop cracks due to shrinkage in dry and windy conditions. Addition of fibers could reduce propagation of this crack. Plastic shrinkage cracks can be one of the earliestobstaclestoappear in concrete, and if left uncontrolled, the durability and life of the structure can be compromised. The main driving mechanisms of plastic cracking have been found to be settlement of solid particles, bleeding, evaporation, capillary action, as well as surface finishing. These, in combinationlead to a 3 dimensional volume contraction which if restrained, causes plastic cracking of concrete. The effects of various fibers on the plastic shrinkage crackbehaviorofcement based materials have been studiedfor many years.Moststudieshave concluded that the fiber type studied has succeeded in controlling the degree of plastic shrinkage cracks. However, there is no clear understanding of which fiber properties have the greatest impact.

Key Words: Plastic shrinkage, Synthetic, Fibres, Cracking, Concrete,Overlay.

As plastic shrinkage cracking can dramatically reduce the durability of a concrete member and causes considerable repaircostsannually,acomprehensiveunderstandingofthe mechanismofthephenomenonisessentialtopreventthese damages in future. In its plastic state, which lasts from castingtoabout3 8hours,concreteundergoesvolumetric andotherchangesthatstronglyinfluencethepropertiesof the hardened material. Among the volumetric changes is plastic settlement and plastic shrinkage which in combination with other factors may lead to cracking of concreteinthisfragilestate.Themainreasonbehindplastic shrinkagecrackingisconsideredtoberapidandexcessive surface water evaporation of the concrete element in the plasticstage(freshlycastconcrete)whichinturnleadsto the so called plastic or capillary shrinkage. Consequently, manyfactorsaffectthelikelihoodofplasticshrinkagecrack formationsuchaswater cementratio,admixture,member size, fines content, concrete surface temperature and ambientconditions(i.e.relativehumidity,airtemperature and wind velocity). When the pace of water evaporating from the concrete exceeds the rate at which it can be replacedbyrisingbleedwater,acombinationofautogenous processesandcapillarypressureoccursintheporestructure at the surface, causing the concrete to contract. During

plastic state, concrete resists volume changes and other changesthathaveasignificantimpactonthepropertiesand behaviourofhardenedconcrete(Combrinck,Kayondoand Boshoff2019).Theconcretedriesifthewaterevaporates quickerthanitevaporatesfromtheconcrete.Theamountof plastic shrinkage is determined by the amount of evaporation.Furthermore,environmentalparameterssuch astemperature,relativehumidity,andwindspeedinfluence evaporationrate.Bleedingisgovernedbythemixingratioas well.Themixingratioisdeterminedbythewater/cement ratio as well as the meteorological conditions that the cementmatrixissubjectedto.(Juarezetal.,2015;Juarezet al.,2015).

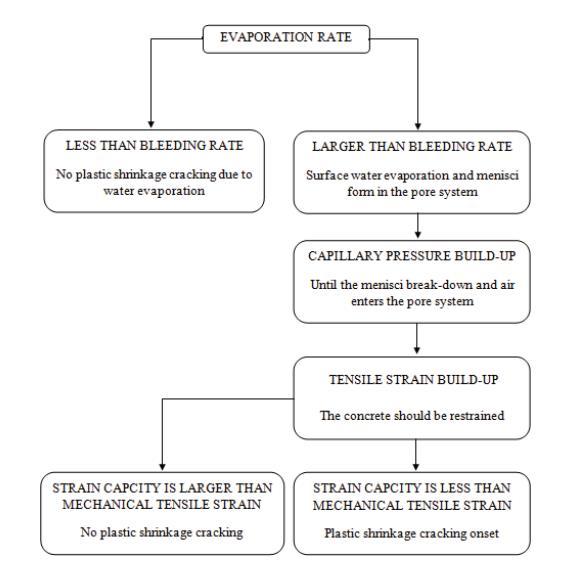

Many factors affect plastic shrinkage in concrete figure 1 summarizes the process of plastic shrinkage cracking and the factors which can affect the phenomenon. A deep comprehension on how these factors influence the whole cracking process can lead to invention of new crack preventative methods. Some of the factors are briefly describedinthefollowing.

Fig 1:Factorsaffectingplasticshrinkage.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Thesyntheticfibersthatareinvestigatedinthestudies includepolypropylene,polyester,glass,basalt,engineered Once bleed water reaches the surface of concrete, its conversionintothegaseousstateistermedasevaporation. Themainfactorsthatinfluencetheevaporationrateare: windspeed,relativehumidity,airtemperature,concrete temperature, difference between air and concrete temperature, as well as solar radiation. In general, the higher the wind speeds, concrete temperature, solar radiationandthelowertherelativehumidity,thehigher theevaporationrate.

Themechanism of bleeding is driven by consolidating particles(duetofreesettlement)displacingwatertowards the surface, where it gathers as a thin film. Bleeding is facilitated by the spaces between the solid particles creatinganinterconnectedsystemofporesthroughwhich waterisdeliveredtothesurface.Bleedingisalsosaidtobe duetothesuctioneffectcausedbycapillaryporepressure which occurs once the thin bleed water layer starts to disappear(duetoevaporation)[vDao,P.Dux,P.Morris,L. O’Moore2010].

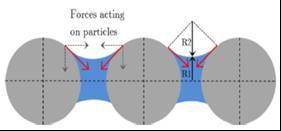

Oncetheconcretesurfacebleedwaterstartsevaporating up to the point exposing the solid surface, the solid particlesatthesurfacethenformacomplicatedsystemof menisci[M.Kayondo,R.Combrinck,W.P.Boshoff2019], asillustratedinFigs.2and3(C early&C later).Oncethis state is reached, the increasing curvature of the water menisciatthesurfacecausesa negative pressureinthe capillarywater[V.Slowik,M.Schmidt,R.Fritzsch2008]. Thenegativecapillarypressuresacttodrawmorewater tothesurfaceofconcrete,andintheprocessacttobring the solid particles as close as possible; but this is counteracted by the repulsive forces between the solid particles.Furtherevaporationatthesurfaceactstoreduce themenisciradiitoathresholdvalue,atwhichpointthe localtensilecapillarypressuresinduceashrinkagestrain which if not withheld by the tensile capacity of the still plasticconcrete,causescrackingtooccur.

Hydrationofconcreteprogressesandinfluencesseveral mechanismsofearly agecrackingviathedifferentstages suchasstiffening,setting/solidificationandhardening[M. Schmid, V. Slowik 2013]. As far as plastic shrinkage crackingisconcerned,thebeginningofhydrationmeans lossoffreewateronwhichtheplasticnatureofconcreteis based. This water loss is usually via evaporation, absorption by unsaturated aggregates, formation of hydrationproducts,etc.[P.L.J.Domone,J.M.Illstone2010]. The progression of hydration gives an indication of the physical state of concrete. The start of the exothermic processesofhydrationareprecededbyadormantstage whichoffersnumerousadvantageswiththehandlingand placingofconcrete.Hydrationinplasticconcreteisusually associatedwitharbitrarytermssuchasinitialandfinalset. Thesetermsgiveanindicationoftheendofthestiffening stageandstartofsetting(initialset),aswellastheendof settingstageandstartofhardening(finalset).Inpractice, thesetimesareinfluencedbyanumberoffactorsandmay greatly vary between laboratory and field tests. Since hydrationischaracterisedbylossoffreewater,therateat whichthishappensdirectlyinfluencestheprogressionof othermechanismsofplasticshrinkage cracking,suchas freesettlement,bleeding,andcapillarypressure.Ideally, hydration affects the stiffness of plastic concrete, which significantly influences plastic cracking behaviour[S. Ghourchian, M. Wyrzykowski, M. Plamondon, P. Lura 2019].

The classical gravitation laws largely drive free settlementofsolidparticlesinfreshconcrete,anditworks in such a way to cause denser packing of the solid particles. Settlement of solid particles displaces water upwards, imparting an upward force due to the viscous dragcausedbytheflowingwater Freesettlementremains active until the point where hydration of cement starts,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

and can be ceased mechanically before the end of the dormant period if the solid particles physically come in contactwithoneanotherhinderingfurthersettlement[H. G. Kwak, S. Ha, W.J. Weiss 2010]. The outcome of this phenomenonisaverticalvolumecontraction.

Theadditionoffibersismostwidelyacceptedmethodfor controllingplasticshrinkagecracking.

•The fibers prevent the micro cracks from further propagate on, developing into actual plastic shrinkage cracksbyimpartingbridgingactionacrossthecracks.

•Sometypesoffibershavealsobeenshowntoincrease earlyagetensilestrengthofthematerial,thuslowering thepossibilitiesforthestressestoreachthestrengthof theconcreteintheplasticstate.

•Fibers added to the fresh mixture tend to reduce the segregation of especially coarser aggregates, which thereforetendtoremainclosertothesurface.Extensive segregation could also lead to an uneven fiber distribution.Itwasobservedthatfinefibershadabetter distributioninsidethematrixthancoarserfiberswitha highdensitywhichtendtosegregate.

•Asplasticshrinkagecrackingiscloselyassociatedwith the evaporation rate, several researches also explored the fiber influence on the amount of moisture loss. However, there are a few paradoxes in the literatures. Some studies reported that fibers tend to reduce the quantity of bleeding water by reducing segregation, whichsucceedsatlowerwaterevaporationrates.Onthe contrary, other studies reported higher water evaporation rates that were attributed to the developmentofso calledchannelsalongthefibers.These channelsmayallowmixingwatertorisetothesurface, which provides water to replenish the drying surface. (Bertelsen,Ottosen,andFischer2020).Inthispaper,the influence of randomly distributed fibers on cracking caused by plastic shrinkage is discussed (Bertelsen, Ottosen,andFischer2020)

•Theadditionfibersnotonlytoreducecrackformation, but to disperse the cracks so that many micro cracks appear instead of fewer larger ones by improving the straincapacityoftheconcreteintheplasticstate.

•Sometypesoffibershavealsobeenshowntoincrease earlyagetensilestrengthofthematerial,thuslowering thepossibilitiesforthestressestoreachthestrengthof theconcreteintheplasticstate.

•Fibers added to the fresh mixture tend to reduce the segregation of especially coarser aggregates, which thereforetendtoremainclosertothesurface.Extensive segregation could also lead to an uneven fiber distribution.Itwasobservedthatfinefibershadabetter distributioninsidethematrixthancoarserfiberswitha highdensitywhichtendtosegregate.

value:

The test methods for evaluating the plastic shrinkage crackingofcement basedmaterialsusesdifferenttypesof restraints which induce cracking by preventing the specimen from deforming freely and specimen size and shapevaries.Thetestmethodsusedinthestudiesincluded inthisliteraturearelistedbelow:

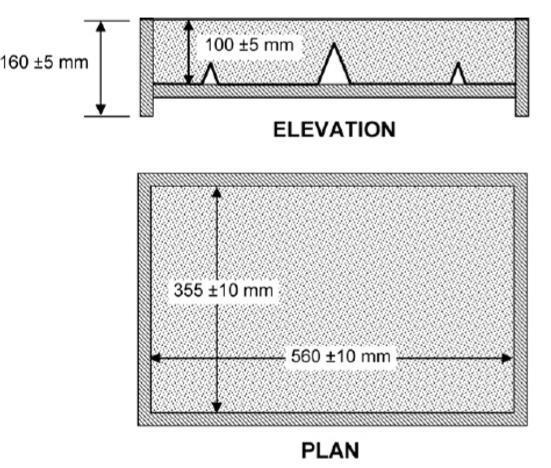

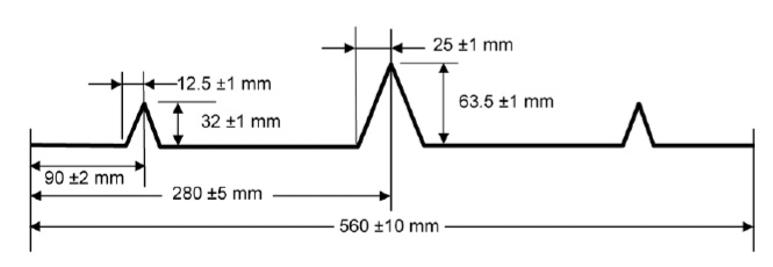

i.ASTM C1579 13 method in which the specimen is preparedinamouldwithinternalrestraints.Theconcrete specimen is placed in drying settings which prompt plasticshrinkagecrackingintheconcretespecimen. ThemouldusedisshowninFig 3and4

Fig 3:Specimendimensions

Fig 4:Stressrisergeometry

ii. Overlay method with bottom restraint in which a freshcement basedoverlayiscastoveranunderlying concretesubstratewhosesurfaceisroughenedorthe surface has protrusions in order to provide uniform bottom restraints. The cracks formed are then measuredusingadifferenttechnique.Cracksaremost commonlymeasuredusingmicroscopeorbycapturing images of the cracks and analysing images by using computersoftware.(BanthiaandGupta2007)

iii. Kraaimethodwithedge restraints:inthisaslab like specimen cast in a mould with built in edge restraints providedalongtheperimeter.Thetestspecimenisrather thinwithalargesurfaceareatovolumeratiomakingit vulnerabletoplasticshrinkagecrackingasintended.This methodoftenresultsinscatteredcrackpatternsasshown inFig.5.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Theadditionof anyfiber witha diametersmaller than 40 µm, an aspect ratio above 200, in volume fraction 0.2% 0.4%,shouldeffectivelyeliminateplasticshrinkagecracking in concrete. (Branston et al. 2016). For the purpose of comparingtheresultsandanalysingtheeffectofdifferent fibersonplasticshrinkagecracking,thestudiedfibersare broadlyclassifiedintotwocategories:syntheticfibersand naturalfibers.Theeffectivenessofthefiberswasevaluated byconsideringthereductioninnumberofcracksandtotal crackarea.

concrete structures considered a highly irregular and variableprocessand,dependingonthetypeofrestraint, often results in scattered crack patterns The rates at whichthecracksoccurcanvarysignificantlydepending onparameterssuchasthetestsetup,materialproperties, environmental conditions etc. Thus, studying the formation of plastic shrinkage cracking is challenging, since the material properties are time dependent and change rapidly over time There is no standardized techniqueforcrackdetectionandcrackmeasurements; but commonly used are manual measuring techniques using microscopes, handheld lenses etc.; and more advancedimage basedtechniquessuchasdigitalimage processing(DIP)anddigitalimagecorrelation(DIC).With the more advanced techniques, very fine flaws can theoreticallybedetectedonthesurface.Hence,thereis alsoaneedforastandardizeddefinitionofwhichfineness ofsuchflawsthatshouldbedefinedasactualcracks.

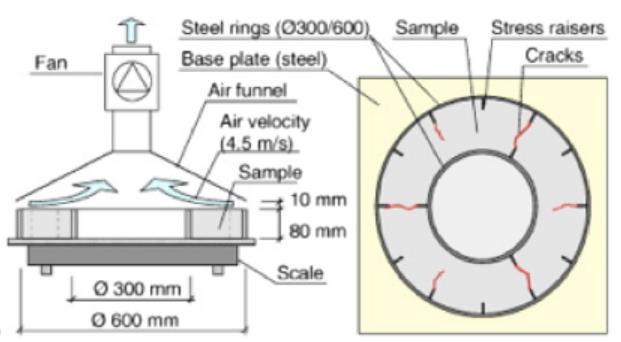

v. Ringtestmethod:Theringtestmethodset updeveloped byJohansenandDahlconsistsoftworing shapedmoulds ofsteelmountedtoasteelplatformasshowninFig.6[M. Kayondo, R. Combrinck , W.P. Boshoff 2019]. In this method, average crack width is used as a measure of cracking tendency, and the cracking is induced by the radialgeometryofthemould.

Afterconcreteiscast,andiftherateofwaterevaporation ishigherthanthatofthemigrationofwaterfromtheinside of the fresh concrete to the outer surface, the capillary suction will produce shrinkage, which induces a tensile stress into the fresh concrete. When small quantities of polypropylenefibersareaddedtoconcrete,theintertwining systemfeaturesofthefiberswillpreventthelargeparticles fromsettling.Bleedingmaybebroughtdown.Alternatively, becauseofthecohesionbetweenthefiberandthecement system, the tensile strength of the fresh concrete will increase.(Ma,Tan,andWu2002).

Theadditionofmicrosyntheticpolypropylenefibershada pronouncedeffectonthecrackingbehaviorofconcreteand reducedthecrackingofconcrete.Thetimetoformtheinitial crack was also delayed upon the addition of fibers. The additionofsyntheticfibersimprovesconcreteinter particle locking and consequently reduce plastic settlement and therebyreduceplasticshrinkage.Nopronouncedeffecton capillarypressurewasrecordedupontheadditionoffibers. Theadditionoffibersalsoreducedbleedingandevaporation and increased internal temperature of concrete. This increaseintemperaturemaybebecauseoflessbleedingand thus less evaporative cooling. Additionally, internal temperature could have increased because of the heat of hydration in the concrete mix. (Olivier et al. 2018). In general,fiberimpartscrack bridgingabilityandtherefore, contributeagainstshrinkagecrackingoccurrence(Islamand Das2016).Itcanbeobservedthatthecrackwidthandcrack areareducedasthefibercontentincreased.

It has been well established that the addition of short, randomly distributed fibers to concrete is an effective methodinmitigatingplasticshrinkagecracking.Thefibers areeffectiveinthisregardfortworeasons:first,theyreduce the overall shrinkage strains and lower the possibility of tensilestressesexceedingtensilestrength,andsecond,the fibersareabletorestricttheirdevelopmentiftheydooccur.

Reinforcementusingpolypropylenefiberreducessettlement andincreasestherateandmagnitudeofevaporation.Fine fibersaremoreefficientindecreasingsettlement,whilethe longer fibers demonstrate an increase in bleeding. With higher fiber contents, plastic shrinkage crack width is reduced. Multiple secondary cracks are introduced at sufficientfibercontents.Thetotalcrackwidthissignificantly decreased. In plastic shrinkage cracking control, coarse fibersarelessefficientthanfinerfiberreinforcementatthe samevolume.(Qi,Weiss,andOlek2003)Withtheadditionof 0.1 0.25% (by volume) polypropylene fibers, visibly restrainedthecrackwidthcomparedtocontrolsample.The crackwidthisreducedby72 93%withtheadditionofupto

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

0.25%.Theshrinkagecrackingisreducedby50 99%bythe addition of fibers up to 0.3%. (Islam and Das 2016). Polypropylenefibersshowedsuperiorabilitytocontrolthe plastic shrinkage cracks even at volume fractions as low 0.1%.(Shenetal.2020)

In a comparative study between the performance of mixtures made of various types of polypropylene fibers (polypropylenefibersmadeinthedrawing wiretechnique (DW PP), polypropylene fibers made in two different fibrillatedfilmtechniques(FF PPIfiberandFF PPIIfiber) the difference between them is the different interlinking statebetweentheirelementsandpolypropylenefibersmade with Y shape (Y PP fiber) in mitigating plastic shrinkage cracking, it was concluded that the order of reduction in dryingshrinkagecrackingisFF PPIfiber<FF PPIIfiber< Y PP fiber < DW PP fiber. When 0.10% or more DW PP fibers are added into cement mortar, drying shrinkage crackingcanbeavoided.Theresultsimplythatalthoughall the fibers are of polypropylene type, they have different effects on drying shrinkage cracking because of their differentgeometricshapes(cross section)(Ma,Tan,andWu 2002).

Theresultsfrompreviousstudiesinbasaltfiberreinforced concretedonotsuggestthefibersareparticularlyeffective inenhancingthepost crackingresponseofconcrete,which isoneofthemostsignificantbenefitsoffiberreinforcement. Literaturessuggest thatthe addition basaltfiberswithout anyprotectivecoatingdoesnothavelong termdurabilityin alkaline atmosphere. One study (Branston et al. 2016) suggests that the effectiveness of varieties of basalt fibers (bundle dispersion fibers, filament dispersion fibers, and minibars)ininhibitingplasticshrinkagecrackinginconcrete wereassessed.Itisclearthatthebenefitofthefibersisnot justoftheirabilitytoreducefreeshrinkagestrain.Thefibers are effect partly, due to their ability to bridge cracks and restricttheirgrowth.Preliminarytestingshowedthatatthe lowest dosage of 0.05% by volume, 25mm filament dispersionfiberscompletelyeliminatedshrinkagecracking in the concrete. 25mm filament dispersion fibers had the greatest effect in reducing crack area and width. Nevertheless,literaturessuggeststhathigh modulusfibers such as basalt affects workability when compared to low modulusfibers.Therefore,theapplicationofbasaltfibersfor plastic shrinkage crack control is likely best suited for general useconcrete,wherew/cratioisoftenhighenough that the fibers will not require additional measures to restoreworkability(Branstonetal.2016).

In a comparative study between the performance of mixtures made of natural fibers (flax & agave lechuguilla) andPVAfibersinmitigatingplasticshrinkagecracking,the results obtained suggest that both natural fibers were

successful in regulating plastic shrinkage cracking of concretelikethecommerciallyavailablesyntheticfibers.The crack evolution was influenced by the fibers’ geometrical characteristics, such as its length and aspect ratio. An incrementinaspectratiopromotedthereductionofcrack widthandpropagation.Naturalfibershavebetterabilityto absorb water, which may cause internal curing of the concrete,causingadditionalreductioninthecrackingcausedby autogenousshrinkage(Juarezetal.2015).

Theadditionofflaxfiberstoconcrete,newbridgingforces aredevelopedduetothepresenceoffibers,whichprevent crackpropagation.Also,theadditionofflaxfiberslowersthe bleeding,whichimprovesthestiffnessoffreshconcrete.The increaseinfiber lengths leadsto the reductionofthe rate andamplitudeofplasticshrinkage,whichmaybeattributedto the large area taken up by fibers that holds particles of concrete together. There is stress concentration localized abovethestressriserusingtheshorterlengthoffibers.In fact, longer fibers permit achieving an adequate stress transmission and a decreasing of the stress concentration acrossthecrack.Thehorizontalplasticshrinkageofconcrete decreaseswiththeincreaseofthepercentageandlengthof flax fibers. No macro cracks have been observed with mixtures containingflaxfibersdue tothe reduction ofstress concentration above the stress riser of the mould. An increaseinthestraindistributionhasalsobeenobservedat the specimen surface with an increase of the fiber length indicating a better stress transfer (Kouta, Saliba, and Saiyouri2020)

Plasticshrinkagecrackingisacomplexinteractionofseveral variablesthatmaychangeunderdifferentcircumstancesand conditions at the very early ages. These variables have a directinfluenceontheevaporation,capillarypressurebuild uprateandthedurationofdormantperiod.Afterathorough review on the subject of plastic cracking of concrete, the followingremarksarederived:

Plastic cracking of concrete is not a new phenomenon;itisdeeplyestablishedinliterature datingback over60yearsago. However,overthe years, the understanding of the subject of plastic cracking has been enriched, relative to the advancementofconcretetechnologies.

Fundamentally, mechanisms such as settlement, bleeding, evaporation, hydration, and capillary pressureareallproportionatelyknowntoinfluence plastic cracking of concrete (plastic settlement crackingandplasticshrinkagecracking).

The currently existing test methods (for the respectivefundamentalmechanisms),simulations, and models have widened the understanding and predictionofplasticshrinkagecrackingbothinthe laboratory and in the field. Based on these,

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

preventative measures have been developed to mitigateplasticcrackingofconcrete.

[1] Bertelsen,I.M.G.,Ottosen, L.M.,&Fischer,G.(2020). Influence of fiber characteristics on plastic shrinkage cracking in cement based materials : A review. ConstructionandBuildingMaterials,230,116769.

[2] Kayondo, M., Combrinck, R., & Boshoff, W. P. (2019). State of the artreviewonplasticcrackingofconcrete. ConstructionandBuildingMaterials,225,886 899.

[3] Ghourchian,S.,Wyrzykowski,M.,Plamondon,M.,&Lura, P. (2019). Cement and Concrete Research On the mechanism of plastic shrinkage cracking in fresh cementitiousmaterials.CementandConcreteResearch, 115(October2018),251 263.

[4] Olivier,G.,Combrinck,R.,Kayondo,M.,&Boshoff,W.P. (2018).Combinedeffectofnano silica,superabsorbent polymers , and synthetic fibers on plastic shrinkage cracking in concrete. Construction and Building Materials,192,85 98

[5] Islam, G. M. S., & Das, S. (2016). Evaluating plastic shrinkage and permeability of polypropylene fiber reinforcedconcrete.InternationalJournalofSustainable BuiltEnvironment,5(2),345 354.

[6] Branston, J., Das, S., Kenno, S. Y., & Taylor, C. (2016). Influenceofbasaltfibresonfreeandrestrainedplastic shrinkage.74,182 190.

[7] Juarez C.A., Fajardo G., Monroy S., Duran Herrera A Valdez, P., & Magniont, C. (2015). Comparative study between natural and PVA fibers to reduce plastic shrinkagecrackingincement basedcomposite.

[8] ASTMC1579 (2013), “Standard Test Method for Evaluating Plastic Shrinkage Cracking of Restrained FiberReinforcedConcrete(UsingaSteelFormInsert)”, ASTMInternational AmericanSocietyforTestingand Materials,1 7.

[9] ASTMC1581 (2004), “Standard Test Method for DeterminingAgeatCrackingandInducedTensileStress CharacteristicsofMortarandConcreteunderRestrained Shrinkage.”,ASTMInternational AmericanSocietyfor TestingandMaterials.

[10] Sayahi F., M. Emborg, H.Hedlund, “ Plastic shrinkage Crackinginconcrete Influenceoftestmethods”.2ndInt. RILEM/cost Conf. Early age Crack in Serv. Cement. Mater.Struct EAC2,2017

[11] Sirajuddin, Moghul; Gettu, Ravindra (2018), “Plastic shrinkage cracking of concrete incorporating mineral admixturesanditsmitigation.”MaterialsandStructures, 51,48.

[12] A.Sivakumar,ManuSanthanam(2007),“Aquantitative studyontheplasticshrinkagecrackinginhighstrength hybrid fibre reinforced concrete.” Cement & Concrete Composites,ELSEVIER,29,575 581.

[13] BooyaE.,GorospeK.,GhaedniaH.,DasS.(2019),“Free and restrained plastic shrinkage of cementitious materials made of engineered kraft pulp fibres.” Construction and Building Materials, ELSEVIER, 212, 236 246.

[14] Qi, C., Weiss, J., & Olek, J. (2003). Characterization of plasticshrinkagecrackinginfiberreinforcedconcrete

usingimageanalysisanda modifiedWeibullfunction. 36(July),386 395.

[15] Ma, Y., Tan, M., & Wu, K. (2002). Effect of different geometric polypropylene fibers on plastic shrinkage crackingofcementmortars.35(April),165 169.

[16] Kouta,N.,Saliba,J.,&Saiyouri,N.(2020).Effectofflax fibers on early age shrinkage and cracking of earth concrete. Construction and Building Materials, 254, 119315.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified