Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

***

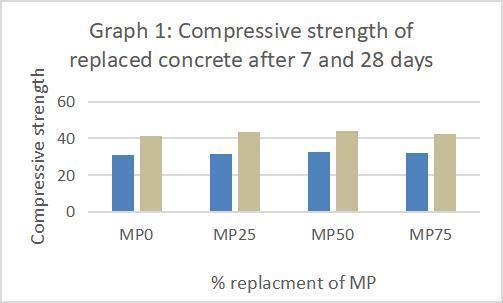

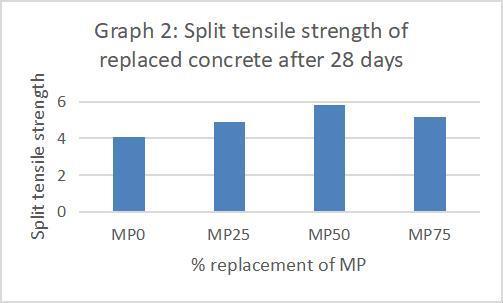

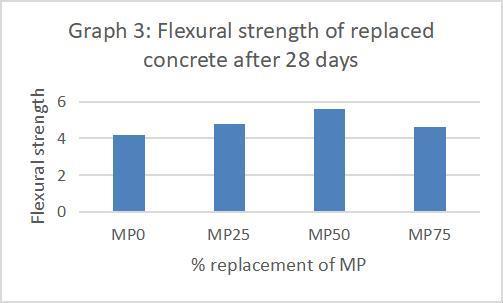

Abstract The Concrete is the important construction material and it is used in the construction industry due to its high compressive strength and its durability. Now a day’s various studies have been conducted to make concrete with waste material with the intention of reducing cost and unavailability of conventional materials. From the examination, it was discovered that the basalt fiber expandedthe strength of concrete not withstanding when unprotected to sulphate attack bit by bit when compared with consistent concrete. the ideal strength of concrete was accomplished with an addition of 2% basalt fiber by the heaviness of cement. This paper investigates the strength properties of concrete specimens cast using 2% basalt fiber as optimum and waste marble powder as the partial replacement of fine aggregate. The marble pieces are finely crushed to powdered and the gradation is compared with conventional fine aggregate. The marble powder is added to M40 grade of concrete at 0%, 25%, 50% and 75% partial replacement by weight of fine aggregate. The results obtained from compressive strength test after 7 days and 28 days are then evaluated. And the split tensile strength and flexural strength after 28 days are also evaluated. Finally, the results obtained after partial replacement of fine aggregate by marble powderis compared graphically. The idea is to achieve higher strength of concrete at an economical rate. Moreover, the use of industrial wastes like marble powder would also help to solve various environmental problems.

Key Words: Marble Powder, Basalt Fibre, Fine AggregateConcreteisanextensivelyusedbuildingitemandconsists ofcement,coarseaggregate,fineaggregateanddeliberate amount of water. Natural sand is usually used as fine aggregate. For appropriate rapid growth in structural activities, accessible natural sand supply is exhausting. In addition,therearetimeswhenitisnecessarytotransport high class sand from a long distance, and because of the expense of construction, it is essential to partially or completely substitute the ordinary sand in the concrete

with a substitute matter without weakening the superiority of the concrete. To substitute sand as fine aggregate, waste marble dust can be used. The project aims to exploit the usage of waste marble powder in concreteinsteadofsandasfineaggregate. From the experiments it is known that 2% of basalt fiber by the total weight of cement shows the maximum strength in the concrete. therefore taking 2% of basalt fiber as optimum value and changing the proportion of marble powder from 0% to 75% with an increment of 25%,theoptimumstrengthofconcreteisdetermined.

Marble is one of the most extensively used types of rock/stone nowadays. It is the end product of the metamorphism process of sedimentary carbonate rocks, most commonly limestone or dolomite rock. Marble has retained its importance over time, due to its attractive decorative purposes and its variety of appearances and colors. Like other waste materials, the disposal of the marble powder has become a serious environmental problem.So,toovercomethisseriousproblemwecanuse several types of waste coming from the industry, e.g. by replacing or partially replacing the constituents of concrete (cement, sand or aggregates) thus conserving natural resources.Marble wastecanbeutilized invarious ways and marble slurry can be used as fine aggregates in concrete replacing, at least partially, river sand. The utilization of marble dust powder (MDP) as cement replacementwasstudied.Thefineaggregatewaspartially replacedwithMPupto75%byweightwithanincrement of25%.

Basalt is a natural, hard, dense, dark brown to black volcanicigneousrockoriginatingatadepthofhundredsof kilometers beneath the earth and resulting the surface as molten magma. Basalt fiber is a typical ceramic fiber, it’s easy to disperse when mixed with cement concrete and mortar. Therefore, basaltfiber reinforced concreteserves

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

the functions of reinforcement, crack resistance, and can extend the life of construction in the fields of housing, bridges, Highways, railways, urban elevated roads, runways, ports, subway tunnels, the coastal Protection works, plant facilities. Performance of conventional Concreteisenhancedbytheadditionoffibersinconcrete. The brittleness in concrete is reduced and the adequate ductilityofconcreteisensuredbytheadditionoffibersin concrete. Basalt fibers show comparable mechanical properties to glass fibers at lower cost and exhibit good resistance to chemical and high temperature exposure. The various strength properties studied consist of compressive strength, flexural strength and splitting tensilestrength.

The cement exploited for the study is ULTRATECH of 43 grade Portland Pozzolana cement. The specific gravity of cement is 3.15, with a consistency of 33%. And the initial settingtimeis50min.

Thesand whichwaslocallyavailableandpassingthrough 4.75mmISsieveisused.Goodqualityriversandwasused asafineaggregate.

Locally available well graded aggregates larger than 4.75 mm and smaller than 12.5 mm are used as coarse aggregates.ACIMixDesignProcedure.Crushedstoneof10 mmand20mmsize,takenfromalocalquarry.

Super plasticizers (SPs), also known as high range water reducers, are additives used in making high strength concrete.Plasticizersarechemicalcompoundsthatenable the production of concrete with approximately 15% less watercontent.Superplasticizersallowreductioninwater content by 30% or more. Dr. Fixit was used for the experimentalwork.

Waterisanimportantingredientofconcreteasitactively participates in the chemical reaction with cement. It should be free from organic matter and the pH value shouldbebetween6and7.

Based on the Indian Standard (IS: 10262 1982), design mix for M40 grade of concrete was prepared. And tests wereconducted.Bypartiallyreplacingfineaggregatewith five different percentages by weight of marble powder (0%, 25%, 50%, 75%). The concrete cubes of size 150x150x150 mm, beams of size 100x100x500 mm and cylinder sample of diameter 150mm and height 300mm

were casted. The six specimens of cube, three specimens of beam and three specimens of cylinder of each mix were prepared. After 24 hrs the specimens were removed from the mould subjected to water curing for 7 & 28 days. After curing the specimens were tested for compressive strength for 7 and 28 days, and flexural strength and split tensile strength for 28 days.

% replace ment of Marble Powder

Quantity of materials (Kg)

Ceme nt Coarse aggrega te

Fine aggrega te

Marble powder Basalt fiber

MP0 24 55 36 0 480

MP25 24 55 27 9 480

MP50 24 55 18 18 480

MP75 24 55 9 27 480

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3408

All cubes were tested in the ambient curing process. For the different proportions, cubes were tested using a 3000 KN volume compression tester 7 days and 28 days after curing. After placing the test piece in the center of the

Figure 1: ImagesofspecimenInternational Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

testing machine, the test was conducted with a uniform stress of 10 kg / cm 2 / min. Loading continued until thereadingswerereversedfromthe incremented value.Reversal of the reading indicates that the test piece has failed. The machine stopped, anditturnedoutthatreadingatthatmomentwasthe ultimate load. The value obtained by isolating the finalloadbythecross sectionalareaofthesampleis equaltothefinalcubiccompressivestrength

% replacement of Marble Dust

7days Compression test results (N/mm²)

28days Compression test results (N/mm²)

MP0 31.03 41.55

MP25 31.40 43.22 MP50 32.66 44.11 MP75 31.77 42.215

% replacement of MP 28 days split tensilestrength (N/mm²)

MP0 4.10

MP25 4.9 MP50 5.8 MP75 5.16

4.2

Thisisanindirecttesttodeterminethetensilestrength ofacylindricalspecimen.Inthedividedtensilestrength test,acylindertestpiecehavingaspanof100mmanda length of 200 mm was subjected to curing for 28 days using a 3000KN capacity compression tester. To avoid direct loading on the test specimen, a cylindrical specimen was placed under the woody specimen. The

Flexuralstrengthfamiliarizedasthemodulusofrupture,or flexural strength or transverse breaking strength is a propertyofmaterialidentifiedasthestressofthematerial before the bending test. The transverse bending test is most commonly adopted and uses a three point bending test technique to bend a specimen either rectangular or circular in cross section to rupture or yield. Flexural strength signifies the maximum stress experienced in the material in that instant. Four point bending is considered. Inrectangularsamplebelowaloadinafour pointbending setup where the loading span is one third of the support span.

%

of MP 28 days flexural strength (N/mm²) MP0 4.2 MP25 4.8 MP50 5.6 MP75 4.6

There is a possibility for the partial replacement of sand with marble powder in the production of concrete.

increased by 10.28% when the replacement becomes 50% and it then decreased by 4.3% when the replacement becomes 75%. So the optimum value of compression is 50%. The split tensile strength of concrete increased by 31.8% when the replacement becomes 50% and itthen decreased by 4.3% when the replacement becomes 75%. So, the optimum value of compressionis50%.

Thesplittensilestrengthofconcreteincreasedby 31.8%whenthereplacementbecomes50%andit then decreased by 11.03% whenthe replacement becomes75%.Sotheoptimumvalueoftensionis 50%.

The flexural strength of concrete increased by 26.7%whenthereplacementbecomes50%andit then decreased by 17.85% whenthe replacement becomes75%.Sotheoptimumvalueofflexuralis 50%.

Thus,anoptimumof50% replacement by weight ofsandwithMPcanbeusedinconcrete.

The basalt can be used as a new mineral admixture in concrete because it does not show negativeeffectonthestrengthofconcrete.

The strength gain of concrete when sand was partially replaced with MP showed that it can be effectively utilized in the manufacturing of concrete and thus contributes in the reduction of naturalresourceutilizationinconcrete.

[1] Aliabdo, A.A., Abd Elmoaty, A.E.M., & Auda, E.M. (2014). “ Re use of waste marble dust in the production of cement and concrete Construction and BuildingMaterials.”

[2] Alyamaç, K.E., & İnce, R. (2009). “ A preliminary concrete mix design for SCC with marble powders. ConstructionandBuildingMaterials.”

[3] André, A., Brito, J., Rosa, A., & Pedro, D. (2014). “ Durability performance of concrete incorporating coarse aggregatesfrom marble industry waste.” JournalofCleanerproduction

Theuse ofMP inconcrete production wouldlead to improved environmental waste management andprofitableutilizationofindustrialwaste.

Marble powder can be used for production of heavyweightconcrete.

Compared to the control mix, the compressive, tensile and flexural strengths of the replaced concrete shows an increase initially with increasing replacement percentage up to an optimumlimitandfromthereitdecreases.

[4] Belaidi,A.S.E.,Azzouz,L.,Kadri,E.,&Kenai.,S.(2012). “ Effect of natural pozzolana and marble powder on the properties of self compacting concrete. ” Constructionandbuildingmaterials.

[5] Binici,H.,Kaplan.H.,&Yilmaz,S.(2007).“Influenceof marble and limestone dusts as additives on some mechanical properties of concrete. ” Scientific ResearchandEssay.

[6] Binici, H., Shahb, T., Aksogan, O., & Kaplan, H. (2008). “Durabilityofconcretemadewithgraniteandmarble as recycle aggregates. ” Journal of materials processingtechnology.

The compressive strength of concrete

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

[8] Corinaldesi, V., Moriconi, G., & Naik, T.R. (2010).“Characterizationof marblepowder for its use in mortar and concrete. ” Construction and Building Materials mortar and concrete. ” Construction and Building Materials mortar and concrete. ” ConstructionandBuildingMaterials

[9] Ergun, A. (2011). “ Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical propertiesofconcrete”

[10] Geseoglu,M.,Guneyisi,E.,Kocabag,M.E.,Bayram, V.,&Mermerdas,K.(2012).“Freshandhardened characteristics of self compacting concretes made with combined use of marble powder, limestonefiller,andflyash.”

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3411