Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

1Assistant Professor, Department of Civil Engineering, Ilahia College of Engineering and Technology, Kerala 2,3,4,5PursuingB.TechinCivilEngineeringfromAPJAbdulKalamTechnicalUniversity,Kerala. ***

Abstract Cement concrete is the most widely used material for various constructions. Here we have investigated the corrosion behavior of steel in reinforced concrete with Supplementary Cementitious Materials (SCM). SCM’s like metakaolin and silica fume are often used to reduce cement contents and improve the workability of fresh concrete and enhance the strength and durability properties of hardened concrete. Here the compressive strength characteristics of M35 concrete is evaluated with varying percentages of silica fume ( 10%, 15%, 20%) and metakaolin (10%, 15%, 20%) separately aspartialreplacementofcement.Theeffectofsilicafume and metakaolin on the corrosion of steel in reinforced concrete using Half cell potential method. For this the specimens withoptimum percentages of silica fume and metakaolin are choosed. It measures the potential difference and electrical resistance between the reinforcement and concrete surface( in accordance with ASTM C876 ). So, through replacing the cement by supplementary cementitious materials we can minimize the use of cement and we can reduce the probability of corrosion.

Key Words: SCM, Silica Fume, Metakoalin, Cement, Corrosion resistance, Compressive strength.

Cement concrete is the most widely used material for various constructions. Supplementary cementitious materials (SCM) can be used for improved concrete performance in its fresh and hardened state. They are primarily for improved workability, durability and strength. The main supplementary cementitious materials aresilica fume, metakaolin,flyashandGGBS. SCMs are known to improve the durability of concrete by making it less permeable, and increasing its compressive strength. Compared to traditional concrete, it is a much eco friendly material. Cement substitutes are used to enhance certain qualities of cement and reduce the environmental effect. Usage of slag as cement replacement in concrete seems to be a good solution against chloride induced corrosion, such asinmarineenvironment.

The corrosion of steel reinforcement in concrete is the mostsignificant durability problemencountered in reinforced concrete structures. Corrosion is a natural process that occurs when the steel rebar with in reinforced concrete structure rusts. As the steel bar corrodesthevolumeofsteel increasesand thisexpansion creates a tensile stress in the concrete, which eventually leads to cracking. Rebar corrosion occurs mainly due to the chloride ion and moisture penetration into the concrete.

SCMs when added to concrete improves the inter particle arrangement, improves aggregate paste bonding and increases the impermeability there by the corrosion resistance of concrete increases. The corrosion behavior of the reinforcement was evaluated based on the half cell potential.

Silica fume also known as micro silica is an amorphous polymorphsofsilicondioxide.Becauseofitschemicaland physical properties, it is a very reactive pozzolan. The average particle diameter is 150nm. Concrete containing silica fume can have very high strength and can be very durable.Placing,finishing,andcuringsilica fumeconcrete requirespecialattention.

Metakaolin is a highly reactive pozzolana formed by the calcination of kaolinite (China clay). It is a product manufactured when kaolin is heated to a temperature between 600℃ and 800℃. Therefore, considerable CO2 emissions are associated with the production of metakaolin.Sizeofmetakaolinrangesfrom1 20µm.

Cement is used as a binding material in concrete and it impartsvariousstrengthpropertiestotheconcrete.Inthe present experimental work, Dalmia OPC 53 was used. As per the standard testing procedure, the compressive strength of cement will be obtained after 28 day. It

ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

provides long lasting durability to concrete structures. Specific gravity, initial setting time, final setting time, fineness and standard consistency of cement were tested.

Fine aggregate is basically sand obtained from the land or marine environment. It consists of natural and crushedstone which passes through 4.75 mm sieve. Its size range from 4.75 mm to 75 microns as per IS 383 1970.Heremanufacturedsand(M sand) is usedasfine aggregate.

Coarse aggregates are commonly considered as inert fillers. The coarse aggregates of size ranging from 20 mm to 4.75 mm are used for casting. The maximum allowable water absorption is 2% as per IS 383:1970. Thevarious propertiesofaggregatesincludeshapeand texture, size gradation, moisture content, specific gravity,reactivity,soundnessandbulkdensity.

Superplasticizers(SPs),alsoknownashighrangewater reducers, are additives used in making high strength concrete. Their addition to concrete or mortar allows the reduction of the water to cement ratio without negativelyaffectingtheworkability.Arment AquaArm proofWP10wasusedfortheexperimentalwork.

Based on the Indian Standard (IS:10262 1982), Design Mix for M35 grade of concrete was prepared and tests were conducted by partially replacing the cement to evaluate optimum percentage of silica fume and metakoalin in M35 equivalent concrete at various replacement levels of cement by weight (10%,15%,20%).Cubesofsize150mm × 150 mm × 150 mm were casted. These were tested usinga compression tester for 7 days,14 days and 28 days after curing. For identifying the corrosion behaviour three cylindrical specimens of height 30 cm and diameter 10 cm were prepared. The specimens wereinsertedwith10mmrod(TMTbars)atthecentre to do the corrosion tests. For this the specimens with optimumpercentagesofsilicafumeandmetakaolinare choosed. The half cell potential measurement test essentially consists of measurement of absolute potential at the concrete surface with a reference electrode.Itistheonlycorrosionmonitoringtechnique standardized in ASTMC876 15. It measures the potential difference and electrical resistance between the reinforcementandconcretesurface(inaccordance

withASTMC876).

Table 1: Detailsofreplacedconcretespecimens

% replacement Quantityofmaterials(Kg) Cement FA CA SF MK

0% 6.45 10.32 16.77 O 0 10% 5.81 10.32 16.77 0.65 0.65 15% 5.49 10.32 16.77 0.96 0.96 20% 5.16 10.32 16.77 1.29 1.29

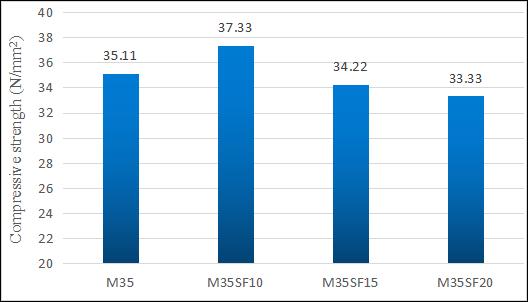

TheCubescasted weretestedforcompressivestrength by using the Compressive testing machine for a time duration of 7 days, 14days and 28 days which is obtainedbydividingtheLoadbyArea.M35SF10,M35SF15, M35SF20 are the main specimens which are M35 equivalent concrete containing 10%, 15%, 20% silica fume.

Table-2: Compressivestrengthresultsofsilicafume addedconcrete

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Table 3: Percentageincreaseordecreasewhen strengthenedusingsilicafume

Table 5: Percentageincreaseordecrease whenstrengthenedusingmetakaolin

Sl No % addition of metakaolin

Compressive strength (N/mm2)

% Increase or decrease

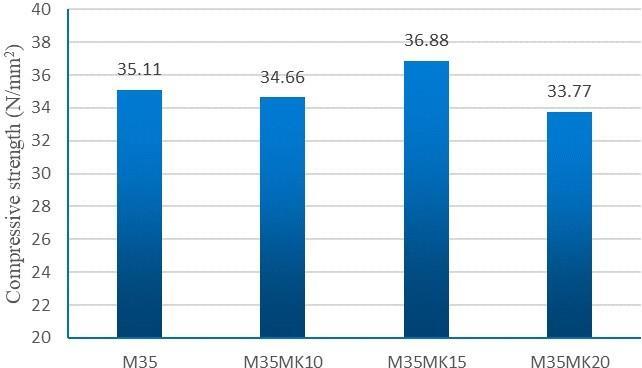

1 0% 35.11 0% 2 10% 34.66 1.28% 3 15% 36.88 5.04% 4 20% 33.77 3.81%

Therefore the addition of metakaolin up to 15% is the optimum percentage where we can get the maximum compressivestrength.

Chart

Therefore the addition of silica fume up to 10% is the optimum percentage where we can get the maximum compressivestrength.

1.2Compressive strength of Metakaolin

M35MK10,M35MK15,M35MK20arethemainspecimenswhich areM35equivalentconcretecontaining10%,15%,20% metakaolin.

Table-4: Compressivestrengthresultsofmetakaolin addedconcrete

Chart 2: Compressivestrengthofmetakaolin

Therefore the addition of metakaolin up to 15% is the optimum percentage where we can get the maximumcompressivestrength.

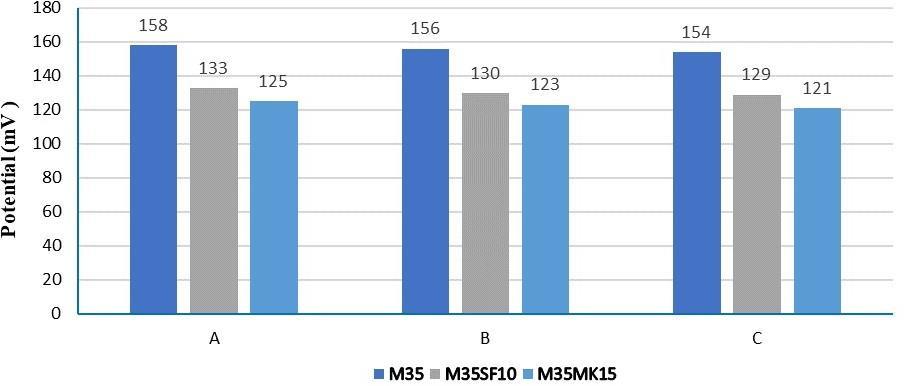

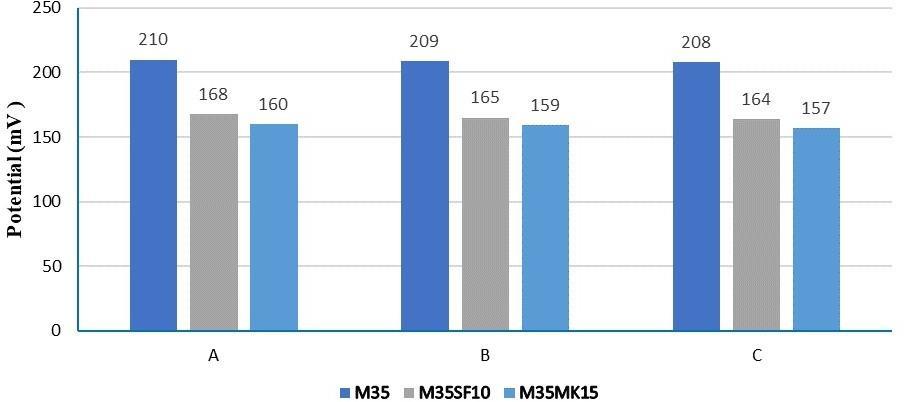

Three cylindrical specimens of height 30 cm and diameter 10 cm were inserted with 10 mm rod (TMT bars)atthecenterwerecastedtodothecorrosiontests. Optimum percentage of silica fume and metakaolin are chosen for the casting of specimens. The main three specimensareM35,M35SF10,M35MK15.Forthismarkthree points (a,b,c) on the cylinder with 10 cm spacing from the tip of the bar. And measure the values on two sides ofcylinder.

Figure 2: Specimensforcorrosiontest

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

There for the corrosion resistance of silica fume on points A, B, C shows 20% ,21.05% and 21.15% of increasethanM35mix.Andthecorrosionresistanceof metakaolin shows 23.805, 23.92% and 24.52% of increasethanM35mix.ThetestresultsshowsthatM35 concrete gives more probability of corrosion than silicafume.Theareawhich ismoreexposedtowater andairshowshigherrateofcorrosion.

The optimum percentage of Silica fume in M35 equivalent concrete at various replacement levels of cement by weight (10%,15%,20%) based on compressive strengthisdeterminedas10%.

supplementary cementitious material we can minimize the use of cement and we can reduce theprobabilityofcorrosion.

[1] Anand Kuber Parande, B. Ramesh Babu (2008), “Study on strength and corrosion performance for steel embedded in metakaolin blended concrete/ mortar”, Construction and Building Materials 22, 127 134.

[2] A.R. Hariharan, A.S. Santhi, G. Mohan Ganesh,(2011) “Study of strength development of high strength concrete containing fly ash and silica fume”, IJEST 3(4).

The optimum percentage of metakaolin in M35 equivalent concrete at various replacement levels of cement by weight (10%,15%,20%) based on compressive strengthisdeterminedas15%.

[3] G. Batis, P. Pantazopoulou, S. Tsivilis (2005), “The effect of metakaolin on the corrosion behavior of cement mortars, Cement & Concrete Composites” 27, 125 130.

When compared with the optimum percentagesofsilica fumeandmetakaolinon M35 mix, M35 concrete mix shows less compressivestrength.

[4] KelestemurOguzhan,DemirelBahar(2015),“Effectof metakaolin on the corrosion resistance of structural lightweight concrete”, Construction and Building Material,ELSEVIER.

The probability of corrosion of silica fume andmetakaolinon30thdayislessthan10%.

The probability of corrosion of silica fume and metakaolin on 60th day is also less than 10%.

[5] LakhbirSingh,ArjunKumar,AnilSingh(2016),“Study of partial replacement of cement by silica fume”, InternationalJournalofAdvancedResearch,Volume4, Issue7,104 120.

TheprobabilityofcorrosionofM35 on30th day is less than 10%and probability on 60th day is between10 90%.

The corrosion resistance of silica fume on points A,B, C, shows 20%, 21.05% and 21.15% of increase than M35 mix. And the corrosion resistance of metakaolin on points A, B, C, shows23.80%,23.92%and24.52%ofincrease thanM35mix.

[6] Rukhsana Rashid, Nishant Kumar (2016),” Study on Effect of Silica Fume on Properties of M40 Grade of Concrete”, International Journal of Engineering Research&Technology(IJERT)Vol.5Issue05.

[7] S. Arunachalam, S. Anandakumar, R. Ranjani (2021), “Corrosion resistant properties of concrete using varioussupplementarycementitious materials”,Today proceedings,ELSEVIER.

M35 concrete shows comparatively more probability on corrosion than silica fume and metakaolin added concrete on 30th and 60th day.

The point which is near to the tip of steel shows comparatively higher probability of corrosionthantheotherpoints.

It shows that the probability of corrosion is decreasedfromthatendpoint.

Alsotheareaofsteelwhichismoreexposedto waterandairshowshighercorrosionrate.

The corrosion resistance of silica fume and metakaolin concrete decrease with increase in age.Therefore, SCM’s when added to concrete improves the inter particle arrangement, improves aggregate paste bonding and increases the impermeability there by the corrosion resistance of concrete increases. Through replacing the cement by