International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Sindu.D1 , Praveen J.V2 , Dr. Ravikumar C.M3, Dr. Murulidhar N4, Roopa M5 .

1M.Tech. student, Dept. of Civil CAD Structural engineering, Sri Siddhartha Institute Of Technology, Tumakur, India.

2 Asst professor, Department of Civil Engineering, Sri Siddhartha Institute of Technology, Tumakuru, India.

3 Professor, Department of Civil Engineering, University B.D.T College of Engineering, Davanagere, India

4Asst professor, Department of Civil Engineering, Sri Siddhartha Institute of Technology, Tumakuru, India.

5 Asst professor, Department of Civil Engineering, Sri Siddhartha Institute of Technology, Tumakuru, India. ***

ABSTRACT - In contemporary practical world, primarily focuses oninfrastructuralevolutionabout functionalaspects, modest and artistic in the construction projects. High Performance Concrete plays a very important role in some areassuchashydraulicstructures,highrisebuildingandlong length bridges and so on. By addition of fibres into the concrete mix, there is an extreme development in the propertiesofconcrete.Here,thisresearchstudydealswiththe exploratory investigation of fibre reinforced HPC for their mechanical properties by replacing the coarse and fine aggregates by crushed concrete waste and foundry sand respectively. Foundry sand is replaced from 0% to 40% with having 5% interval and crushed concrete waste is replaced from 0% to 40% with having an interval of 10%. The mechanical properties like fatigue strength, impact strength, compressionstrength,flexuralstrength,splittensileandshear strength of High Performance Concrete with and without addition fibres are performed. For manufacture of High PerformanceConcrete,M 80Gradeconcretehasbeenchosen. AccordingtoIRC44:2017recommendationandguidelines,the mix design process are conducted. Conventional dosage of super plasticizer was managed in the concrete to make a better execution. Here, the poly propylene fibres have been used as of 0.3% by total cement weight used. Mechanical propertiesareobtainedbymanufacturingtheparticularsizes of mould cured for 7, 14 and 28 days for different tests and resultsweretabulatedforrespectivedaysandconclusionsare discussed.

Key Words: High Performance Concrete (HPC), Poly propylene Fibre, Foundry sand, Crushed Concrete Waste, Conventional concrete, Super plasticizer.

TheHigh PerformanceConcrete(HPC)becomesoneofthe most essential concrete materials for the conventional concrete.Bytakingintoconsiderationitsaccomplishment andaccountabilityintheparticularfieldofapplication,the High PerformanceConcrete’sstrengthisequaloroverofM 80gradewillbeappliedinlargespanofconstructionfield. Byminimizingtheamount ofwater cement ratiowiththe use of special admixtures which leads to improve in the workability,performanceandhigh strengthofHPC.Various

types of polymers or steel based fibres are used in HPC therebymakingtheconcreteintofibrereinforcedconcrete, to improve its tensile strength, toughness and ductility. Cementisthecostliestmaterial,byutilizingbasematerial suchascrushedconcretewastepowderetc.,toreplacethe cementmoderatelyinconcreteistakenaseconomicaland reducesthedetrimentaleffecttoo.Thegenerationofmicro cracksintheconcretestructures,buildingsorpavementsare causes fatigue failure due to periodic application of loads, whichultimatelyleadstothegenerationofmacrocracks,in the course of time the cracks developed that leads to structure fail. Here we focused to study the function of foundry sand and crushed concrete waste used as a replacement in the High Performance Concrete also determinethemechanicalpropertiesoftheFibreReinforced High Performance Concrete (FRHPC), by knowing the optimal replacement of material individually and also investigatethecompressionstrength,flexuralstrengthand fatiguebehaviourHPCwithandwithouttheadditionofthe fibres.

OrdinaryPortlandCement(OPC)53 Gradehavebeenused for this study as a binding material and basic tests were conducted on the cement to know its properties and the resultsareenrolledin Table 1. Riversandandfoundrysand showninFig 1hasbeenusedalsotheirbasictestresultsare listedin Table 2. Naturalaggregatesareacquiredfromnear vendor and Crushed granite aggregates shown in Fig 2 whichpassingthrough20mmsieveandretainedon12.5mm sieve with specific gravity 2.60 and as recommended in IS: 383 1970 is used for all the specimens and their basic tests are tabulated in the Table 3. The water which is used for the preparationofconcreteshouldbefreefromorganicmatter and dirt. Here, Poly Carboxylic Ether is taken as a super plasticizerofspecificgravity1.08.Polypropylenefibresare alsousedanditisaformoflinearpolymersyntheticfibres showninFig 3.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

It is necessary to examine the strength properties of the concrete. Hence, Concrete cubes of size 150*150*150mm, arecastedfor24hoursandthende moulded.Thespecimens are manufactured in two ways such as, by using concrete mixtures accommodate with crushed concrete waste as CoarseaggregateandwastefoundrysandasFineaggregate andalsoconcretemixturewithcrushedconcretewasteas CoarseaggregateandwithoutwastefoundrysandasFine aggregate as partial substitutes in the High Performance Concrete having different varying proportional such as foundrysandwith10%, 20%,30%and40%andcrushed concrete waste with 5%,10%,15% and 20% of concrete cubesatroomtemperature.Polypropylenefibreshavebeen used to achieve the properties of High Performance Concrete, then compared with conventional concrete and replacedconcretewithoutfibres.

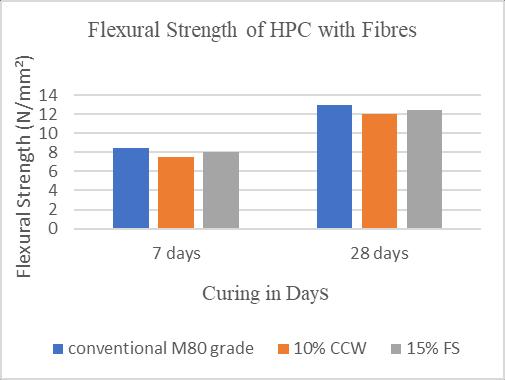

Flexural strength is used to determine tensile strength indirectly.Themouldofsize100mmx100mmx500mmwas preparedandcuredwithrespecttocuringperiods.Testmay dothroughonepointortwopointsloadingtoanalyzethe flexuralbehavioroftheconcrete.Theflexuralstrengthtest resultsarelistedbelow.

Table 6: FlexuralStrengthTestResults

All the concrete cubes were tested to determine their resistivity to compression loads. Compression testing machine having 3000 KN capacity was used to test the concretespecimens.

The test results of all the specimens are listed below and conclusionsarediscussedbasedontheobtainedresult.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

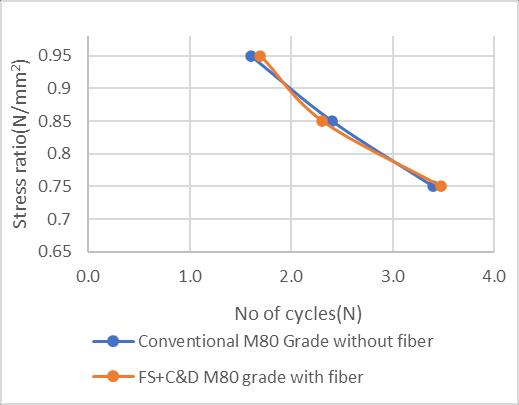

To conduct fatigue test, it is essential to know the static flexuralstrengthofconcrete.Basedupontheobtainedstatic flexural strength, the required load to conduct the fatigue testwascalculated.Fatiguetestwasconductedfordifferent stressratioslike0.95,0.85and0.75.Thefrequencyof3Hz remains kept constant till the end of the experiment. The numberofcyclessustainedbythespecimenswasrecorded andS Ncurveisdesigned.

Table 7: NumberofCyclesforDifferentStress RatiosconvertedintoLogValues

Type of concrete

Number of Cycles for different Stress Ratios 0.95 0.85 0.75

FS+C&DM80 Gradewithfibre 1.602 2.401 3.398 Conventional M80grade withoutfibre 1.698 2.307 3.477

Fig 7: GraphofFatiguetestresult

1) Byprovidingthepoly propylenefibresof0.3%dosage byvolumeofcementitiousmaterialtotheHPC,thereisa considerableincreaseinbothcompressionstrengthand flexuralstrengthofthecompositesectioncomparedto conventionalconcrete.

2) Incompressionstrengthtestthemaximumreplacement of foundry sand is 15% and crushed concrete waste is 10%.

3) InCompressionStrengthTest,oncethesampleconcrete cubewithoutadditionoffibrereachestheultimateload, theinternalstressoftheconcretecubewillgetfailand specimen sample breaks by blasting with immense sound. On other side, the sample concrete cubes are accommodating with poly propylene fibre, the stress loadwouldtransfertothefibresfromtheconcreteand strainintheconcretecubeislessanditwilltaketimeto fail.

4) In Flexural Strength Test, the failure section of the specimen precisely about the point, where the load appliesalsocalledshearzone.Hence,theconcretecube didnotgetbreakduetothepresenceoffibre,butability of a material to receive forces will get fail by brittle failure.Comparedtoconventionalconcrete,thevalueof flexuralstrengthofFRHPCincreasedby5 10%duetothe betteraspectratiooffibres.

5) AscomparedwithIRC58 2002values,alltheconcrete sectionsresistagreaternumberofloadrepetitions.One of all, composite sections (FS+C&D M80 with fibre) withstandmorerepetitionsoffatigue.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

6) In fatigue test, the maximum replacement of foundry sandis15%,byprovidingpoly propylenefibreof0.3% dosagebyvolumeofcemetitiousmaterialstoHPC.For stress ratio 0.95, FS+C&D M80 with fibre can sustain 19.8% more repetitions than Conventional M80 grade concretewithoutfibre.

7) Forstressratio0.85,FS+C&DM80withfibrecansustain 7.12%morerepetitionsthanConventionalM80without fibre.

8) Forstressratio0.75,FS+C&DM80withfibrecansustain 5.45%morerepetitionsthanConventionalM80without fibre.

9) Fromthesestudiesandbasedontestresults,itisnoticed thatthecompositeconcrete sectionFS+C&DM80 with fibreisagoodsolutionforthestructures,alsoithasthe power of resisting a more number of cyclic loads as compared to single layer of normal or conventional concrete.

1. Job Thomas and Ananth Ramaswamy, “Mechanical PropertiesofSteelFiber ReinforcedConcrete”,Journal ofMaterialsinCivilEngineering,Vol.19,No.5,May1, 2007.

2. Nobili,L.Lanzonietal“Experimentalinvestigationand monitoringofapolypropylene basedfiberreinforced concreteroadpavement”October2013.

3. M.Heralaletal:FlexuralFatigueCharecteristicsOfSteel FiberReinforcedRecycledAggregateConcrete(Sfrrac) 2009.

4. YanHQ,WangQYandYanNing:ExperimentalResearch on Fatigue Behavior of Recycled Aggregate Reinforcement Concrete Made from Building Scrap. ISSN:1662 8985,Vol.339.

5. DushyantR.Bhimani,JayeshkumarPitroda“AStudyon Foundry Sand: Opportunities for Sustainable and EconomicalConcrete”Volume 2:Issue 1;Jan2013.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal