International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Abstract - Plastic as a synthetic polymer substitute for natural materials has become an essential aspect of our lives. The disposal of plastic garbage is a significant problem for waste management since it poses a covert threat to the environment. Nowadays society does not have any alternative to plastic products like plastic bottles, plastic sheets, etc. In spite of all efforts made to limit its use, unfortunately, its utility is increasing day by day. Improper disposal of used plastics has led to increasing litter, which is contaminating the environment, harming wildlife, and wasting valuable resources. One of the most crucial steps in various waste management strategies is the sorting of plastics. There are different types of sorting techniques like Dry sorting, Air sorting, IR & X Ray sorting, Electrostatic sorting, Wet sorting, Melting sorting, and Hydrocyclone sorting. Manual sorting is suitable when plastic components are present in large amounts but it is a labor intensive process. Our project makes use of the sorting technique by thermal adhesion quality of the plastic. This sorting technique is suitable for sorting plastic based on its grade. To be able to use this method, it is essential that the softening temperatures of the plastics are significantly different. This technique consists of a heated conveyor belt. Sorting takes place by the selective thermal adhesion of the softened particles to the rolls or belt with a low operating cost.

Key Words: Plastic Segregation, Recycling, Heating, Softening.

Waste generation and disposal are naturally part of any developing and industrial society. Because garbage exists in every community and because it comes from both commercialandhomesources,theproblemofsolidwaste isglobal inscope. The quantityandrateof thegeneration of solid wastes within any city are dependent on the population, level of industrialization, socio economic status of inhabitants as well as the kind of undertakings being dominant. An unkempt surrounding affects the living standard, the health status of the inhabitants, and thusthequalityoftheirlives.Itisinviewofthis,thatsolid wastemanagementeffortswhichwereinitiallydirectedat just the removal of waste from the urban centers and subsequent destruction of such waste later has their attention shifted to the utilization of waste, waste reduction, reuse recycling, management of hazardous

substances and prevention of pollution resulting from wastedisposal.

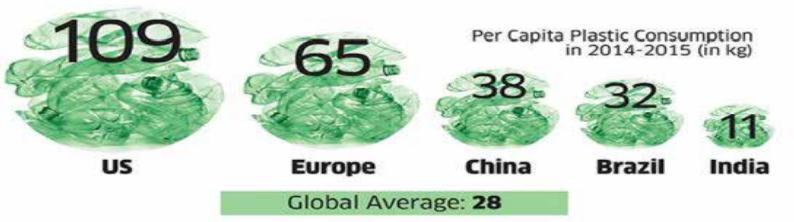

Plastic as a synthetic polymer substitute for natural materials has become an essential aspect of our lives. We have witnessed a considerable escalation in the production of plastics in the last few decades and simultaneously increased consumption of plastic materials. The proportion of plastic trash generated from plasticpackagingproductsis estimatedtobeover70%.It is also estimated that 83% of drinking water contains plasticandin30yearsthereislikelytobemoreplasticin oceans than fish. Consuming plastic has been linked to cancer, changes in hormone levels, and cardiac damage, according to studies. Waste generation and disposal are naturally part of any developing and industrial society. Theproblemofsolidwasteisthereforeauniversaloneas waste exists in every society and the waste from both commercialanddomesticsourcesisconsiderablygrowing everyday.Thequantityandrateofthegenerationofsolid wastes within any city are dependent on the population, level of industrialization, socio economic status of inhabitants as well as the kind of undertakings being dominant. An untidy surrounding affects the living standard, the health status of the occupants, and thus the qualityoftheirlives.

Ithasbeennotedthatincorrectcollectionandsegregation of plastic garbage makes its disposal a severe problem. Oneofitsbiggestdrawbackswhenitcomestothedisposal ofplasticsisthatitisdurableandresistanttobreakdown. Theenormousissueofplasticpersistenceiscausedbythe man made chemical bonds in plastic being extremely difficultfornaturalorganismstobreakdown.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

According to reports for the 2017 18 fiscal year, the Central Pollution Control Board (Cpcb) estimated that India produces about 9.4 million tonnes of plastic waste annually, or 26,000 tonnes of waste per day, of which about 5.6 million tonnes are recycled (15,600 tonnes of waste perday) and 3.8 milliontonnesareleftuncollected or left to litter, amounting to 9,400 tonnes of waste per day.

Out of the 60% of recycled plastic, 70% is recycled at registered facilities, 20% is recycled by THE Unorganized Sector, AND 10% of the plastic is recycled at home. While thesestatsare38%higherthantheglobalaverageof20%, there ARE no comprehensive methods in place for plastic waste management. Additionally, there is a constant increase in plastic waste generation. One of the major reasonsforthisisthat50%ofplasticisdiscardedaswaste after a single use. This also adds to AN increase in the carbon footprint since THE single use of plastic products INCREASESthedemandforvirginplasticproducts.

and sea turtles, which would be devastating. In wealthy nations, billions of bags are discarded annually, the majorityofwhichareonlyusedonce.Themainissuewith plastic bags is that they take a long time to decompose in the environment. The ordinary plastic carrier bag is used forfiveminutesonaverage,yetittakes500yearsforitto breakdown.

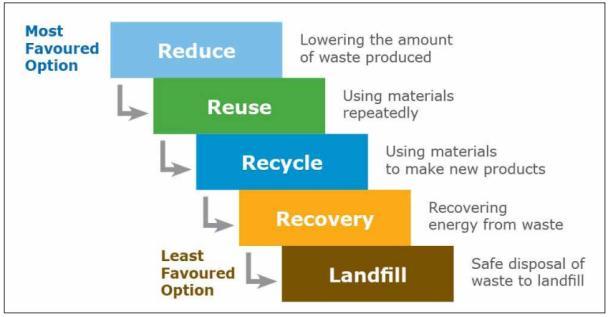

Byfollowingthestepswecanreduceplasticwaste:

● Reduce

● Reuse ● Recycle

● Recovery

Figure 1.2: PlasticwasterecycledinIndia

Consumers and merchants alike choose plastic bags because they are practical, lightweight, robust, affordable, and sanitary for transporting food and other goods. Some of them are recycled after use, but the majority end up in landfills and waste piles. Once abandoned, plastic bags may contaminate our streets, parks, and rivers. Despite representing a very modest portion of global trash, plastic bags have a big impact. Plastic bags can affect both aquatic and terrestrial creatures in addition to causing difficulties with visual pollution. Due to their bulk and potential for slow breakdown, plastic bags are particularly prominent components of the litter stream.Many carry bags become unattractive trash in trees, streets, parks, and gardens, which not only looks bad but may also harm wildlife like birdsandsmallanimals.Bagsthatmakeittotheoceanrun the risk of being mistaken for jellyfish by marine animals

Separation of plastic represent one of the major problematic processes in the waste plastic management system e.g. it is very difficult to distinguish shredded bottles of PVC from shredded PET bottles and this separation process has to be done prior to the next process because the presence of PVC may decrease the quality of the whole batch. However mechanical separation allows plastic from other materials. In many cases, it is also required to separate different types of plastics such as PVC, PET, and Polyethylene. In several cases,plasticsarealsosortedbycolorinordertoimprove the physical appearance of the products derived from post use material. Mixed plastic waste containing up to 15% PVC is not considered to pose technical problems. Due to the presence of additives and contaminants and also due to the modification of the original polymeric structure during its first use, mechanically recycled plastics only find use in lower grade applications. In the cracking process, such pre treatment consists of a sorting orseparationstepoftheusedinput thatallowsadjusting the chlorine content of the main waste stream. A second possibilityisathermalorchemicaldehalogenationbefore the pre treated product is further processed and this can bedoneinliquidorfluidizedbedpyrolysis.Inthisprocess,

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

HCl is produced and is neutralized or separated for industrialuse.TherelativelylowPVC/chlorinecontent,as found in mixed plastic waste is acceptable for existing feedstock recycling processes as long as an appropriate pre treatment of the plastics waste is guaranteed. In mixed plastics separation, not all plastics materials are sensitivetothealienasPETorcontaminationasPVC.

Postconsumer plastic is intrinsically heterogeneous and, thereby, of undefined quality. It consists of a variety of plastic items that are made of a varietyofpolymerse.g.,mainlyPE,PP,andPET,andoften contain minor amounts of foreign materials e.g., foreign polymers,additives,andothercontaminants.Forinstance, postconsumer plastic bottles, trays, and films have been showntoconsistof75to90wt%dominantpolymer(PE, PP, PET, or PS), 5−14 wt % foreign polymers, and paper, and 5−14 wt % residue. The foreign material and residue were mainly encountered in the cap/lid and labels. The material heterogeneity is even larger for multilayered films, as the main polymer was found to account for only 55wt%ofthefilm.

● AndresTorres García,OscarRodea Aragón, Omar Longoria Gandara (2015): Intelligent Waste Separator(ISSN2007 9737):Thispaperproposes a prototype of the Intelligent Waste Separator (IWS) that consists of a common trash can, with morecontainersinsideit.

● Xiang Cheng, Xianhai Yanga, Xia Liu,Lupeng Song (2016): Study on the separators for plastic wastes processing: We observed that centrifugal bearing by the plastic is in direct proportion to themassoftheplasticparticles.

● Olawale James, Nicholas Akhaze, Samuel Kolo (2018): Design and Fabrication of a Solid Waste Sorting Machine( ISSN: 2645 2685): Design specification for slow moving conveyor and fast movingconveyorbelt.

● Seeram srinivasa rao, Shaik. Mastan Vali, Amaresan. Akanksh (2019): Designing And Fabrication Of Waste Separator (ISSN: 2278 3075): This paper presents the achievement of a "squander separator" at family degree using Arduino UNO, to manage the whole strategy effectivelyandwithease.

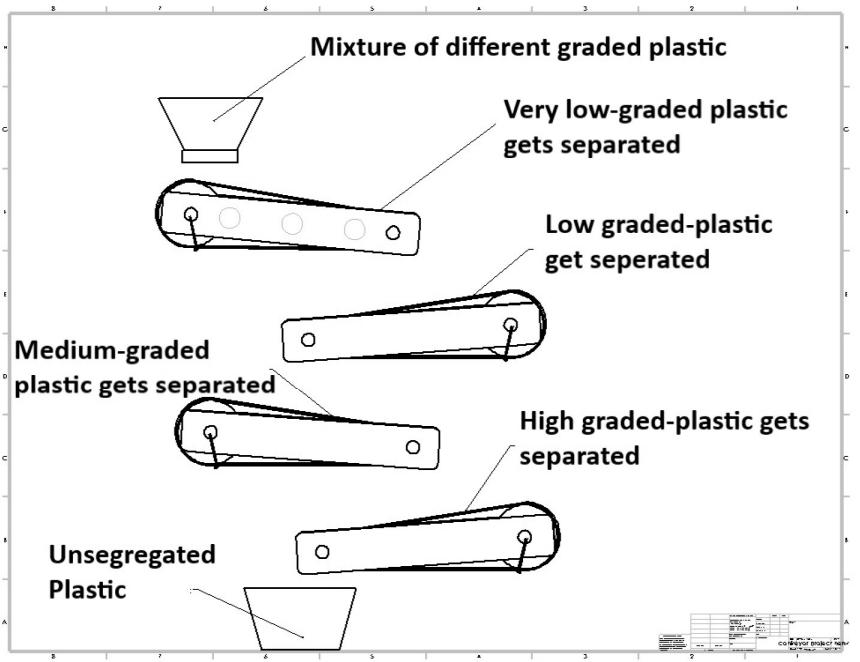

A mixture of plastics of varying grades is deliveredtotheconveyor.Theconveyorismadeofametal mesh belt drive, where plastic is heated to a specific temperature and examined to see if it softens at the desired temperature. In this procedure, many belt conveyors are set up and kept at varying temperatures in descending order to separate various grades of plastic. The mixture of plastic is poured into the hopper, which dischargesitontothefirstconveyorthatispreheatedtoa specific temperature. If the softening temperature of the plastic materials is achieved, they stick to the steel mesh belt drive and are eventually collected in a different containerwiththeaidofthescraperthatisattachedtothe end of the conveyor. The plastic which does not meet the softeningpoint ispassedontothenextconveyorwhichis set at a higher temperature according to the grade table. This process is continued until all of the various graded polymershavebeengathered.

Amixtureofplasticwasdeliveredintothesystem through the hopper, the mixture of the plastic contained Polyethylene Terephthalate (PET), High Density Polyethylene (HDPE), and polypropylene (PP) and Polycarbonate (PC) types of plastic which have different softening points. Depending on the softening point of the plastic, we set the various temperatures at various levels. In the first stage, we had set an initial temperature of 110∘C,andinthesecondstagewehadsetatemperatureof 120∘C and in the third stage, we had set a temperature of 140∘ C. During the first stage, we observed that

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

polypropylene plastic got stuck to the grate mesh under heatingandgotsegregatedinthefirststageandthehigher graded plastic which has a higher softening point didn’t getstucktothegratemeshandpassedontothenextstage. Similarly, during the second stage, High Density Polyethylene plastic got stuck to the graded mesh under heating and was segregated. The unsegregated Polyethylene Terephthalate plastic during the second stagewentontothethirdstageandgotstucktothegrate mesh and segregated during the third stage of the cycle. After the segregation in the third stage, the unsegregated PC plastic does not meet any softening point in the above process and gets collected as unsegregated high graded plastic.

This machine is designed to be an efficient and cost effective machine capable of sorting plastic into various types on the base of their melting point, which can be recycled or used in generating energy. Management of solidwastehasbecomeone oftheissuesofgreatconcern in most developing countries. The need for concerted efforts to manage these plastic wastes cannot be overemphasized. So Automated segregation of different grades of plastic for recycling is capable of sorting plastic basedonitsquality.Thiswasdonetomanagesolidwaste by recycling and reusing. Based on the experiments conducted, it can be concluded that the plastic sorting machineiscapableofseparatingdifferenttypesofplastic.

1. Stephen Kwasi Adzimah and Simons Anthony (2009): Design of Garbage Sorting Machine (ISSN 1941 7020)

2. AndresTorres García,OscarRodea Aragón, Omar Longoria Gandara (2015) : Intelligent Waste Separator(ISSN2007 9737)

3. Xiang Cheng, Xianhai Yanga, Xia Liu,Lupeng Song (2016): Study on the separators for plastic wastesprocessing.

Only two types of plastic can be sorted at once using this procedure. Plastics must have considerably varied melting points and must be maintained in accordance with the grade table in order to preserve the softening point. A heated conveyor belt separator is the key component of this method. Sorting is accomplished throughthesoftenedparticle'sselectivethermaladhesion. Ithasalowcostofoperation.

4. Olawale James, Nicholas Akhaze MUSA2,* Samuel Kolo ZHIRI3 (2018): Design and Fabrication of a SolidWasteSortingMachine(ISSN:2645 2685)

5. Seeram srinivasa rao , Shaik. Mastan Vali, Amaresan. Akanksh (2019): Designing And Fabrication Of Waste Separator (ISSN: 2278 3075).

6. Sreedavi, S. (2014). Solid Waste Generation and its Management A Case Study. International Research Journal of Environment Sciences, 3, 35 44.

7. Karthik, R.., Hans., B. & Mohammed., T. T. (2013). Solid Waste Management and Environment. JournalofDevelopmentManagement,1(1),1 8.

8. Jean Paul Lange(2021): Managing Plastic Waste─Sorting, Recycling, Disposal, and Product Redesign, ACS Sustainable Chemistry & Engineering 2021 9 (47), 15722 15738 DOI: 10.1021

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056 Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

9. Serranti,S.;Bonifazi,G.UseofRecycledPlasticsin Eco efficient Concrete; Elsevier, 2019. DOI: 10.1016/B978 0 08 102676 2.00002 5.

10. Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. WasteManage.2017,69,24−58.

11. Ugduler,S. Van eem, . . Roosen, . Del e e, E. I. P.; De Meester, S. Challenges and opportunitiesofsolvent basedadditiveextraction methods for plastic recycling. Waste Manage. 2020,104,148−182.