International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Abstract As a popular saying goes ‘A penny saved is a penny gained’ this will be apt in the field of construction because it is facing huge losses because ofinternalreasons like wastage, delay, poor quality of work, improper planning etc. Lean construction is a concept which is derived from TPS which was designed by Toyota for manufacturing purpose, after a lot of improvisation by many people it had been brought into the field of construction. The main concept of Lean method is ‘Minimizing waste and Maximizing value’ , main goal of this method is to reduce the overall cost of the project, improve the quality of work done, reducing wastage on site and increasing value and respect the workers.

In construction industry we don't need to generate extra profits instead the savings we'll manage will leave us with huge profits. This industry is a typical type where in the product is manufactured on site rather than in factory and there will be very less repeated task unlike manufacturing. Most of techniques which exist today are trying to improve the things on the site from off site in which they are miserably failing; more over the major reasons for losses are on the site effects rather than off site reasons. The techniques majorly used are: • 5s, • Daily huddle meetings, • Increased visualization and • Last planner.

Keywords 5S, Last Planner Increased Visualization.

As a famous saying goes "a Penny saved is a Penny Gained".Inconstructionindustrywedon'tneedtogenerate extraprofitsinsteadthesavingswe'llmanagewillleaveus withhugeprofits.Thisindustryisatypicaltypewhereinthe productismanufacturedonsiteratherthaninfactoryand therewillbeverylessrepeatedtaskunlikemanufacturing. Mostoftechniqueswhichexisttodayaretryingtoimprove the things on the site from off site in which they are miserablyfailing;moreoverthemajorreasonsforlossesare onthesiteeffectsratherthanoff sitereasons

TheconstructionindustryinIndiaisavastindustrywhichis contributingabout8.3%ofthecountry’sGDP;itisoneofthe fastestdevelopingindustriesinworld,andincountrylike India with its infrastructure playing a major role in doing that.InIndiaConstructionhasaccountedforaround40per cent of the development investment during the past 50 years. About 16% of the nation's working population depends on construction for its livelihood. The Indian constructionindustryemploysover30millionpeopleand

createsassetsworthover200billion,eventhoughthereis lotofinnovationinthefieldtilldate.Itistheindustrywhich is highly dependent on human resource. It has both advantage and disadvantages. Creating employment is an advantage where as handling human resource is a tough task.Thisisaonesideofit,inspiteofmanyadvantagesthe industry is still running in huge losses because of many reasonslikeprojectoverrun,improperplanningtechniques, visibleandinvisiblewastagesinmanyforms,un skilledand uneducatedlabor, notusing latesttechniques, notadopting new technology, very much dependent on man power, impropersafetymeasuresatsite,notadoptingalternative raw materials, not maintaining standard quality, delay in cash payments, wastage of raw material, exploiting raw materialandmanymore.Outofallthesefactorsthemajor factorsareprojectoverrun,visibleandinvisiblewastages, notbelievinginnewtechniques.

The construction industry is kind which is growing changing and improving day by day. The objective of this studyistoimplementtheleantechniquesinIndianscenario and testing its fitness. Lean Techniques have been widely acceptedinmanycountriesbutwhereasinIndiaitisnotthe case because only few companies are implementing these techniquesandmostofthemareinlargescaleconstructions. Thesitesforthisstudyareselectedfrommediumandsmall scaleconstructionslocallyreflectingIndianscenario.

•

In the initial stages a thorough study on lean constructionandit'stechniquesisdone

• Six sites are selected for observation where there canbesomefreedomtoimplementnewthings

•

Inthesecondstagethesiteshavebeenvisitedfor10 working days, few teams have been selected and theirquantityofworkdoneis calculated

• The different events selected are Brick work in differentlevels,Plasteringandpainting.Onlythese eventsareselectedbecausethechancesofwastage isveryhighhere

•

Inthethirdstagethetechniquesareimplemented onsites

• Dailydata hadbeencollectedbothinthemorning and evening for about ten weeks depending upon thecontinuityofwork

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

• Theperformanceoftechniqueindividuallyhadbeen measured

• Thechallengesintheimplementationarelisted

• Thecostpersquarefeetandcubicfeetaremeasured soastoconcludewhichteamingismoreeffective

• Various graphs included inorder to represent the databeforeandafterimplementation.

• While implementing the 5S method the things more specifiedarecleanlinessatsite,properplacingoftools,the sametypeofworkdoneisbeingrepeatedsuchthatitcanbe completedwithease,insteadofmixingthecementonfloor steel sheets were provided such that material wastage is reducedandcleanlinessisalsoimproved,thesortingoutof unnecessarymaterialsisperformedregularlysuchthatno wasteisaccumulatedattheworkplaceforthisaseparate placewasallottedwhereinun necessarytoolsaredumped safelyforfutureuse.Byemployingthistechniquematerial wastagewasmorefocused

• Two way communication is the key of the daily huddle meetingprocessinordertoachieveemployeeinvolvement. As part of the improvement cycle, a brief daily start up meetingwasconductedwhereteammembersquicklygive the status of what they had been working on since the previousday'smeeting,especiallyifanissuemightprevent thecompletionofanassignment.Thistoolissimilartothe leanmanufacturingconceptofemployeeinvolvement,which ensuresrapidresponsetoproblemsthroughempowerment of workers, and continuous open communication through thetoolboxmeetings.Thesemeetingsareheldforatimeof 5 10minutes,thesearehelpfulinspeeduptheworkofthe teams which are lagging behind and hence increasing productivityfortheday.Thereisnoparticulartimeforthis meetitcanbedoneatanytimeinworkinghours

The 5 S's in 5S stand for Sort, Set In Order, Shine, StandardizeandSustain.Themainfocusofthismethodlies uponthecleanliness,appearance&movementatthesite.

•Sortfrequentlyneededthingsandlesserneededthings so that frequently needed things are available nearbyandaseasytofindaspossible.

•SetinordermeansRelocateorgetridofunnecessary things. Arrange essential things as accessible as possibletoreducethewasterelatedtoa worker’s motioninlocatingoracquiringaneededthingsand alsospecifiessettingthingsinapropermannerso thattheycanbeeasilyaccessiblewheneverneeded iftheyarenotsetinorderifwouldbedifficulttouse

wheneverrequiredmaterialsitalsocoversplacing oftools,materialsetcinapropermannersothatit doesn'tcauseanyhindrancewhileworkinprogress.

•Shineindicatescleanandsharp,thetoolsatworkarea andmachinesshouldbecleanedeverydayafterthe work is completed so that they are in perfect conditionwithoutanydust,cementetcuponitthey cleanedsothatitiseasytoworkwiththenexttime they are used , even the site should be properly cleanedattheendoftheday

• Standardize and diffuse the first 3 S’s throughout the workingplacebymeansofclearprocedures.

•Sustainmeanscontinuingalltheaboveactivitiesevery time required so that all of them are repeated on regular bases which will in turn improve the productivity.

5S is one of the most effective tools of lean manufacturingbecauseitis thebasisfor5Sisaneffective lean implementation. Recently 5S was changed to 6S (5S+Safety)whichisamethodusedtocreateandmaintaina clean, orderly and safe work environment. Lean implementation in the construction industry show this integrationbyaddingasixthS,totheleantool5S,forsafety by conducting a process improvement event in the continuousimprovementprocessdedicatedtosafety

Last Planner System (LPS) is a technique that shapes workflowandaddressesprojectvariabilityinconstruction. The Last Planner is the person or group accountable for operational planning, that is, the structuring of product designtofacilitateimprovedworkflow,andproductionunit control,thatis,thecompletionofindividualassignmentsat the operational level. In the last planner system, the sequences of implementation (master schedule, reverse phaseschedules(RPS),six week lookahead,weeklywork plan (WWP), percent plan complete (PPC) sets up an efficient schedule planning framework through a pull technique, which shapes work flow, sequence, and rate; matches work flow and capacity; develops methods for executing work; and improves communication between trades. The important role of the Last Planner tool is to replace optimistic planning with realistic planning by evaluatingtheperformanceofworkersbasedontheirability to reliably achieve their commitments. The goals of Last Planner are to pull activities by reverse phase scheduling throughteamplanningandoptimizeresourcesinthelong term.

The increased visualization lean tool is about communicating key information effectively to workforce

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

through posting various signs and labels around the constructionsite.Workerscanrememberelementssuchas workflow,performancetargets,andspecificrequiredactions iftheyvisualizethem.Thisincludessignsrelatedtosafety, schedule, and quality. This tool is similar to the lean manufacturingtool,VisualControls,whichisacontinuous improvementactivitythatrelatestotheprocesscontrol.Asa partofincreasedvisualizationasafetypledgeistakenbefore beginningofworkeveryday.Agoodwaytomaximizethe safetyontheconstructionsiteistousecommitmentcharts. Mobile signs were also used to promote safety on the job site.Thesesignsweredesignedtobecolorfulandhumorous in order to attract the attention of the workers better. Establishingguidelinesformaterialandequipmentstorage reduces waste, such as, lay down space, searching time, transportationanddoublehandlingofmaterial.Divertingor managing site water (rain or snow) can greatly improve efficiencywithrespecttotransportation,materialhandling andmovementofpeople.Theprojectlogisticsplanlaysout theexpectationsforthesubcontractorsinwordsandassite layout drawings. These plans can then be posted (visual management)andreferredtocommunicatethestandardof performance

Whileimplementingthe5Smethodthethingsmore specifiedarecleanlinessatsite,properplacingoftools,the sametypeofworkdoneisbeingrepeatedsuchthatitcanbe completedwithease,insteadofmixingthecementonfloor steel sheets were provided such that material wastage is reducedandcleanlinessisalsoimproved,thesortingoutof un necessarymaterialsisperformedregularlysuchthatno wasteisaccumulatedattheworkplaceforthisaseparate placewasallottedwhereinunnecessarytoolsaredumped safelyforfutureuse.Byemployingthistechniquematerial wastagewasmorefocused.

Table4.1.1:WeeklyaveragequantityofBrickWork(ft3)

Table4.1.2:WeeklyaveragequantityofPlastering(ft2)

S.No Day Plastering1st Coat Plastering2st Coat

1 Week 1 115 430 2 Week 2 115 430 3 Week 3 119 450 4 Week 4 123 450 5 Week 5 125 460 6 Week 6 128 460 7 Week 7 128 480 8 Week 8 132 480 9 Week 9 134 480 10 Week 10 135 480

Whileworkingonincreasedvisualizationtechnique the different resources used are charts, boards, posters, electronic devices like mobile tablet phone etc by which workersareputonanalertonsite.Themainaimoftheseis to remind the workers about safety, target, quality, technique,specifications.Withthehelpofelectronicdevices thelatestandbestmethodtoperformataskcanbeviewed using internet. The best method is discussed with the site engineerandthenimplementedandthebestpracticesfrom othersitesarealsosuggestedsoastoimprovethequality andquantityofworkdone.Byusingalltheseresourcesthe major advantages are decreased accidents, improved executionofwork.Themainaimofthistechniqueistoknow thelatestwaysofperformingatask,improvingsafetyatthe site.

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Table4.2.1:WeeklyaveragequantityofBrickWork(ft3)

S.No Day Brick Work 0' 3'

Brick Work 3' 7'

Brick Work 7' 10'

1 Week 1 70 59 51

2 Week 2 73 59 53

3 Week 3 75 59 53

4 Week 4 77 61 56

5 Week 5 80 61 56

6 Week 6 81 66 57

7 Week 7 82 65 59

8 Week 8 83 65 60

9 Week 9 85 68 60 10 Week 10 87 69 59

Table4.2.2:WeeklyaveragequantityofPlastering(ft2)

S.No Day Plastering1st Coat Plastering2st Coat

1 Week 1 115 430

2 Week 2 117 440

3 Week 3 118 446

4 Week 4 121 449

5 Week 5 124 459

6 Week 6 127 467

7 Week 7 130 470

8 Week 8 132 470 9 Week 9 134 480

10 Week 10 137 483

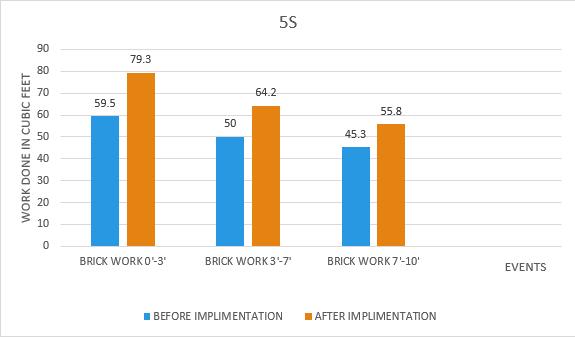

Table4.2.3:Averagequantitiesbeforeimplementation

S.No Event Quantityofworkdone

1 BW0' 3' 59.5

2 BW3' 7' 50 3 BW7' 10' 45.3

4 Plastering1st 96.7

5 Plastering2nd 284.1

Table4.2.4:Averagequantitiesafterimplementation

S.No Event 5S DHM IV

1 BW0' 3' 79.3 77.4 79.3

2 BW3' 7' 64.2 66.3 63.2 3 BW7' 10' 55.8 55.6 56.4 4 Plastering1st 125.8 126.5 125.5 5 Plastering2nd 460 453.5 459.4

Theliteraturereviewedaboutleanconstruction,specifies thecontributionofvariouspeopleindevelopingtheconcept of lean construction inspired from TPS a manufacturing improvementtechniqueintothefieldofconstruction.These includeddevelopingvarioustechniqueswhicharesuitablein fieldofconstruction.Theimpactofconstructionwastesand its effect upon the cost of the project.. The study about various techniques and their implementation, different resourcesrequiredforatechnique.Theimplementationto lean techniques in different countries is also mentioned. Even though many papers specified about various techniquesbuttherewerenopaperspublishedincludingthe quantityofworkdone.InIndianScenariotherewerepapers includinglargescaleconstructionbutnoresearchhadbeen doneinmiddleandsmallscaleprojects.So,itisconcludedto carryoutworkinsmallandmediumscaleprojectsinIndian Scenariosoastoineasetheusageofleanconstruction.

[1] Sequential SWARA and fuzzy VIKOR methods in eliminationofwasteandcreationofleanconstruction processes,2021,JournalofBuildingEngineering.

[2] Implementing lean construction techniques and managementmethodsinChineseprojects:Acasestudy inSuzhou,China,2021,JournalofCleanerProduction

[3] Bridging biophilic design and environmentally sustainable design: A critical review, 2021, Journal of CleanerProduction

[4] A Conceptual Framework for Implementing Lean ConstructioninInfrastructureRecoveryProjects2022, Buildings.

[5] ISM ANPhybridapproachtoprioritizethebarriersin green lean Six Sigma implementation in construction sector2022,InternationalJournalofLeanSixSigma.

(UG Student, Department of Civil Engineering, ISL Engineering College,Hyderabad,Telangana)

(UG Student, Department of Civil Engineering, ISL Engineering College,Hyderabad,Telangana)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Mohammed Misbah Uddin(UG Student, Department of Civil Engineering, ISL Engineering College,Hyderabad,Telangana)

Mir Firasat Ali

Mir Firasat Ali

(AssociateProfessor, DepartmentofCivilEngineering, ISLEngineeringCollege, Hyderabad,Telangana)

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal