International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

***

Abstract Plastic shrinkage cracking is one of the earliest forms of concrete cracking, occurring in its plastic state. Concrete structures with large exposed surface areas are prone to plastic shrinkage cracking, resulting in premature durability issues. Controlling concrete plastic shrinkage crackingiscrucialfordevelopingdurableconcretestructures with longer service life and fewer maintenance costs. The addition of arbitrary distributed fibers is a successful technique to mitigate plastic shrinkage cracking. Natural fibers have beenutilizedtoassesstheirpotentialforreducing plastic shrinkage. Natural fibers are widely available, renewable, biodegradable, with low cost and specialized qualities. Many of them have represented adequate behavior in controlling cracks caused by plastic shrinkage. So, natural fiberscanbeafeasibletechnologicaloptiontomitigateplastic shrinkage cracks and it is possible to consider them as a potential replacement for some synthetic fibers. Various studies show that natural fibers are effective in controlling plastic shrinkage cracking in concrete, which has been summarized in this literature.

Key Words: Plastic shrinkage, Durability, Cracking, Natural fibers, Concrete

Concreteispronetoshrinkwithinthefirstfewhoursafter casting,whilestillinaplasticstate,iftherateatwhichwater evaporation from the surface exceeds the bleeding rate in concrete. Cracks occur to relieve the tensile stresses that developwhensuchshrinkageisrestrained[3] Suchcracks can further propagate and allow the entry of aggressive agentslikechlorides,water,etc.,leadingtothecorrosionof thereinforcement.Plasticshrinkagecracksmayreducethe durability and lead to premature deterioration of the structures[2].Lowambienthumidity,highwindspeeds,and high temperatures, might increase the risk of plastic shrinkage cracking on the surfaces of structural and non structural concrete, as well as Portland cement based mortar [6]The primary factors that influence plastic shrinkagecrackingarebleedingandevaporationofinternal concrete moisture [7]. Water menisci form between solid particleswhenthelayerofbleedwaterevaporatesfromthe surfaceasaresultcapillarypressurestartstobuildup.This capillarypressurecausesthecontractionofconcreteandifa critical limit is reached, cracks may [2]. Plastic shrinkage crackingoccursinstructureswithlargesurfaceareassuch

asbridgedeck,parkingslabs,industrialfloors,tunnellining andthinconcretesurfacerepairs.

Achieving a balance between bleeding of concrete and evaporation of bleed water is a key for the mitigation of plasticshrinkageofconcrete.Theplasticshrinkagecracking canbemitigatedthroughanappropriatemixdesign,usage ofsuperabsorbentpolymers,liquidandmineraladmixtures etc.Theultimatewaytocontrolplasticshrinkagecrackingis topreventthesurfacefromextensivedrying.Apartfromthe material basedmitigationmeasures,otherapproacheslike wind breakers, temperature control of both material and environment,waterspray(fogging)canbeutilised[7].The addition of randomly oriented fibers is a widely adopted method for the mitigation of the plastic shrinkage in concrete [2]. Being inexpensive and due to its regional availability,naturalfiberscanbeafeasibleoptiontocontrol plastic shrinkage cracking. In the present study, the emphasis is on the influence of natural fibers on cracking causedbyplasticshrinkage.

Addition of appropriate percentage of randomly oriented fibers in the concrete matrix can give good results in controlling plastic shrinkage cracking. By improving the straincapacityoffreshmixture,fibresinconcretecannot onlyminimisecrackformationbutalsospreadcrackssothat numerousmicrocracksappearinsteadoffewerlargerones. Fibers also prevent the propagation of micro cracks by providingbridgingforcesacrossthecracks.Fibresaddedto the fresh concrete tend to reduce the segregation of especially coarser aggregates, keeping them closer to the surface. Some types of fibres have shown good results in improvingtheearlyagetensilestrengthofthematerial,thus loweringthechancesforthestressestoreachthestrengthof theconcreteinitsplasticstate[2].Naturalfibershavethe potentialtocontrolplasticshrinkageofconcrete.Theyare abundant,inexpensiveandmostlyunderutilizedresources. They are generally produced as waste by product of agricultural or industrial processes [3]. Even though productionofsyntheticfibersisexpensive,theirefficiencyin reducing plastic shrinkage cracking is widely known. However,veryfewstudieswereconductedtodeterminethe effectofnaturalfibersincontrollingplasticshrinkagecracks

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

inconcrete.Inexpensivefibressuchascoir,sisal,jute,flax, lechuguilla,andothersmaybeaviabletechnicaloptionfor mitigatingconcretecrackingcausedbyplasticshrinkage.In thispaper,theinfluenceofnaturalfibersoncrackingcaused byplasticshrinkageisdiscussed.

Variousstudieswereconductedwithdifferenttypesoffibers topreventtheplasticshrinkagecrackingincement based materials. Fibres of different geometries, mechanical propertiesshapesandvolumefractionswereused.Animal based,mineral derived,andplant basedarethethreetypes of natural fibres usually used in concrete reinforcement. Various forms of natural fibers have been investigated in somestudies.Naturalfibressuchascellulose,sisal,coconut fiber,flax,Lechuguillaetc.areamongthem.Othermaterials usedinthestudiesconductedincludecement,aggregates, otherbindertypeslikesilicafume,flyash,GGBSforcement replacement,mineraladmixtures,chemicaladmixtureslike shrinkage reducing admixtures. Some of the plant based naturalfibresarethefollowing[11].

Bastfibresareobtainedfromtheouterbarkoftheplant's stemandareremovedthroughtherettingprocess.Jute,flax, kenaf etc are some of the examples of these fibers. Bast fibres have long fibre bundles with high tensile strength, whichiswhytheyaretraditionallyusedtomakeyarn,cloth, rope,sacks,andsoon.

Leaf fibres are coarse and hard fibres They are usually obtainedbyhandscrapingfromleaftissuesfollowedbythe beating/rettingprocess. Thesefibersarehavingrelatively highstrengthduetowhichtheyareusedtomanufactureof ropes,textiles,carpets,andmats.Examplesaresisal,caroa, henequenandpineapple.

One of the best examples of seed fiber is coir fiber. These lightweight and robust fibres are mostly utilised in the manufactureofropes,matting,sacks,brush,geotextiles,and other products. Other examples are cotton, kapok and milkweed floss which are soft, buoyant materials that are commonly utilised in textile, water safety equipment, insulation,upholstery,andmattressproducts.

These are plant stalk fibres that are typically taken fromeggplant, sunflower, wood, and the straw of various graincropssuchasbarley,wheat,rice,andsoon.

Ryegrass,elephantgrassswitchgrassandbambooaresome oftheimportantsourcesoffibres.fibrouscropresiduessuch aspulseseedcoat,peanutshell,hazelnuthusk,cornhusk, millet stover etc. can be used as fibre reinforcements in concrete.

Woodfibresareobtainedfromawiderangeoftrees.Asa result,theyareingreatabundanceallovertheworld. The twomaintypesofwoodfibresaresoftwoodandhardwood. Themaindistinctionbetweenthesetwotypesisthat,while softwood fibres are often longer, hardwood fibres have thickerandtoughercellwalls.Specialtycellulosefibres,on the other hand, are industrially processed plant based natural fibres with unique properties such as bond strengthening and alkali resistance. Furthermore, the quality controlledmanufactureofthesefibresensuresthat the enormous range in geometrical and mechanical propertiesassociatedwithunprocessedplant basedfibresis considerablyreduced

Varioustestmethodsadoptdifferentinternalandexternal restraintstoinduceplasticshrinkagecrackingbypreventing the specimen deforms freely. The test methods used to determineplasticshrinkagecrackinginthestudiesincluded inthisreviewareasfollows:

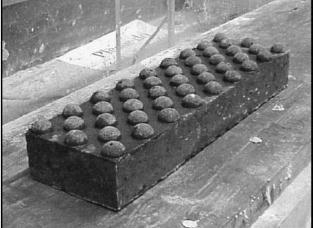

Overlaymethodwithbottomrestraintisamethodinwhich concretesubstratesaremadeandoverwhichcement based materialsarecast.Thismethodemploysabottomrestriction topromoteplasticshrinkagecracking. Regularpatternsof semicircularprotuberancesareprovidedoverthesubstrate asrestrainttoinducecracking[12]

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

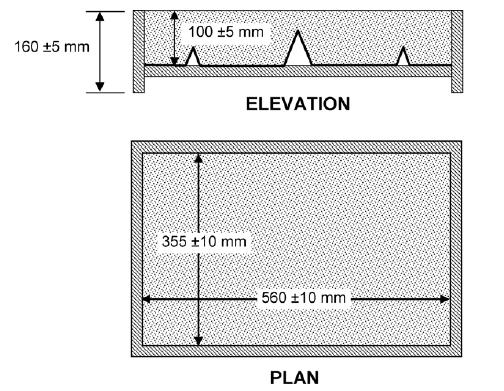

ASTMC1579methodwithstressrisersisthestandardtest method for evaluating plastic shrinkage cracking of restrained fibre reinforced concrete. This test method compares surface cracking of fibre reinforced concrete panels to surface cracking of control concrete panels subjected to specified constraint conditions. This method aimsto quantifythe relativeperformance of a given fresh concretemixturebycontrollingatmosphericvariables.The specimeniscastinamouldofinternalrestraints.Thismould ishavingadepthof100±5mmandrectangulardimensions of355±10mmby560±15mm.Thecentralriseris64±2mm highandservesasaninitiationpointforcracking[13].

microscope. The method is often used to test cement or mortar materials rather than concrete due to the small heightoftheslab.

This is a method developed by Johansen and Dahl. Three identical moulds, each with two concentric steel rings are used in this test method. Stress ribs induces cracking in concreteandthelengthandwidthofthecrackaremeasured usingadigitalmicroscope[10].

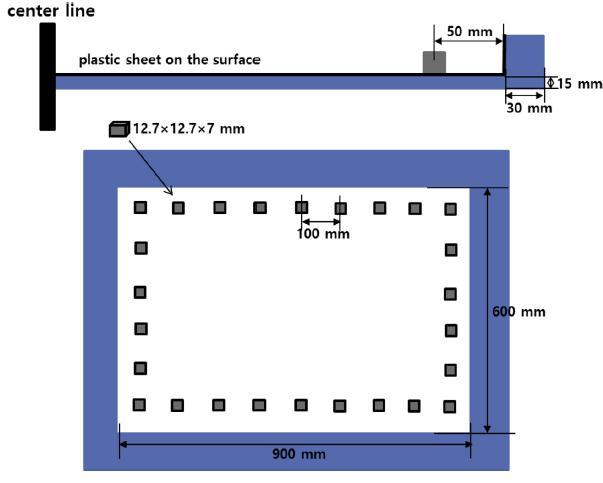

Kraaimethodwithedgerestraintsisamethodinwhichslab likespecimeniscastinamouldandareprovidedwithedge restraints.Thespecimenisthinwithalargesurfaceareato volumeratio. Specimenofsize900x600x150mmareused. [14]. Edge restraints are positioned all through the entire perimeter of the mould and are made up of of L shaped hardwarecloth/wiremeshhorizontalboltsorsteelblocks placed at a fixed distance on the bottom of the mould. To maximize plastic shrinkage, the specimen was kept in a chamberandexposedtoaconstanttemperatureof282C,a relativehumidityof405%,andawindvelocityof6m/sfor 24 hours. After 24 hours, the width and length of cracks were evaluated with a 0.01 mm precision using a

It specifies the laboratory determination of the age at crackingandinducedtensilestresspropertiesofmortaror concretespecimenssubjectedtocontrolledshrinkage.Ina circularmould,asampleoffreshlymixedmortarorconcrete iscompactedaroundaninstrumentedsteelring.Fromthe timeofcasting,thecompressivestraincreatedinthesteel ringduetoshrinkageofthemortarorconcretespecimenis measuredwithfourstraingauges.Aquickdecreaseinthe steelringstrainindicatescrackingofthetestmaterial.The ageatcrackingandrateoftensilestressdevelopmentinthe testspecimenshowthematerial'scrackingresistanceunder controlled shrinkage. This test method can be used to determine the relative likelihood of early age cracking in variouscementitiousmixturesandtoaidintheselectionof cement based materials that are less prone to cracking underretrainedshrinkage.Theactualcrackingtendencyin service is determined by a variety of factors, including structure type, degree of restraint, degree of property development, construction and curing processes, and environmentfactors[16].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table 1: Detailsofthematerialsandtestmethodsusedin thestudiesincludedinthisreview

Mortar Flax 0.05, 0.1, 0.3% by volume of mortar

Mortar Flax & agave lechuguill a

Overlay Boghossian E.etal.

0.1,0.7 % by volume of mortar

Earth concrete Flax 0.3,0.6 % by volume of mortar

Mortar Sisal 0.1,0.2, 0.5% by volume of mortar

Mortar Coconut fiber 0.5% by volume of mortar

Foam concrete coir 0.3,0.4, 0.5% by volume of concret e

Mortar Pighair 8 kg/m3 of mortar

Overlay Juarezetal.

ASTM C1579 Kouta N.et al.

Jringtest FilhoR.etal.

microscopes is included in the manual procedures. Crack lengthsweremeasuredinseveralstudiesbyplacingastring along the length of the crack and measuring it. The total crackareaisusuallycalculatedbymultiplyingtheaverage valueofthecrackwidthsbythelengthofthecrack,andthe accuracyoftheresultsisthusdependentonthenumberof measurements [17]. The benefits of using these manual approachesaretheirsimplicityandabilitytobeperformed on site. They are, on the contrary, criticised for being subjective, time consuming, and complicating constant monitoring. The use of optical cameras to capture high resolutionimagesofthespecimensurface,whicharethen analysed by various types of software, is one of the more advanced image based techniques. DIP (Digital Image Processing) techniques operate by processing photos and calculating crack dimensions based on pixels [18]. DIC technique is considered to be more useful than the DIP methodsinceitpermitsnotonlyautomaticcomputationof crack widths, but also analysis of surface strain and displacement fields. However, there are still obstacles in using the DIC method to study plastic shrinkage crack formationsincerecordingsurfacedisplacementsrequiresa high contrastsurfacepattern, whichisdifficulttoputona wetsurfacewithbleedingwater (Bertelsen et al., 2020).

Jringtest FilhoR.etal.

ASTM C1579 RajB.etal.

Very few studies have been conducted to investigate the effectofnaturalfibersontheplasticshrinkageinconcrete. Thismaybeprobablyduethechancesofdegradationand lowdurabilityoftheminsidehighlyalkalinecement based matrix.Naturalfibersarehydrophilicinnaturesothatthey absorblotsofwatercomparedtoothertypesoffibers.The natural fibers that are investigated in the studies include sisal, coconut fibers, flax, Lechuguilla, kraft pulp fibers. Amongthesefibres,severalvariationsingeometry,aspect ratio,volumefractionwereconsidered.

ASTM C1579 Letelier et al.

Therateatwhichcracksdevelopmightvaryconsiderably dependingonfactorssuchastestsetup,materialproperties, climatic conditions, and so on. Thus, understanding the formationofplasticshrinkagecrackingisdifficultbecause material properties vary rapidly over time. There is no standardtechnique for crack detectionandmeasurement. manual measuring techniques are microscopes, handheld lensesetc.[2].Theuseofseveralkindsofopticallensesor

Reduction in plastic shrinkage was observed with the addition of flax fibers in cement based composites. The observationsbyBoghossianetal.showthatwhenflaxfibres were added at a volume fraction of 0.1 percent, the total crack area on the surface of specimens within the first 24 hoursandthemaximumcrackwidthswerereducedbymore than 95% and 90% compared to plain mortar specimens. These reductions were 99.5 percent and 98.5 percent, respectively, at a volume fraction of 0.3 percent. When optimallengthwascompared,flaxfibresperformedbetter than other synthetic fibres, especially monofilament polypropylene,fibrillatedpolypropylene,andalkaliresistant glassfibres,intermsofreducingtotalcrackareaandlimiting crackwidthsinfreshmortarspecimens.Thismaybedueto the superior quality of flax fibers in improving the tensile

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

capacityoffreshmortar.Thehydrophilicnatureofflaxfibers improve the bond between fiber and fresh mortar. An increase in volume fraction also led to the reduction of plastic shrinkage cracking [3]. In a comparative study betweenPVAfibersandnaturalfibers(flaxandLechuguilla) inthemitigationofplasticshrinkagecracking,flaxfibresat 0.7% volume fraction of mortar presented adequate behaviourinreducingplasticshrinkagecrackingcompared to other two fibers. Addition of flax fibers at a volume fractionof0.7%yieldedthebestresultbyloweringthetotal crackarea,cumulativecrackwidth,widestcrackobserved by98%,97%and78%respectively.Highervolumefraction ismoreeffectivethanfiberlengthinminimisingtheplastic shrinkage cracking. Increase in aspect ratio decreases the evolutionofplasticshrinkagecracking[6].Plasticshrinkage of earth concrete can be reduced by increasing the percentageandlengthofflaxfibres.Theplasticshrinkageis decreasedto2to2.4timeswiththeincorporationof0.3% and0.6%offlaxfibersrespectivelycomparedtothecontrol mix.Increasingthefiberlengthledtothedecreaseinrate and amplitude of plastic shrinkage. The effect of fiber lengthsismorenoticeablefortheformulationwith0.3%of fibers. Addition of flax fibers also reduced the cracking in earthconcreteinitsplastic.state.Duringthefirst24hours after casting, no macro cracks were noticed due to the decreaseinthestressconcentrationabovethestressriserof themould[8].

Filho R. et al. observed that adding 0.2 percent volume fraction of 25mm sisal fibre to the mortar matrix greatly reducedfreeplasticshrinkage.Sisalfibersgiverestraintto the sliding of the matrix by means of frictional resistance. The addition of 0.2% sisal fibers reduced the restrained plastic shrinkage by delaying the initial cracking and effectively controlling the crack development in the compositeinitsplasticstate.Theinclusionofsisalfibersis effective in delaying first crack appearance which may be attributedtothehighelasticmodulusoffiberscomparedto thecementitiousmatrix,inadditiontoitsabilitytoprovide bridgingforcesacrossthecracks.Theadditionof0.2%and 0.1%ofsisalfibers(25mmlong)resultedinthereductionof free plastic shrinkage of the mortar mixes by 29.6% and 24.1%respectively.Thefirstcrackappearedinthematrix90 minafterplacingthemix,whereaswiththeadditionof0.5% volume fraction of sisal fibers, it appeared after 180 min. Fiberswereeffectiveindelayingthefirstcrackappearance and in reducing the cracking tendency of the matrix at its plasticstate.Thishappensduetothehighelasticmodulusof fiberscomparedtothecementitiousmatrix[4].

In a comparative study between PVA fibers and natural fibers(flax and Lechuguilla) in the mitigation of plastic shrinkagecracking,Lechuguillafiberswithalengthof40mm anda0.7%volumefaction,thetotalcrackarea,cumulative crack width, and widest crack observed were reduced by 93%,89%,and67%,respectively.Thesurfaceroughnessof the Lechuguilla fibers increases its contact area with cementitious matrix, resulting in a similar strength as the one obtained for flax fibers. The addition of Lechuguilla fibersat0.7%volumefractionresultedinthereductionof numberofcracksappearedinthemortar[6].

Coir is a hard and stiff biodegradable lignocellulosic fibre obtained from the fibrous mesocarp of coconut fruits, accountingforaround25%ofthenut.Coirfibresarestrong, weather resistant, and somewhat waterproof due to their high lignin concentration, and they can be chemically changed. The fibres also have a high elongation at break, whichmeanstheycan bestretched pasttheir elasticlimit without breaking. Coir fibres have many advantages, including low cost, high lignin content, low density, availability, strong elongation at break, and low elastic modulus. Coir fibres are mostly composed of lignin, hemicellulose, and cellulose. Coir fibres' average chemical compositionrangesfrom32to50percentcellulose,0.15 15 percenthemicellulose,30 46percentlignin,and3 4percent pectin.Thisemphasisesthefactthatcelluloseandligninare the two most abundant components of plant fibres. The variationsincoirfibrecharacteristicscanberelatedtothe source of the coconut plant from which the fibres were extractedorthemethodofextractionused.Coirfibreshavea densityof1.1 1.5g/cm3,ayoung'smodulusof2 8GPa,and a tensilestrength of 105 593MPa.10 180percent water absorption and 15 51 percent break elongation These qualities can vary depending on the fiber's origin, pre treatment,andextractionprocesses[19].Areductioninthe restrainedplasticshrinkagewasobservedwiththeaddition of0.5%coconutfiberoflength25mminthestudybyFilhoR. etal.Thefirstcrackappeared90minafterplacingthemixin the plain mortar specimen. Furthermore, two new cracks appearedafter95and145min,whilethreecracksappeared in the coconut fiber reinforced composites after 180 min fromcasting.Thecrackwidthsincoconutfiberreinforced specimensarenarrowerthaninplainmortarspecimens[5]. Thefirstcrackappearedat15mininthecontrolmixoffoam concrete,whereasthetimesofoccurrenceofthefirstcrack were35,25,and27minfortheadditionofcoiratavolume fraction of 0.3%, 0.4%, and 0.5%, respectively. So, the additionofcoirtothefoamconcreteresultedinthedelayof thefirstcrackappearance[9].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Recycled pig hair could be a cost effective alternative for improvingthemechanicalcharacteristicsanddurabilityof cement basedmaterials(CBM),whilealsohelpingtoreduce environmental challenges associated with the global pork industry. In recent decades, the use of waste to replace components and/or improve the properties of CBM has intrigued the interest of researchers worldwide, and significantprogresshasbeenmadebyincorporatingwastes such as recycled aggregates, plastic bottles, rubber tyres, glass,orflyashintocement basedmaterials.Theadditionof fibrestoCBMcouldprovidecrackingcontrolatearlyages andboostfracturetoughnesstovaryingdegreesdepending on matrix strength, fibre type, fibre modulus of elasticity, fibreaspectratio,fibreorientation,andaggregatesize.Pig hairiscurrentlyalargecomponentoffoodindustrywaste. Animal fiber (pig hair) is a massive food industry waste whichhasshowngoodresultsinreducingplasticshrinkage cracking in mortars. Pig hair considerably reduced plastic shrinkage cracking, particularly at high fibre doses (8 kg/m3).Thestiffnessofthe mortaratearlyagesincreases withtheadditionoffibersanditredistributewaternearthe surface.Thesemechanismsareprobablyresponsibleforthe reductioninplasticshrinkagecracking.Theincorporationof pig hair decreases the crack width and delays the appearanceofmacroscopiccracks.Theadditionofpighair consistently decreased the width of the crack as the fiber dosageincreasesupto8kg/m3ofmortar[1].

Areviewcoveringexistingresearchonplasticshrinkagein fiber reinforcedcement basedmaterialswascarriedoutto analyse the influence of the addition of different types of natural fibers. Several test procedures for assessing restrained plastic shrinkage cracking of concrete are mentioned in this literature. Different crack measuring techniquesarealsodiscussedwhicharemanualprocedures, DIP(DigitalImageProcessing)anddigitalimagecorrelation (DIC). The effect of different natural fibers on plastic shrinkagecrackinginconcreteisalsodiscussed.

Theadditionofflaxfibersincement basedmaterialsleadsto the reduction inplasticshrinkage. Thismay bedue to the hydrophilicnatureofflaxfibersanditssuperiorqualityin improvingthetensilecapacityofconcrete.Theincreasein fibre content results in fewer concrete plastic shrinkage cracks.Theinclusion ofsisal fibersis effectiveindelaying firstcrackappearancewhichmaybeattributedtothehigh elastic modulus of fibers compared to the cementitious matrix,inaddition toitsabilitytoprovidebridgingforces acrossthecracks.IncorporationofLechuguillafibersat0.7% volume fraction significantly reduced the total crack area, cumulative crack width and widest crack observed in the mortar. Coconut fibers were also effective in delaying the

first crack appearance, decreasing the crack width etc. Animal fiber (pig hair) significantly prevented plastic shrinkagecracking,especiallyathighfibredoses(8kg/m3).

[1] Araya Letelier G., Antico F.C , Carrasco M., Rojas P., & García HerreraC.M,“Effectivenessofnewnaturalfiberson damage mechanicalperformanceofmortar.”Construction andBuildingMaterials,ELSEVIER,vol.152,pp.672 682,July 2017,http://dx.doi.org/10.1016/j.conbuildmat.2017.07.072

[2] Bertelsen I.M.G., Ottosen L.M., Fischer G. “Influence of fibrecharacteristicsonplasticshrinkagecrackingincement based materials: A review.” Construction and Building Materials,ELSEVIER,vol.230,pp.116 769,Aug2020

https://doi.org/10.1016/j.conbuildmat.2019.116769

[3]BoghossianE.,WegnerL.D.“Useofflaxfibrestoreduce plasticshrinkagecrackinginconcrete.”Cement&Concrete Composites, ELSEVIER, vol30, pp.929 937, Sep, 2008, doi:10.1016/j.cemconcomp.2008.09.003

[4]FilhoR.D.T.,SanjuanM.A.“Effectoflowmodulussisaland polypropylenefibreonthefreeandrestrainedshrinkageof mortars at early age.” Cement and Concrete Research, ELSEVIER,vol.29,pp. 1597 1604,Jun,1999

PII:S0008 8846(99)00136 2

[5] Filho R.D.T., Ghavami K., Sanjuan M.A., England G.L, “ Free, restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres.” Cement & ConcreteComposites,ELSEVIER,vol.27,pp.537 546,2005 doi:10.1016/j.cemconcomp.2004.09.005

[6] Juarez C.A., Fajardo G., Monroy S., Duran Herrera A., ValdezP.,MagniontC.,“Comparativestudybetweennatural and PVA fibers to reduce plastic shrinkage cracking in cement based composite.” Construction and Building Materials, ELSEVIER, vol. 91, pp.164 170, May, 2015, http://dx.doi.org/10.1016/j.conbuildmat.2015.05.028

[7]KayondoM.,CombrinckR.,BoshoffW.P.,“State of the art review on plastic cracking of concrete.” Construction and Building Materials, ELSEVIER, vol.225, pp. 886 899July,2019, https://doi.org/10.1016/j.conbuildmat.2019.07.197

[8] Kouta N., Saliba J., Saiyouri N., “ Effect of flax fibers on early age shrinkage and cracking of earth concrete.”Construction and Building Materials, ELSEVIER, vol.254,pp. 119 315, Apr 2020, https://doi.org/10.1016/j.conbuildmat.2020.119315

[9]RajB.,SathyanD.,MadhavanM.K.,RajA.“Mechanicaland durability properties of hybrid fiber reinforced foam

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

concrete.” Construction and Building Materials, ELSEVIER,vol.245,pp.118 373, Feb 2020, https://doi.org/10.1016/j.conbuildmat.2020.118373

[10] Sayahi F., M. Emborg, H.Hedlund, “ Plastic shrinkage Cracking in concrete Influence of test methods”. 2nd Int. RILEM/cost Conf. Early age Crack in Serv. Cement. Mater. Struct EAC2,2017

[11]ObinnaOnuaguluchi,NemkumarBanthia,“Plant based natural fibre reinforced cement composites: A review”. Cement&ConcreteComposites,ELSEVIER,vol.68,pp.96 108, Feb2016,doi.10.1016/j.cemconcomp.2016.02.014

[12] Nemkumar Banthia ,Rishi Gupta , “Influence of polypropylenefibergeometryonplasticshrinkagecracking inconcrete”.CementandConcreteResearch,ELSEVIER,vol. 36, pp. 1263 1267, July 2006, https://doi.org/10.1016/j.cemconres.2006.01.010

[13] ASTMC1579, “Standard Test Method for Evaluating Plastic Shrinkage Cracking of Restrained Fiber Reinforced Concrete(UsingaSteelFormInsert)”,ASTMInternational AmericanSocietyforTestingandMaterials,1 7.

[14]Jang HoJayKima,Chan GiParkb,Si WonLeeb,Sang Woo Lee b, Jong Pil Won , “Effects of the geometry of recycledPETfiberreinforcementonshrinkagecrackingof cement based composites”. Composites, ELSEVIER, Part B vol.39, pp.442 450, April 2008, https://doi.org/10.1016/j.compositesb.2007.05.001

[15]Su JinLee,Jong PilWon,“Shrinkagecharacteristicsof structural nano synthetic fibre reinforced Cementitious composites.” Composite Structures, ELSEVIER, vol.157, pp.236 243, Dec 2016, https://doi.org/10.1016/j.compstruct.2016.09.001

[16] ASTMC1581 (2004), “Standard Test Method for Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete under Restrained Shrinkage.”, ASTM International American Society for TestingandMaterials.

[17]Sirajuddin,Moghul;Gettu,Ravindra,“Plasticshrinkage crackingofconcreteincorporatingmineraladmixturesand itsmitigation.”MaterialsandStructures,vol.51, pp.48. Mar 2018,doi:10.1617/s11527 018 1173 4

[18]A.Sivakumar,ManuSanthanam, “Aquantitativestudy on the plastic shrinkage cracking in high strength hybrid fibrereinforcedconcrete.”Cement&ConcreteComposites, ELSEVIER, vol.29 ,pp.575 581, Aug 2007, https://doi.org/10.1016/j.cemconcomp.2007.03.005

[19] AdewaleGeorgeAdeniyi*,DamilolaVictoriaOnifade, JoshuaO.Ighalo,AkoredeSamsonAdeoye,“Areviewofcoir fiber reinforced polymer composites.”Composites Part B,

ELSEVIER, vol.176, pp.107 305, Nov 2019, https://doi.org/10.1016/j.compositesb.2019.107305

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal