International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Department of Refrigeration and Air Conditioning Technology, Faculty of Technology and Education, Helwan University, 11282, Cairo, Egypt ***

Abstract Theexperimentalinvestigationofthedouble concentric tube heat exchanger is presented with inner tube dimples. The internal tube side heat transport enhancement characteristics of double tube heat exchangers composed of a dimpled tube with an elliptic shapethatareinvestigated experimentallyintherangeof Reynoldsnumberfrom2570to14405forinnertubefluid whileforoutertube fluidis 1477to8103. The purpose is to present a clear view of the thermofluid characteristics of this type of heat exchanger with different key design parameters leading to design optimization. The effects of dimple angles on the inner tube side thermo fluid characteristics are also explored. The effectiveness, number of transfer units, and Nusselt number of the double tube heat exchanger with dimples are higher than thatofthedoubletubeheatexchangerwithoutdimplesby approximately87%,107.8%and53%,respectively.

Key Words: Double tube, Dimple tube, Cooling performance,Heatexchangers.

The need to achieve high thermo hydraulic performance and compact heat exchangers have pushed a Lot of industries to find new ways to promote heat transfer of double tube heat exchanger [1 7]. Applying dimpled surface is one of the passive techniques for heat transfer enhancement of double tube heat exchanger. In this respect, the dimpled surface has emerged as one way to increase thermo hydraulic performance. The improved characters create rotating and secondary flows that increase the effectiveness of the heat transfer area of a double tube heat exchanger. It interrupts thermal and velocity boundary layer development with increasing degrees of turbulence close to the rough tube wall. These accompanying increases the convective heat transfer constant(h)witharesultantincreaseinthepressuredrop onthetube.

Sarmadian et al. [8] investigated condensation heat transfer in a helically dimpled tube using refrigerant R 600aasaworkingfluid.Theirresultsshowedthattheheat transfer rate was increased up to two times greater than thatofa smoothstraighttube. Ming Lietal.[9] examined the thermo hydraulic performance of a dimpled tube in steady state single phase (liquid to liquid) fluid flow for Reynolds numbers ranging from 500 to 8000 and for a

water/glycol.ShuaiXieetal.[10]studiedtheheattransfer and thermal performance of enhanced tube with cross ellipsoidal dimples. They observed that the cross ellipsoidal dimples induced the transverse and longitudinal dimples, which caused the reattachment and periodic impingement flows that helped improve thermal performance. Aroonrat and Wong wises [11] studied the effect of dimpled depth on heat transfer enhancement, pressure loss and overall performance of dimpled tubes. Their results showed that the dimpled tube with the largest dimpled depth gave the highest heat transfer enhancement and pressure loss up to 83 and 892% over those of the smooth tube. Recently, nanofluids were applied in dimpled tubes for further heat transfer enhancement. In the present study, a thermo hydraulic performance of a dimpled tube heat exchanger is investigated. The effects of a dimpled tube with dimple anglesof45˚,60˚andplaintubearestudied.

The experimental setup includes a double dimpled tube heat exchanger and three circuits, namely, closed loop chilled water cycle, R 22 vapor compression refrigeration cycle,andclosedloophotwatercycle.Thedoubledimpled tubeheatexchangermadeofcopperwitha thicknessof 1 mm, and a length of 1100 mm associated with the necessary measuring instruments. The inner tube diameteris18 mm,andtheoutertubediameteris20 mm Thegeometricalcharacteristicsdataofthedoubledimpled tubeheatexchangeraregiveninTable[1].Twofluidsare beingconsideredwhicharechilledwaterintheoutertube andhotwaterintheinnertubeoftheheatexchanger.The chilledwatersystemincludesa0.5 m3 thermallyinsulated tank,andacoolingsystemthatiscontrolledbyadjustinga temperature controller, the chilled water is generated by thecooling system. The closed loop hot water cycle consists of a 0.56 m3 thermally insulated tank suppliedwith 5electricalheaters with total powerof 7.5 kW and an adjustable temperature controller. Figure [1] shows a photograph of the experimental setup andthe doubletubeheatexchanger.Thesetupcontainstwo

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Geometricalcharacteristics Innertube Outertube

Outerdiameterof tube, , 20 54

Innerdiameterof tube, , 18 52

Lengthoftube, , 1100 1500 Thickness,δ, 1 1

Tubematerial Copper Copper Dimpledtube

Depthofdimple 1.5 Diameterofanellipsoidal dimple

Dimplepitch 12

Anglebetween dimples, (45 60) Dimpleshape Elliptic

Centrifugal pumps which are used to pump the water of the chilled water and hot water system; the capacity of eachpump is 1hp. Two ball valvesareused tocontrol the flow rate of those pumps, while water flow rates are measuredusingtwoflowmeterswithaccuraciesof ±0.5% offullscale.Theoutersurfaceoftheheatexchangeriswell insulated,and necessaryprecautionsaretakentoprevent leakages from the system [12]. To stabilize the consumed electric power of the electric circuits, voltage stabilizers are conducted on the electric component of the circuits [13]. The temperatures are measured at the inlet and outlet of the test rig by a digital thermometer with J type thermocouples.

The chilled water and hot water temperatures were adjustedtoalmostconstantvalues(20 oC ± 0.7 oC),(and 80

Inlet chilledwatertemperature(TC,i), oC 20 oC ± 0.5

Inlet hotwatertemperature(Th,i), oC 80 oC ± 0.5

Inlet innertubewatervelocity(v1), m/s 0.13 1.18

Inlet outerannuluswatervelocity(v2), m/s 0.04 0.37

oC ± 0.7 oC). However, the inlet and outlet temperatures were measured using four barked pre calibrated J type thermocouples.Thechilled andhotwaterflowrateswere measured using two flow meters with a range of (2 to 18 L/m). Water pressure drop across the test rig was measured using a U tube manometer. The data range of theexperimentalisgiveninTable(2).

Heat transfer and flow characteristics of the dimple tube heat exchanger are investigated experimentally.The influence of inner tube fluid velocity, hot water temperature, flow arrangement, and dimple angles were investigated.Themajorgoalistoimprovethethermofluid coolingperformanceoftheDTHE.Thefindingsaredivided into three sub sections that detailed and analyzed the comprehensiveperformancecriteria.

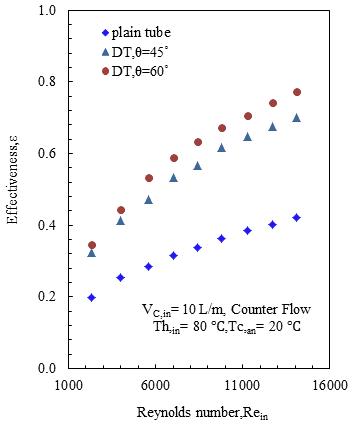

Figure (2) shows the relationship between the effectiveness of the double tube heat exchanger against the Reynolds number for the hot water side at different dimple angles (θ) and plain tube at a constant chilled water flow rate of ⁄ . It can be seen from this figure that the effectiveness increases with the increase of the Reynolds number for all cases. At a constant Reynolds number of , the effectiveness for the dimple angle (θ =60˚) is higher than the plain tube by approximately 87% for the same condition, and the effectivenessoftheheatexchangerfordimpleangleof(θ= 60˚) is higher than the dimple angle of (θ =45˚) by approximatelyof11.8%.Becausetheheatexchangerwith adimpledtubehasasurfaceareaforheatgreaterthanthe surface area for heat transfer in the heat exchanger with plain tube. In addition, it creates eddy currents in the direction of the inner tube working fluid that leads to an improvement in heat transfer coefficients. Figure (3) shows the relationship between the number of transfer

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

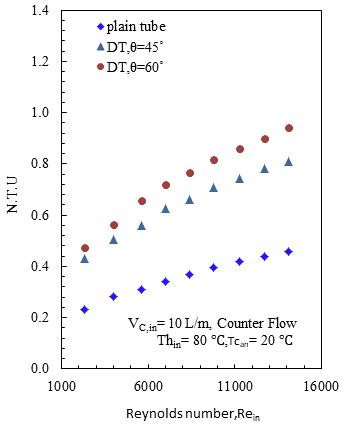

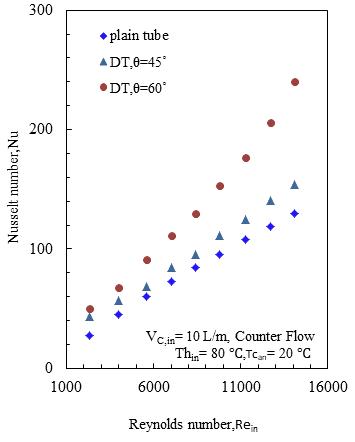

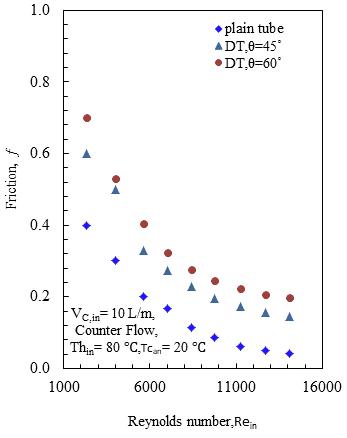

units(N.T.U)ofthedoubletubeheatexchangeragainstthe Reynolds number for the hot water side at different dimple angles (θ) and plain tube at a constant chilled water flow rate of ⁄ . It can be seen from this figure that the (N.T.U) increases with the increase of Reynolds number for all cases. At a constant Reynolds number of ,the(N.T.U)forthedimpleangle(θ=60˚) ishigherthantheplaintubebyapproximately107.8% for the same condition, (N.T.U) of the heat exchanger for dimpleangleof(θ=60˚)ishigherthanthedimpleangleof (θ =45˚) by approximately of 15.7%. Because the heat exchangerwithadimpledtubehasasurfaceareaforheat greater than the surface area for heat transfer in the heat exchanger with a plain tube. In addition, it creates eddy currents in the direction of the inner tube working fluid thatleadstoanimprovementinheattransfercoefficients. Figure (4) shows the relationship between the Nusselt number of the double tube heat exchanger against the Reynolds number for the hot water side at different dimple angles (θ) and plain tube at a constant chilled water flow rate of ⁄ . It can be seen from this figure thattheNusseltnumberincreaseswiththeincreaseofthe Reynolds number for all cases. At a constant Reynolds number of , the Nusselt number for the dimple angle (θ = 60˚) is higher than the plain tube by approximately 53% for the same condition, Nusselt numberoftheheatexchangerfordimpleangleof(θ=60˚) is higher than the dimple angle of (θ =45˚) by approximatelyof35.5%.Becausetheheatexchangerwith adimpledtubehasasurfaceareaforheatgreaterthanthe surface area for heat transfer in the heat exchanger with the plain tube. In addition, it creates eddy currents in the direction of the inner tube working fluid that leads to an improvement in heat transfer coefficients. Figure (5) shows the relationship between the Friction factor of the double tube heat exchanger against the Reynolds number for the hot water side at different dimple angles (θ) and plain tube at a constant chilled water flow rate of ⁄ .It can be clearly seen from this figure that the friction increases with the increase of the Reynolds number for all cases. At a constant Reynolds number of , the Friction factor for the dimple angle (θ = 60˚) is found to be higher than the lower inlet plain tube by approximately for the same condition. Because the heat exchanger with a dimpled tube has a surfaceareaforheatgreaterthanthesurfaceareaforheat transfer in the heat exchanger plain tube. In addition, it createseddycurrentsinthedirectionoftheinhibitorflow, workingonanimprovementprocessofheattransfer.

Fig.2 VariationsofƐagainstRefordifferentdimpleangles (θ)

Fig.3 VariationsofNTUagainstRefordifferentdimple angles(θ)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

2570 to 14405 for inner tube fluid and 1477 to 8103 for outer tube fluid. The influences of dimple angles are investigated. The number of transfer units, as well as the effectiveness of the heat exchanger, are investigated. The followingisasummaryoftheconclusion:

The effectiveness, number of transfer units, and Nusselt number of the double tube heat exchanger with dimples is higher than that of the double tube heat exchanger without dimples by approximately 87%,107.8%and53%,respectively.

The double tube heat exchanger with dimples contributes higher effectiveness and more energy savingthanthedoubletubeheatexchangerwithplain tubes.

Fig.4 Variationsof(Nu)againstRefordifferentdimple angles(θ)

A Area(m2) Cp Specificheat(kJ.kg 1.K 1) D Diameter(m) Ƒ Frictionfactor h Heattransfercoefficient(W.m 2.K 1) k Thermalconductivity(W.m 1.K 1) L Length(m) m Massflowrate(kg.s 1) Nu Nusseltnumber Δp Pressuredrop(N.m 2) Re Reynoldsnumber( ) T Temperature(oC) U Overall heat transfer coefficient (W.m 2 K 1)

GreekSymbols δ

Thickness(m) ε Effectiveness θ Dimpleangle μ Viscosity(kg.m 1.s 1) ρ Density(kg.m 3)

DT Dimpletubeheatexchanger NTU Numberoftransferunits

Fig.5 Variationsof(ƒ)againstRefordifferentdimple angles(θ)

The thermofluid performance of the double concentric tube heat exchanger is investigated in this study. The study is carried out for Reynolds numbers ranging from

Scripts av average c cold h hot hy hydraulic i inlet/inner o outlet/outer min minimum max maximum

2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal

[1] Wael I. A. Aly, "Thermal and hydrodynamic performance of aqueous CuO and Al2O3 nanofluids in an annular coiled tube under constant wall temperature and laminar flow conditions", ASME Journal of heat transfer, 138:102401(2016).

[2] Wael I. A. Aly, "Numerical study on turbulent heat transfer and pressure drop of nanofluid in coiled tube in tube heat exchangers", Energy Conversion and Management.(79C)304 316(2014).

[3] Wael I. A. Aly, "Computational fluid dynamics and optimization of flow and heat transfer in coiled tube in tube heat exchangers under turbulent flow conditions", ASME, Journal of Thermal Science and Engineering Applications.6(3)031001 031001 10(2014).

[4] Abdalla Gomaa, M.A. Halim and Ashraf Mimi Elsaid, “Enhancement of cooling characteristics and optimization of a triple concentric tube heat exchanger with inserted ribs”,InternationalJournalofThermalSciences )120( 106 120(2017).

[5]AbdallahGomaa,WaelI.A.Aly,EldosukiI.Eid,Ashraf Mimi Elsaid, “Thermal Performance of the Chilled Water Spirally Coiled Finned Tube in Cross Flow for Air Conditioning Applications”, Ain Shams Engineering Journal,(3)49 59(2012)

[6] Ashraf Mimi Elsaid, Emad M.S. El Said, Gamal B. Abdelaziz, Swellam W. Sharshir, Hamed R. El Tahane, and M.F. Abd Raboo, “Performance and Exergy Analysis of Different Perforated Rib Designs of Triple Tubes Heat Exchanger Employing Hybrid Nanofluids”, International JournalofThermalSciences(168)107006(2021).

[7] Abdalla Gomaa M.A. Halim and Ashraf Mimi Elsaid, “Experimental and numerical investigations of a triple concentric tube heat exchanger”, Applied Thermal Engineering(99)1303 1315(2016)

[8] A. Sarmadian, M. Shafaee, H. Mashouf, S.G. Mohseni,"Condensation heat transfer and pressure drop characteristics of R 600a in horizontal smooth and helically dimpled tubes." Experimental Thermal and Fluid Science(86)54 62(2017).

[9]MingLi,TariqS.Khan,EbrahimAl Hajri,ZahidH.Ayub. "Singlephaseheattransferandpressuredropanalysisofa dimpled enhanced tube." Applied Thermal Engineering (101)38 46(2016).

[10] Shuai Xie, Zheng Liang, Liang Zhang, Yulin Wang, Hu Ding, Jie Zhang, "Numerical investigation on heat transfer performance and flow characteristics in enhanced tube with dimples and protrusions." International Journal of HeatandMassTransfer(122)602 613(2018)

[11] K. Aroonrat and S. Wongwises, "Experimental investigation of condensation heat transfer and pressure drop of R 134a flowing inside dimpled tubes with different dimpled depths." International Journal of Heat andMassTransfer(128)783 793(2019).

[12]AshrafMimiElsaid,“Anovelapproachforenergyand mass transfer characteristics in wet cooling towers associated with vapor compression air conditioning system by using MgO and TiO2 based H2O nanofluids”, Energy Conversion and Management (204) 112289 (2020).

[12] Emad M.S. El Said, GB. Abdelaziz, SW. Sharshir, Ashraf Mimi Elsaid, “Experimental Investigation of the TwistAngleEffectsonThermo hydraulicPerformanceofa Square and Hexagonal Pin Fin Array in Forced Convection”, International Communications in Heat and MassTransfer(126)105374(2021).

Wael Aly, is Professor of Mechanical Engineering and the head of the Refrigeration and Air Conditioning Technology Dept, Faculty of Technology and Education, Helwan University. He obtained his B.Sc. (1994) from Benha University, Egypt and M.Sc. (1997) from Eindhoven University of Technology, the Netherlands. He obtained also the PhD (2007) from Okayama University, Japan. He is the author and co author of more than 40 papers in the fields of Thermofluids, RHVAC,andCFD.

aly_wael@techedu.helwanedu.eg

Ashraf Mimi Elsaid is Associate Professor of RHVAC Technology, FacultyofTechnologyandEducation, Helwan University Mimi is the authorandco authorofmorethan20 international papers (Q1) in the fields of Thermofluids, RHVAC, Desalination,Solarsystems,andCFD.

AshrafMimi@techedu.helwan.edu.eg

Nermin Mahmoud is a Demonstrator at the Refrigeration and Air Conditioning Technology Department, Faculty of Technology and Education, Helwan University, Cairo,Egypt

nerminmahmoud@techedu.helwan.e du.eg

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page3182