International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN:2395-0072

S. Solomon Raj1 , Venkata Sushma Chinta2, G. Laxmaiah3, Manthri Neelima4

Associate professor1 , Assistant professor2, Professor3 , B.E Student4 Department of Mechanical Engineering, Chaitanya Bharathi Institute of Technology, Gandipet, Hyd 75 ***

With the growing applications of composite materials in industry, it is becoming more involved with regard to characterization of them for carrying out analysis. Especially usage of hybrid composites is finding enormous applications now days Composite materials give freedom to stitch them to meet particular design criteria as they posses’ intrinsic coupling effects. Scientists from all around the world are interested in the possibilities of natural fiber plastic composites that use jute, wood, hemp, coir, or sisal as reinforcing fibre in a thermosetting resin matrix. Since demand for lightweight materials with high strength for specific applications grow, composites reinforced with synthetic or natural fibres are becoming more important. The major applications are found in aerospace, military and navy industries. Characterization of composite materials and the associated fabrication methods pose a big challenge to the engineers as the behavior of them is going to be anisotropic in nature because of these. In the present study, an effort has been made to characterize the hybrid composite materials experimentally through fabrication and testing using jute cloth/polyester and chopped E glass/polyester materials. Hand layup technique is used for fabrication of specimens, followed by cutting and testing. Tensile test, flexural test and charpy tests are carried out to evaluate the young's modulus, flexural strength and impact strength respectively.

Keywords:glassfiber,jutefiber,polyester,mechanicalproperties.

Fiber reinforced polymer composites perform ascending functions in various applications due to their high modulus, meticulous resistance and reduced carbon footprint in the environment [1]. Rapid growth in manufacturing industry has necessitated the development of new materials with enhanced strength, stiffness, density and cost effectiveness. Composite materials have emerged with such improved qualities, allowing them to be utilized in a wide range of applications [2 5]. Compositematerialsarecomprisedoftwoormoreconstituents,oneofwhichisthematrixphaseandtheotherisintheform ofparticleorfiberphase.Naturalorsyntheticfibershavefoundmajoruseswithinthemanufacturingofcompositematerials invariousfieldslikeconstruction,mechanical,automobile,aerospace,biomedical,andmarine[6 9].

Themostrecentstudyaddstothedevelopmentofhybridcompositesthatcombine differentnaturalandsyntheticfibers. Hybridcompositesarecompositestructuresthatconsistofmorethanonetypeoffiber Stackinglayersoffibres,intermingling fibres,andmixingtwotypesoffibresinthesamelayertocreateaninterplayhybrid,selectivepositioningoffibrewhereitis needed for improved force, and arranging each fibre according to certain orientation are all strategies for combining these fibres.[10].Stackingfibersisthesimplestapproach,whileotherscreatechallengesinachievingapositivehybridizationeffect.

Fiber reinforced polymer composites not only have a high strength to weight ratio, but they also have outstanding features including great durability; stiffness; damping property; flexural strength; and resistance to corrosion, wear, impact, and fire. Composite materials have found applications in mechanical, construction, aerospace, automobile, biomedical, marine, and many other manufacturing industries due to their vast range of unique properties. Natural fibers are inexpensive and biodegradable, making them environmentally friendly whereas synthetic fibers provide additional stiffness. Despite the fact thatbothtypesoffibersareeffectiveinvarietyofapplications,theexcellentperformanceofhybridfiber reinforcedcomposite materialshasbeenrevealedbyrecentstudies,astheycombinethebenefitsofboth.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

A fibre reinforced composite depends also on some additional characteristics like matrix properties, filler material, fibre matrix ratio, coupling agents and processing techniques [11]. Fiber length, fiber matrix adhesion, fiber treatment, fiber content(loading),fiberdispersioninthematrixareallpropertiesthataffectcompositeperformance.

Fiberreinforcedcompositesarealsowidelyusedintheautomobileindustry,sportinggoodsindustryandpackagingmaterials, aerospaceindustry(tails,wings,propellers),boathulls,storagetanks.Thereplacementofsteelwithcompositematerialscan besaved by60 80%ofcomponent weightand20 50% ofaluminiumalloycomponents[12].Foranorganicproduct,natural polymer based packaging can also be combined with natural fibers. It has no allergic reaction and does not burn the human skin.Organiccompoundsbasedonnaturalfibersattackattentionbecauseoftheirlowcost,biodegradability,lowdensity,high specificunits,andrecyclingcapacity[13 15].

The matrix is essentially a monolithic, homogeneous and continuous material during which a fiber system of a composite is embedded.Thematrixprovidesamediumforholdingandbindingreinforcementstogetherintoasolid.Amongdifferingtypes ofmatrixmaterials,polymermatricesaretheforemost commonlyusedduetomanyadvantageslikesimple fabrication with lesstoolingrate,costeffectivenessandtheyevenhaveoutstandingtemperatureproperties.

The iso polyester Resin being a strong material commonly used for composites, boat building, autos and other repairs. This ISO grade polyester resin is often used with fiberglass mats or cloths on surfaces because it is excellent for repairing, rebuildingandrecreatingdamagedparts.Alongwithitsstrength,polyesterresinisalsosimpletouse.Itiseasilymixedusing theMEKPcatalystandcobaltaccelerator.

MethylEthylKetonePeroxideCatalyst(MEKP),isorganicperoxide,acolourless,oilyliquid,whichinitiatestheCrosslinkingof polyesterresinsusedinglass reinforcedplastic,andcasting,initiallycausingagelandthenanentirecure.Cobaltaccelerator is an efficient accelerator for polyester. It affects curing or polymerization of Polyester Resins together with catalyst likes MEKP Resins formulated for a cure at room temperature require accelerators to increase the rate of peroxide catalysts to breakdown into free radicals. Iso polyester resin, MEKP catalyst, Cobalt accelerator and Glass fiber is collected from Carbonblackcompositeswebsiteasshowninfig.1.

Fig.1.Polyesterresinandfiberglass

Reinforcementmaterial wasaddedtothematrixmaterial toenhancethephysical properties likestiffness, highstrengthand

otherimprovedmechanicalpropertiestothecompositematerial.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Jute is a soft, long, shiny fiber which is obtained from the plants which is spun into coarse, strong threads. Jute fibers are primarilycomposedofcelluloseandligninplantcomponents.Thefibersrangeincolourfromoff whitetobrownwith1 4m long. Jute is one among the cheapest natural fibers and 100% biodegradable, eco friendly and recyclable. Woven jute fiber having an average weight of 400GSM and average thickness of 0.96 mm is directly procured from local market as shown in fig.2.

Glassfibreisamaterialcreatedfromincrediblyfineglassfibresthatislightweight,extremelystrong,andexceedinglydurable. Thefibreglassmatisaversatilerepairmaterialthatmaybeusedonavarietyofsurfaces,includingautos,boats,tubs,showers, sinks, pools, and hot tubs. Fiberglass mat is a non woven fabric with a high strength to weight ratio that aids in the reinforcement of repairs. Fiberglass cloth has a lot of advantages includes resistance to expansion and contraction as temperatureschange,moistureabsorption,non flammability,andchemicalresistance.Fromthefig.3,thefiberglassof0.3mm averagethicknessand300GSM.

Fig.2.Jutefibermat Fig.3.Glass fibermat

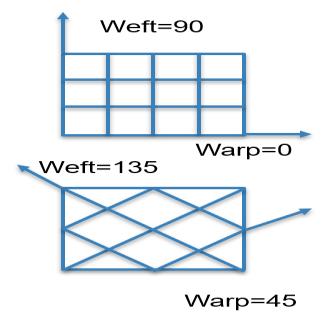

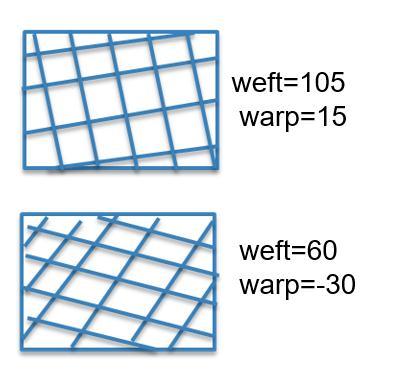

Thefabricationsofcompositeslabarecarriedoutbyconventionalhandlayuptechnique. Thebidirectionaljutefibreandthe E glassfibresareusedasreinforcementandpolyesterresinistakenasmatrixmaterial. Amouldofdimension280×280mm2 with 10 mm thick wood flats to maintain the desired thickness and a clean, smooth surface is preferred to get the finished surfaceisusedforcastingthecompositelaminate.Thelowtemperaturecuringpolyesterresin,MEKPandcobaltaccelerator are mixed in a ratio of 10:1:1 by weight percentage. We provide a thin non reactive plastic sheet on the flat smooth surface. Forthisstudy,wearevaryingtheorientationofjutefibersin0°and45°respectivelyaspresentedinTable.1.Afterpreparation ofmatrixmaterial,firstpourthepreparedresinandplacetheglassfibersheetsonmold. Then,pourtheresinontotheglass sheetoncemoreandspreaditevenlywithrollers.Now,arrangethejutefibreinthedesiredorientations,suchas0°and45° Foroptimizingtheresults,wearetakingthesetwoorientations. Thesameprocedureisfollowedfortheremaininglaminato formsymmetriccomposite.Finally,therequiredhybridcompositesareformedasperourrequirements.Thesecompositesare curedunderaloadfor72hours.Thenthiscastispostcuredintheairforanother24hoursafterremovingoutofthemould. Figure.4showshybridcompositematerial.Specimensofappropriatedimensionarecutforphysicalandmechanicaltests.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Table.1:Designationofcomposite

LAMINA ORIENTATION(Degree) COMPOSITION

L1

L2

Polyesterresin+choppedglassfibermat

Polyesterresin+choppedglassfibermat

L3 0 Polyesterresin+jutefibermat

L4 45

L5 45

L6 0

L7

L8

Polyesterresin+jutefibermat

Polyesterresin+jutefibermat

Polyesterresin+jutefibermat

Polyesterresin+choppedglassfibermat

Polyesterresin+choppedglassfibermat

Fig.4.Jute/glasshybridpolyestercomposite

Thespecimensarecutintwodifferentorientationsnamely0°and30°asshowninfig.5.Asthishybridcompositeissymmetric aboutaxisandorientationofjutefibersarealsosymmetricabout0°and45°.Thus,twospecimensarecutin0°and30°taking 0°asreferenceforeachtestandtestsareconducted.

Thetensiletestisusedtodetermineamaterial'sabilitytoresistappliedforcesthattearitapart,aswellastheextent towhich thematerialstretchesbeforebreaking.Tensilepropertydataisfrequentlyusedtocomparedifferenttypesofplasticmaterials such asstrength, modulus, and elongation data. The tensile test specimen is prepared according to the ASTM D638 III standardasshowninfig.6.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3151

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Theflexuraltestisusedto measureamaterial'sabilitytowithstandbendingbeforeitreachesitsbreakingpoint.Auniversal testing machine is used to perform this test, which is based on the three point bend test. As a result, we must treat it as a simplysupportedpointloadbeam.Byapplyingabendingloadtothespecimen,itcanbesustaineduptoaspecificpointbefore collapsingandcomestofracture.Flexuraltestingspecimenasshowninfig.7.

Polymeric material’s impact characteristics are mostly determined by their toughness. The ability of a polymer to absorb appliedenergyisreferredtoastoughness.Theimpacttestspecimensarepreparedinaccordancewiththestandardandtothe specified dimensions of ASTM A370. The specimen must be inserted into the testing equipment, which then permits the pendulumtoswinguntilitcracks.ThedifferentspecimensusedforimpacttestingispresentedinFig.8.thetestisperformed onCharpyImpacttestmachine.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

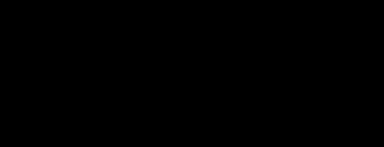

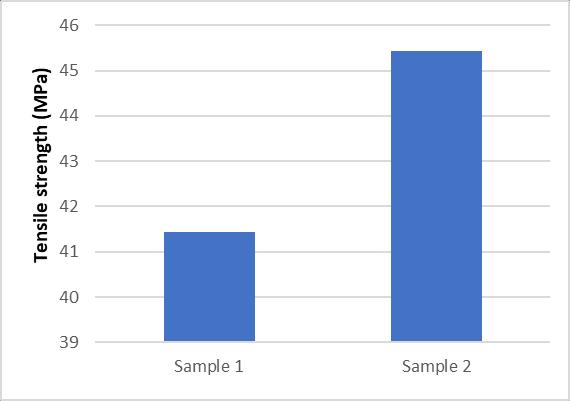

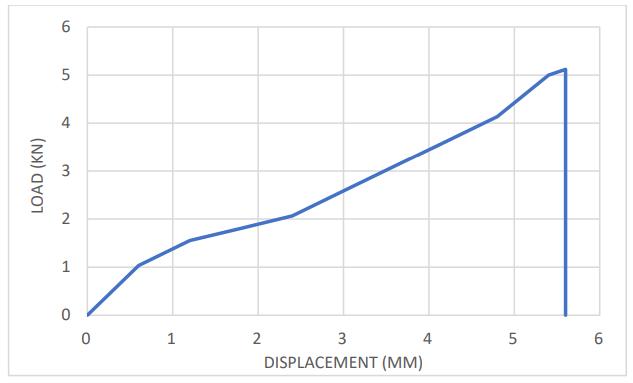

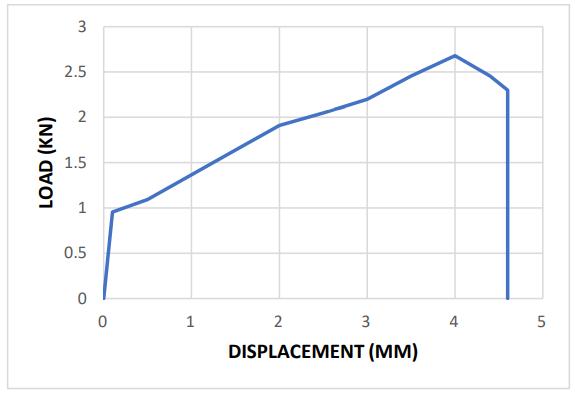

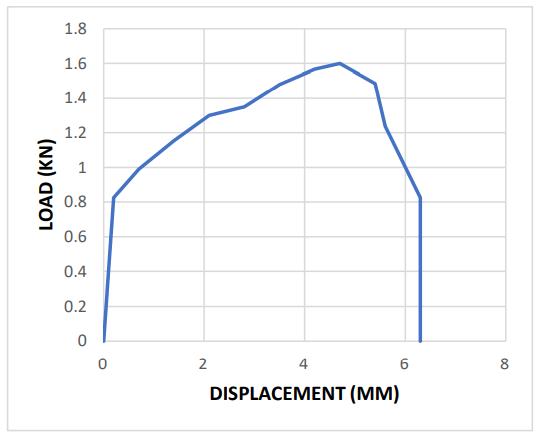

Thecompositesspecimens’sample1andsample2aretestedfortensilepropertiesinUTMandobtainedtensilepropertiesare shown in Table.2. The load vs displacement curves are shown in Figure 10 and 11. The Sample 1 which is oriented at 30° showsahightensilestrengthof45.436N/mm2andSample2whichisorientedat0°showsalowertensilestrengthof41.447 N/mm2,socomparativelySample2showsbetterresultsthantheSample1.

Table.2.Tensilepropertiesofcomposite sample yieldstrength(n/mm2) ultimatestrength(n/mm2) Elongation(%) 1 28.9 41.447 6.10 2 30.841 45.436 6.10

Fig.9Comparisonoftensilestrength

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Fig.10LoadvsdisplacementcurveofSample1 Fig.11LoadvsdisplacementcurveofSample2

Young's modulus is a measurement of a material's ability to endure length changes when subjected to lengthwise tension or compression. A material's Young's modulus is a useful property to know in order to forecast how it will behave when subjectedtoaforce.Figure12showstensilemodulusofSample1andSample2were679.459and744.852N/mm2

Young's Modulus (MPa)

760

740

720

700

680

660

640

Sample 1 Sample 2

Fig.12ComparisonofYoung’smodulus

Fiber fracture and pull out, as well as fibre tearing, are visible on the tension cracked surface. We observed no stretching or pullingofpolyesteronthecompositesurfaceinbothsamples,howeverthereisasharpcutsurfaceduetothebrittlenature of polyesterresin.

Due to tensile load, two forms of behaviour are observed on the surface of the hybrid composite in Sample 1, glass fibre stretchingandjutefibrefracturewithoutstretching.Thejutefibreandmatrixbondingisgood,yetbreakingoccursduetothe brittlenatureofjutefibre.Glassfibresarealsodebondingfromoneanother,andtransversefibresare notcarryinganyload (fig.13).Becauseoftheinadequateinterfacialbonding,thefibrespullawayfromtheresinsurface,asshowninfigure14.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Fig.13Orientationofjutefibersinsample1 Fig.15.Orientationofjutefibersinsample2 a b c

Fig.14.(a),(b),and(c)areImagesoftensilefracturedcompositeofsample1 a b c

Fig.16.(a),(b),and(c)areImagesoftensilefracturedcompositeofsample2

Forsample2,theintegrationofglassfibrewithpolyesterincreasedthepolymer'sstrength,asseenbythestretchingofglass fibre.Fromthesurfaceofthecompositeshowninfig.16,littlejutefibrestretchingandfibrebreakagecanbeseen. Thereason thatthereisnovisiblefibrepulloutonthesurfacemaybeattributedtoincreasedadhesionbetweenthefibreandthematrix, whichleadstoimprovedcompositestrengthqualities.Thisisduetobrittlenatureofthecomposites.Itwasobservedthat,pull outof both weftand warp fibers(fig.15),thus strength increasesand all orientationfibers will contribute to stresscarrying. Thiscanbecorrelatedtointerlaminarshearstrength.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Thedifferentcompositespecimensamplesaretestedintheuniversaltestingmachineandthesamplesaretakesdisplacement tillthebreakoccurs.Thecompositespecimenssample1andsample2aretestedforflexuralpropertiesinUTMandobtained flexural properties are shown in Table 3. The load vs displacement curves are shown in Figure 17 and 18. Load vs displacementcurveofSample1isplottedinfig.17

Fig.17.LoadvsDisplacementcurveofflexural test specimenofSample1

Fig.18.LoadvsDisplacementcurveof flexuraltestspecimenofSample2

The displacement increases with increasing applied load up to a point about 2.68KN, beyond which it tends to decrease. Breakingoccurs,inotherwords.Sample1hasamaximumdisplacementof4.6mm. LoadvsdisplacementcurveofSample2is plottedinfig.18.

The results showed that when the load increases, the displacement increases as well. There is a break after the 6.3mm displacement.ThemaximumdisplacementobservedinSample2is6.3mm.

Table.3.Flexuralpropertiesofcomposite

SAMPLE ULTIMATESTRENGTH(N/mm2) ULTIMATELOAD(KN) MAXIMUMDISPLACEMENT(mm)

1 10.984 2.68 4.6

2 5.626 1.6 6.3

In flexural test, the greater extensibility of glass fibers resulting in large fiber pull out and matrix failure was observed. For flexuralspecimen,thereisnodelaminationbetweenthejuteandglassplies.Heretransversestressisactingonthespecimens. Twotypesof behaviourare observed,oneisthe brittlenessofjutefiber andanother isthe bendingofglassfiber.Cracksare also formed due to flexural load. For sample 1, bending and pulling out of fibers are observed. In which, horizontal fibers gettingelongateandtransversefibersshownoeffect.Figure13and19showsitsbehaviour.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3156

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Fig.19.(a)and(b)showsImagesofflexuralfracturedspecimenofsample1

For sample 2, due to flexural load, some fibre splitting may be seen on the surface of the composite, as well assharp cuts in some areas. The brittle nature of the jute fibre in composite is defined by this. Both fibers of different orientation are participating, but shearing between fibers is taking place. Also, we can observe out of plane compression, i.e., buckling is happeningfromfigure15and20

Fig.20.(a)and(b)showImagesofflexuralfracturedspecimenofsample2

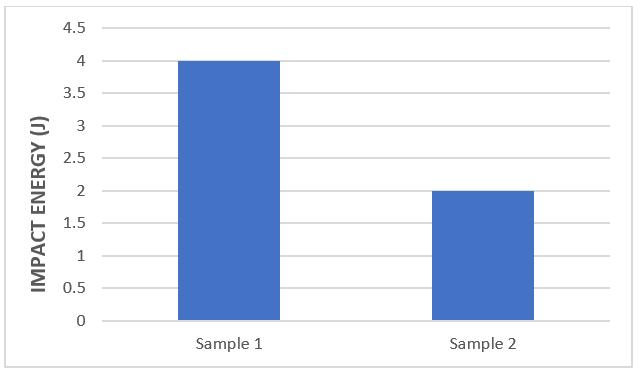

The impact test carried out for the present investigation is Charpy impact test. Figure 21 shows a comparison between energyabsorbedbythevariouscompositesamples.TheSample1showsveryhighimpactenergycomparetoanothersample. TheSample2showsverypoorimpactstrengthof2J.

Fig.21.Comparisonofimpactenergy.

The resultsindicatedthat themaximum impact energy isobtained for Sample1compositefollowed by Sample 2composite. Whentheamountofjute, whichismore brittlethan glassfibre,isincreased, the overall brittlenessofthe material increases andimpactstrengthdecreases.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Delaminationisconstrainedbythrough thicknesscompressionstress.Commonthingobservedisglassfiberfractureandpull out,considerabledamagetojutefibersduetosplittingfromthestrands.Transversecrackscanbeseenattheimpactpointin bothcases,withthesample1impactedspecimenhavingalongercrack.

In fig.22, the damage appears to be primarily in the form of matrix cracking and interlayer delamination for sample 1 A progressive bending of the central part and, as a result, local buckling of the compressed specimens occurs as the impact energy increases, suggesting increasing internal damage and involving an increase in delamination. The propagation of delamination is caused by out of plane deflection and local buckling, which mostly impacts the compressive performance of thedamagedspecimens.

(b)

1

Forsample2,thispartshowsaspecimenfailureduetotheeffectofdelaminationandaserratedfracturesurfacefromfig.23 Thespecimenhasa flatfracturesurface, withthefibre pull out,fibre breaking and matrixcracking havinga dominant effect onthecompositefailure.

Fig.23.(a)and(b)showImagesofimpactfracturedspecimenofsample2.

The experimental investigation on the fabrication and mechanical behaviour of jute/glass fibre reinforced polyester based hybridcompositesleadtothefollowingconclusions:

1. The successful fabrication of hybrid jute/glass fibre reinforced polyester composites by simple hand lay up technique.

2. The present investigation revealed that effect of stacking and orientation of jute and glass mat on mechanical propertiesofjute/glassfibrereinforcedpolyestercompositeshavebeenexperimentallystudiedandthevariation inmechanicalpropertiesareexplainedbystudyingthefracturefeaturesandcrackprofiles.Mechanicalproperties

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

ofthecompositeswereimprovedwiththeincrease ofstackingsequencesanddifferentspecimens orientedw.r.t referenceaxissuccessfully.

3. Forzerodegreeorientation(Sample1):

i. Ultimatestrength=41.447N/mm2 ii. Yieldstrength=28.9N/mm2 iii. Young’smodulus=679.459N/mm2 iv. Maximumflexuralstrength=10.984N/mm2, v. Maximumimpactenergy=4Jispredicted.

4. For30degreeorientation(Sample2):

i. Maximumultimatestrength=45.436N/mm2 ii. Maximumyieldstrength=30.84N/mm2 iii. Young’smodulus=744.852N/mm2 iv. Flexuralstrength=5.626N/mm2 v. Impactenergy=2Jispredicted.

5. The use of jute fibre in glass fibre composites improves mechanical properties and increases the use of natural fibresinmanyapplications,resultinginacostsavings.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3159

[1] JayavaniS,DekaH,VargheseT,NayakS.Recentdevelopmentandfuturetrendsincoirfiber reinforced greenpolymer composites:reviewandevaluation.PolymCompos2016;11(37):3296 309.

[2] Yashas Gowda, T.G.; Sanjay, M.R.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. SSPolymer matrix naturalfibercomposites:Anoverview.Cogent.Eng.2018,5,1446667

[3] Sherif, G.; Chukov, D.; Tcherdyntsev, V.; Torokhov, V. Effect of formation route on the mechanical properties of the polyethersulfonecompositesreinforcedwithglassfibers.Polymers2019,11,1364

[4] Chukov,D.;Nematulloev,S.;Zadorozhnyy,M.;Tcherdyntsev,V.;Stepashkin,A.;Zherebtsov,D.Structure,mechanicaland thermalpropertiesofpolyphenylenesulfideandpolysulfoneimpregnatedcarbonfibercomposites.Polymers2019,11, 684.

[5] Linul, E.; Lell, D.; Movahedi, N.; Codrean, C.; Fiedler, T. Compressive properties of Zinc Syntactic Foams at elevated temperatures.Compos.PartBEng.2019,167,122 134.Clyne,T.W.;Hull,D.AnIntroductiontoCompositeMaterials,3rd ed.;CambridgeUniversityPress:Cambridge,UK,2019.

[6] Zagho, M.M.; Hussein, E.A.; Elzatahry, A.A. Recent overviews in functional polymer composites for biomedical applications. Polymers 2018, 10, 739. Monteiro, S.N.; de Assis, F.S.; Ferreira, C.L.; Simonassi, N.T.; Weber, R.P.; Oliveira, M.S.; Colorado, H.A.; Pereira, A.C. Fique fabric: A promising reinforcement for polymer composites. Polymers 2018, 10, 246.

[7] Movahedi,N.;Linul,E.Quasi staticcompressivebehavioroftheex situaluminum alloyfoam filledtubesunderelevated temperature conditions. Mater. Lett. 2017, 206, 182 184. Pegoretti, A.; Fabbri, E.; Migliaresi, C.; Pilati, F. Intraply and interply hybrid composites based on E glass and poly (vinyl alcohol) woven fabrics: Tensile and impact properties. Polym. Int. 2004, 53, 1290 1297. Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibrecompositesandtheirmechanicalperformance.Compos.PartAAppl.Sci.Manuf.2016,83,98 112.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056 Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3160

[8] Ajith Gopinath, Senthil Kumar. M, Elayaperumal A, Experimental Investigations on Mechanical Properties of Jute Fiber ReinforcedCompositeswithPolyesterandEpoxyResinMatrices,ProcediaEngineering,2014,97,2052 2063.

[9] Yusriah, L., Sapuan, S. M., Zainudin, E. S., & Mariatti, M., Characterization of physical, mechanical, thermal and morphological properties of agro waste betel nut (Areca catechu) husk fibre. Journal of Cleaner Production. 2014, 72, 174 180.

[10] K.O. Reddy, C.U. Maheswari, M. Shukla, J.I. Song, A.V. Rajulu, Tensile and structural characterization of alkali treated Borassusfruitfinefibers.CompositesPartB:Engineering.2013,44(1),433 438.

[11] M.H.P.S. Thakur Jawaid, H.A. Khalil, Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. CarbohydratePolymers.2011,86(1),1 18.