International Research Journal of

Engineering

and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of

and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

Mahesh

M1,a), Dr. B R Narendra Babu2,b)1Research Scholar, Department of Mechanical Engineering, Vidya Vikas Institute of Engineering and Technology, Mysuru

2Professor, Department of Mechanical Engineering, Vidya Vikas Institute of Engineering and Technology, Mysuru ***

Abstract This research article presents the investigation of three body abrasive wear behaviour of glass fiber and ramie fiber reinforced epoxy hybrid composites (HFREC) by varying the proportions of glass fiber and ramie fibers. The hybrid composites was manufactured using hand layup method with the aid of compression moulding technique. The manufactured composites are tailored according to ASTM standards and tested for three body abrasive behaviour with different parameters like composite content, load and sliding distance with the help of L9 orthogonal array with three levels of each parameters to find optimal parameters. From the main effect plots optimal parameters was found to be A3, B1, and C2 gives lowest specific wear rate for HFREC. From the ANOVA table it is clear that sliding distance (P=0.008) is highly significant factor followed by load (P=0.046), and Wt. % of HFREC (P=0.212) was the least influencing factor. The wear surface morphology also studied using scanning electron microscope. From the SEM micrographs micro plaguing, micro cutting, and micro cracks can be clearly seen. The better wear resistance was seen in Ra10G30 composite.

Key words: Ramie Fibers, glass fibers, Hand layup, three boy abrasive wear, scanning electron microscope,

Natural fibers of different properties and dimensions, produced from plants, animals have been widely used to outfittextileindustrydemandsovertheperiodoftime[1]. Likecotton,fibershavebeenvaluableforthousandsofyears, attained the nickname “white gold.” Now a days two are more plant based materials are being utilised in combinationswithdifferentpolymermatrices[2,3].Inthe recenttimespolymercompositesoutperformingtraditional materials in terms of engineering, chemical resistance, biodegradable and replenishable because of their remarkable physical and mechanical properties. The advantagesofnaturalfibersoversyntheticfibersaregood abrasivenature,lowerdensity,goodacousticproperties,less expensive, abundant in nature, readily available and biodegradable [4]. On the other hand Fiber glass in fabric formoffersanexcellentcombinationofpropertiesfromhigh strength to fire resistance. Wide ranges of yarn sizes and weavepatternsprovideunlimiteddesignpotential,allowing the end user to choose the best combination of material performance,economicsandproductflexibility.Fiberglass

fabricsareusedina widerangeofindustrialapplications. Fiber glass have some disadvantages like high processing costnondegradableandlessresistanttochemicals. Inthis contextthecombinationofnaturalandsyntheticfiberscan becombinedinthesamematrixtoformhybridcomposites, which are perfect, superior, and cost effective [5, 6]. Synthetic naturalfiberhybridcompositeresearchfocuses on decreasing the number of artificial fibers. Some of the literaturesregardinghybridcompositesincludes,Josephet al.[7]testedbananafiberandglassfiberwithvaryingfiber length and fiber content as well. The analysis of tensile, flexural,andimpactpropertiesofthesecompositesrevealed that composites with good strength could be successfully developedusingbananafiberasthereinforcingagent.Amit Bindaletal.[8]developedthehybridcompositeconsistingof E glass fabric and treated jute fiber reinforced with polyestercomposite.Themechanicalassessmentiscarried out on the hybrid composite prepared by hand layup techniquebyvaryingpercentageofjute glassfibercontent conductingtensile,flexural,impactandthewaterabsorption tests.Thetestresultsshowthattheintroductionofjutein the composite has enhanced the mechanical properties. Ramesh et al. [9] studied the mechanical properties and failure morphology of glass sisal/jute reinforced epoxy hybridcompositetakinglengthofthenaturalfibersasmin constituent.Itwasreportedthatthehybridizationofglass sisal reinforced epoxy composite shows good flexural property and the interfacial characteristics of the hybrid composite are analyzed by SEM.Romanzini et al. [10] investigatedtheeffectoffibrehybridizationandfrequency on the dynamic mechanical characteristics of polyester compositesreinforcedwithramie/glasshybridfibres.The storage modulus (E′), the loss modulus (E′′), and the dampingbehaviour(tanδ)weredeterminedasafunctionof variousglass/ramiefibrevolumeratios.Thesignificanceof thereinforcing effectabove Tgwasshownforthestorage modulus.Additionally,thepeakheight,peakbreadthathalf height, and relaxation area of the loss modulus and tan δcurveswerestudied,demonstratingtheeffectofashoulder below Tg in each instance. Finally, by increasing the frequency, the tan peak moves to higher temperatures. Higher activation energy was discovered for composites comprising75%glassfibre.Kapilaetal.[11]developedand analyzedpureramiefabric/epoxycompositesaswellasits hybrids ramie glass/epoxy and ramie basalt/epoxy composites. The research demonstrates that combining

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3118

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

naturalfibre(ramie)withsyntheticfibre(glass)andmineral fibre (basalt) results in a composite with superior mechanicalcapabilitiesthanpureramie.Additionally,ramie glasshybridcompositeshaveagreatertensilestrengththan ramie basalthybridcomposites.Thedefectsintheflexural specimen were discovered using a scanning electron microscope(SEM).SEMscansrevealthathybridcomposites includefewerdefectsthanpureramiefabriccomposites.As a result, it may be deduced that the addition of advanced fabric to the exterior layers of natural fibre composites would increase their strength. From these observations it canbeconcludedthatmostoftheresearchersinvestigated hybridcompositesformechanicalpropertiesandveryfew studieshavebeencarriedouttoinvestigatethethreebody abrasivebehaviourofhybridcomposites.

Inthiscontextanattempthasbeenmadetodevelopglass fiberandramiefiberreinforcedepoxyhybridcompositesby handlayupmethodwiththeaidofcompressionmoulding technique. The manufactured composites are tailored according to ASTM standards and tested for three body abrasivebehaviourwithdifferentparameterslikecomposite content, load and sliding distance with the help of L9 orthogonalarray.Thewearsurfacemorphologyalsostudied usingscanningelectronmicroscope.

Lapox L 12 with the Density: of 1.1 1.2 g/cm3, having a tensilestrengthof60 70MPaat25˚CandShelllifeof2years and K6 Hardener was procured from Suntech fibers, Bangalore.E Glassfibers with360GSMwasalso procured from Suntech fibers Bengaluru. Ramie fibers with the diameterof25 30µmandhavingadensityof1.5 1.55witha tensilestrengthof400 600MPawasprocuredfromDoshi GroupMumbai.

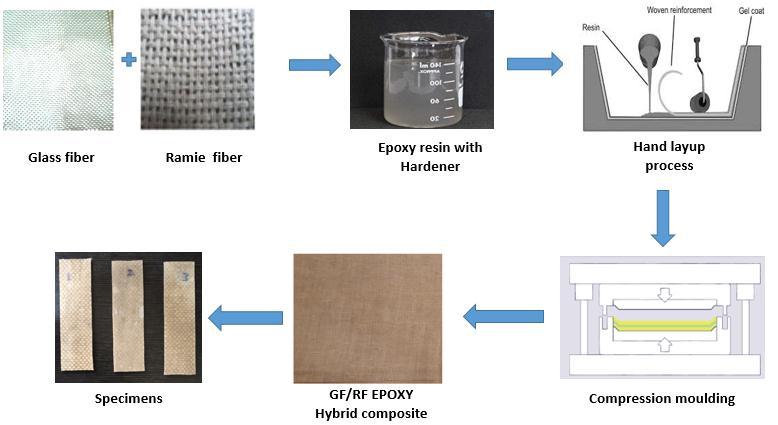

InthepresentworkaplainweavematofE glassfabricsof 0.3 mm thickness as synthetic reinforcement and plain weavematofRamiefiberswithadiameterof25 30µmwith thicknessof 0.4 mm thicknessasa natural reinforcement. ThematrixmaterialwasEpoxyresin(LapoxL 12)withthe Density: of 1.1 1.2 g/cm3 was used to manufacture composites. Hand layup process was employed to manufacture composites as it is less expensive than other manufacturingmethods.Inthehandlayupprocessfirstly,a mouldreleasingagentisappliedonaglasssheetthenalayer of resin is applied. Further, alternate layers of ramie fiber mat and glass fiber mat is placed and resin mixed with hardener is applied at every layer of glass fiber mat and ramie fiber mat. This step is repeated until thickness accordingtotherequirements.Thehandlayuppedlayers arethenplacedinmouldandkeptincompressionmoulding machine of 10 ton capacity at 80° C and pressed at a

pressureof24kg/cm2foraperiodof2hours.Themouldis curedataroomtemperatureof24hoursandcompositeis removed from the mould. The manufactured composite is tailoredaccordingtoASTMstandards.Thespecimensthen testedforthreebodyabrasivewearbehaviouraccordingto ASTMstandards.Themanufacturingprocessofcomposites isasshowninfigure1.Thedetailsofspecimencomposition ofcompositesisgivenintable1.

Table 1: Detailsofspecimencompositionofcomposites

Composition Weight % of epoxy Weight % of glass fibre

Weight % of ramie fibre

Ra30G10 60 10 30

Ra10G30 60 30 10 Ra20G20 60 20 20

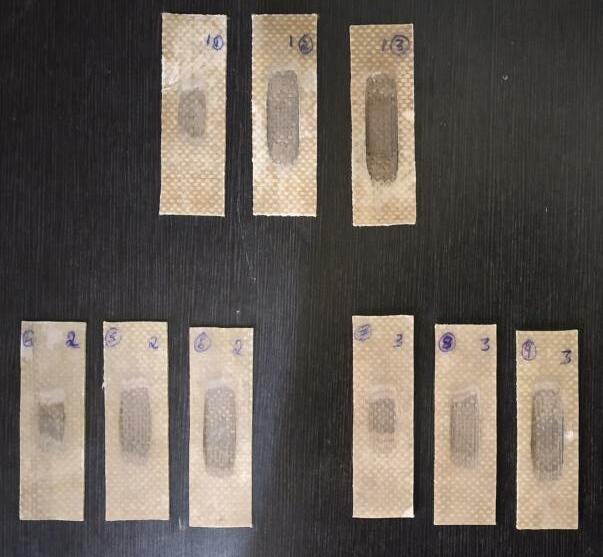

A three body abrasive wear test is utilized in the present work todetermine the wearrate of theHFRECcomposite. Theabrasivedrysandisintroducedbetweenthestandard test specimen and rotating chloro butyl rimmed rubber wheelofaspecifichardnessandaspeedof345rpm.Thetest loadisachievedbyweightof580g.silicasandofsize150 250 μmwithsharpedgeswasusedasabrasive.Thespecimens arewashedanddriedaftereachtestandthenweightedon the scaleswith accuracy 0.0001 g. HFREC specimens subjectedtoweartestareshowninfigure2.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3119

Figure 1. ManufacturingprocessofGF/RFfiberhybrid epoxycompositeInternational Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Hence,togettheoptimalparametersforwearrate,lower the betterfunctionwastakenasshowninequation1.

S/N= 10log1/n(∑▒y^2)...................Equation1

Where, “n” is the number of observations, and Y is the observed data. Thereafter a statistical analysis of variance(ANOVA) tool was used to identify the optimal combinationoftheprocessvariables.

Table 2: Processparametersandlevels

Level Process Parameters

Wt. % of HFREC (A) Load (B) Sliding Distance (C)

TheTaguchidesignofexperimentswasusedtoreducethe numberofexperimentalrunsandtofindouttheoptimum compositionofcomposites. Thismethodiswidelyused to optimize the quality characteristics with a combination of input parameters. Taguchi method gives the optimal parameterbydecreasingthenumberoftrialsforaparticular combination. This power full tool is employed here to simulate the experimental runs using Minitab 17. Table 2 shows the factors and levels selected for analysis. L9 orthogonal array was chosen with three levels of each parameters.IntheSignaltoNoiseRatio(S/N)analysis,three typesofthequalitylossfunction,thatis,lower the better, higher the better, and nominal the better; were obtained.

1 Ra30G10(1) 10 0.25

2 Ra20G20(2) 20 0.5

3 Ra10G30(3) 30 0.75

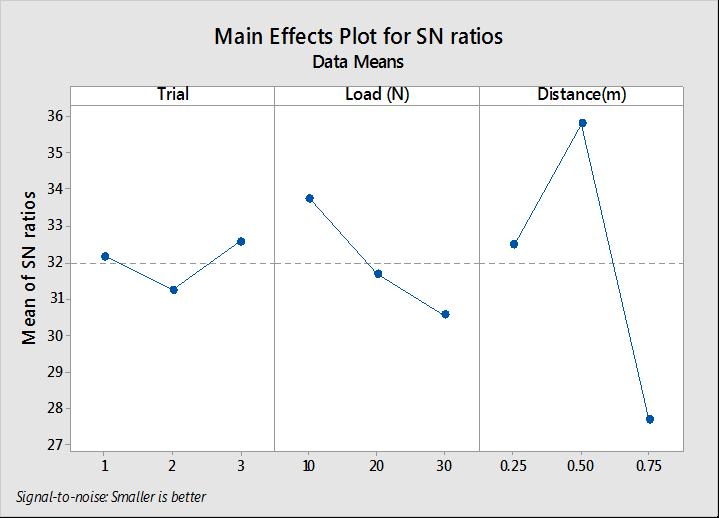

The experiments were performed according to L9 orthogonal array. The specific wear rate and the correspondingS/Nratioisshownintable3.Themaineffect plotforS/Nratioisshowninfigure3forHFRECcomposites.

Table3:ExperimentaldesignusingL9orthogonalarray Wt. %

1 10 0.25 4.836 4.740 0.097 1.284 0.075 0.0195 34.1977 1 20 0.5 4.885 4.583 0.302 1.284 0.236 0.0156 36.0913 1 30 0.75 4.741 4.211 0.530 1.284 0.413 0.0488 26.2309 2 10 0.5 5.023 4.885 0.138 1.410 0.098 0.0147 36.6132 2 20 0.75 4.926 4.594 0.332 1.410 0.235 0.0477 26.4256 2 30 0.25 5.066 4.550 0.516 1.410 0.366 0.0292 30.6910 3 10 0.75 7.235 7.093 0.142 1.282 0.111 0.0301 30.4396 3 20 0.25 7.227 6.921 0.306 1.282 0.239 0.0235 32.5597

30 0.5 6.929 6.368 0.562 1.282 0.438 0.0183 34.7327

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

The experiments were performed according to L9 orthogonal array. The specific wear rate and the correspondingS/Nratioisshownintable3.Themaineffect plotforS/Nratioisshowninfigure3forHFRECcomposites.

Figure 3. EffectofcontrolfactorsontheS/Nratioof HFRECcomposite

From the S/N plots it can be observed that the mean S/N ratioforexperimentalwerefoundtobe32.06dBforHFREC composites.Theresultswasanalysedat5%significantlevel which is denoted by “P”. The value of P denotes its contribution on the total variation of the output (SWR). LowerthevalueofPdenoteshigherwillbeitscontribution. Theorderofpercentagecontributiononwearperformance of HFREC is Sliding Distance (P=83.77%)>>>Load (P=13.23%)>>>Wt. % of HFREC (P=2.35%).It is depicted fromthefigure3thatfactorcombinationofA3,B1,andC2 giveslowestspecificwearrateforHFREC.Thespecificwear rateresultsofHFRECarepresentedintable3.Outcomesof thesimilartestconditionsisincorporationoframiefibers alongwithglassfibershowsmuchlowerwearratedueto the good wear resistant properties of ramie fibers.The analysis of variance (ANOVA) is studied to know the statisticalsignificanceofthecontrolparameters.ANOVAis performedfor5%significancelevelofconfidence.Table4 showsANOVAresultsofHFREC.FromtheANOVAtableitis clear that the factor sliding distance (P=0.008) is highly significantfactorfollowedbyload(P=0.046),andWt.%of HFREC (P=0.212) was the least influencing factor. Last column of table P% shows the percentage contribution of eachfactor.Thereforeitisclearfromthisanalysis,thatthe incorporationoframiefibersinacompositesshowsbetter mechanicalandabrasivewearproperties.

4.

ofHFREC

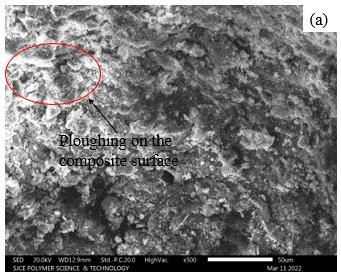

The worn surface morphology of worn out samples was investigatedusingscanningelectronmicroscope.Abrasive wear often caused by three separate mechanisms: micro ploughing,microcutting,andmicro cracking.Inthree body abrasivewear,dryandlooseabrasiveparticlesareutilized; the material removal rate is determined by a variety of factorsthatregulatetheamountofeffortnecessarytoinduce materialfailure[12,13].

Wornsurfacesofhybridcompositeswiththecompositions Ra30G10, Ra20G20, and Ra10G30 were examined under SEM to comprehend structural changes such as scratches, groovesandsmoothsurfaceswhensampleswereexposedto

load and sliding distance, as shown in Fig. 4 (a c). This investigationalsohelpsinexaminingwearconditionsand theirimpactonthefibresandmatrix.TheSEMmicrograph of the Ra30G10 hybrid composite is shown in Fig. 4 (a). Duringthetestingofthecomposite,adefinitefailurecanbe seen, as well as debris. Deep ploughing is generated even whenasmallerloadof10Nisappliedtothecomposite.This exhibitstheramie/glassfiber reinforcedcomposite'spoor weightbearingcapabilities.

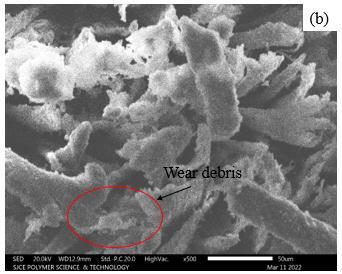

Fig.4(b)showstheSEMmicrographofRa20G20ataloadof 30N,fromthemicrographitisclearthathybridcomposite eventuallylosestopsurfacehoweverthereisnoindication of fibre breakdown. However, deboning of the reinforcements and the matrix has only just occurred.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3121

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Furthermore, abrasion and cracks are detected on the samplesurfacethatwasdrivenbyagreaterslidingdistance, aswellasincreaseddebrisaccumulation.

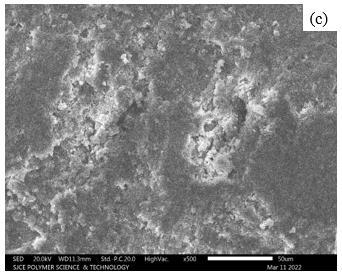

Figure 4 (c) depicts the micrograph of Ra10G30 sample. From the micrograph it is found that lowest wear rate obtainedinRa10G30compositewiththemaximumsliding distanceless weardebriscanbeseen[14].Alsothere is a goodregistrybetweenfibresurfaceswiththematrix,which

maybethereasonfortheexceptionalwearresistancefound in the hybrid composite. This finding was consistent with previousstudyfindings,whichstatedthattheincorporation ofglassfibreisencouragedfornaturalfiber basedpolymer compositesinordertoimprovethewearbehaviourofthe composites [15, 16]. Thus, strong adhesion between the reinforcementsandtheepoxymatrix,aswellasthestiffness ofthefibre,maybeascribedtoasubstantialdecreaseinthe wearrateofthesecomposites.

Fig. 4 (a-c): SEM picture of worn surface of HFREC - 4(a) Ra30G10, 4(b): Ra20G20, 4(c) Ra10G30

In this research glass fiber and ramie fiber reinforced epoxy hybrid composites was developed by hand layup method with the aid of compression moulding technique. The manufactured composites are tailored according to ASTM standards and tested for three body abrasive behaviourwithdifferentparameterslikecompositecontent, load and sliding distance with the help of L9 orthogonal array. The wear surface morphology also studied using scanningelectronmicroscope.Thefollowingconclusioncan bedrawn.

• Fromthemaineffectplotsoptimalparameterswas foundtobeA3,B1,andC2giveslowestspecificwearratefor HFREC.

• From the ANOVA table it is clear that sliding distance (P=0.008) is highly significant factor followed by load(P=0.046),andWt.%ofHFREC(P=0.212)wastheleast influencingfactor.

• From the SEM micrographs it was observed a perfect registry between glass fibers/ramie fiber and the epoxymatrix.Alsothewearmechanismslikemicroplaguing, micro cutting, and micro cracks can be clearly seen. The betterwearresistancewasseeninRa10G30composites.

1. M. Ramesh, K. Palanikumar, and K. Hemachandra Reddy,“Plantfibre based bio-composites:sustainable and renewable green materials,”Renewable andSustainable EnergyReviews,vol.79,pp.558 584,2017.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3122

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

2. M.Ramesh,“Hemp,jute,banana,kenaf,ramie,sisal fibers,” in The Textile Institute Book Series, Handbook of PropertiesofTextileandTechnicalFibres(SecondEdition), pp.301 325,WoodheadPublishing,2018.

3 A. Shahzad, “Hemp fiber and its composites a review,” Journalof Composite Materials, vol. 46, no. 8, pp. 973 986,2012.

4. K. S. Ahmed, S. Vijayarangan, and A. C. B. Naidu, “Elasticproperties,notchedstrengthandfracturecriterion inuntreated woven jute glass fabric reinforced polyester hybridcomposites,”MaterialsandDesign,vol.28,no.8,pp. 2287 2294,2007.

5. P.Lyu,L.Xia,X.Jiangetal.,“Efficientextractionof technical fibers from hemp in an ethanol water mixture,” IndustrialCropsandProducts,vol.178,2022.

6. G.Marom,E.Drukker,A.Weinberg,andJ.Banbaji, “Impact behaviour of carbon/Kevlar hybrid composites,” Composites,vol.17,no.2,pp.150 153,1986.

7. J.S.,S.M.S.,O.Z.,K.P.,andS.T.,“AComparisonof the Mechanical Properties of Phenol Formaldehyde Composites Reinforced with Banana Fibers and Glass Fibers,”Compos.Sci.Technol.,vol.14,no.62,pp.1857 1868, 2002.

8. A. Bindal, S. Singh, N. K. Batra, and R. Khanna, “Development of Glass/Jute Fibers Reinforced Polyester Composite,” Indian J. Mater. Sci., vol. 2013, pp. 1 6, Nov. 2013,doi:10.1155/2013/675264.

9. M. Ramesh, K. Palanikumar, and K. H. Reddy, “Comparative Evaluation on Properties of Hybrid Glass Fiber Sisal/Jute Reinforced Epoxy Composites,” Procedia Eng., vol. 51, pp. 745 750, 2013, doi: 10.1016/j.proeng.2013.01.106

10. D. Romanzini, H. L. Ornaghi, S. C. Amico, and A. J. Zattera, “Influence of fiber hybridization on the dynamic mechanical properties of glass/ramie fiber reinforced polyestercomposites,”J.Reinf.Plast.Compos.vol.31,no.23, pp. 1652 1661, Dec. 2012, doi: 10.1177/0731684412459982.

11. K.Kapila,S.Samanta,andS.Kirtania,“Fabrication and Characterization of Ramie Fiber Based Hybrid Composites,”inRecentAdvancesinMechanicalEngineering, K.M.Pandey,R.D.Misra,P.K.Patowari,andU.S.Dixit,Eds. Singapore: Springer Singapore, 2021, pp. 839 848. doi: 10.1007/978 981 15 7711 6_83.

12. S.Taj,M.Ali,andS.Khan,“Naturalfiber reinforced polymercomposites,”Pak.Acad.Sci.,vol.2,no.44,pp.129 144,2007.

13. S.E.Gad,“Polymers,”inEncyclopediaofToxicology, Elsevier, 2014, pp. 1045 1050. doi: 10.1016/B978 0 12 386454 3.00912 X.

14. R. Maria Florea and I. Carcea, “Polymer Matrix Composites Routes And Properties,” Int. J. Mod. Manuf. Technol.,vol.4,2012.

15. R. Petre, N. Petrea, G. Epure, and T. Zecheru, “Polymer Composite Materials And Applications For ChemicalProtectionEquipments,”Int.Conf.Knowl. BASED Organ., vol. 21, no. 3, pp. 873 877, Jun. 2015, doi: 10.1515/kbo 2015 0148.

16. D.H.V.,L.Naik,andY.B.,“ProcessingTechniquesof PolymerMatrixComposites AReview,”Int.J.Eng.Res.Gen. Sci.,vol.4,no.3,Jun.2016.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3123