International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

1Research Scholar, Department of Mechanical Engineering, Vidya Vikas Institute of Engineering and Technology, Mysuru

2Professor, Department of Mechanical Engineering, Vidya Vikas Institute of Engineering and Technology, Mysuru ***

Abstract Natural fibres have recently paying close attention to synthetic fibres in a variety of areas, including building, packaging, and automobile. In comparison to thermoplastic and thermoset matrices, the use of natural fibres as reinforcement in composite materials has progressively increased. The present work is to validate the impact of E glass and ramie fibre with epoxy matrix for cost effective composite materials. The composite material is processed through the hand lay up with compression moulding process to make PMCs. Mechanical characteristics areexaminedbyconductingtestssuchastensiletest,Flexural test, impact test and hardness on the produced samples of polymer matrix composite. Tensile test results of several laminatesrevealedthatthespecimenwith50%glassfibreand 40% ramie fibre has the highest tensile strength. In addition, equal amount of glass fibre and ramie fibre has shown better flexural strength and hardness. However, enhanced impact strength can be obtained with 50% wt. of ramie fibre. The mechanicalcharacteristicsobtainedforglassandramiefibres are validated with the analysis of grey relational model.

Key Words: Natural fiber, glass fibers, Hand layup, Grey Relational Analysis

Materials are the building blocks of human progress and well being.Sincethedawnofcivilization,mankindhavehad accesstoandusedmanytypesofmaterials.Examiningthe developmentofhumancivilizationrevealsthatitisbuilton human access to and use of materials, as well as science, technology, and social productive forces. It signifies humanity's power to understand and transform nature. Productionflourishesandcivilizationprogresseswhenevera newepoch makingmaterialisfound.Thus,materialshave cometosignifyhumancivilization'sdevelopment,aswellas a line that separates the past from the present. Elevated polymersandcomposites,whichfirstaroseinthetwentieth century,haveinvadedtheeconomicdevelopmentandsocial unitsina variety of industriesatan unimaginable pace of development. They have replaced conventional materials and have demonstrated enhanced performance. Materials nowplayamajorroleinthenationaleconomyandmilitary, thankstofastadvancesinscienceandtechnology[1].

Interfacial adhesion between matrix and fibres is a major factorin determining the tensilecharacteristicsof natural fiber reinforcedthermoplasticsandthermosets,accordingto Ku & Wang et al [2]. As far as mechanical qualities are concerned, jute reinforced polyester composites were shown to have superior strength than wood composite materialswhenevaluatedfortheirmechanicalpropertiesas reportedbyGoudaetal[3].Josephetal[4]alsoexamined banana fibre and glass fibre with varied fibre length and composition. The mechanical characteristics of these compositeswereanalyzed,anditwasdiscoveredthatstrong composites could be effectively made employing banana fibreasareinforcingelement.Pavithranetal[5]compared theimpactcharacteristicsofunidirectionallyorientedsisal fiber polyester composites to those of ultra high density polyethylene(UHDPE)andglassfibrecomposites.Whenthe densityofsisalfibrecompositesisconsidered,theworkof fractureissimilartothatofultra high moduluspolyethylene composites, and the toughness of sisal fibre composites is only 25% less than that of glass fibre composites. The abrasivewearbehaviorofbagassefibrereinforcedpolymer (BFRP) composites has been described by Mishra and Acharya[6].Abrasivewearrateislargelydependentonload andabrasivegrainsize,accordingtoBFRPcomposite.The rate of wear grows as the load and grit size increase. Composites' wear rates are greatly affected by the orientationoftheirfibres.Yongetal[7]studiedthenatural fibersandbiodegradableresinswhichwereusedtoprepare environment friendlybiodegradablecompositesbecauseof theiradvantagessuchaslowdensity,lowcost,acceptable specificstrengthandbiodegradability.Therecentresearches and developments of green composites were reviewed in this paper. The goal of Rao et al [8] is to introduce novel naturalfibresintopolymericmatrixessothatcompositesfor load bearingconstructionsmaybemadeeconomicallyand lightweight. An extraction procedure of vakka, date and bamboo fiber has been taken. Singh et al [9] studied mechanical behavior of banana fiber based hybrid composite. Increased elasticity and decreased tensile strengthmaybeachievedbyincludingbananafibreintothe epoxy.Thetensilestrength, compressive strength,and in planeshearstrength of a carbon fibre reinforced polymer matrix weremeasuredby PrashanthBanakaretal [10] at both room temperature and high temperature. The test resultsareexaminedstatistically.Comparedtospecimensat roomtemperature,samplesatelevatedtemperaturewere

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3112

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

showntohavealowerlevelofstrength.AccordingtoNirmal etal[11],compositelaminateswithpolyethylenefibreplies on the bottom face of unidirectional carbon fiber/Poly (methyl methacrylate) composite laminates have higher flexuralstrengththanthosewithpoly(methylmethacrylate) fibre plies alone in a hybrid composite. A study by Raghavendraetal[12]focusedatthetensile,compressive, andin planeshearstrengthsofwovenglassfibrereinforced polymermatrixatambientandhightemperatures.Anepoxy compositereinforcedwithglassandramiefibresistested fortensilestrength,flexuralstrength,impactstrength,and hardness,andthefindingsarethenconfirmedviatheuseof greyrelationalanalysis.

Reinforcement in the material is provided only by glass fibres, which have been proven to have remarkable fiber forming properties. Its high strength and stiffness, cheap cost, low density, high production rates, non flammable, superiorchemicalresistanceandheatresistancehavemade E glass a popular fibre glass material. In polymer matrix composites,E Glassisoftenutilizedasareinforcingmaterial. Optimalstrengthattributesmaybeachievedwhenfibresare alignedinasingledirection. Strengthmaybeincreasedin multipledirectionsbyconstructinglaminatestructureswith continuousfibresorientedappropriately.Asaresult,oneof thereinforcingmaterialsisE glassfibre.Ramieisoneofthe oldestfibreandisatypeofbastfibre.Becauseramiefibre maybereinforcedwithavarietyofcomposites,itcangive improvedmechanicalqualitiesforavarietyofapplications. Hence, ramie fibre was also chosen as the reinforcing materialandepoxyresinwaschosenasthematrixmaterial forthisinvestigation.Thematerialsarechosenbasedonthe literature review conducted for different combinations of composite. Different mechanical characteristics are evaluatedbyconductingtestssuchastensiletest, flexural test,impacttestandhardnessontheproducedsamplesof polymermatrixcomposite.TheASTMstandardsareusedto prepare the samples for the tests. The evaluation of mechanicalpropertiesiscarriedoutforindividualPMC.The Natural&SyntheticfiberslikeRamie,EglassfibreandEpoxy areprocuredfromGoGreenProducts,Chennai.

Thecharacteristicsofthematerialsusedandtheprocedures usedtofabricateandtestindividualPMCsarediscussedin depthintheexistingwork.

Thehandlay upwithcompressionmouldingprocessisone of the most popular ways to make PMCs. Cleaning, gel coating, laying up, curing, and component removal are all considered hand lay up methods for processing PMCs.

Followingtheselectionofthefoundationmaterial,various weightproportionsofreinforcementsareusedtoprepare thestructure.Inthismethod,twomatchedmetalmouldsare usedtofabricatecompositeproduct[13].Thebaseplateofa compression moulder moves, while the upper plate is stationary.Themetallicmouldisfilledwithreinforcement andmatrix,andtheentireassemblyisheldinplacebetween compressionmoulders.Foracertainamountoftime,heat and pressure are applied in compatible with the requirementofcomposite.Duetotheapplicationofpressure andheat,thematerialplacedbetweenthemouldingplates flows and precisely conforms to the shape of the mould cavity,dependingonthemoulddesign.Atroomtemperature or at a higher temperature, the composite may be cured. Aftercuring,themouldisopenedandthecompositeproduct removedforfurtherprocessing.

Tensile tests are performed on fully standardized electromechanical or Universal Testing Machines (UTM) according to the ASTM D638 standard [14]. Universal testing machines are widely available, with sizes ranging from0.02Nto2000kN.

Stress, MPa Strain,%

FIGURE 1. Effectofstress straincurveoncomposite

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

(a)

(b)

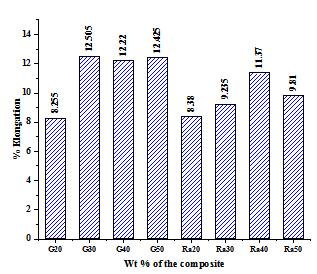

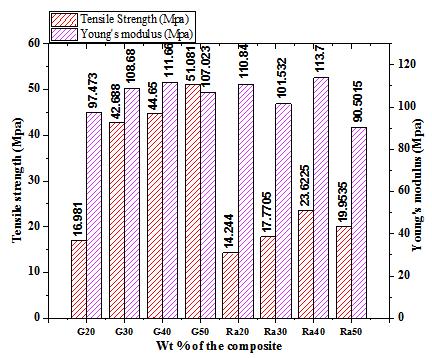

FIGURE 2. (a)Effectoftensilepropertiesofcomposite(b) Percentageelongationofcomposite

Tensile test results of several laminates revealed that the specimenwith50%glassfibreand40%ramiefibrehasthe highest tensile strength. Fig. 2 shows the results of the tensiletest,whichshowthatglassfibrewithaweightof50% has a higher tensile strength than other prepared composites.ThisisbecausethedefectsintheE glassfibre havebeenreduced.The40percentwt.ramiefibrealsohas exceptional tensile strength, modulus, and percent elongationamongthevarious compositionsoframiefibre [15 17]

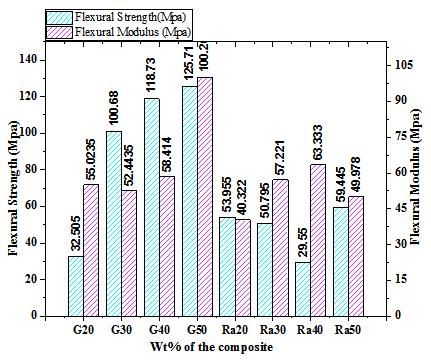

Flexuraltestsarecommonlyusedtodetermineamaterial's flexuralstrengthandmodulus.Flexuralmodulusandflexural strength are both used to assess a material's ability to sustain bending forces.The most common flexural test

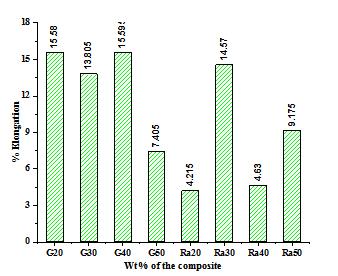

performedonUniversalTestingMachinesisthethree point bendingtest(UTM).Standardspecimensforflexuraltesting arepreparedaccordingtoASTM D790[18].Theflexural strengthand%elongationasshowninfigure3(a)and(b). Amongthevariedcompositionsofglassandramiefibres,50 %wt,ofglassfibreshowedthebestbreakloadand20%wt, ofglassfibreshowedtheleastbreakload.Asaresult,glass fibre with a weight of 50% has increased the specimen's flexural strength and flexural modulus. However, the laminate'sflexuralstrengthandmoduluscanbeshownto followasimilarpatterntothoseofitstensilecharacteristics whentheramiefibrecontentisvaried.Duetothegreater numberoffibrebundlespresentasabridge,theresistance toloadisgreaterwhenthecompositionoframieisincreased [19].Thelossofstrengthinthespecimenwith20%wt.of glassfibreisduetoagglomerationcausedbypoorbonding between the fibre reinforcement and the matrix material [15 17]

FIGURE 3. (a)Effectofflexuralpropertiesofcomposite (b)Percentageelongationofcomposite

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

16

14

12

10

8

2

4

6

Theamountofenergyabsorbedduringfractureisusedinan impact test to measure the material's resistance or toughness.Themostcommonapplicationofimpacttestingis to validate material behavior at maximal deformation speeds. The impact test is carried out in accordance with ASTMD 256. 4.3

17.6 18.6 0.22 0.48 1.35 2.3 G20G30G40G50Ra20Ra30Ra40Ra50 0

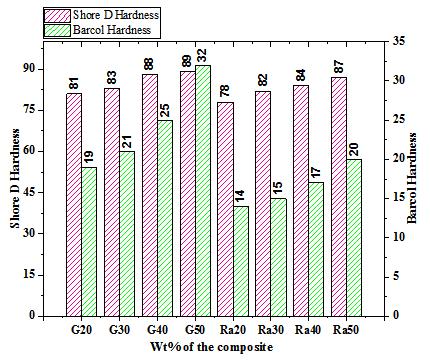

cuttingresistance.Toevaluatethehardnessofasurface,the ASTMD2240andD2583standardsarefollowedforShoreD and Barcol Hardness Test. Fig. 5 represents the hardness values obtained for the prepared samples The maximum Shore D and Barcol hardness values of 89 and 32, respectively, were achieved with 50% wt. of glass fibre. Uniformfibredistributionhasledtoanincreaseinhardness.

11.4

When the results of the impact test were analyzed, it was discoveredthattheimpactstrengthoftheramiefibreswas lowerthanthatoftheglassfibrereinforcement.Asaresult, fillers in glass fibres assisted in absorbing more energy duringtheimpacttest[20].Glassfibrewithaweightof50% hasabsorbedmoreenergyof18.6kJ/m2.Ramiefibre(20% wt.)absorbstheleastamountofenergy,asseeninfigure4.

Materialshardnessisaqualitythatallowsittoresistplastic deformation,mostcommonlythroughpenetration.However, hardnesscanalsoapplytobending,scratching,abrasion,or

FIGURE 5. ShoreDandBarcolhardnessofcomposite

Grey Relational Analysis (GRA) is a technique for determining the optimal condition of numerous input parametersinordertoacquirethehighestpossiblequality features. GRA is often used in analyzing or appraising the performanceofacomplicatedprojectwhenonlya limited amountofinformationisavailable.Byassigningweightages toindividualresponses,GRAmaybeusedtodeterminethe optimalconditionformulti objectivechallenges. TABLE 1. GreyRelationalCoefficientsandGreyGradesofcomposite

0.580 3 G40 0.825 0.926 0.927 0.302 0.946 0.611 0.741 0.871 0.873 0.417 0.902 0.563 0.728 2 G50 1.000 0.764 1.000 1.000 1.000 1.000 1.000 0.679 1.000 1.000 1.000 1.000 0.947 1

Ra20 0.000 0.000 0.254 0.000 0.000 0.000 0.333 0.333 0.401 0.333 0.333 0.333 0.345 8

Ra30 0.096 0.816 0.221 0.282 0.014 0.056 0.356 0.731 0.391 0.411 0.337 0.346 0.429 5

Ra40 0.255 1.000 0.000 0.384 0.061 0.167 0.401 1.000 0.333 0.448 0.348 0.375 0.484 4

Ra50 0.155 0.187 0.311 0.161 0.113 0.333 0.372 0.381 0.420 0.373 0.361 0.429 0.389 7

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

GRGrepresentsastrongercorrelationbetweentheresponse andtheinputvariables.Fromthetable 1representsGlass fibrewith50%wt.hasamaximumaverageGRGvaluewith rank 1, it is the condition where all the properties of a specimen are optimal with 50% wt. glass fibre reinforced withepoxyresin.Amongtheramiefibres,Ra40i.e.,40%wt. oframiefibrehasamaximumaverageGRGvaluewithrank 4, whereas 30% wt. of ramie fibre has the second largest averageGRGvalue.SinceRa40hasranked1withaverage GRGvalueof0.484,itisconsideredtobeanoptimallevelof composite.

Mechanical properties of the different compositions of E glass, ramie and epoxy used to prepare the individual compositesbyPortableCompressionMouldingMachineare concludedasfollows,

Tensiletestresultsrevealedthatthespecimenwith 50% glass fibre and 40% ramie fibre had the highesttensilestrength.

Glassfibrewithaweightof50%hasincreasedthe specimen'sflexuralstrengthandflexuralmodulus.

TheimpactstrengthofGlassfibrewithaweightof 50%hasabsorbed22.26kJ/m2moreenergy,Ramie fibre(20%wt.)absorbstheleastamountofenergy, inthiscomposites.

50%wt.glassfibreobtainedthegreatesthardness valuesof89and32ofShoreDandBarcolhardness respectively, the increased values of Shore D hardnessisduetothearrangementoffibers.

GRGrepresentsastrongercorrelationbetweenthe responseandtheinputvariables.Glassfibre with 50% wt. has a maximum average GRG value with rank1.Itistheconditionwhereallthepropertiesof a specimen are optimal with 50% wt. glass fibre reinforcedwithepoxyresin.

1. Ru Min Wang, Shui Rong Zheng and Ya Ping Zheng, “Polymer Matrix Composites and Technology”, Woodhead publishinginMaterials

2. H Ku, H Wang, N Pattarachaiyakoop and M Trada, “A reviewonthetensilepropertiesofnaturalfibrereinforced polymercomposites”,UniversityofSouthernQueensland

3.TMGowda,ACBNaidu,andRChhaya,“SomeMechanical Properties of Untreated Jute Fabric Reinforced Polyester Composites”,JournalofCompositesPartA:AppliedScience andManufacturing,30(3)(1999),pp.277 284.

4.SJoseph,MSSreekala,ZOommen,PKoshy,andTSabu,“A Comparison of the Mechanical Properties of Phenol FormaldehydeCompositesReinforcedwithBananaFibers and Glass Fibers”, Composites Science and Technology, 62(14)(2002),pp.1857 1868.

5.PavithranC,MukherjeePS,BrahmakumarM,Damodaran AD,“Impactperformanceofsisal polyestercomposites”, JournalofMaterialsScienceLetters,London,Volume7,pp. 825 826,1988.

6.PunyapriyaMishraandSKAcharya,“Anisotropyabrasive wear behavior of bagasse fiber reinforced polymer composite”, International Journal of Engineering, Science andTechnology,Vol.2,No.11,2010,pp.104 112.

7 CAO Yong, GODA Koichi, CHEN Hemei, “Research and development of green composites”, Chinese Journal of MaterialsResearch,Vol.21,No.2,April2007.

8. Murali Mohan Rao K, Mohana Rao K, “Extraction and tensilepropertiesofnaturalfibers:Vakka,dateandbamboo CompositeStructures”,volume77,(2007),288 295.

9.SinghVK,GopePC,ChauhanSakshi,BishtDeepakSingh, “Mechanical Behavior of Banana Fiber Based Hybrid Bio Composites”,J.Mater.Environ.Sci.3(1)(2012),ISSN:2028 2508,185 194.

10.PrashanthBanakar,H K Shivananda,“Preparationand CharacterizationoftheCarbonFiberReinforcedEpoxyResin Composites”,ISSN:2278 1684,Volume1,Issue2,2012,pp. 15 18.

11.NirmalSaha,AmarNathBanerjee,“Flexuralbehaviorof unidirectional polyethylene carbon fibers PMMA hybrid compositelaminates,”J.App.Poly.Sci.Volume60,1996,pp. 139 142.

12. M Raghavendra, C M Manjunatha, M Jeeva Peter, C V Venugopal andHK Rangavittal, “Effectofmoistureonthe mechanicalpropertiesofGFRPcompositefabricmaterial”, InternationalSymposiumofResearchStudentsonMaterial ScienceandEngineering,2004.

13. Dipen Kumar Rajak, Durgesh D Pagar, Pradeep L Menezes and Emanoil Linul, “Fiber Reinforced Polymer Composites: Manufacturing, Properties, and Applications” InstituteofEngineeringEducation&Research,12October 2019.

14. Zainab Raheem, “Standard Test Method for Tensile PropertiesofPlastics1”,January2019,DOI:10.1520/D0638 14.

15. Ravi Gupta, Kamlesh Kushwah, Sanjay Goyal, Brijesh Gangil,AnkushSharma,“Ramie glassfiberreinforcedepoxy composites Impact of walnut content on mechanical and slidingwearproperties”,JournalofMaterialsScience,2020.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

16.RajivKumar“Dryslidingfrictionandwearbehaviorof ramie fiber reinforced epoxy composites”, Materials ResearchExpress,2018.

17.ElsevierBV,“FlexuralPropertiesofSymmetricCarbon and Glass Fibre Reinforced Hybrid Composite Laminates”, Journalspreproff,25September2020.

18. B.C. Chakraborty, Debdatta Ratna, “Experimental techniques and instruments for vibration damping”, PolymersforVibrationDampingApplications,2020.

19.SinghDP,“Ramie(BohmeriaNivea)”,CentralResearch InstituteforJuteandAlliedFibers”,W.Bengal.

20. R N Rothan, “Mineral Fillers in Thermoplastics: Filler Manufacture and Characterization”, Advances in Polymer Science,Volume139,1999,pp67 107.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal