International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

1

Abstract:

Friction stir processing (FSP), a process, derived from the friction stir welding (FSW) process, is an emerging novel, green and energy efficient processing technique to fabricate surface composite. In the present study,theFSPtechniquehasbeenusedforthefabrication of surface composites using AA7075 as base metal and TitaniumDioxideandSiliconCarbidepowdersareusedas reinforcement. AA7075 has been selected as the matrix phase, as being widely used by the automotive and aerospaceapplicationandhasthehigheststrengthamong allcommercialAlalloys. Inpresentworkdetailsaboutthe fabrication of surface composites using various reinforcement combinations like AA7075 SiC, AA7075 TiO2 and AA775 TiO2+SiC at constant tool rotation, tool travel speed and number of passes have been discussed. The mechanical characterization like ultimate tensile strengthand wear resistance offabricatedcomposites are steadied Wear Resistance is found to be improved compared to the parent metal. It is found that yield strengthisalsoenhancedthanthebasematerial.

Keywords: Friction Stir Processing, Surface Composites, AA7075, Titanium Dioxide, Silicon Carbide, Tensile strengthandwearresistance

Introduction:

Friction stir processing principle is same as friction stir welding technique which is used for microstructural modifications1 FSW is used for joining purpose but FSP is developed to modify the surface properties of base materials2, 3 . The pin of the solid FSP tool plunges into the material. While rotation of the tool heat is generated at contact surfaces of shoulder and pin withworkpiecematerialduetofrictionbetweensurfaces Material is plastically deformed and recrystallized at stir zone.Itwasobservedthatsurfacepropertiesofreinforced friction stir process materials were enhanced when compared with unreinforced friction stir processed materials. The hardness of SiC reinforced friction stir

processed of AA6061 T4 is enhanced by 20 HV at 1600 RPMrotationalspeedand80mm/mintraversespeedand observed that SiC particles were dispersed and grain size reducedwhichcausesthegrainsizerefined1,4 Toimprove thepropertieslikemeltingpoint,strainratesensitivityand tribologicalofAA7075,boroncarbideparticlesofdifferent sizes like 160 µm, 60 µm and 30 µm were added using friction stir processing1,5. It was observed that the surface cracks are formed along the tool traverse direction at higher turning speed due to severe plastic deformation and also observed that the improper mixing of boron carbide reinforced particles due to low rotational speed like less than 750 rpm. Surface metal matrix composite wasformedwithoutanydefectsatrotationalspeedof925 to 1000 rpm and traverse speed of 30 mm/min and hardnessofmaterialisenhanced1,5 .AluminiumAlloy6063 is friction stir processed using boron carbide (B4C) and titanium diboride (TiB2) All the samples of 100% B4C, 25% B4C 75% TiB2 and 100% TiB2 are processed and compared.It was observed that the curtailment of gap between fine reinforcement particles by increase the proportionofTiB2particlesbecausetheTiB2particlesare more compact than B4C particles that had the notable impact on the hardness6 Al7075/B4C surface composite were fabricated using FSP at three different traverse speeds and tested wear and hardness properties. It was observedthatthereisnomuchconsiderableimpactonthe particlesdistributionatstirzoneandbest.Microhardness and wear resistance of friction processed samples were decreased byincreasingtraversespeed duetoinsufficient stirring time and lack of distribution of particles7 . After friction stir processed of AA6061with Al2O3 and CNTs Particles, It has been observed that the dispersion of particles was found to be more uniform as the number of thepasswereincreased.InAl2O3 Uniformdistributionwas observedbutinthecaseofCNTs,itwasnotvisiblebecause after first pass CNTs are breaking and they could not be observed after third pass. There is a considerable enhancement in yield strength and ultimate strength than base material when Al2O3 was added. There was an increaseinyieldstrengthbutultimatestrengthwasfound

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

tobe decreased in thecase ofonly CNTsadded.But when both Al2O3 and CNTs were added together as reinforcement the ultimate tensile strength and yield strengthincreasedremarkably 1, 8 Thehardnessoffriction stir processed aluminium alloy 7075 composites with silicon carbide and titanium dioxide reinforcement was increased.9.

The machine used for friction stir processing was a conventional vertical milling machine which was transformed into a friction stir welding machine and frictionstirprocessingmachinebydesigningafixturethat makes the milling machine capable of performing friction stir welding and friction stir processing. The fixture was fitted on the milling machine table. Two types of tools were used for this process the first tool without pin, and thesecondtoolusedforprocessingwas withpin.Thetool hasashoulderdiameterof20mmandataperedpinof3 6 mmdiameterofaheightof4.5mmasshowninfigure1

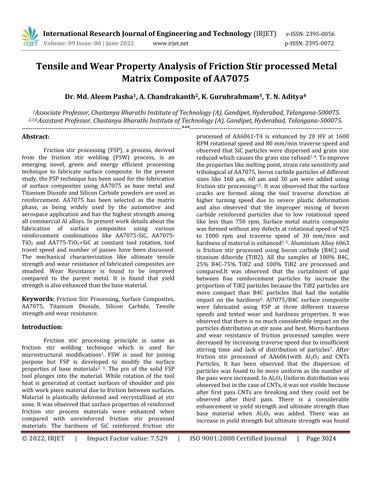

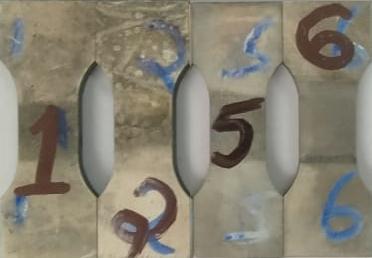

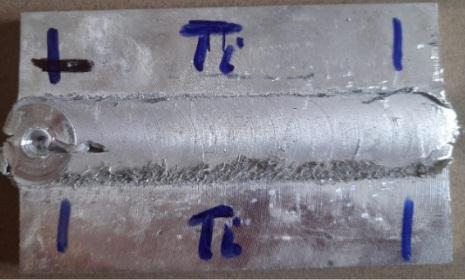

The grooves are filled using powders. The three plates arefilledwith15%volumeofTiO2,15%volumeofSiCand 15%volumeofTiO2+SiCrespectivelyassowninfigure4.

AluminiumAlloy7075sheetsweretaken.Thesheetswere produced into plates with the dimensions 100X60X6 mm as shown in figure2. A groove100X2X4 was developed on alltheplatesasshowninfigure3

The first pass is done with the tool without a pin andthenextthreepassesaredonewiththetoolhavingthe pin. Friction stir processing has been done at a rotational speed of 1110 RPM. 20 mm/min Traverse speed and 5KN Axialloadandtiltangleis20

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Therotationalmotionofthespindlestartsandthe tool comes into the contact with the surface of the plates and the probe is penetrated at the grove developed to a depth so that the shoulder of the tool is firmly in contact withtheplatethatneedstobeprocessed.Thetoolisgiven some time as it rotates in contact with the surfaces to softenthematerialduetothefrictionalheatproduced,this timeiscalleddwelltime,andafterthedwelltime,thetool is given forward motion. The tool without a pin is withdrawn after the first pass is done. The tool with the pinisfixedandconsecutive threepasseswereperformed. Theprocessleavesaholeinsuchawaythatthepartwith theholeinitiscutandnotusedforthefurtherprocess as shown in figure 7.Micro Hardness test was performed using Vickers hardness test on processed specimens. Hardness is measured and compared using base material hardness as shown in figure 8 Hardness of friction stir processedspecimenswasrecordedasshownintable1.

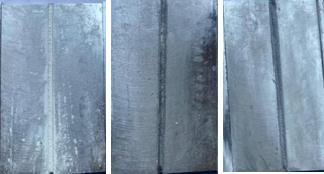

The tensile test specimens are e fabricated as per ASTM E8 2013 standards using Wire EDM as shown in figure 8. ThetestwasconductedonUTMMCS/UTE 20Tmachineof column clearance 500 mm and Capacity of 200KN The tensile test results are tabulated in table 1. The wear resistance specimens are fabricated as shown in figure 9. Specimensarecircularshapeof12mmdiameter.

TheweartestwasperformedonaPinonDiscMachinefor durationof8mintsat500 RPMspeedwith5KNload. The pin diameter is 12 mm, Track radius is 20 mm, sliding

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

distance502.655mmandslidingvelocityis1.0472m/sare considered. Wear Test results are tabulated as shown in Table2.

compared to Titanium dioxide and mixture of silicon carbide and titanium dioxide. Tensile strength of Friction stir processed composites was less compared to base material aluminium alloy 7075. Friction stir processed compositesarebrittleinnatureduetoadditionofceramic

reinforcement powders that’s whys tensile strength was decreasedbutyieldstrengthwasincreased..

It is observed that the wear resistance of the reinforced aluminium alloy 7075 is greater than that of the unreinforced aluminium alloy 7075. The unreinforced aluminium alloy 7075 wear resistance is 30.709 Micron. Greater wear resistance is observed in aluminium alloy 7075reinforcedwithSiC.

Table 1: UTM Test results

Runs Yield Strength (MPa)

Tensile Strength (MPa)

% of Elongation

AA7075+TiO2 100.92 113.86 1.60

AA7075+SiC 182.58 223.00 4.40

AA7075+SiC+TiO2 161.09 201.91 7.20

AA7075 Specimens of 6mm successfully friction stir processed with reinforcement.It is observed that the hardness of the FSP reinforced aluminium alloy7075 is greater than that of the unreinforced aluminium alloy 7075. The friction stir processed Aluminium Alloy 7075 composites yield strength was enhanced but tensile strength was decreased due to brittle in nature. Wear resistance of friction stir processed composite was increased compared to base material. Finally it has been observedthatthemechanicalpropertiesareenhanced.

References:

AA7075 140.00 228.00 1000 Runs WEAR(micron) AA7075+TiO2 34.781 AA7075+SiC 77.674 AA7075+SiC+TiO2 52.304 AA7075 30.709

Table 2: Wear Test Results

Theyieldstrengthsofthefrictionstirprocessedcomposite materials of AA7075 are increased than base material i.e AluminiumAlloy7075buttensilestrengthsoffrictionstir processed composite materials of AA7075 are decreased than base material. It has been observed that Silicon carbide reinforced composites yield strength was more

[1] Kaushal Kumar, PiyushGulati, and Akash Gupta, Dinesh Kumar Shukla, AReview of friction stir processing of Aluminiumalloys using different types of reinforcements, International Journal of Mechanical Engineering and Technology, Volume 8,Issue7,July2017,pp.1638 1651

[2] AxelFehrenbacher,NeilA.Duffie,NicolaJ.Ferrier, Frank E. Pfefferkorn, Michael R. Zinn. Effects of tool-workpiece interface temperature on weld quality and quality improvements through temperature control in friction stir welding. Int J AdvManufTechnol;2014;71:165-79.

[3] Xiaomin Deng, ShaowenXu. Two-Dimensional finite element simulation of material flow in the Friction Stir Welding process. J Manuf Process; 2004;6:125-33.

[4] Don-HyunCHOI,Yong-IlKIM,DAE-UpKIM,SeungBooJUNG.EffectofSiCparticlesonmicrostructure andmechanicalpropertyoffrictionstirprocessed

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

AA6061-T4.Trans.NonferrousMet.Soc.China22; 2012;pp614-618.

[5] I. Sudhakar, G. Madhusudhan Reddy, K. SrinivasaRao. Ballistic behavior of boron carbide reinforced AA7075 aluminium alloy using friction stir processing An experimental study and analyticalapproach.DefenceTechnology;2015;pp 1 7.

[6] Mohammad Narimani, BehnamLotfi, ZohrehSadeghian. Evaluation of the microstructure and wear behavior of AA6063 B4C/TiB2 mono and hybrid composite layers produced by friction stir processing. Surface & CoatingsTechnology285;2016;pp1 10.

[7] H.G.Rana,V. J.Badheka,A. Kumar.Fabricationof Al7075/B4CsurfacecompositebynovelFriction Stir Processing (FSP) and investigating on wear properties.ProcediaTechnology23;2016;pp519 528.

[8] ZhenglinDu,MingJenTan,JunFengGuo,GuijunBi, Jun Wei. Fabrication of a new AlAl2O3 CNTs composite using friction processing (FSP). Materials Science & Engineering A 667; 2016; pp 125 131.

[9] Dr.Md.AleemPasha,"FabricationofSurfaceMetal Matrix composite of AA7075 using Friction Stir Processing", International Journal of Scientific Research in Science and Technology (IJSRST), Online ISSN : 2395 602X, Print ISSN : 2395 6011, Volume 9 Issue 3, pp. 551 555,May June 2022. Available at doi: https://doi.org/10.32628/IJSRST2293108Journal URL:https://ijsrst.com/IJSRST2293108

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3028