International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

1Shine Elsa Mathew, M.Tech Student, Dept. of Civil Engineering, Sree Buddha College of Engineering, Kerala, India 2Midhila V.S, Assistant Professor, Dept. of Civil Engineering Sree Buddha College of Engineering, Kerala, India ***

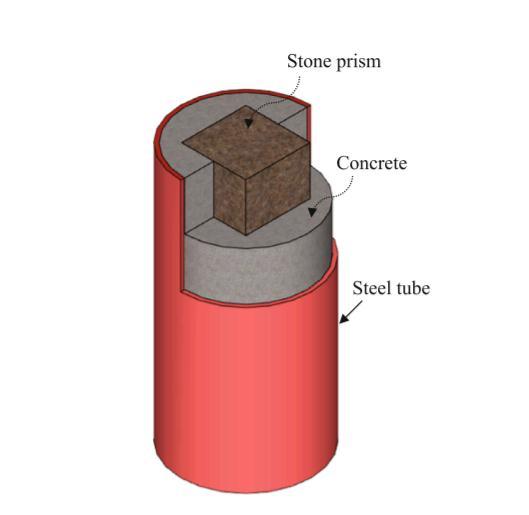

Abstract - The core component of the concrete filled steel tube (CFST) is replaced with a stone prism in this new type of CFST. This stone prism can be made either from newly mined and manufactured stone or from stone buildings that have been destroyed. Due to the high compressive strength of the stone and the efficient confinement offered by the steel tube, these columns should be able to support more weight than typical CFST columns. The high strength of the stone offers additional confinement from the inside of the concrete, therefore it is envisaged that the infilled stone prism will improve the local bearing behaviour of CFST. Using ANSYS software, thestructuralperformanceofthecompositecolumns encased in stone prisms under axial compression was investigated.

Key Words: Axial Compression, CFST, Composite, Confinement, Infilled, Stone prism, Ansys

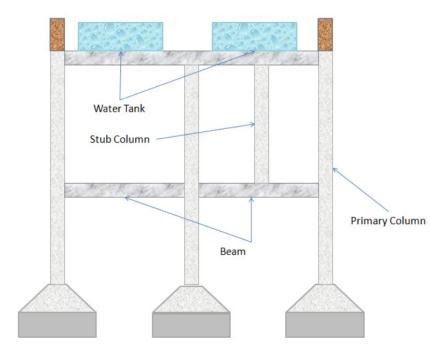

A vertical structural component intended to convey a compressive load is known as a column. The foundation receives the load from the beam and slab supporting the ceilingorroof,includingitsweight,throughacolumn.Asa result,itshouldbeclearthatifonecolumnfails,theentire structure will crumble. Stub columns are referred to as columnsthatarenotimmediatelyattachedtothefooting.To transfertheloadfrom the primary beam,it isbuilt over a beamoraslab.Stubcolumnshavearelativelysmallheight. Figure1displaysastubcolumn.Additionally,itisofferedif theroomislonger.Toincreasetherigidityofbuildings,stub columnsarealsoavailable.Itaidsinthetransmissionofload fromonebeamtoanother.Stubcolumnsareutilisedinthis project. In order to take advantage of each material's advantageousqualities,compositecolumnsareconstructed usingavarietyofstructuralsteelandconcretemixtures.The composite column is a rigid, economical, and hence structurally effective part in the construction of buildings and bridges due to the behaviour of concrete and steel elements.OnekindofpopularcompositecolumnistheCFST column. Concrete Filled Double Skin Tubes (CFDST), Reinforced Concrete Filled Double Skin Tubes, Composite Column System, Concrete Encased CFST column, and StiffenedCFSTcolumnaresomeofthedifferentvarietiesof CFST columns. Compared to regular steel or reinforced concrete, a concrete filled steel tube (CFST) column structurehasvariousbenefits

It was proposed that confining stone inside steel tubes wouldincreaseitsductility.Therefore,anewtypeofCFST memberissuggestedhere,knownasStonePrismEncased CompositeColumns,whichswapsoutthecoresectionofthe infilledconcretewithastoneprism.AStonePrismEncased CompositeColumnisexaminedinthisthesis.Additionally,a composite column encased in a stone prism of a different shape is also studied. ANSYS 21 is a finite element programmeusedformodellingandanalysis.

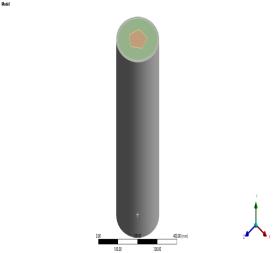

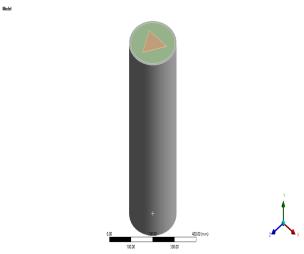

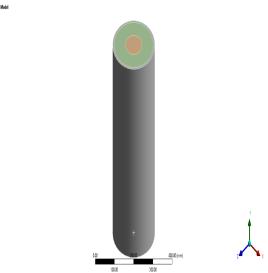

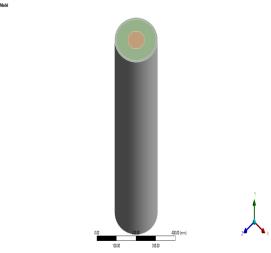

Hereasteeltubefilledwithstoneprismandconcreteis analyzedshowninFig.2.Thesteeltubeisofcircularshape anddifferentshapeofstoneprismsuchascircular,square, triangular,hexagon,rectangularandoctagonareusedhere. Materialusedforthestoneprismisgranite.Thisstoneprism can be either newly mined and fabricated or used from demolished stone structures. While considering the high compressive strength of stone blocks and the effective confinementofferedbythesteeltube,betterload carrying capacity could be expected in the stone prism encased concrete filled steel tubular members than conventional CFSTmembers.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Totallengthofsteeltube 600mm

Outerdiameterofsteeltube 219mm

Wallthicknessofsteeltube 8mm

Theinfilledstoneprismisexpectedtoimprovethelocal bearing behavior of CFST, since the high strength stone providesextraconfinementfromtheinsideoftheconcrete. The proposed system can also decrease negative environmentalimpactsbyreducingconcreteproductionand providingareusemechanismfordemolishedstoneblocks.

To investigatethe effect of circularsteel tube filled with concrete and different shapes of stone prism like circular, square,triangular,pentagonal,hexagonal,rectangularand octagonalunderaxialloading.

Itdealswiththedimensionaldetails,modellingdetailsand analysisandresultsofcircularsteeltubesfilledwithconcrete and different shapes of stone prism like circular, square, triangular,pentagonal,hexagonal,octagonalandrectangular inANSYSsoftware.

In order to determine the effective shape for the stone prism, six shapes of stone prism were selected for the analysis. The seven different shapes chosen for the comparisonarecircular,square,triangle,pentagon,hexagon, octagonandrectangular.Theendsupportingconditionwas providedasbottomendfixedandtheloadwasappliedonthe other end. The dimensional details of circular steel tubes filled with concrete and different shaped stone prism are giveninTable1andTable2.

Circular Diameter=84.7mm Height=600mm Square Width=75mm Height=600mm Triangular Width=114mm Height=600mm

Pentagon Width=57.2mm Height=600mm Hexagon Width=46.5mm Height=600mm Octagon Width=34.15mm Height=600mm Rectangle Width=113mm Height=600mm

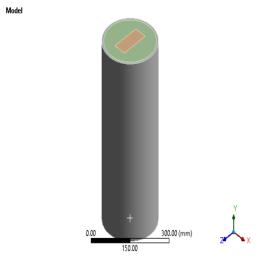

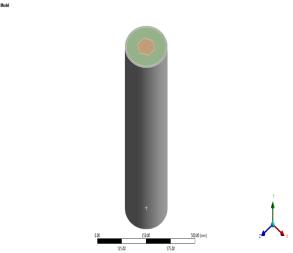

Modellingofcircularsteeltubesfilledwithconcreteand square shaped stone prism is done by using element type SOLID186.Coefficientoffriction0.3isgiven betweensteel tube and concrete to avoid the slip. Modelling of circular steel tube filled with concrete and square shaped stone prismisshowninFig.3.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

(e) (f)

(g)

Fig 2.1: Solidmodelofcircularsteeltubefilledwith concreteanddifferentshapesofstoneprism(a)Circular stoneprism(b)Squarestoneprism(c)Triangularstone prism(d)Pentagonalstoneprism(e)Hexagonalstone prism(f)Octagonalstoneprism(g)Rectangularstone prism

HeretheelementtypeusedisSOLID186.Elementshapeis ofhexahedron.Elementsizeprovidedforsteeltubeis10mm andasizeof30mmforconcreteandstoneprism.Loadingis done based on displacement convergence criteria with a valueof8mmandthecorrespondingultimatevalueisnoted.

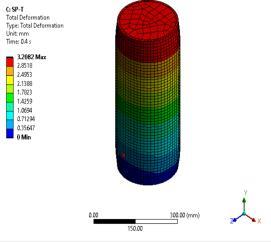

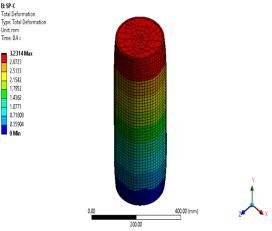

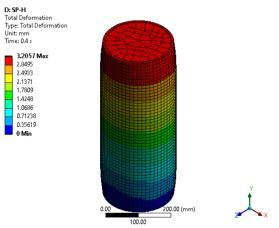

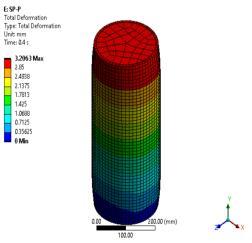

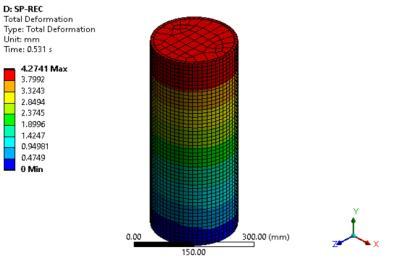

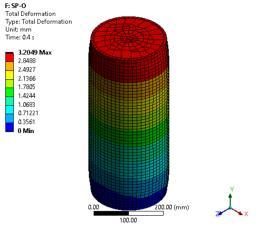

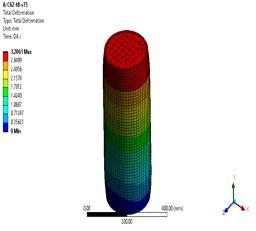

Non linear static analysis is carried out in circular steel tubefilledwithconcreteanddifferentshapesofstoneprism to find the maximum ultimate load corresponding to the deformation. The deformation of circular steel tube filled withconcreteanddifferentshapesofstoneprismareshown inFig.4.

(c) (d) (e) (f)

(g)

Fig 2.2: Deformationofcircularsteeltubefilledwith concreteanddifferentshapesofstoneprism(a)Circular stoneprism(b)Squarestoneprism(c)Triangularstone prism(d)Pentagonalstoneprism(e)Hexagonalstone prism(f)Octagonalstoneprism(g)Rectangularstone prism

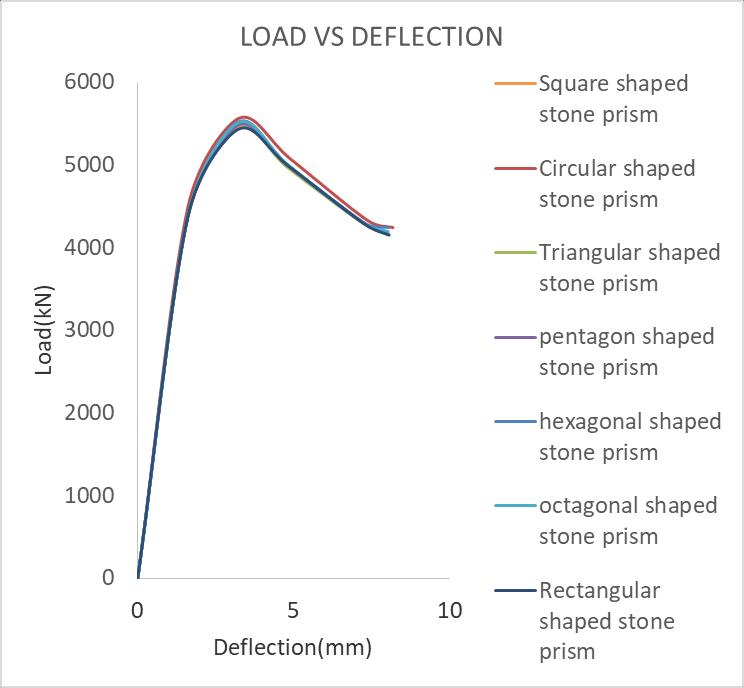

Theload deflectiongraphofDeformationofcircular steeltubefilledwithconcreteanddifferentshapesofstone prismisshowninFig.5

Table 3:Comparisonofresults

(a) (b)

ShapesofStoneprism Deflection(mm) Load(kN) Square 3.2061 5464.2 Circular 3.2314 5561.6 Triangular 3.2082 5470.7 Pentagon 3.2063 5481.6 Hexagonal 3.2057 5517.1 Octagonal 3.2049 5507.9 Rectangular 3.2158 5429.7

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

[1] YongYe,YangLiu,Stoneprismencasedconcrete filled steel tube columns subjected to axial compression, Structures33,(2021)1853 1867.

[2] NeetuDeviSingh,AnuragWahane,Bucklinganalysison CFSTcolumnswithdifferentslendernessratios&RCC columnsusingANSYS,InternationalJournalforResearch in Applied Science & Engineering Technology,2020, ISSN:2321 9653.

[3] Han LH, Xu CY, Tao Z,Performance of concrete filled stainless steel tubular (CFSST) columns and joints: Summary of recent research. J Constr Steel Res ;2019,152:117 31.

[4] Jing Liu, Zhe Li and Fa Xing Ding,Experimental Investigation on the Axially Loaded Performance of NotchedHexagonal Concrete FilledSteel Tube(CFST) Column,Volume2019,ArticleID2612536.

Chart

Herecircularshapedstone prismhasbetterultimateload carryingcapacitythantheothers.Thepercentageincreasein loadcarryingcapacityofcircularshapedstoneprismcarries 1.782%moreloadthanothers.

Thisstudyexaminesthestructuralbehaviourofacomposite columnencasedinaStoneprism.Analysisofstoneprismsis done to determine the best shape. The findings are as follows:

Stone prisms with a round shape have a higher maximumloadcarryingcapabilitythantheothers. The stone prism with a round shape has a 1.782 percent greater load carrying capability than the competition.

[5] Chen J, Chan TM and Castro JM, Experimental assessment of the cyclic behaviour of concrete filled steeltubularbeam columnswithoctagonalsections,Eng Struct2019;180:544 60.

[6] Shen Q, Wang J, and Ding Z,Axial compressive performance of circular CFST columns partially wrapped by carbon FRP. J Constr Steel Res 2019;155:90 106.

[7] WangY,YangLandYangH,Behaviourofconcrete filled corrugated steel tubes under axial compression , Eng Struct2019;183:475 95.

[8] TaoZhang,ChengzhiWang,BehaviorofConcrete Filled Steel Tube Columns Subjected to Axial Compression, Volume2018|ArticleID4059675.

Thereissymmetryinthecircularcolumn.Whilea rectangle only has two axes of symmetry and a square has four, respectively. In order to prevent bucklingfailure,themomentofinertiawillbethe samealongallaxes.

[9] Qing XinRena, KanZhoub, Dune sand concrete filled steel tubular (CFST) stub columns under axial compression:Experiments,Thin Walled Struct2018;124:291 302.

Thecircularcolumnhasnoweakplacesbecauseit isshapedlikeacylinder,unliketherectangularor squarecolumn,whichhasfour.

[10] M.H.Laia,J.C.M.Ho,Ananalysis basedmodelforaxially loadedcircularCFSTcolumns,Thin WalledStructures, 2017,Volume119,Pages770 781.

Thecircularcolumnisstrong incompressionwhen comparedtothesquarecolumninthesamecross sectionalarea.

[11] Ghanbari Ghazijahani, Hui Jiao and Damien Holloway,Concrete Filled Circular Steel Tubes with a Timber Infill under Axial Compression, Journal of StructuralEngineering,2017,Volume143Issue7.

[12] ZhangS,HuangLandChanC,Compressivebehaviorof hybriddouble skintubularcolumnswithalargerupture strainFRPtube.ComposStruct2017;171:10 8.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

[13] M.Pragna,Partheepan Ganesan, Analysis of Concrete FilledSteelTubesusingAnsys,InternationalJournalof Latest Engineering Research and Applications (IJLERA),2016,ISSN:2455 7137Volume 01,Issue 09, PP 71 78.

[14] Ye Y, Han LH, Sheehan T and Guo ZX,Concrete filled bimetallictubesunderaxialcompression:Experimental investigation,Thin WalledStructures2016;108:321 32.

[15] Vishal V. Gore, Popat D. Kumbhar, Performance of ConcreteFilledSteelTube(CFST) Section:AReview, International Journal of Science and Research (IJSR),2015,ISSN(Online):2319 7064.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |