International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

DESIGNING FRAMED STRUCTURE IN ETABS AND STAAD PRO

Aamir1, Ravinder2, Sheela Malik3, Rashid Ahmad4

1 (M.tech Scholar) 2nd year, Department of Civil Engineering, Ganga Institute of Technology and Management, Jhajjar Haryana (India)

2Assistant Professor, Department of Civil Engineering, Ganga Institute of Technology and Management, Jhajjar Haryana (India)

3Assitant Professor, Department of Civil Engineering, Ganga Institute of Technology and Management, Jhajjar Haryana (India) 4Civil Engineer ***

Abstract - As the use of steel building increases daily, it is crucial to create aesthetically pleasing structures that are also cost effective. Since no software is perfect, designers must rely on a variety of tools to create unique architectures, specific components, or connections. In this study, we'll create a PEB structure and assess its viability and simplicity using two distinct pieces of software, then compare the outcome.

Key Words: Software,designing,structure,BIM,steel,construction.

1. INTRODUCTION

Steelconstructionisgrowingdaybydayandit’simportanttodesignthestructureelegantlyandeconomically.Softwareisused todesignthestructureandhandcalculationiscarriedouttochecktheaccuracyofthedesign.Inmanycountries,it’simportant to check the integrity of design using hand calculation. There is various software in the market with each having certain capabilitiestodesigncertainstructuresmoreefficiently.Thereisvarioustypeofstructureandsomegeneralstructuresuchas concrete,steel,aluminum,andwoodstructureusedmoreoftenandcountrieshavedifferentcodesandregulationtodesign these structures. No software is complete and thus designers have to depend upon various software to design different structuresorcertainpartsorconnections.Inthisstudy,wegoingtodesignaPEBstructureandcheckthefeasibilityandease withwhichwedesignthesamestructureintwodifferentsoftwareandcomparetheresult.Wewillusethesameloadsand memberssizetodesignthestructure.Wewillcheckthequalityofthefinalresultsofthetwosoftware.

1.1 OBJECTIVE AND RESEARCH PROPOSAL Theobjectiveofthisresearchistocheckthedesigncapabilityoftwosoftware bycomparingtheresult.Thestructuredesignisasteelconnectionandthemembersusedindesigningisapproximatelythe same.

2. MATERIAL AND METHODS Beforedesigningthestructureweassumedvariousdataregardingthestructure,itsuse,its locationandtheforcesitcancountupon.WeassumedLSMmethodologyusingIndianstandardcodestodesignthemembers, thestructurefallsinearthquakezoneIVandthestructureisframedPEBstructureandthestructureispartiallyopened.

2.1 LIMIT STATE METHOD - Thelikelihoodofastructurefailingislowestwhenitisthoughtfullyplannedanddeveloped. Inordertoaccountforvariationsinmaterialpropertiesandtheloadtobesupported,thestructureisdesignedusing characteristicvaluesofitsmaterialstrengthsandappliedloads.Applyingpartialsafetyfactorsresultsindesignvalue.

ThedesignactionQdisexpressedas And,thedesignstrengthSdisobtainedas =

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Table

Section Object Type No of Pieces Length Weight m kN

member_700mm

Beam 34 154.098 166.0928 mem_1_prismatic_800mm_to_700mm Beam 22 147.3982 173.1145 member_2_prismat_700mm_to_900mm Beam 22 147.3981 227.7299

Column400mm Column 21 138.6 133.8249

Columnmiddle Column 26 130 124.8399 member_3_900_to_700 Beam 22 73.6992 113.8653 ISMC Beam 104 791.54 273.43

ROD50 Beam 36 366.54 16.72 ROD50 Brace 12 109.83 5.08

2.4 LOADS CALCULATION

–

Dead load DeadloadiscalculatedusingIndiancode875part1

Member’sDeadload

Therearetwoframesinthesection

1) Gabbleendframe

2) mainframeorcenterspanframe DeadLoad themembersinthemainframeconsistof membersofvarioussizesfromrodsectiontonon prismaticmembersconsisting = 3.1 KN/m DeadLoadintheEndframe GabbleEnds = 1.4 KN/m Loadsfromdifferentpartssuchassheets,purlin,HVACfitting, Solarpaneletc. = 40.0 Kg/m²

TheseloadsareeithercalculatedusingIS875part1thenassigntothemembersorcodescanbeselectedwhendesigning thestructureandweightcanbeassignedusingself weightoption.

Live load LiveloadscanbecalculatedusingIndiancode875part2

LiveLoadsonmembers areaonwhichliveloadactsis2600sqm2

Liveload/unitarea = 75.00 Kg/m²

DeadLoadcenterspan = 5.5 KN/m

DeadLoadGableEndSpan = 3 KN/m

Wind load ForcalculatingthewindloadweusedIS875part3

Vb =33m/s Isgivenby ( =0.9 Clause7.2.1

=0.80 Clause7.2.2 =0.90 Clause7.3.3.13

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2873

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

=0.648>0.7 =0.457KN/m2

PressureCoefficientsistakenfromIS875part3usingthefollowingvalues

PercentageAreaoftheOpening=9.65%(Between5%to20%)

Enclosurecondition= Partially Enclosed

ExternalPressureCoefficient Usetable4fromIS:875part3

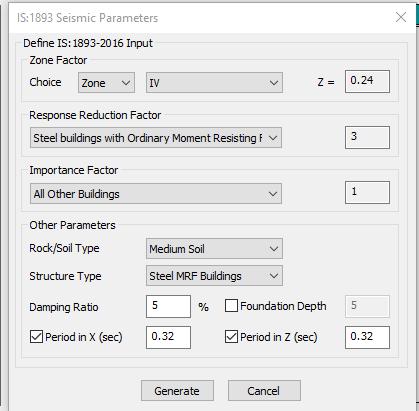

Earthquake load EarthquakeloadcanbecalculatedusingIndianstandardcode1893

TocalculateearthquakeloadaccordingtoIndianstandardfollowIS1893part1.

a) Findzoneforthestructure

b) Thestructureissteelbuildingwithordinarymomentresistingframeandresponsereductionfactorforthestructureis 3

c) Importancefactor 1

d) Soiltype mediumsoil

e) Structuretype SteelMRFBuildings

f) Dampingratio 5%

g) Periodicaccelerationintimeperiod 0.32sec

h) Firstcalculateseismicweight followclause7.3.1table8IS:1893part1

i) Calculatefundamental clause7.6.2ofIS:1893part1

Fig DefiningseismicloadforthestructureinStaadpro

Designbaseshear followclause7.5.3ofIS:1893part1

3. RESULT

Followingresultarecompairedwitheachother

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2874

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

3.1 SUPPORT REACTION

Table SupportreactionresultfromStaadPro

Horizontal Vertical FxkN FzkN FykN

MaxFx 88.44 0.084 130.07

MinFx 88.43 0.083 130.10 MaxFy 0 0.001 313.436

MinFy 0.04 4.61 6.452

MaxFz 0.015 14.723 21.973 MinFz 0.024 14.73 36.62

MaxMx 20.784 0.056 48.817

MinMx 20.784 0.056 48.817 MaxMy 20.784 0.056 48.817

MinMy 20.784 0.056 48.817

MaxMz 20.784 0.056 48.817

MinMz 20.784 0.056 48.817

Table SupportreactionbyEtabs

TABLE: Base Reactions

Output Case FX FY FZ kN kN kN

Dead 0.0 0.0 181.3

Live 0.0 0.0 27.6

1.5(DL+LL) 0.0 0.0 82.4 1.2(DL+LL+WL1) 36.6 0.0 59.9 1.2(DL+LL+WL2) 13.9 0.0 39.6 1.2(DL+LL+WL3) 0.0 5.0 41.6 1.2(DL+LL+WL4) 0.0 0.2 61.9

1.5(DL+LL+WL1) 45.7 0.0 33.4

1.5(DL+LL+WL2) 17.6 0.0 8.0 1.5(DL+LL+WL3) 0.0 0.0 105.6 1.5(DL+LL+WL4) 0.0 0.0 36.0

0.9(DL)+1.5WL1 45.7 0.0 170.2

0.9(DL)+1.5WL2 17.4 0.0 83.3 0.9(DL)+1.5WL3 0.0 0.0 58.5 0.9(DL)+1.5WL4 0.0 0.0 19.5

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2875

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

3.2 Beam End Forces

Fig 1:supportreactionusingetabs

TABLE Beam End forces by staad Pro FxkN FykN FzkN MxkN m MykN m MzkN m

MaxFx 313.436 0 0.001 0 0 0 MinFx 14.427 0.017 0.149 1.2 1.498 0.215 MaxFy 57.543 158.13 0 0.001 0.004 523.103 MinFy 57.543 158.13 0 0.001 0.004 523.105 MaxFz 0.839 4.892 5.04 0.038 7.611 3.625 MinFz 2.139 8.111 5.04 0.038 9.273 9.017

MaxMx 0.697 6.392 2.116 1.923 8.024 3.288 MinMx 0.957 3.791 2.116 1.923 9.442 0.124 MaxMy 0.418 3.837 0.406 1.409 14.448 1.97 MinMy 0.699 6.372 0.408 1.409 14.64 3.28 MaxMz 57.543 158.13 0 0.001 0.004 523.105 MinMz 150.85 72.991 0 0 0 364.957

Table Beam End forces by ETABS

TABLE BEAM END FORCES

Type P V2 V3 T M2 M3

MAXP 67.4950 145.7338 0.0008 0.0070 0.0035 343.5496

MINP 83.1259 1.5565 0.0000 0.0000 0.0000 0.8301

MAXV2 2.5212 165.1478 0.0089 0.0059 0.0172 497.4287

MINV2 5.2157 146.0349 0.0009 0.0070 0.0035 344.7351

MAXV3 21.9101 116.2113 0.0156 0.0059 0.0222 52.3802

MINV3 14.5278 116.2113 0.0156 0.0059 0.0222 52.3802

MAXT 5.9496 146.0348 0.0008 0.0070 0.0035 344.7346

MINT 13.0919 146.0349 0.0010 0.0070 0.0034 344.7351

MAXM2 28.3501 0.4330 0.0082 0.0034 0.0313 5.5319

MINM2 2.1094 0.4330 0.0082 0.0000 0.0313 5.5319

MAXM3 5.1489 4.6209 0.0013 0.0050 0.0024 348.2012

MINM3 4.6765 165.1477 0.0112 0.0059 0.0198 497.4299

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

3.3 JOINT DISPLACEMENT RESULT

TABLE JointdisplacementbyStaadPro

Xmm Y mm Z mm Resultant mm rXrad rYrad rZrad

MaxX 9.627 14.42 0.127 17.339 0 0 0.001

MinX 9.62 14.42 0.128 17.34 0 0 0.001

MaxY 5.568 2513 0.012 6.109 0 0 0 MinY 2.65 24.5 0.03 24.657 0 0 0.01

MaxZ 0.003 0.037 29.561 29.561 0.004 0.002 0

MinZ 0.004 0.061 29.836 29.836 0 0 0

MaxrX 1.2 10.487 5.231 11.781 0.046 0.005 0.001

MinrX 1.202 10.502 5.268 11.81 0.05 0.01 0.001

MaxrY 0 0 0 0 0.001 0.051 0.001

MinrY 0 0 0 0 0.001 0.05 0.001

MaxrZ 0.907 9.266 0.036 9.311 0 0 0.004

MinrZ 0.91 9.264 0.036 9.309 0 0 0.004

MaxRst 0.004 0.061 29.836 29.836 0 0 0

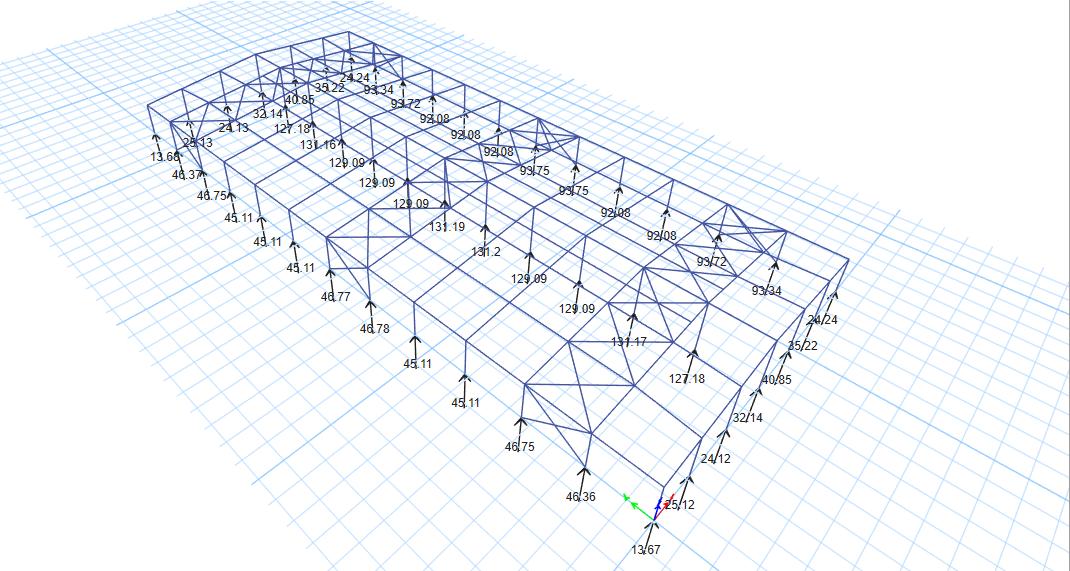

Fig DisplacementdiagramresultusingStaadPro

Factor

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table JointdisplacementbyETABS

TABLE: Joint Displacements

Type Ux Uy Uz Rx Ry Rz mm mm mm rad rad rad

MAXX 9.107 0.001 15.18 0.000556 0.001083 0.000056

MINX 9.107 0.001 15.18 0.000556 0.001083 0.000056

MAXY 2.909E 07 27.712 0.417 0.003843 8.196E 11 4.003E 12

MINY 2.909E 07 27.712 0.417 0.003843 8.196E 11 3.867E 12

MAXZ 5.999 0.371 24.28 0.000072 0.000955 0.000037

MINZ 2.611 0.003 24.4 0.000576 0.002134 0.000058

MAXRx 0 0 0 0.005997 0.000007 0.000007

MINRx 0 0 0 0.005992 0.000007 0.000007

MAXRy 0.891 0.0002275 9.083 0.000265 0.003336 0.000027

MINRY 0.891 0.0002275 9.083 0.000265 0.003336 0.000027

MAXRz 0 0 0 0.001606 0.000022 0.001883

MINRz 0.002 7.968 0.026 0.001572 0.000039 0.001883

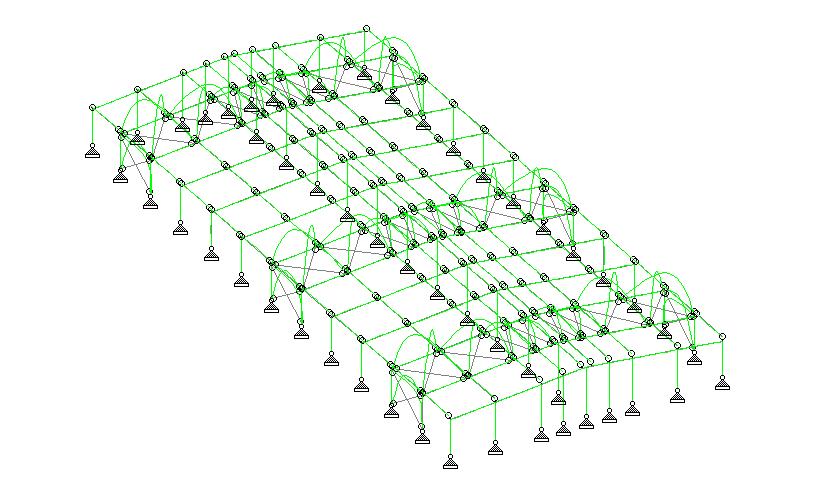

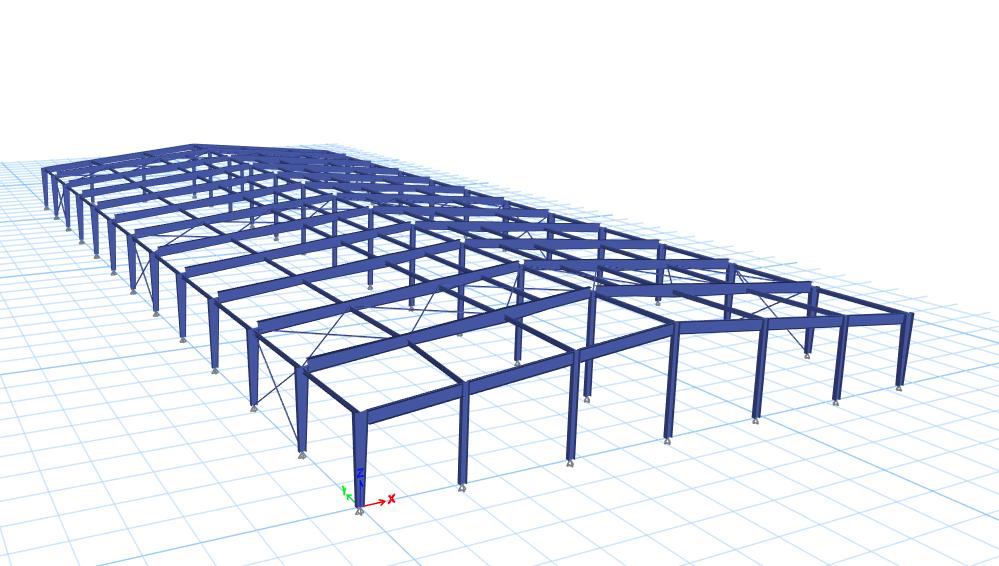

3.4 RENDERING

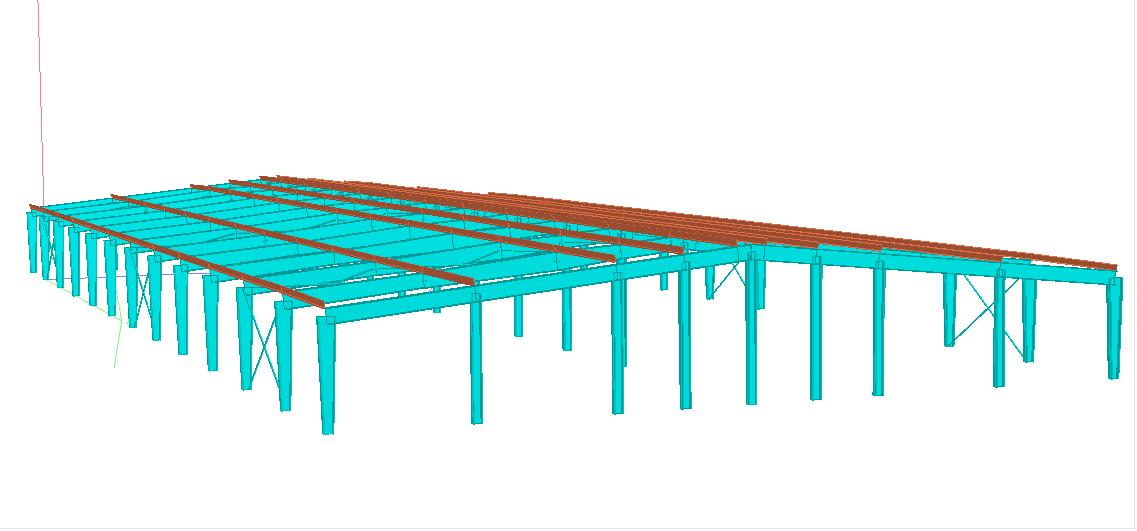

Fig RenderresultofPEBstructureusingETABS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

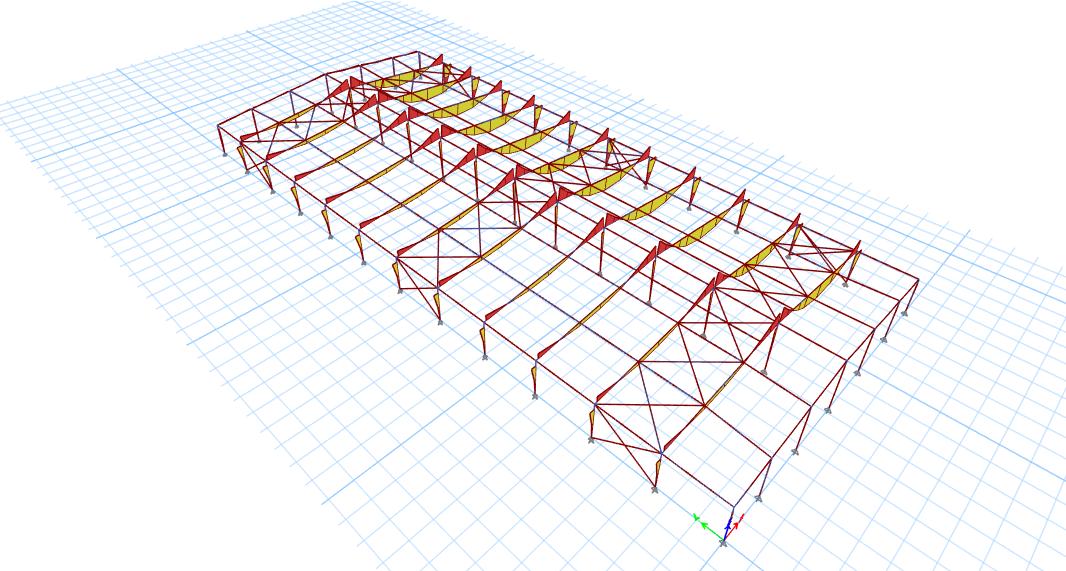

Fig RenderresultofPEBstructureusingStaadPro

3.5 Moment diagram

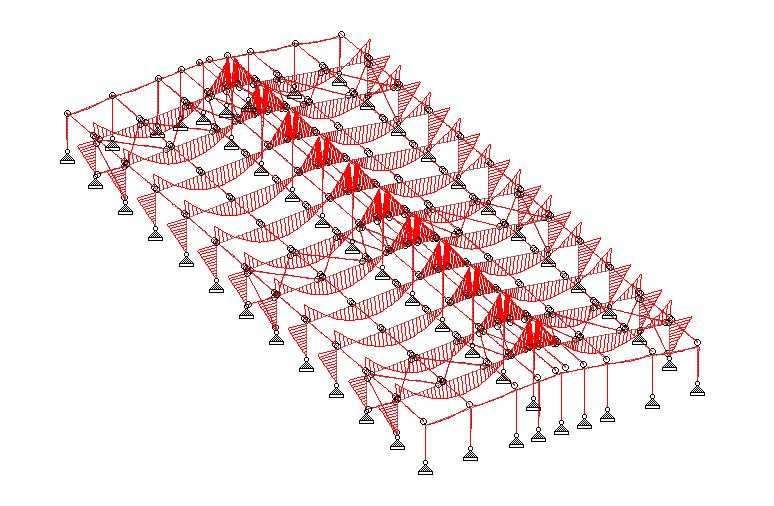

Fig BendingMomentdiagramusingEtabs

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2879

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

3. CONCLUSIONS

Fig BendingMomentdiagramusingStaadpro

Theresultgivenbyboththesoftwareisnotidenticalbutsomewhatsimilarin±5%range.

TheGUIofETABSsoftwareisbetterbutETABSsoftwaredoesn’thaveconnectiondesigningcapabilitiesanddepend uponothersoftwaretodoso.

TheStaadProhaveconnectiondesigningcapabilitiesandcandesignGenericconnectioninsidethesoftwareusingRAM Connectionlink.

Bothsoftwarecantransfersdatafromonesoftwaretoother.

REFERENCES

[1] GeetaMehta,BidhanSharmaandAnujKumar,(2016)OptimizationofMemberSizeandMaterialsforMultistoriedRCC BuildingsusingETABS

[2] T.SubramaniandK.Murali(2018)AnalyticalStudyofTallBuildingwithOuttriggerSystemwithRespecttoSeismicand WindAnalysisUsingETABS

[3] GuangfengWang(2014)ResearchonETABSSteelToweraTopBuildingStructuralSystem

[4] K.SurenderKumar,N.Lingeshwaran,SyedHamimJeelani(2020)AnalysisofresidentialbuildingwithSTAAD.Pro& ETABS

[5] YongheWua,JianchunMub,ShengqiangLicandHuifengXi(2011)DynamicResponseAnalysisonSteel Concrete CompositeFrameBasedonETABS

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2880

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

[6] YongweiSHAN,PaulGOODRUM,CarlHAAS,andCarlosCALDAS(2012)AssessingProductivityImprovementofQuick ConnectionSystemsintheSteelConstructionIndustryUsingBuildingInformationModeling(BIM)

[7] NitinK.Dewani,SanjayBhadke(2018)STUDYOFPRE ENGINEEREDBUILDING,IRJET

[8] Mr.VaibhavThorat,Mr.SamyakParekar2022PreEngineeringBuildingasaModernEra:AReview,IJRASET

[9] MitaaliJayantGilbile,S.S.Mane(2020)AReviewonComparativeStudyontheStructuralAnalysisandDesignofPre EngineeredBuilding[PEB]withConventionalSteelBuilding[CSB],IJERT

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2881