International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN:2395-0072

1Swathy Krishna A K , 2Anjaly M

1M Tech student, Toc H Institute of Science and Technology, Kochi

2Assistant professor, Department of Civil Engineering, Toc H Institute of Science and Technology, Kochi ***

ABSTRACT Wax is one of the latest materials being studied by engineers in concrete technology mainly for its phase change temperature adjustment property. Paraffin wax added concrete is proved to be self curing and it make sure that the concrete is free from water evaporation and hence improve its water withholding capacity compared to usual concrete. But strength of the concrete self cured with paraffin wax is less than conventional concrete hence it is required to be improved by some method. The addition of fly ash to improve the strength of concrete self cured with paraffin wax is studied through the research work. The experimental research work consists of comparing the properties of self cured M35 concrete with 0%, 0.5%, 1%, 1.5%, 2% paraffin wax liquid and M35 concrete with 0%, 0.5%, 1%, 1.5%, 2% paraffin wax liquid as well as 40% fly ash. The compressive strength, split tensile strength, flexural strength are conducted for comparing the mixes The aim of the research is to propose a self curing, phase changing and better strength concrete.

Key words: paraffin wax, fly ash, self curing, compressive strength, split tensile strength, flexural strength.

Concreteself curedwithparaffinwaxhaveapplicationinhighandlowtemperatureregionduetoitstemperatureadjustment property. The paraffin wax in the concrete changes phase from solid to liquid and vice versa at hot and cold region respectively, thus reduces the cracks. However concrete self cured with paraffin wax does not meet the strength of conventional concrete. The possibility of improving strength of concrete self cured with paraffin wax is studied through this research.Mineraladmixtureflyashwasaddedtothisconcretewiththeaimofincreasingstrength.Comparativestudyofself cured conventional concrete and concrete self cured with paraffin wax based on compressive , tensile and flexural strength areconducted.

Relevanttestswerecarried outforthe materialsusedinthestudyincludingcement,flyash,paraffinwax,aggregates,super plasticizer.M35concretewith0%,0.5%,1%,1.5%,2% paraffinwaxesbyweightofcementwerepreparedand self curedfor 28days(MPmixes) ThesemixesaredenotedbyMP0,MP0.5,MP1,MP1.5,MP2respectively.FlyashbasedM35concretewith 40%flyashreplacementforcementand0%,0.5%,1%,1.5%,2%paraffinwaxesbyweightofcementwerealsopreparedand self curedfor28days(MFPmixes) ThesemixesaredenotedbyMFP0,MFP0.5,MFP1,MFP1.5,MFP2respectively.Thenthese mixesweresubjectedtocompressive,tensileandflexuraltestandtheresultswerecompared.

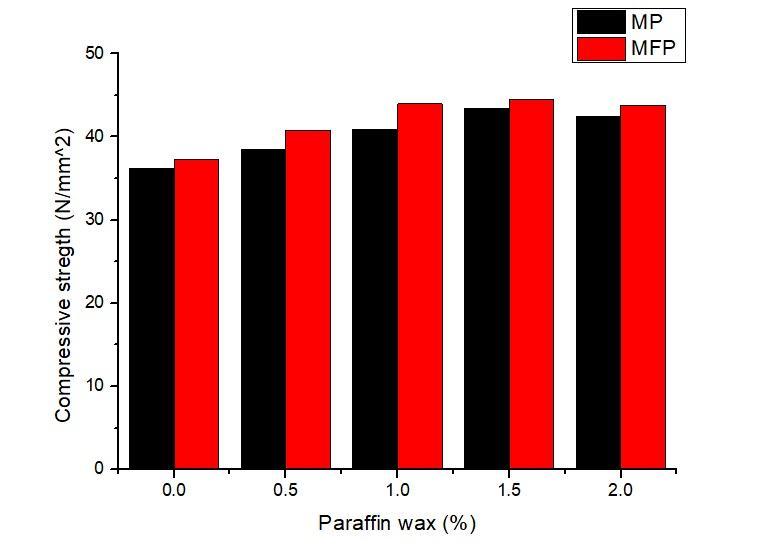

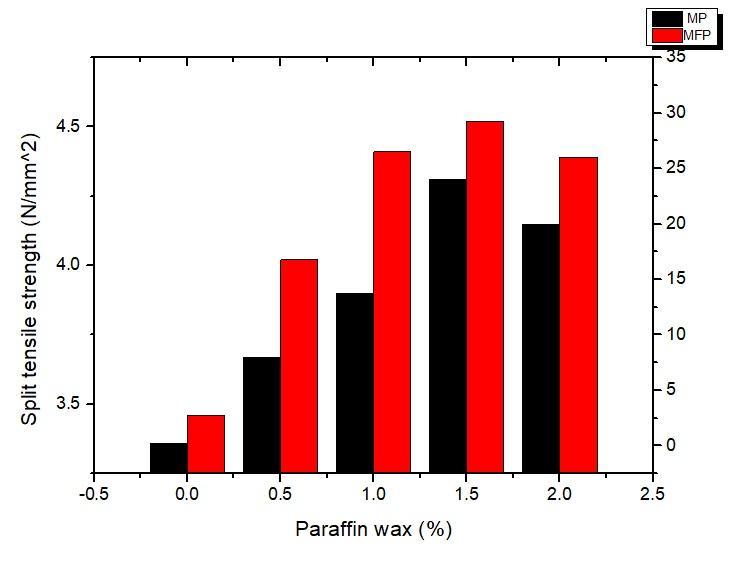

Table1showsthecompressive,tensileandflexuraltestresultsofallmixes.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

MP1 40.92 3.9 6.1

MP1.5 43.4 4.31 6.3 MP2 42.5 4.15 6.35 MFP0 24.87(7DAY) 3.746 5.9

MFP0.5 40.77 4.02 6.8

MFP1 43.96 4.41 7

MFP1.5 44.45 4.52 7.3 MFP2 43.8 4.39 6.5

Fig 1:Compressivestrengthdiagram

Fig.1showsthecompressivetestresultsofthestudy.Theblackcolourindicatemixwithparaffinwaxandredcolourindicates mixeswithflyashandparaffinwax.Thecompressivestrengthofflyashandparaffinwaxaddedconcreteisgreaterthanonly paraffinwaxaddedconcrete.Thegraphofflyashandparaffinwaxbasedconcreteshowssteepincreaseinstrengthat0.5to 1%, then it slightly increases at 1.5% and then slightly decreases at 2%. While paraffin wax based concrete shows steep increase in strength up to 1.5% and then decreases at 2%. The strength is maximum at 1.5% for both type of mix (MP1.5 = 43.4Mpa, MFP1.5 = 44.45 ). This shows 1.5% is enough dosage for self curing the concrete mix. After 1.5%, the compressive strengthhasdecreasedduetoreducedcementcontentbyreplacinghighpercentageofparaffinwaxoroverdosageofparaffin wax.Thishighlightsthebenefitofwatercuringcomparedtoself curing.ThemaximumcompressivestrengthattainedbyPW added mix was at 1.5% is attained by fly ash added incorporated mix at just 1 % PW dosage. This shows the strength of concreteself curedwithparaffinwaxcanbeimprovedbyaddingflyash.Thisalsoindicateparaffinwaxiscompatiblewithfly ashconcrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p-ISSN:2395-0072

Analyzingfig.2wecanunderstandthatthetensilestrengthgraphshowssimilartrendtocompressiongraph. Themaximum value of tensile strength is at 1.5% of paraffin wax dosage. At 1%, the fly ash added concrete attain a strength greater than thatof maximumstrengthattainedbyonlyparaffinwaxaddedconcreteat1.5%.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Fromfig.3wecanunderstandtheflexuralstrengthtrendwasslightlydifferentthancompressionandtensilestrengthgraph. Fly ash and paraffin added concrete shows increase in strength in all Paraffin wax dosages than paraffin added concrete similartocompressionandtensilestrength.Butwithjustadditionof0.5%PW,flyashincorporatedconcreteshowsastrength of6.8Mpawhilethemaximumflexuralstrengthshownbyparaffinwaxaddedconcretewas6.35Mpa.Theflexuralstrengthof fly ash and paraffin added concrete increased to 7.3Mpa which was very near to the strength of control mix at 1.5%. Then therewassuddensteepdecreaseofstrengthto6.5Mpaat2%indicatingtheoverdosage.ThisshowschangeinPWdosagecan affect the flexural strength performance of fly ash concrete largely. While in case of paraffin added concrete the over dosage doesnothavemucheffectupto2%PWastheflexuralstrengthvalueremainedconstantfor1.5%and2%.

Thecompression(19.92%),tensile(28.27%)andflexuralstrength(20%)of self curedM35concreteincreaseswithaddition of paraffin wax up from 0% to 1.5%. Because as the paraffin wax (self curing agent) dosage increase in concrete mix, better waterretentionandcontinuoushydrationprocessofcementpasteresultsinlessvoidandporesandgreatbondforcebetween cement and aggregate. After 1.5%, the strength decreases as the cementitious content is reduced due to high percentage replacement of paraffin wax. This is due to lowest available cement content and high water availability. The compressive, flexuralandtensilestrengthhasincreasedwithreplacingcementwithof40%flyash.Thisisbecauseofthepozzolanicactivity of fly ash. Compared to optimum MP mix (concrete self cured with paraffin wax), the compressive, tensile and flexural strength increased by 4.87%, 4.9% and 15.87% for optimum MFP mix (fly ash based concrete self cured with paraffin wax) Betterstrengthconcretecanbemadewithincorporationofflyashinconcreteself curedwithparaffinwax.

[1]. William R Turner, Donald S Brown, Donald V Harrison (1955), “Properties of paraffin waxes composition by mass spectrometeranalysis”, Industrial and engineering chemistry ,vol.4,pp1 25.

[2]. Qing wang, Jing zhang, Zhaoyang Ding, Linge Qiu (2012), “Studyonpropertiesofparaffinphasechangeenergystorage concrete”, Elsevier ,vol.16,pp365 370.

[3]. Qing Wang, Jing Zhang, Zhaoyang Ding, Linge Qiu (2012), “Study on properties of paraffin phase change energy storageconcrete”, Elsevier, vol.16,pp365 370.

[4]. N P Rajamane, Ambily P S (2013), “Flyashasasandreplacementmaterialinconcrete astudy”, Indian concrete journal, vol.87,no.7,pp1 7.

[5]. Madduru Sri Rama Chand, Garje Rajesh Kumar, Pancharathi Rathish Kumar, Pallapothu Swamy Naga Ratna Giri (2014), “Paraffinwaxasaninternalcuringagentinordinaryconcrete”, ICE Publishing,vol.12,pp1 19.

[6]. C Yoganantham, M Helen Santhi (2015), “Performanceofself compactingselfcuringconcretewithflyashandMsand”, International journal of science and engineering, vol.8,no.1,pp491 497.

[7]. Shikha Tyagi (2015), “Comparison of strength characteristics of self cured concrete”, International research journal o engineering and technology,vol.4,no.8,pp2190 2193.

[8]. A D Pofale, S V Deo (2015), “A study of fine aggregate replacement with fly ash an environmental friendly and economicalsolution”, International journal of environmental health,vol.4,pp1 17.

[9]. Dan Sun, Lijiu Wang (2015), “Utilization of paraffin/expanded perlite material to improve mechanical and hermal propertiesofcementmortar”, Elsevier,vol.101,pp791 796.

[10].Madduru Sri Rama Chand, Garje Rajesh Kumar, Pancharathi Rathish Kumar, Mupparisetty V Krishna Roa, Pallapothu Swamy Naga Ratna Giri (2015), “Influence of paraffin wax as a self-curing compound in self- compacting concrete”, ICE publishing,vol.28,no.2,pp110-120.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

[11]. Tumadhir M Al Jabiri (2016), “Propertiesofconcretecontainingparaffinwax”, IJET,vol.6,no2,pp10-16

[12]. Ali Al Mohamadauri, Karim Benhabib,Rose Marie Dheilly, Adeline Goulliex (2016), “Influence of lignocellulosic aggregatecoatingwithparaffinwaxonflaxshiveandcementshivecompositeproperties”, Elsevier,vol.102,pp94-104.

[13]. M Pavan kumar, G Tirupathi Naidu (2016), “An experimental study on self curing concrete using liquid paraffin wax”, International journal of research in engineering and technology,vol.5,n0.5,pp2321-7308.

[14]. Ankammaro Thiruvalluri, Perikala Rajesh (2016), “Self curing compaction by using liquid paraffin wax and conplastsp430”, Elixir international journal,vol.100,pp43797-43802.

[15]. M S Krishna Hygrive, Siva Kishore, KJB Chari (2017), “Comparative study on compressive strength of fly ash concrete”, International journal of civil engineering and technology,vol.8,no.4,pp1737-1745.

[16]. V Revathy, C J Ganga Lakshmi (2017), “Experimental study on self curing concrete with fly ash and quarry dust”, International journalofcivilengineering,pp180-183.

[17]. Yaghoob Farman, Hadi S Esmaeeli, Pablo D Zavattieri, John Haddock, Jason Weiss (2017), “Incorporating phase changematerialsinconcretepavementtomeltsnowandice”, Elsevier, vol.84,pp134-145.

[18]. T Rama Linga Reddy,M Nageswararao (2018), “Study on self curing concrete using liquid paraffin wax as external agent”, International journal of research,vol.5,no.19,pp46-53.

[19]. Jakkam Snehavi, A Yashwanth (2018), “Experimental study on self curing concrete with replacement of cement withflyashandsilicafumeandsandwithquarrydust”, International research journal of engineering and technology, vol.5, no.4,pp4383-4386.

[20].Zameer K, Karthik N M (2018), “Study on strength characteristics of self curing concrete incorporated with fly ash”, International research journal of engineering and technology,vol.5,no.5,pp1429-1434.

[21]. P Rathish Kumar, M Sri Rama Chand, P S N R Giri, G Rajesh Kumar (2018), “Effect of paraffin wax as self curing agent in recycled aggregate based self compacting concrete (SCC)”, International journal of advances in mechanical and civil engineering,vol.5,no.1,pp2394-2827.

[22]. Lifang Liu, Yue Qu, Tao Xu, Jiayu Chen, Huijun Wu, Gonagsheng Huang, Xiaoqing Zhou, Lixiu Yang (2018), “Experimentalstudyonpreparationofa novelfoamedcementwithparaffin/expandedgraphitecompositephasechange thermalenergystoragematerial”, Elsevier, vol.158,pp4799-4804.

[23]. Jolanta Harasymiuk, Andrzej Rudzinski (2019), “Old dumped fly ash as a sand replacement in cement composites”, Buildings ,vol.10,no.67,pp1-18.

[24].

[25]. Luo Tao, Ma JuanJuan, Liu Fang, Zhang Ming Yi, Sun Chaowei, Ji Yan Jun, Yuan Xiaosa (2021), “Direct incorporation of paraffin wax as phase change material into mass concrete for temperature control: mechanical and thermalproperties”, Science in cold and arid regions, vol.13,no.1,pp30-42.