LaboratoryEvaluationOnAsphaltBinders&MixturesContaining SugarcaneWasteMolasses

NaveenKumarP1,Dr.VinayA2

1Student,DepartmentofConstructionTechnology&Management,DayanandaSagarCollegeofEngineering, Bengaluru,Karnataka,India.

2,AssistantProfessor,DepartmentofCivilEngineering,DayanandaSagarCollegeofEngineering,Bengaluru, Karnataka,India. ---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract-Asphalt,aresidueofpetroleumdistillation,isthe mostimportantbinderinroadconstructionaroundthe world.Crudepetroleumisafossilfuelandmineralresource thatwillbedepletedinthenext40to50years.Risingenergy pricesandastrongworld-widedemandforpetroleum,as wellasrisingenvironmentaltoxins&pollution,have encouragedthedevelopmentofalternativebindersto modifyorreplaceasphaltbinders.Toreducecarbon emissions,anon-toxicviscousfluidwasaddedtotheasphalt. Onesuchmaterialismolasses.Molasses,oftenknownas blacktreacle,isaviscousfluidmadefromsugarcaneorsugar beetthathasbeenrefinedintosugar.Thequantumofsugar, theextractionmethod,andtheageoftheplantallinfluence molasses.

Thegoalofthisstudyistodeterminehowwellanasphalt bindermodifiedwithsugarcanewastemolassesperformsin ACmixes.Toachievethisgoal,theeffectsoffoursugarcane wastemolasseslevelsof5%,10%,15%,and20%byasphalt weightasasubstitutetobasebinderontheperformance parametersofthebinderandasphaltconcretecombination wereevaluated.Traditionalbindertestswereusedto determinetheconventionalcharacteristicsofthemodified binder.Andthemechanicalcharacteristicsofthesugarcane molassesmodifiedbinderinasphaltconcretemixeswere alsoassessedutilizingtestssuchasMarshallstabilityaswell asMoisturesusceptibilitytest.Thesugarcanemolasses modifiedbindermayconsiderablyboostmoisturedamage resistanceaswellasMarshallcharacteristicssuchasload andflowratesofasphaltspecimens,accordingtotheresults ofthetestscarriedonasphaltmixtures.Accordingtothe resultsoflaboratorytests,itissuggestedthatanoptimum molassescontentof10%bybaseasphaltweightshouldbe employedasabasebinderreplacementinaHotMixAsphalt plantfortheconstructionofflexiblepavement.

KeyWords:Asphaltbasebinder,Sugarcanewaste molasses,Non-toxicviscousfluid,Optimumbitumen content,TensileStrengthRatio,

1.INTRODUCTION

Thelaboratoryexperimentsarecarriedoutonaseriesof bitumenreplacementspecimensrangingfrom1%to15%.

ThebitumengradechosenhasaviscosityVG30.The behaviourofmolassesmodifiedbituminousmixwas investigated,anditwasdiscoveredthatthemodifiedmix hadbetterMarshallCharacteristics.Whenmolassesisadded, theMarshallstabilityvalueincreasesforabriefperiod beforedecreasing,andtheflowvaluelikewiselowers.The OBCofthemix4.7percent.Thistestallowsfora13percent molassescontentsubstitution.Thisdemonstratesthatupto acertainamountofmolassesmaybesubstitutedwith bitumen.[1].

Thepurposeofthisinvestigationwastoseehowadding threestagesofcanemolasseswithvaryingpercentage replacementsaffectedtheperformanceoftheoriginal bitumen(40/50).Thepercentagesubstitutionofmolasses mixedbasebitumenwith(0percent,5percent,10percent, 15percent,and20percent)wasevaluated.Theperformance gradeofthetreatedbasebitumen(40/50)with20% molasses-A,10%molasses-B,and5%molasses-Cenhances theperformanceoftheoriginalbitumenby28.12percent, 15.79percent,and8.17percent,respectively,accordingto testdata.[2].

Theyperformedlaboratorystudiesonmaterialssuchas bitumen,aggregate,andbitumenwithmolasses,aswellas strengthandbehaviourtestsonbitumenandbitumenwith molasses.Theadditionof0.10percent,0.15percent,or0.20 percentmolassestothebindercomponentincreasesthe mixture'sstructuralstability,enhancingruttingresistance andweightbearingcapacity.[3].

Thispaperisforthemodificationofbitumenwithsugarcane molasses,coconutshellcharcoal,andamixtureofthetwo. Thebitumenismodifiedwithsugarcanemolassesatvarious percentagesrangingfrom1%to15%,andexperimentswere carriedoutforeachpercentagetodeterminethebest proportion.

Thebitumenischangedwithcoconutshellcharcoalat variouspercentages,suchas5%,10%,15%,20%,25%, 30%,and35%,andtestswereundertakenforallofthe percentagesinordertodeterminethebestproportion.The optimummolassescontentformodifiedbitumenis9%. Coconutshellcharcoalshouldbeusedasmodifiedbitumen atarateof20%.Theidealratioofmolassesandcoconut

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net ©2022,IRJET|ImpactFactorvalue:7.529|ISO9001:2008CertifiedJournal

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net

shellcharcoalinmodifiedbitumenis8%molassesand4% charcoal.[4].

AstheMolassescontentincreases,thesolidityofHMA arrangedbylargelyreplacingblack-topcoverwithMolasses decreases.ThestrengthoftheHMAisunaffectedasthe molasseslevelincreasesto3%,butasthemolassescontent increasesfurther,thesoliditydecreasesby1.5%,17%,22%, and27%formolassescontentsof6%,9%,12%,and15%, respectively.Despitethefactthatstrengthdecreasedas Molassescontentincreased,thedependabilityofblendswith upto11percentMolassescontentwaswithintheMarshall Criteriaforoverwhelmingtraffic,i.e.,above8KN.[5].

Thebitumensamplesarepartiallyreplacedwith5%,10%, 15%,and20%sugarcanemolasses,andtheresultsare comparedwiththeadditionof21%quarrydust.Laboratory methodswereusedtostudytheconventionaland mechanicalcharacteristicsofbitumensamples.Bypartially replacingbitumenwithsugarcanemolassesandquarrydust (upto15%and21%respectively),allofthesequalitiesof bitumengraduallyimprove.[6].

Theperformancepropertiesofasphaltbindertreatedwith sugarcanewastemolassesinACmixeswereexaminedinthis work.Theyputvariedpercentagesofsugarcanewaste molassescontentsof5%,10%,15%,20%,and25%by asphaltweighttothetest.Thesugarcanemolassesmodified basebindergreatlyimprovedruttingresistanceand moisturedamageresistanceinasphaltmixes,accordingto thetestingresults.TheyproposedthatanidealSWM concentrationof10%bybaseasphaltweightbeusedasan alternativetobasebinderinHotMixAsphaltbasedonthe findingsofthelaboratoryexperiments.[7].

1.1AStatementofProblem

Theworldhasgrownmoreconcernedaboutglobalclimate change,whichisassumedtobeproducedbygreenhouse gases,themostprominentofwhichisanthropogeniccarbon dioxide,whichisemittedintotheatmospherewhenfossil fuelsareused.Asaresult,moreecologicallyfriendlyand non-toxicbitumenreplacementshavebeenintroduced. Becauseofitsoutstandingnon-pollutingcharacteristics, molassesisemployedinawiderangeofindustries.Ithasan advantageoverotherbindingmaterialssuchastarand ligninsulphonateinthatitdoesnotemitpoisonousfumes whenburned,makingitmoresaferfortheenvironment. Furthermore,becauseitisaliquid,itissimpletohandleand incorporateintomanyindustrialprocesses.

Thecurrentstudyisprimarilyconcentratingonand conductingvariouslaboratoryexperimentstoinvestigate theeffectofaddingsugarcanewastemolasseswithvarying percentagereplacementontheperformanceoftheoriginal asphalt.

1.2ObjectivesofStudy

Tocomparelaboratoryevaluationresultsand engineeringcharacteristicsandpropertiesof asphaltbindersandmixtureswhichcontaining sugarcanewastemolasses.

Todeterminetheperformancecharacteristicsof asphaltbinderandmixturescontainingsugarcane wastemolasses.

Todeterminetheoptimumsugarcanewaste molassescontenttobeaddedtotheasphaltmixto achievethedesiredstrength.

2.MATERIALSUSED

Fine&coarseaggregates,hotMixasphaltbinder,and sugarcanewastemolasseswereemployedinthis experiment.

2.1Aggregates

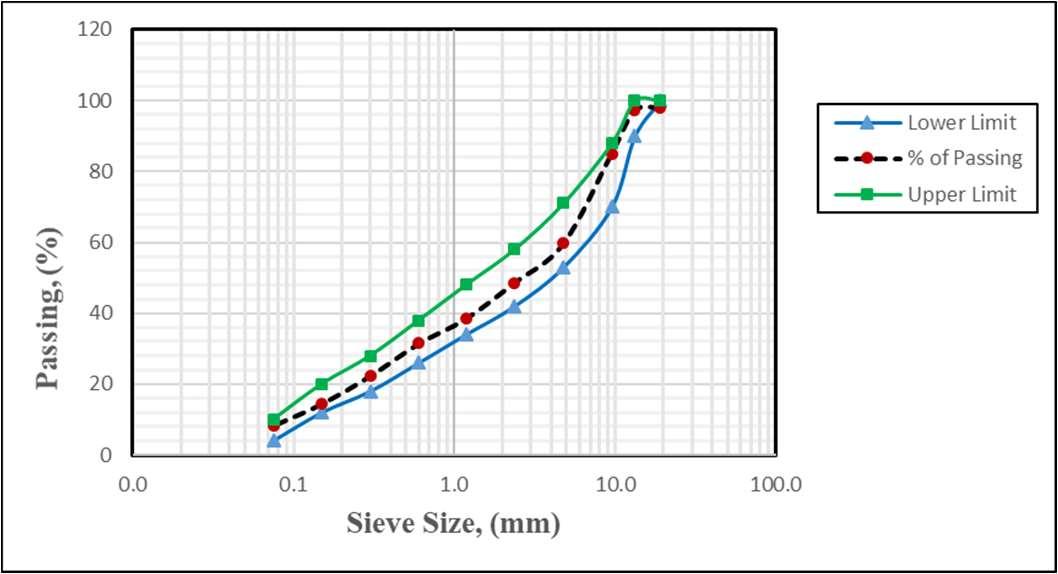

TheaggregateswereobtainedfromtheL.GBLUEMETAL crusherinTamilnadu.Thefigure-1belowdepictsthe combinedgradationPercentagepassingoftheAggregateby JobMixFormula.Thequantityofaggregateswasaccurately measuredto±0.1gramsinaccordancewithIndian Standards:2386(Part1)-1963.

2.2HotMixAsphaltBinder

Inthiswork,60/70penetrationgradebitumen(VG-30)was utilizedasacontrolbinderisbroughtfromMangalore.

2.3SugarcaneWasteMolasses

Sugarcanewastemolasseswascollectedfromasugar factoryinKMDoddivillage,Mandyadistrict,Karnatakastate. Mandyaismostlyrecognizedasasugar&jaggery productiondistrictinthestateofKarnataka.Sugarcity (SAKKARENAGARAINKANNADA)isanothernameforit sincesugarcaneisamajorcrop.Inthisregion,the inhabitantsandfarmersmanufacturesugarandjaggeryin theirhomes.Asaresult,wastemolasseswillbeproducedon abigscaleinthisregion.Mandyais100kilometersfrom Bengaluru.

3.METHODOLOGY

Basedonpreviousresearchandareviewoftheliterature, thefoursugarcanewastemolassesconcentrationsof5%, 10%,15%,and20%werechosenbyasphaltweight.

Inthisproject,weusedbituminousconcretegrade2. (MORTHtable500-17).

First,typicaltestswereperformedoncoarseaggregatesin accordancewithIS:2386(part1&2)-1963.

©2022,IRJET|ImpactFactorvalue:7.529|ISO9001:2008CertifiedJournal

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net

Then,themodifiedasphaltbindersincorporatingsugarcane wastemolassesweresubjectedtotraditionalasphaltbinder testinginaccordancewithIS:1203,1205,1206(part3),1208, 1209.

Toinvestigatetheeffectivenessofsugarcanewastemolasses contentasanalternativetoasphaltbinderinasphalt concretemixes,hotmixasphaltmixturetestssuchasthe MarshallStabilitytestandindirecttensilestrengthtestwere performed.

Theresultsofallconventionaltestsonaggregates, traditionalbinder,andasphaltmixturetestsonmodified bindercontainingmolassesareobtainedandthenanalyzed.

3.1BlendingProportionforbituminous concrete

InthisExperimentalinvestigation,combinedaggregate gradationwasemployedasperfigure-1.

3.2TestsonAsphaltBinder&ModifiedasphaltBinder

ThefollowingarethelistoftestsconductedonbothAsphalt binderaswellasModifiedasphaltwhichcontaining sugarcanewastemolasses.

I.PenetrationValue.

II.KinematicViscosity.

III.FlashPoint.

IV.SofteningPoint. V.Ductilityvalue.

3.3Testsonasphaltconcretespecimen.

Therearemajorlytwoasphaltmixturetestswereconducted ontheasphaltconcretespecimen.

I.MarshallStabilityTest.

II.Indirecttensilestrengthtest. 3.3.1MarshallStabilityTest 3.3.1.1MixDesign

Table-1:MarshallMixProportions.

PROPORTIONS

Figure-1:Blendingproportion 3.1.1TestsonCoarseAggregate

ThelistofTestsconductedonthecoarseaggregatesas follows, I.Specificgravityofaggregate a)Specificgravity. b)ApparentSpecificgravity. c)Waterabsorption. II.Impacttestofaggregate. III.Abrasiontestofaggregate. IV.Crushingvalueofaggregate. V.CombinedIndex-(Flakiness&Elongation).

Optimum binder contentby weightmix

5.5%byweightofmix66Gms (16.07.0 mm) 42%byweightofAggregate504Gms (7.0-3.0mm) 10%byweightofAggregate120Gms (3.0-0.0mm) 46%byweightof Aggregate552Gms

CementFiller 2%byweightofAggregate24Gms

Table1depictstheproportionsformarshallspecimen preparationbasedonMORTHtable500-17,aswellasthe jobmixformularestrictions.

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net

Table–2:CombinedGradationAggregate.

downed.ThenBulkVolume,BulkSpecificGravity,%Air Voids,%VMA,%VFB,aredeterminedusingbelow equationsmentioned.Thenbasedontestresultsgraphsare plotted.

MarshallStabilityLoad,(KN)=Appliedloadin Division*CorrectionFactor*ProvingRingFactor.

BulkVolume(cc)=(MassofSaturatedSurfacedry SpecimeninAir)-(MassofSpecimeninwater)

BulkSpecificGravity(Gmb)(gm/cc)=(Massof SpecimeninAir)/(BulkVolume)

%AirVoids=((MaxSGoflooseMixture)-BulkSG Specimen))/(MaxSGofLooseMixture)*100

%VoidsinMineralAggregate=100-((BulkSGof Specimen*PercentageofAggregates))/(BulkSGof Aggregate)

%VoidFilledwithBitumen=100*((%Voidsin MineralAggregate-%AirVoids))/(%Voidsin MineralAggregate)

Table2depictsthejobmixformulaofcombinedgradation percentagepassingasperMORTH(table500-10)specified limits.

Table–3:Amountofmolasses&asphaltcontent.

3.3.2Indirecttensilestrengthtest.

TensileStrengthRatioisusedtoassessthemoisture susceptibilityofahotmixasphaltmixture.Themarshall specimenwassubjectedtoanindirecttensilestrengthtestin ordertocomputethetensilestrengthratioinaccordance withMORTH(table500-13)andAASHTOT283.

Table3Providespreciseinformationaboutthemolassesand asphaltcontentneededtopreparethespecimenforthe marshallstabilitytest.Asthe%ofmolassesareadded correspondingtothattheasphaltcontentisreducedforthe partiallyreplacementofasphaltcontent.

Inthelaboratory,thebasebinderandmolassescombination wasmadeinamixerbyaddingmolassestomeltedbitumen andmixingat150±2℃foraround10minutesataspeedof 1600rpmtoobtainawell-homogenizedblend.Forthe compactedsamplesfortheconventionalasphalt concretemixturewereundertakenatvariousbinder amountstoidentifytheoptimumbitumencontent.Thenfor eachpercentage3mouldsarepreparedasperabove mentionedmixdesign.Thenmarshallstabilitytestis performedonthespecimeninaccordancewithASTMD 1559-76.Thenthemarshallload&flowvaluesarenote

Theindirecttensilestrengthtesthasthesamemixdesignas themarshallmixdesign.Eightmouldsarecreatedforeach %.Fourofthemouldsarekeptconditioned,whilethe remainingfourareunconditioned.Thedryconditiontensile strengthofthefirstsetofcompactedsampleswasmeasured inanenvironmentalchamberat25℃fortwohours.The secondsetofcompactedsampleswasplacedina60-degreeCelsiuswaterbathfor24hoursbeforeconditioningina25degree-Celsiuswaterbathfortwohours.Thedryandwet specimensweretestedforindirecttensilestrengthata displacementrateof50mm/minatatemperatureof25℃

©2022,IRJET|ImpactFactorvalue:7.529|ISO9001:2008CertifiedJournal|Page2667

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net

4.RESULTSANDDISCUSSION

4.1LaboratoryresultsofCoarseAggregates

Thefollowingphysicalpropertiesofaggregatesare determinedusingdifferenttestsforevaluatingthesuitability ofcoarseaggregatesinroadconstruction

Table–4:laboratoryresultsforcoarseaggregates.

SLNONAMEOFTHETESTSTESTRESULTS

1SPECIFICGRAVITY2.71

2APPARENTSPECIFICGRAVITY2.708

3WATERABSORPTION0.10%

4IMPACTTEST23.38%

5ABRASIONTEST13.58%

6CRUSHINGTEST16.90%

7COMBINEDINDEX26%

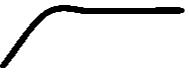

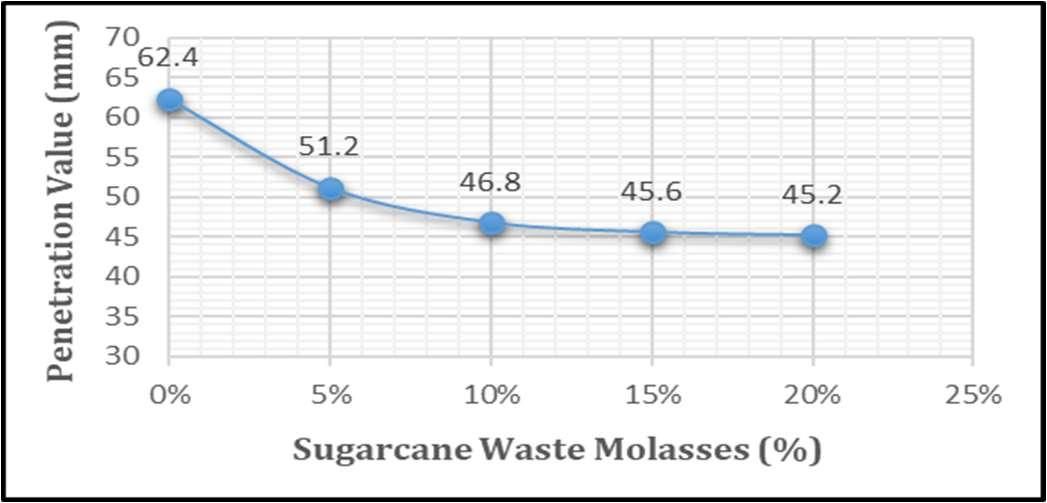

Figure–2:PenetrationValue.

Thepenetrationvaluesdecreaseingeneralas themolassescontentincreases.Thedropinpenetration valuewasfairlysignificantbetween10%and20%changes.

395 385 375

AsreportedinTable4,Theaggregatesmeetthecriteriafor specificgravity&apparentspecificgravity[2.5-3],And waterabsorption[0.1-2%],impactvalue[<35%],abrasion value[<30%],aggregatecrushingvalue[<30%],combined indexvalue[<35%]asperIS2386-(part1,3,4,5).Therefore, thelaboratorytestresultsaresatisfactoryforroad construction.

4.2BasicTestResultsofAsphaltwithSWM

Thefollowingpropertiesofasphaltwithsugarcanewaste molassesaredeterminedusingdifferenttestsforevaluating thesuitabilityofbitumeninroadconstruction.

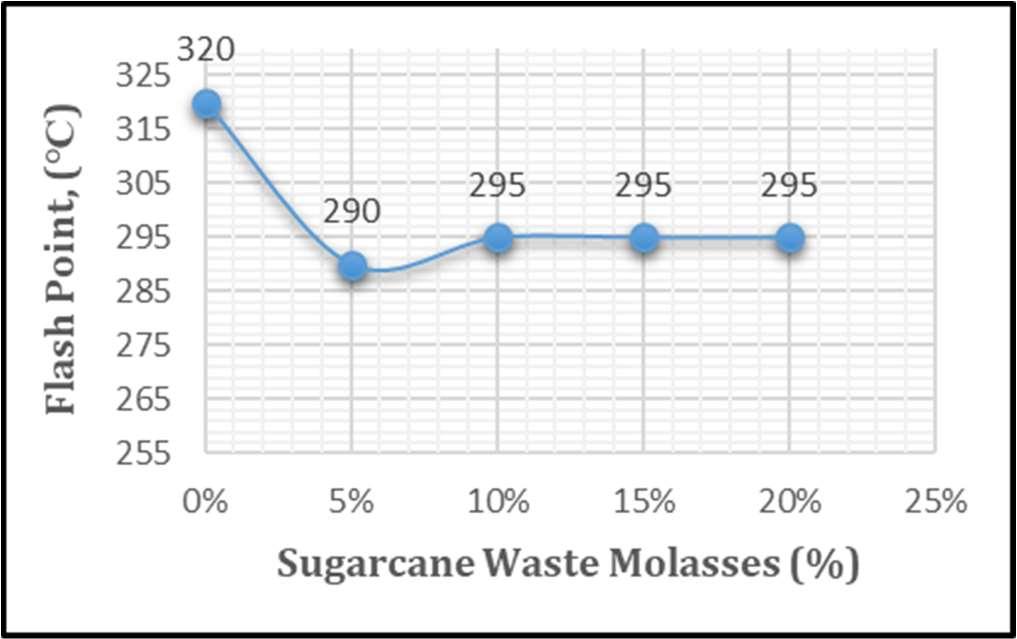

Table–5:laboratoryresultsofAsphalt&AsphaltwithSWM.

Viscosity,(Cst) Sl No Nameofthe Test SugarcanewasteMolasses,(%) 0%5%10%15%20%

1PenetrationValue,(1/10mm)62.451.246.845.645.2 2KinematicViscosity,(Cst)351.017382.65383.42383.67383.92 3Flashpoint,(℃)320290295295295 4Softeningpoint, (℃)50.551.551.95252.6 5DuctilityValue,(cm)110114118125128

382.65383.42383.67383.92 365 351.017 355 345 335 325 0%5%10%15%20%25% SugarcaneWasteMolasses,(%)

Figure–3:KinematicViscosity

Withincreasingmolassescontent,viscosityofthemodified asphaltwithmolassesisalsoincreased.Theviscositydata showthattheviscosityvalueincreasesdramaticallywith5% molassestreatedasphalt,butthereisnosignificant differencebetweentheviscosityof5%,10%,15%,and20% molassesmodifiedasphalt.

Figure–4:FlashPoint. Itisthelowesttemperatureatwhichabituminousmaterial's vapourquicklycatchesfireintheformofaflashunder specifictestcircumstances.Incomparisontobaseasphalt, thefirepointofmolassesflashesatquicklyat290℃

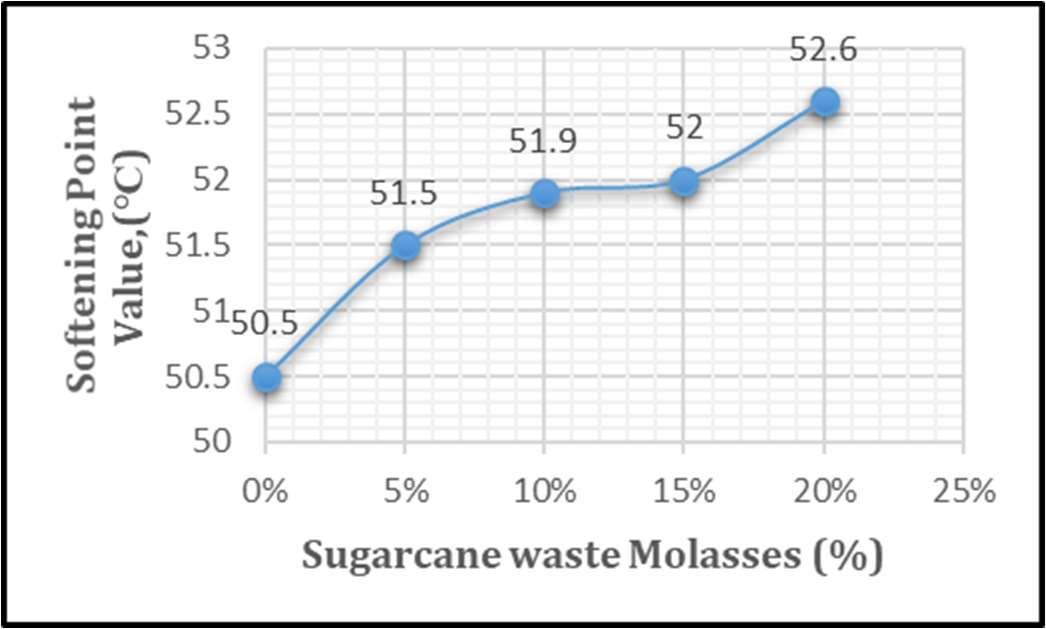

Figure–5:SofteningPoint.

Whenthemolassesconcentrationofthemodifiedbinder wasincreasedincomparisontothebaseasphalt,the softeningpointtemperatureofthemodifiedbinder increased.Thistendencyindicatesthatthechangedbinders arestifferandhavereducedtemperaturesusceptibility, whicharecrucialproperties,especiallywhenthereis substantialvariationinhightemperaturecircumstances.

p-ISSN:2395-0072

Theoptimumbindercontent5.5%wasdeterminedby calculatingtheaveragevalueofthebitumencontentthat correspondstomaximalstabilityandmaximalbulkweight& alsoforaveragevalueofbitumencontentcorrespondsto4% ofairvoids.Basedontheoptimumbitumencontentof traditionalasphalt,subsequenttestsonasphaltmodified usingsugarcanewastemolassesarebeingdone.

4.3.2Marshallstability[optimumsugarcane molassescontent]

Thefollowingarethetestresultsforoptimumsugarcane wastemolassescontent:

Table–7:Optimumsugarcanewastemolassescontent.

SWM Content(%) Stability, (kn) Flow, (mm) Density, (gm/cc) AV, (%) VMA, (%) VFB, (%) 011.902.82.42024.15016.52974.893 511.403.22.42454.13016.38074.925 1011.203.62.42704.11116.29774.990 159.604.02.42204.01016.98575.230 208.704.52.41093.90117.39875.652

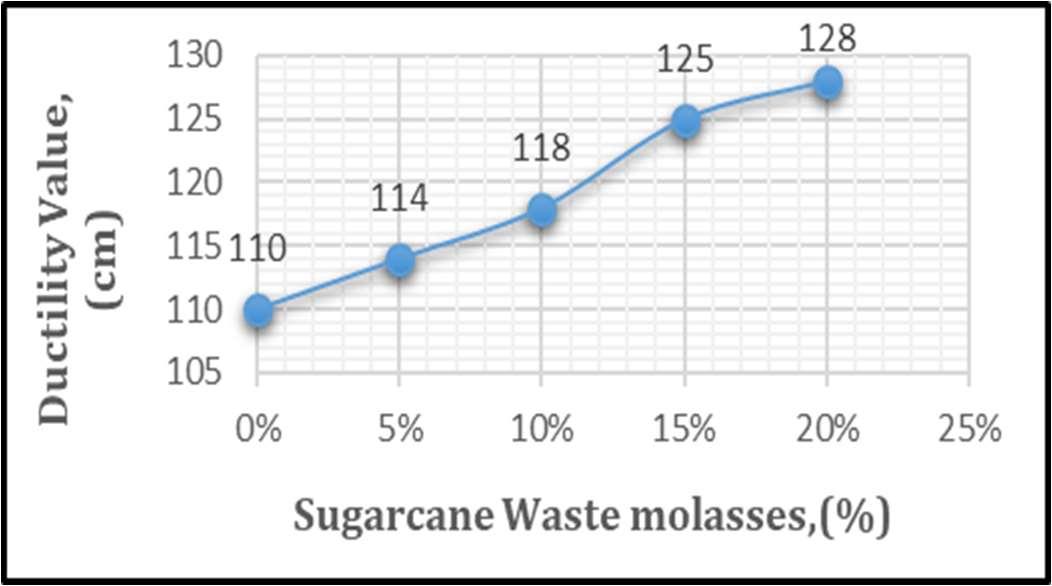

Figure–6:DuctilityValue. Theductilityfindingsofthemolassesmodifiedbinderare greaterthan100cm,whichsatisfiedtherequiredlimitfor binders.

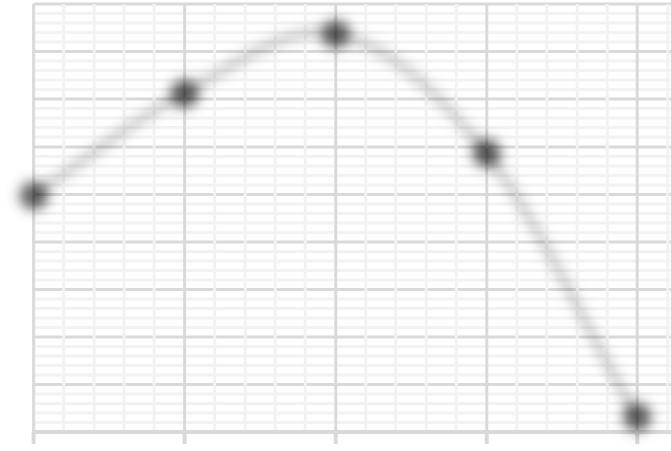

Figure–7:StabilityvsSWM.

Themarshallstabilityvalueofmolassesthatreplaces5%, 10%,15%,and20%ofthetotalbinderweighthasbeen slightlyreduced.Themarshallstabilityofmolassesmodified asphaltmixesis11.40kn,11.20kn,9.60kn,and8.70knfor molassesconcentrationsof5%,10%,15%,and20%, respectively,whichis5%,7%,23%,and32%lowerthan thatofnormalasphaltconcretemixtureof11.9kn.Thedrop inmarshallstabilityreadingsmightberelatedtothe aggregateadhesionabilityinasphaltconcretemixes. AccordingtoASTMD6927-06,themarshallstabilityvalue mustbemorethan8.0kntoachievetheminimumstandard forroadpavement.Asaresult,SWMsubstituting5%,10%, and15%,20%ofthebasebindermaybeutilisedtochange thebasebinderinhotmixasphaltmixes.Fortheoptimum sugarcanewastemolassescontent,themaximumstability valuecorrespondingtoSWM%isconsideredjustbeforethe stabilityvaluedecreases.Thatis11.40KNat5%.

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net

AIR VOIDS, (%)

4.1504.130 4.111 4.010 3.901 3.850 3.900 3.950 4.000 4.050 4.100 4.150 4.200 0510152025

Figure–10:AirVoidsvsSWM

Figure–8:FlowvsSWM.

TheflowvalueistheoveralldeformationoftheMarshalltest specimenatmaximumload,measuredinmillimeters.The maximumflowvalueis4.5mmat20%&theminimumflow valueis2.8at0%.AccordingtoMORTHtable500-11,the flowvalueformodifiedbitumeninhottemperature conditionsshouldbe2.5-4.Theflowvaluesdeterminedin thelaboratoryarewithintherequiredrange.Lowflow valuesareundesirablebecausepavementsmadewithsuch mixturesarepronetocrackingowingtolargemovement loads.Fortheoptimumsugarcanemolassescontent,the flowisconsideredatthemidpointoftheflowvaluechart thatis3.6@10%.

Fortheoptimumsugarcanewastemolassescontent,theair voidsexactlyselectedat4%correspondingtosugarcane wastemolassescontenti.e.,15%.Ifwechooseanoptimum bitumencontentlessthan4%,thepavementwillrutandwill notfulfilltheVFBrequirements.Ifwechoosea3%OBC, therewillbereducedvoids(1%)ornovoidsafterrunning traffic.Allofthiscausesruttingandbitumentodrainoffthe surfaceinsummerseason.Ontheotherhand,ifwechoose OBCwithmorethan5%airvoids,thepavementwillbe permeabletoairandwaterevenafterrunningcontinuous traffic.Thepavementwillloseitsdurability,andasaresult ofthis,apotholeinthepavementmayformordestroythe entirepavement.

Figure–9:BulkDensityvsSWM.

Asindicatedinthefigureabove,thepartialsubstitutionof molasseshasaffectedtheunitweightofasphaltconcrete mixtures.Theoveralltrenddemonstratesthatasthe molassescontentincreases,thebulkspecificgravitydrops. At10%swm,thehighestbulkdensityis2.4270g/cc,while thelowestbulkdensityis2.4109g/ccat20%.Highbulk densityindicatescompactionofspecimen&lowporosity. Fortheoptimumsugarcanewastemolassescontent,the maximumbulkdensityvaluecorrespondingtoSWM%is consideredjustbeforethedensityvaluedecreases.Thatis 2.4270gm/ccat10%.

16.985

VMA, (%) SUGARCANEWASTEMOLASSESCONTENT,(%)

17.398 16.2 16.4 16.6 16.8 17 17.2 17.4 17.6 0510152025

16.529 16.380 16.297

Figure–11:VMAvsSWM

VMAdenotesthevolumeofvoidsinaggregatesandisthe sumofairvoidsandbitumenvolume.VMAisessentialto understandbecauseitindicatesthespaceavailableto accommodatetheeffectivevolumeofasphaltandthevolume ofairvoidsrequiredinthemixture.Asaresult,aminimum VMAisrequiredtoestablishanacceptableasphaltfilm thickness,whichresultsinalong-lastingasphaltpavement. ThegraphaboveshowstheminimalvalueofVMAat10%of swm.

©2022,IRJET|ImpactFactorvalue:7.529|ISO9001:2008CertifiedJournal|Page2670

Figure–12:VFBvsSWM.

Asseeninthegraphabove,theVFBofthemixtures increasesasthemolassescontentincreases.Thecausefor thisriseisduetoandecreseinVMAandareductioninair voidswhenmolassescontentrises.Fortheoptimum sugarcanemolassescontent,theVFBisconsideredatthe midpointoftheVFBgraphthatis74.990@10%.

4.3.3Indirecttensilestrengthtest

Thefollowingaretheindirecttensilestrengthvaluesof modifiedasphaltwithsugarcanewastemolassescontentat dryandwetconditionsandalsoTensilestrengthratio:

Table–8:ITS@DryCondition.

ITSDry Condition 0% SWM 5% SWM 10% SWM 15% SWM 20% SWM

Sample11950.6602173.9922448.1842181.8231802.790

Sample21938.9522166.1622467.7292224.9221763.599

Sample31966.3912193.5372499.1142236.6361783.194 Sample42016.8112205.3142385.4772146.5541700.893 Average load,(K.pa)1968.2032184.7512450.1262197.4831762.619

Table–9:ITS@WetCondition.

ITSWet Condition 0% SWM 5% SWM 10% SWM 15% SWM 20% SWM

Sample11609.8801915.4612307.1731938.9521426.555

Sample21598.1701903.6842330.6641978.1041371.688

Sample31637.3221931.1222346.3251997.7121410.879

Sample41688.2511935.0052224.9221904.0021356.011 Average load,(K.pa)1633.4051921.3182302.2711954.6921391.283

Figure–14:ITS@WetConditionvsSWM

Figure–13:ITS@DryConditionvsSWM

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net ©2022,IRJET|ImpactFactorvalue:7.529|ISO9001:2008CertifiedJournal

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net

Themoisturesusceptibilitymaybedeterminedusingthe tensilestrengthratio.Whentestingmoistureresistance,TSR alonewasdeterminedtobeinsufficient.Toevaluatethe moisturedamageresistanceofasphaltmixtures,itis recommendedtotestbothTSRandwetITSstrengthatthe sametime.Table8Showsindirectstrengthvaluesatdry condition&Table9showsindirectstrengthvaluesatwet conditions.

Theindirecttensilestrengthvaluesatbothdry&wet conditionsaremaximumat10%correspondingtosugarcane wastemolasses.

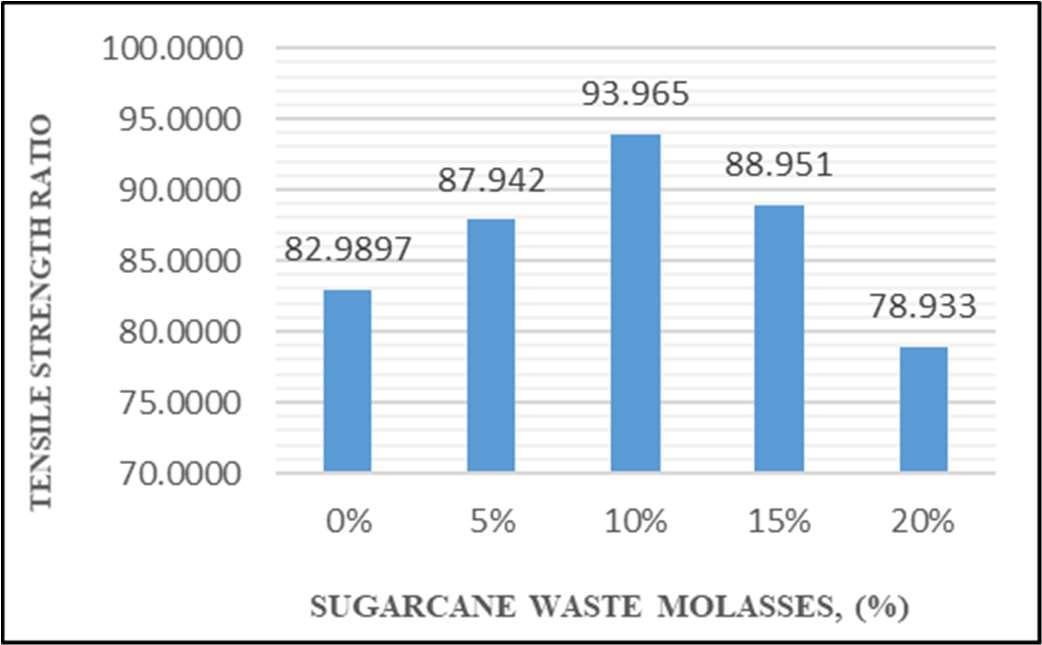

Tensilestrengthratiovaluesare87.942percent,93.965 percent,and88.951percentforsugarcanewastemolasses contentsof5%,10%,and15%,respectively,whichis5%, 11%,and6%higherthanthoseofthetypicalasphalt mixture(82.989percent).Ontheotherhand,tensile strengthvaluesof20%sugarcanewastemolasses,arelower thanthoseofthecontrolasphaltconcretemixture.Thedrop intensilestrengthvaluesofthesemodifiedmixesmightbe attributedtotheirreducedadhesionabilityundersaturated conditions.Itwasfoundthatreplacingmorethan20%of sugarcanewastemolasseswithasphaltbinderwas insufficienttoachievetheminimumcriterionof80%.

Thismodifiedbinderwith10%sugarcanewastemolasses contentseemedtohavethemaximumcoatingabilitywith aggregatesinallmodifiedmixes.Asaresult,intermsof moisture-damagedresistance,theoptimumsugarcanewaste molassescontentof10%maybeemployedasareplacement tothebasebinderinasphaltconcretemixes.

5.CONCLUSIONS

Thecurrentstudywasprimarilyconcernedwiththe utilizationofsugarcanewastemolassesasanalternativeto asphaltbinderinasphaltmixtures.Thefollowing conclusionsarereachedbasedonthefindingsof experimentaltesting:

1].Theuseofsugarcanewastemolassesasareplacementto basebindersmaygreatlyincreasebinderpenetration resistance,softeningtemperature,andkinematicviscosity, whichisadvantageoustoimprovingthehigh-temperature performanceofthemodifiedasphaltbindersandasphalt concretemixtures.

2].Theoverallstabilityvalueexceeds8.0knforall percentagesandmeetstheminimumcriteriaforroad pavement.andthehigheststabilityvalueforsugarcane wastemolassesis11.40KN.

3].Theresultsofmoisturesusceptibilitytestsrevealedthat usingsugarcanewastemolassesasanalternativetobase binderscangreatlyenhancethemoisturesusceptibilityof themixtures.However,replacing20%ofthewithasphalt binderreducesthetensilestrengthvalue.Itwasdetermined

thatthemodifiedbinderwith10%sugarcanewaste molassescontenthasthemaximumtensilestrength ratiovalue.

4].Accordingtotheresultsoftheresearchofthebehaviorof molassesmodifiedasphalt,theasphaltcanbemodifiedwith sugarcanewastemolassesuptoanoptimumproportionof 10percent.Thisoptimumpercentageresultsinasignificant riseinthevaluesofbitumen'sfundamentalattributes. Furthermore,itsignificantlyincreasesthemoisturedamagedresistanceofasphaltconcretemixtures.

5].Itisrecommendedthatthefurther(SEM&EDS) experimentalinvestigationsshouldbeperformedfor sugarcanewastemolassesandsugarcanewastemolasses withasphalt.Oneofthemostprevalenttechnologiesfor examiningthemicrostructureandmorphologyofmaterials &chemicalcharacterizationandelementanalysisof materialsisthescanningelectronmicroscope(SEM).& Energy-dispersiveX-rayspectroscopy(EDS).

REFERENCES

[1]K.ShyamPrakash,M.Phanindra,S.RamSurya,andJ. Naresh,"Percentagereplacementofbitumenwith sugarcanewastemolasses,"July2014.

[2]GemechuYilikalMose,PalaniPonnurangam, “InvestigatingtheEffectofCaneMolassesonthe PerformanceofBaseBitumen,”June2018.

[3]K.M.Padmapriya,M.Gouthamkumar,M.Hariharan,R. Shanmugam“Experimentalinvestigationonbitumen withpartialreplacementofsugarcanewastemolasses,” March2019.

[4]HariKrishnan,JithinPrakash,SameehaShaji,Smrithi, Bhamini“Modificationofbitumenwithsugarcane molassesandcoconutshellcharcoal,”April2019.

[5]UjjwalGupta,DeepakJuneja,“PartialReplacementof BitumenwiththeSugarcaneWasteMolasses”. InternationalJournalofInnovativeTechnologyand ExploringEngineering,”June,2019.

[6]A.Rangaraj,N.P.Srinivasan,“Experimentalinvestigation onpartialreplacementofbitumenwithsugarcane molassesandquarrydust”January2020.

[7]VanPhucLe,“Performanceofasphaltbindercontaining sugarcanewastemolassesinhotmixasphalt,”June 2021.

[8]MORTH–SpecificationsforRoad&BridgeWorks.(Fifth Revision).

[9]IS:2386(Part1&2)-1963–MethodsofTestfor AggregateforConcrete.

InternationalResearchJournalofEngineeringandTechnology(IRJET)e-ISSN:2395-0056 p-ISSN:2395-0072 Volume:09Issue:06|Jun2022www.irjet.net

[10]IS:1203,1205,1206(part3),1208,1209-Methodsfor TestingTarandBituminousMaterials,1978

[11]ASTMD1559-1976–ResistancetoPlasticFlowof BituminousMixturesUsingMarshallApparatus.

[12]AASHTOT283–ResistanceofCompactedAsphalt Mixtures-InducedDamage.

[13]ASTMD6927-StandardTestMethodforMarshall StabilityandFlowofBituminousMixtures.

BIOGRAPHIES

NAVEENKUMARP, M.techStudent,Departmentof Constructiontechnology& Management,DayanandaSagar CollegeofEngineering,Bengaluru, Karnataka,India

Dr.VINAYA, AssistantProfessor,Department ofcivilEngineering,Dayananda SagarCollegeofEngineering, Bengaluru,Karnataka,India.

©2022,IRJET|ImpactFactorvalue:7.529|ISO9001:2008CertifiedJournal