International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1Student, Department of Electrical Engineering, Fr. C. Rodrigues Institute of Technology, Vashi, Navi Mumbai, Maharashtra, India

2Professor, Department of Electrical Engineering, Fr. C. Rodrigues Institute of Technology, Vashi, Navi Mumbai, Maharashtra, India ***

Abstract The rechargeable lithium ion battery has been extensively used in mobile communication and portable instruments due to its many advantages, such as high volumetric and gravimetric energy density and low self discharge rate. Early detection of inadequate performance facilitates the timely maintenance of battery systems. This reduces operational costs and prevents accidents and malfunctions.Prognosticandhealthmanagement(PHM)can ensure that a lithium ion battery is working safely and reliably. The main approach of the PHM evaluation of the battery is to determine the state of health (SoH) and state of charge (SOC) of the battery. This paper presents the preliminarydevelopmentofthedata drivenprognostic,using an LSTM (RNN) approach to predict the SoH and SoC of the lithium ion battery. The effectiveness of the proposed approachwasassessedinacasestudyusingabatterydataset from NASA's Ames Prognostics Center of Excellence (PCoE) database. The proposed LSTM algorithm was compared againstothermachinelearningbasedontheRMSEvalue.The experimentalresultsrevealthattheperformanceoftheLSTM algorithm could either match or outweigh other machine learning algorithms.

Key Words: lithium ion battery, battery management system, Prognostic and health management, State of Health, State of Charge, LSTM

Li ion batteries are playing a crucial role in the fields of renewable energy systems and electric vehicles. Batteries hold the potential to transform the transportation sector, which now emits considerable volumes of CO2. They also provide a solution to the intermittent energy powered by solarandwindgenerators,assistingintheviabilityofthese green solutions. However, batteries may not be the clean energysolutiontheyseematfacevalue.Obtainingresources forbatteries,suchaslithium,hasbecomeanenvironmental issue[1]. The reliability of these systems depends on a batterymanagementsystem(BMS)whichmonitorsthestate of charge (SoC) and state of health (SoH) effectively[2]. Knowing the SoH of a battery in advance enhances the system'sreliability.TheproposedSoHestimationmethodis simulated in Python using the LSTM algorithm by

considering the ageing factors such as temperature, charge/dischargerates,anddepthofdischarge[3]

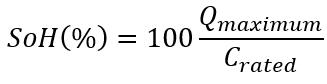

Duetotherestrictedmanufacturingprocess,theactualfull capacity of a new battery may differ from the nominal batterycapacityclaimedbythemanufacturer.Asaresult,a newbattery'soriginalmaximumcapacity,Qf,iscalculatedby averaging the full capacities of multiple charging/dischargingcycles.Whenabatterybeginsacyclic charging/discharging operation, the inevitable aging will lead to performance deterioration, with a decrease in the maximum chargeable or releasable capacity, QM, which is acquiredbycumulatingthebatterychargeseitherfroman empty to full or full to empty operation[5]. The "state of health" of a battery describes the difference between an examinedbatteryandanewbattery,takingintoaccountcell ageing. It's the ratio of a battery's maximum charge to its ratedcapacity[6]

For an aged battery, the capacity fading causes not only a decrease in the maximum releasable capacity but also a mistakeinSOCestimation.Thestateofchargeofabattery describesthedifferencebetweenafullychargedbatteryand thesamebatteryinuse.Itisassociatedwiththeremaining quantityofelectricityavailableinthecell[6].Itiscalculated bydividingthebattery'sremainingchargebythemaximum chargethebatterycanproduce.

Thelithium ionbatterydataemployedintheprognostics analysis of this work was retrieved from the NASA Ames PrognosticsCenterofExcellence(PCoE)datarepository[4] This dataset contains the test results of commercially availablelithium ion1850 sizedrechargeablebatteries,and the experiments have been performed under controlled

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

conditions in the NASA prognostics testbed. The dataset containsthetestresultsofcommerciallyavailablelithium ion 1850 sized rechargeable batteries. A set of four Li ion batteries(#5,6,7,and18)wererunthroughthreedifferent operationalprofiles(charge,discharge,andimpedance)at roomtemperature.Chargingwascarriedoutinaconstant current(CC)modeat1.5Auntilthebatteryvoltagereached 4.2V and then continued in a constant voltage (CV) mode until the charge current dropped to 20mA. Discharge was carriedoutataconstantcurrent(CC)level of2Auntilthe batteryvoltagefellto2.7V,2.5V,2.2V,and2.5Vforbatteries 5, 6, 7, and 18 respectively. Impedance measurement was carried out through an electrochemical impedance spectroscopy (EIS) frequency sweep from 0.1Hz to 5kHz. Repeatedchargeanddischargecyclesresultinaccelerated ageing of the batteries, while impedance measurements provide insight into the internal battery parameters that changeasageingprogresses.Theexperimentswerestopped whenthebatteriesreachedend of life(EOL)criteria,which wasa30%fadeinratedcapacity(from2Ahrto1.4Ahr).The various parameters in the data set consist of charge, discharge,andimpedancefields.

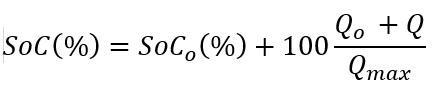

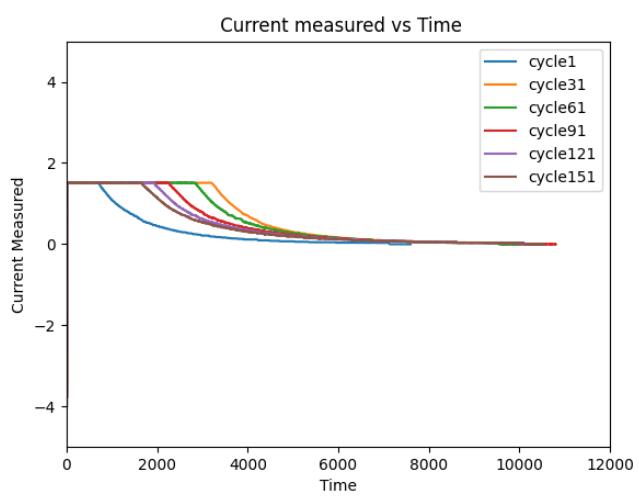

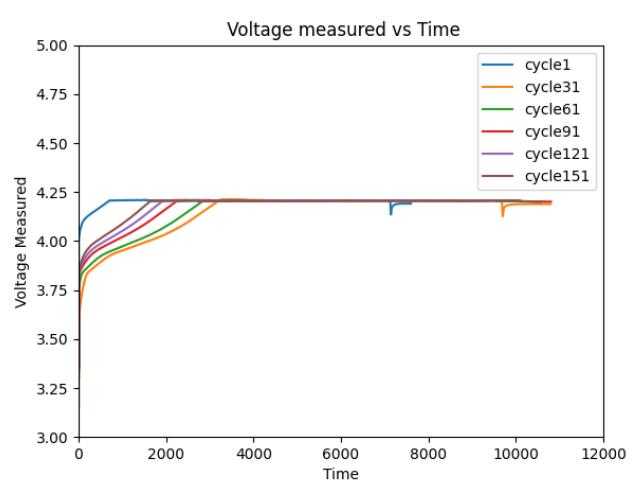

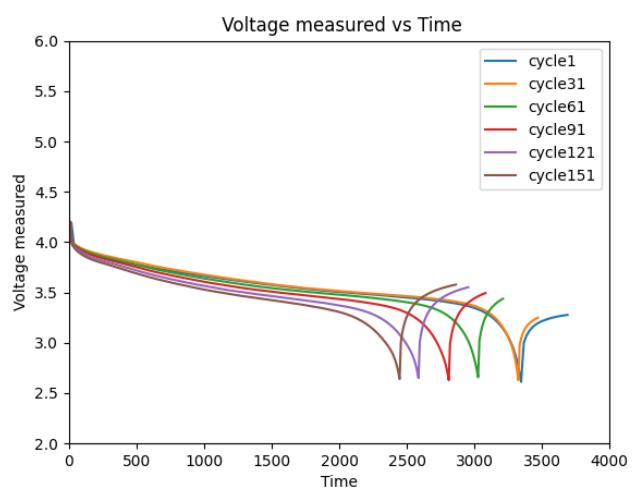

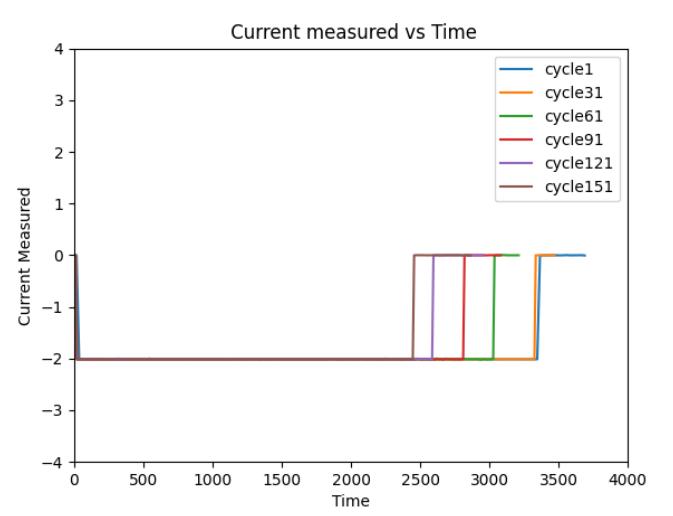

ThefollowingdatasetwasparsedinPython3.9usingthe SciPy library and the following characteristics were observedduringchargeanddischargeofBatteryno.5across atotalof164cycles.Graphswereplottedatintervalsof30 cycles to get a clear idea of the distinct nature of the characteristicswiththepassingcycles.

Chargingwascarriedoutinaconstantcurrent(CC)mode at1.5Auntilthebatteryvoltagereached4.2V,whichisthe thresholdvoltage,andthencontinuedinaconstantvoltage (CV)modeuntilthechargecurrentdroppedto20mA.The voltagemeasuredacrossthebatteryincreasesslowlyineach cycle. However, because the battery cannot maintain its initialvoltagevaluewitheachcycle,weobserveavariation in the starting level of the voltage (as after one complete cycleofdischarge,someamountofenergyisstoredwithin thebattery)Thechargingvoltageisslightlygreaterthanthe currentmeasuredduetosomedropassumed.Theamountof timetakenforfullychargingthebatteryisaspecifictime(1 hr)afterthebatteryenterstheCVmodeofcharging,usually whenthecurrentreaches10percent

Chart 1:VoltagemeasuredVsTimewhilecharging (BatteryNo.5)

Chart -2:CurrentmeasuredVsTimewhilecharging (BatteryNo.5)

Thebatterywasdischargedataconstantcurrent(CC)of 2A until the voltage dropped to 2.7V. Since the battery's capacityis1.9Ahr,thebatteryisdischargedat1.1Cinthis situation.Inthegraphsshownbelow,weobservethatwith the passing of cycles, the rate of discharge increases, suggestingthatthecut offvoltageisreachedsooner,which isanindicationthatthebatteryisgettingolder.Oncethecut offvoltageisreached,thebatterycannotbedischargedany furtherasit'scriticalforthebattery'slongevity.Discharging ofabatterytakesplacewhenthebatteryisconnectedacross theload.Thevoltageacross theloadisslightlylessdueto the drop across the circuit and battery back emf with a constantcurrentof2Aappliedthroughout

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Chart -3:MeasuredmeasuredVsTimewhiledischarging (BatteryNo.5)

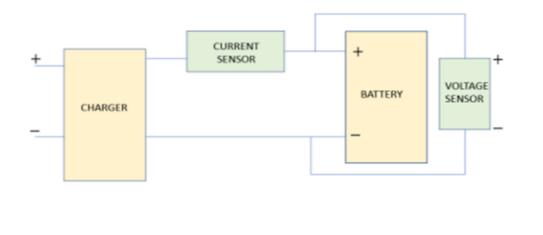

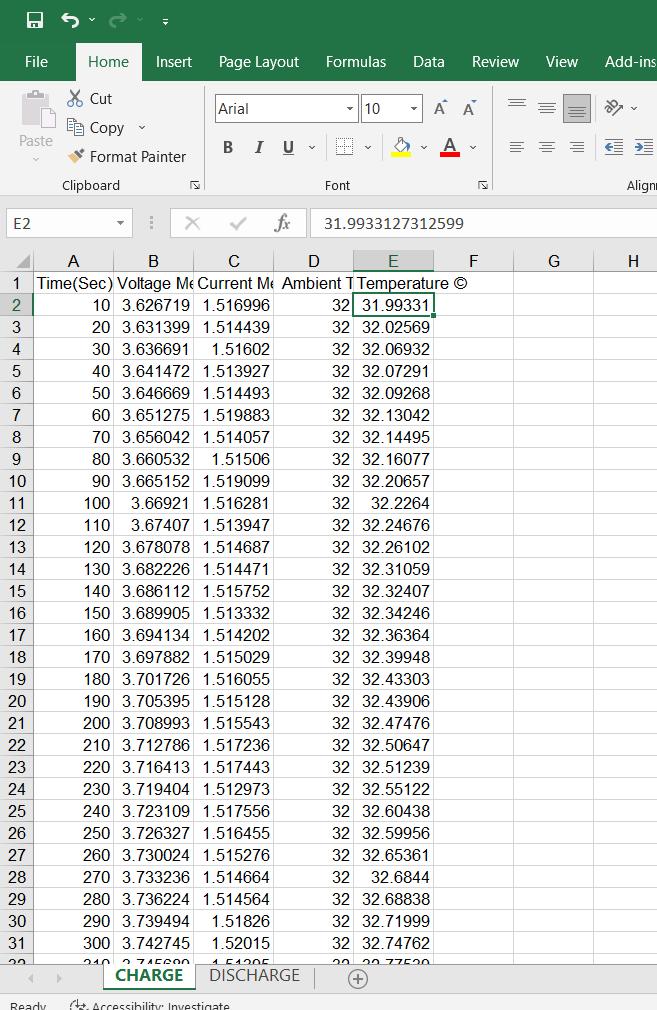

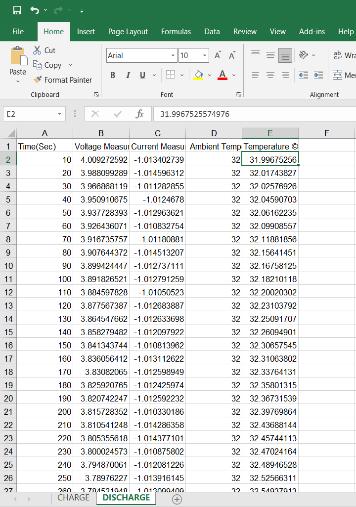

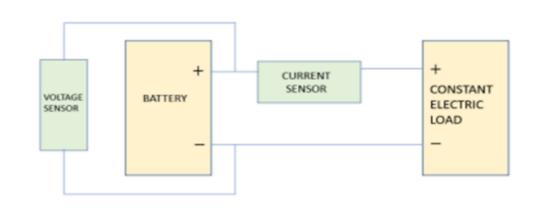

current dropped to 19mA. Discharge was carried out at a constantcurrent(CC)levelof1Auntilthebatteryvoltagefell to2.7V,2.5V,2.2V,and2.5Vforthebattery[8].Thecurrent sensorisalwaysinserieswiththebattery.Therefore,aclose resemblance was observed between the practically performeddataandthetheoreticallyobserveddatainthe datasheetmentionedinourchosenresearchpaper.Thedata was acquired by connecting the chassis to the LabVIEW using the laptop interface. An electronic load was used to carryoutthedischargingofthebattery,andprobesfromNI modulesacrossthebatterywereconnectedtomeasurethe voltage. A current sensor was connected in series to the batterytomeasurethecurrentandwascalibratedusingthe ArduinoUno.AK TypeThermocouplewasplacedoverthe battery with the help of insulation tape for accurate measurementofthebatterytemperature[9].Forcharging,a calibratedchargerwasdismantledandthephaseandneutral terminals were directly inserted into the supply charging slots. Data for charging or discharging cycles was continuouslymonitoredintheLabVIEWatafrequencyof1 Hz until the end of the cycle. The challenges faced while executingthehardwarewerethattheLabVIEWcouldonly acquiredatafromoneNI Moduleatatime,whichledtous performingdifferentcyclesforthemeasurementofvoltage andtemperaturefortheirrespectiveNI Modulestogetthe readingsforasinglecycle[10].Thedatawasacquiredand provedtobeauthenticasitfollowedtheideal(theoretical) charginganddischargingtraits.

Chart 4:CurrentmeasuredVsTimewhiledischarging (BatteryNo.5)

Assemblyofhardwareequipmentwasinitiallyproblematic because to the COVID 19 outbreak, but once the college reopened, hardware was installed to validate the data obtained from our study paper, which we referred to for benchmark results. This was achieved by charging and discharging 18650 Li ion batteries with identical specifications (nominal voltage 3.7V, peak voltage 4.2V, ampere hourcapacity2000mAh)usingLabVIEWsoftware andNI Modules.

Chargingwascarriedoutinaconstantcurrent(CC)mode at 1.3A until the battery voltage reached 4V and then continuedinaconstantvoltage(CV)modeuntilthecharge

Fig -1:Hardwaresetupforgeneratingreal timedata

Fig -2:blockdiagramforchargingcycle

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Fig 3:Blockdiagramfordischargingcycle

Thefollowingparameterswerecapturedduringthecharging anddischargingofthebatteries,

i. Thevoltagerosefromthenominalvoltageof3.7Vto 4V,4.1Vduringcharging,andthenfellto2.7V, which was the cut off voltage during discharging.

ii. Thecurrentwasdrawnusingaconstantelectronic load of 1A during discharging at 0.5C. While charging,itfollowstheCC CVprotocolswhere first the charging takes place at a constant current of 1.3A till the voltage rises from the nominalvoltageof3.7Vto4.2V,afterwhichthe currentstartstofall,tillitreaches50milliamps.

iii. The temperature at which the entire setup was beingperformedwas32°Croomtemperatureor ambient temperature. We observed that with the rise of current, the temperature gradually rosefrom32°Ctoasmallamountof34°Catits peak current and then the temperature subsided gradually. But the temperature rise during discharging was rapid as a constant currentof1amperewasbeingabsorbedbythe load continuously, which led to a rise in temperatureto36°C.

Fig -4:DataacquisitionofchargingSetup

Fig 5: DataacquisitionofdischargingSetup

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Machinelearningalgorithmsaregoodathandlingdatathat ismultidimensionalandmultivariate,andtheycandothisin dynamicoruncertainenvironments.AsMLalgorithmsgain experience,theykeepimprovinginaccuracyandefficiency. Thisletsthemmakebetterdecisions.Sayyouneedtomakea weather forecast model. As the amount of data, you have keepsgrowing,youralgorithmslearntomakemoreaccurate predictionsfaster[7].ThereisalotofscopeinMLtobecome thetoptechnologyinthefuture[4].Thereasonisthatithasa lot of research areas in it. This helps us improve both hardwareandsoftware

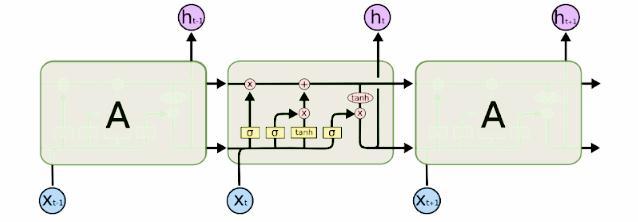

Long Short Term Memory networks usually just called “LSTMs” areaspecialkindofRecurrentNeuralNetwork, Capable of learning long term dependencies. They were introduced by Hochreiter Schmidhuber (1997) and were refined and popularized by many people. They work tremendously well on a large variety of problems and are nowwidelyused[11]

achieved by an efficient, gradient based algorithm. LSTM outperformsandalsolearnstosolvecomplex,artificialtasks nootherrecurrentalgorithmhassolvedbefore.Theother advantagesofusingLSTMareasfollows: Forlongtimelag problems, LSTM can handle noisy distributed representationsandcontinuousvalues.Incontrasttofinite state automata or hidden Markov models, LSTM does not require an a priori choice of a finite number of states. In principle, it can deal with unlimited state numbers. There appears to be no need for parameter fine tuning. LSTM works well over a broad range of parameters such as learningrate,inputgatebias,andoutputgatebias.Positions ofwidelyseparated,relevantinputsintheinputsequencedo not matter. The LSTM algorithm updates complexity per weightandtimestep[12].LSTMislocalinbothspaceand time.

Recurrent networks can, in principle, use their feedback connectionstostorerepresentationsofrecentinputevents in the form of activations (weights). This is potentially significant for many applications, including speech processing,non Markoviancontrol,andmusiccomposition. Althoughtheoreticallyfascinating,existingmethodsdonot provide clear practical advantages over backdrops in feedforward nets with limited time. With conventional “Back PropagationThroughTime"or“Real TimeRecurrent Learning",errorsignalsflowingbackwardsintimetendto either (1) blow up or (2) vanish the temporary backpropagatederror.Thismayaffectthemodelandbring about the following consequences: Case (1) may lead to oscillatingweights.Case(2):Learning to bridgelong time lagstakesaprohibitiveamountoftimeordoesnotworkat all. In conjunction with an appropriate gradient based learning algorithm, this paper presents "Long Short Term Memory"(LSTM),anovelrecurrentnetworkarchitecturein conjunction with an appropriate gradient based learning algorithm.LSTMisdesignedtoovercometheseerrorback flow problems. It can learn to bridge time intervals over 1000steps,eveninthecaseofnoisy,incompressibleinput sequences,withoutlossofshorttimelagcapabilities.Thisis

PrecisemeasurementsofSOCarenecessarytoensuresafe operationwhilemaximizingtheuseofbatterycapacity.In earlyapplications,peoplefoundthatthebatterySOChada strong linear relationship with the open circuit voltage (OCV). To measure the accurate OCV, the battery needs hours to rest. While in most conditions, accurate OCV is unlikely to be obtained and is mainly not a method considered in the case of finding a soc for lithium ion batteries. Due to the various internal and external conditions, fixed mathematical transformations cannot be accurate. The coulomb counting method (CCM) is another straightforward method that has the advantage of simple computation and easy implementation. CCM is widely recommended for battery health management. However, CCM is calculated by charge and discharge current time integral,whichisunabletoeliminatecumulativeerrorandis verysensitivetotheinitialvalue.IftheinitialSOCvalueis inaccurate, it will affect all estimates and the error will accumulateduringthewholeestimationprocess.Theinitial SoCvalueisusuallypredictedandisnotverifiedtobe100% accurate. The large amount of data makes it even more difficultforthemodeltogiveanaccurateSOCvalue[14]

Inthissection,ananalysisofbatteryNo.06,No.07,andNo. 18 degradation datasets taken from the NASA Ames Prognostics Center of Excellence (PCoE) database was conducted to evaluate the effectiveness of the developed LSTMtechnique.ThedatasetofbatteryNo.05wasemployed

Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

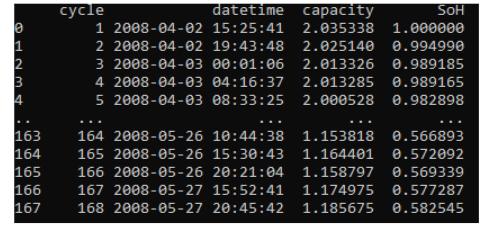

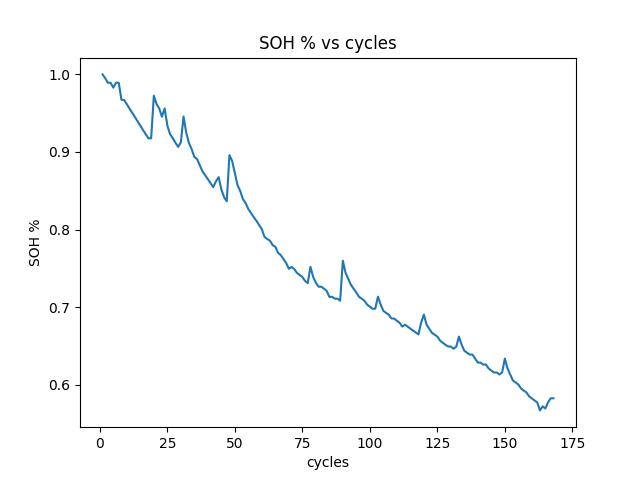

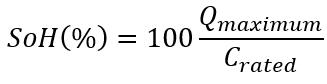

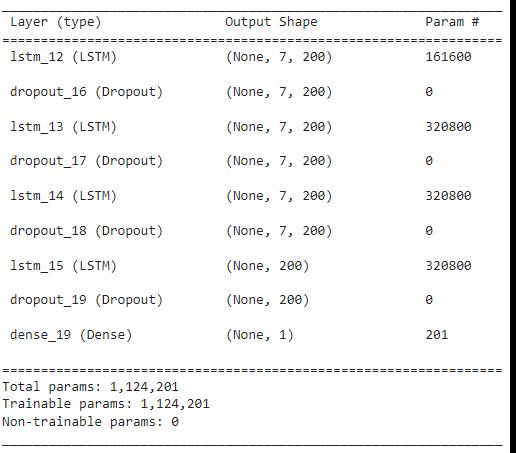

as a training dataset. A detailed description of the experimentaldatahasbeenprovided.TheSoHexperimental results from the conventional DNN and developed LSTM modelwillbepresented.AnLSTM RNNnetworkistrained to model the complex battery dynamics under varying ambienttemperatures.Astep by stepsearchingmethodis presented to determine the optimal network hyper parametersforSOHmodelling[13].Thenetworkwelllearns the battery dynamics, presents good robustness against unknown initial states and provides satisfying SOH estimationsundervaryingtemperatures.Therearenatural recursivelinkagesbetweencurrentSOCandpastinputs,as illustrated by the Coulomb counting approach. An LSTM RNNnetworkisthereforeconstructedtomodelthetemporal dependencies of the input layer, battery current, terminal voltage,andambienttemperaturetoformtheinputvector. SinceitisnecessarytocalculatetheSoHofthebattery,as thisisthedatathatwillbepredictedusingtheLSTMmodel, a theoretical calculation of SOH was performed in Python basedontheformulagivenbelow: where,

representsthemaximumpracticalcapacity asmeasuredfromtheoperatingbatteryatthecurrenttime.

represents the rated capacity from battery manufacturers.TheoreticalvalueofSoHofallthebatteries wascalculatedandplottedinthegraphshowingtheaging processofthebattery[15]

According to the README file of the dataset, the data is stored in several ".mat" files. Each file corresponds to a specificbattery,andthedatastructureofeachfilecontains the parameters mentioned in the above section. For the LSTMmodel proposedinSectionV,itisonlynecessaryto collectthedatarelatedtothedischargeofthebattery.For this, a function is created in Python that is in charge of reading this data from the ".mat" file and storing it in memoryintwopandasDataFramesforlateraccess.After loadingthedataset,adescriptionofthedataismadeusing pandasfunctionstoverifyifthedataloadingwascorrect.

Thedatasetispreparedinsuchawaythatitcanbeusedby TensorFlow during the training phase; two structures are constructed corresponding to the predicted input and output.Fortheinputdata,therelevantcharacteristicsofthe datasetarefiltered,whichare: •Batterycapacity

Voltage

Current

Temperature

Chargingvoltage

Chargingcurrent

Instantoftime(fromthestartofthedownload)

Fortheoutputdata,theSoHofthebatteryiscalculatedand, inbothinputandoutputcases,thevaluesarenormalizedto arangeofvaluesbetween[0]and[1].Forthepreparationof themodel,fourdropoutlayers,onedenselayer,andoneof theADAMtypesareusedasoptimizers.About50epochsare usedfortrainingthemodel.

Fig

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

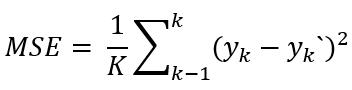

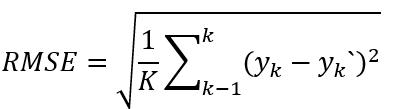

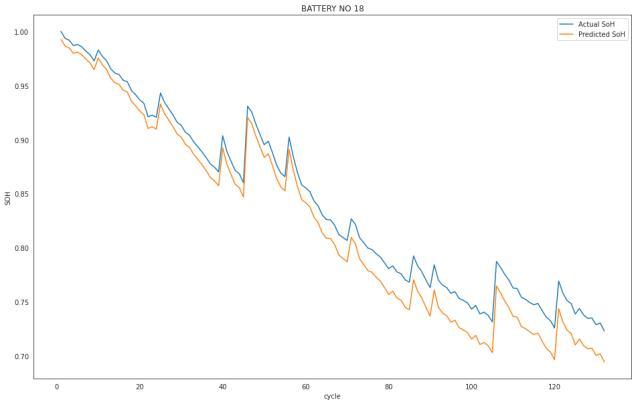

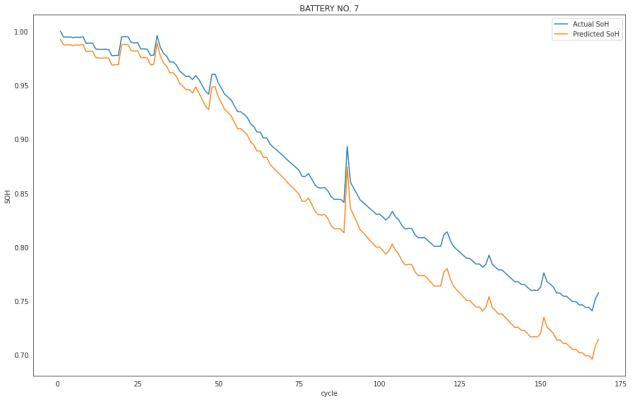

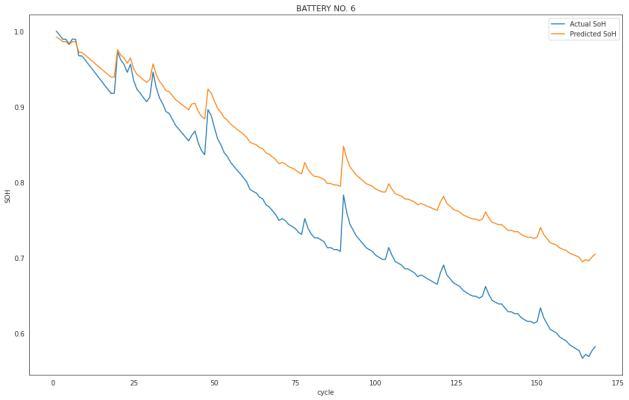

The information (or data) of the test batteries, namely BatteryNo.6,BatteryNo.7,andBatteryNo.18,wasloaded totestthemodel'scorrectness.Therootofthemeansquare error,aswellasthetrueSoHandtheSoHpredictedbythe network, were calculated in a table. In addition, a plot of cyclesvs.SoHforeachofthethreebatterieswascreated.

Chart 6:BatteryNo.6

Chart 8:BatteryNo.18

Inthisexperiment,thedischargedataforall164cyclesfrom batteryNo.5wereemployed.TheSoHwascalculatedfrom theinitialcapacityasbeing1.9AHr.Theresultisconsidered to be a long term SoH estimation of the battery. The followinggraphsshowtheperformanceofbatteryno.6,7, and18usingacomplexDNNalgorithm(LSTM).Thex axis representsthecycles,andthey axisrepresentstheSoH.The bluelineintheplotrepresentstheactualSoHandtheorange linerepresentsthepredictedSoHbythemodel.

Itisclearlyshowninthefiguresthatduetotheaccurate fittingofthetrainedDNNmodelwithbatteriesno.6,7and 18,theLSTMmodelissuccessfullybuiltandtheRMSEofthe SoH estimated by the proposed model is much less as comparedtoothertraditionalmachinelearningalgorithms.

Table -1: RMSEoftheSoHestimationbyusingLSTMand traditionalmachinelearningalgorithms

K NN LR SVM ANN DNN LSTM

5.598 4.558 4.552 4.611 3.427 2.406

Considering the results illustrated above, it is also important to note that the results from battery No. 06 performedslightlyworsewhencomparedtobatteryNo.07 and18.ThiscouldbeduetotheageingpatternofbatteryNo. 06beingslightlydifferentfromthetrainingdataset.

Furthermore, as compared to the other batteries, the results for battery No. 06 had a wider distribution. The results from the table given below show that, overall, the proposedLSTMalgorithmoutperformedallthetraditional machine learning algorithms, including the standard DNN method.LSTMperformedbetter,intermsofcapturingthe RMSEvalue.

Chart 7:BatteryNo.7

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

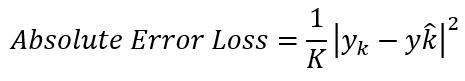

Absoluteerrorsmeasuredthemeanabsolutevalueofthe difference between the elementwise inputs. The absolute errorformulausedasthelossfunctioncanbeexpressedby thefollowingequation:

Where,yiandare,respectively,thepredicteddataandthe inputdataofeachiterationorepochi,andkisthenumberof iterationsorepochs.Inthisexperiment,thetotalnumberof epochswassetto200.

This work aims to develop an LSTM model to predict the stateofhealthoflithium ionbatteries.Thisexperimenthas achieveditsgoalofaiding,asabenchmark,theprognostic data drivenmodelforbatterydatausingmachinelearning algorithms. Based on the results from the case studies, it shows that the LSTM algorithm provides a promising outcome for predicting and modelling prognostic data, especiallyinthebatteryprognosticandhealthmanagement applications. Also, based on several advantages of data drivenmodelsoverthetraditionalphysics basedmodelsand the accuracy achieved, we believe that the traditional physics basedmodelmaybereplacedbydata drivenmodels soon,invariousfieldsandapplications.Thisfuturetrendof data drivenmodelsisinlinewiththerecentachievementof deep learning algorithms and artificial intelligence. These methodologiesarebelievedtobethemainapproachesinthe further development of data driven models. However, the accuracyofpredictionandthehigherperformanceofusing deep learning algorithms also come with the drawback of higher computational time. With rapid advancements in technology, the computational time could be substantially reduced. The future direction of this work will focus on developing a hybrid deep learning model that could be universallyapplicabletomultipletypesofprognosticdata. Due to time constraints and inaccessibility of the lab equipment,itwasnotfeasibletocreateanentiredatasetof the battery as acquiring an entire dataset would take approximately (170×4) 680 hours. Hence, there is uncertaintyinpredictingthewholenatureofthebattery’s operation based on a couple of charge discharge cycles. However, it was found that in the practically performed cycles,allthecharging/dischargingprotocolswereobserved quiteaccurately.

The success of a project like this, involving high technical expertise, patience, and the massive support of guides, is possiblewhenteammembersworktogether.Wetakethis opportunitytoexpressourgratitudetothosewhohavebeen instrumentalinthesuccessfulcompletionofthisproject.We

would like to show our appreciation to Mr Abhishek Shiwalkar and Dr Sushil S. Thale for their guidance and support, which was instrumental in the progress of this project.Wewouldalsoliketothankourprojectcoordinator, MrsSeemaJadhavforprovidinguswithregularinputabout documentationandtheprojecttimeline.Wewouldalsolike tothankMrNikhilSoradeforhisguidanceandsupportin datasetinterpretation.AbigthankstoourHOD,DrBinduS. foralltheencouragementgiventoourteam.Wewouldalso like to thank our principal, Dr S. M. Khot for giving us the opportunityandtheenvironmenttolearnandgrow.

[1] H. C. Hesse, M. Schimpe, D. Kucevic, and A. Jossen, “Lithium ionbatterystorageforthegrid areviewof stationary battery storage system design tailored for applicationsinmodernpowergrids,”Energies,vol.10, no.12,p.2107,2017.

[2] R.Xiong,Y.Zhang,J.Wang,H.He,S.Peng,andM.Pecht, “Lithium ion battery health prognosis based on a real batterymanagementsystemusedinelectricvehicles,” IEEETransactionsonVehicularTechnology,vol.68,no. 5,pp.4110 4121,2018.

[3] J.Duan, X.Tang,H.Dai,Y.Yang,W. Wu, X.Wei,andY. Huang,“Buildingsafelithium ionbatteriesforelectric vehicles: a review,” Electrochemical Energy Reviews, vol.3,no.1,pp.1 42,2020.

[4] P. Khumprom and N. Yodo, “A data driven predictive prognostic model for lithium ion batteries based on a deeplearningalgorithm,”Energies,vol.12,no.4,p.660, 2019.

[5] J.Vetter,P.Nov´ak,M.R.Wagner,C.Veit,K. C.M¨oller,J. Besenhard,M.Winter,M.Wohlfahrt Mehrens,C.Vogler, andA.Hammouche,“Ageingmechanismsinlithium ion batteries,”Journalofpowersources,vol.147,no.1 2,pp. 269 281,2005.

[6] S. C.Huang,K. H.Tseng,J. W.Liang,C. L.Chang,andM. G. Pecht, “An online soc and soh estimation model for lithium ion batteries,” Energies, vol. 10, no. 4, p. 512, 2017

[7] J.S.Goud,R.Kalpana,andB.Singh,“Anonlinemethodof estimating state of health of a li ion battery,” IEEE Transactions on Energy Conversion, vol. 36, no. 1, pp. 111 119,2020.

[8] P. Ferrand, “Gpscan. vi: A general purpose labview program for scanning imaging or any application requiring synchronous analog voltage generation and data acquisition,” Computer Physics Communications, vol.192,pp.342 347,2015.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

[9] S. A. Hasib, S. Islam, R. K. Chakrabortty, M. J. Ryan, D. Saha,M.H.Ahamed,S.Moyeen,S.K.Das,M.F.Ali,M.R. Islam, et al., “A comprehensive review of available battery datasets, rul prediction approaches, and advancedbatterymanagement,”IeeeAccess,2021.

[10] L. Wang, Y. Y. Tan, and X. L. Cui, “The application of labviewindataacquisitionsystemofsolarabsorption refrigerator,”inAdvancedMaterialsResearch,vol.532, pp.581 585,TransTechPubl,2012.

[11] S. Hochreiter and J. Schmidhuber, “Long short term memory,”Neuralcomputation,vol.9,no.8,pp.1735 1780,1997.

[12] T. H. Wu, J. K. Wang, C. S. Moo, and A. Kawamura, “State of chargeandstate of healthestimatingmethod forlithium ionbatteries,”in2016IEEE17thWorkshop on Control and Modeling for Power Electronics (COMPEL),pp.1 6,IEEE,2016

[13] F.Yang,S.Zhang,W.Li,andQ.Miao,“State of charge estimationoflithiumionbatteriesusinglstmandukf,” Energy,vol.201,p.117664,2020.

[14] S.SanthanagopalanandR.E.White,“Onlineestimation of the state of charge of a lithium ion cell,” Journal of powersources,vol.161,no.2,pp.1346 1355,2006.

[15] B.Chinomona,C.Chung,L. K.Chang,W. C.Su,andM. C.Tsai,“Longshort termmemoryapproachtoestimate battery remaining useful life using partial data,” IEEE Access,vol.8,pp.165419 165431,2020.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal