International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

Vyshnavraj M1 , Rohit Robin2 , Sreedev A3 , Vishnu V4 , Assoc.Prof. Aneesh K.S5

1,2,3,4B Tech Student, Department of Mechanical Engineering, Mangalam College of Engineering, Kerala, India686631

5 Assiociate Professor, Dept. of Mechanical Engineering, Mangalam College of Engineering, Kerala, India 686631 ***

Lithium ion batteries are found suitable for hybrid electric vehicles (HEVs) and clean electric vehicles (EVs), and temperature control for lithium batteries is essential for long term performance and longevity. Unfortunately, battery thermal management (BTM) was not given much attention due to misunderstandings of battery temperature behavior. The design of the battery temperature equity is important. The uniformity of the temperature of the lithium battery pack is critical to the performance and life of the lithium battery system. The uneven distribution of temperature can easily lead to a heat escape from the lithium battery pack, which could pose safety hazards for the electric car. Temperature similarity is usually measured with Maximum Temperature Difference (MTD). This paper aims to design a cooling system for battery packs with good temperature similarity. In this project, two battery temperature control solutions are selected and analyzed: a wavy cooling channel and a U shaped cooling system is used. The results show that the wavy tube cooling system hasabettercoolingeffect.

Transportation has become the world's largest consumer of petroleum products, accounting for 49% of oil. The efficiency of fuel consumption in cars is very low, so efficient transportation strategies will help to reduce unnecessary energy consumption without providing additionalservices.Oneofthenewestenergysavingideas is the promotion of clean or green energy vehicles. Great attentionhasbeengiventohybridelectricvehicles(HEV), plug in hybrid electric vehicles (PHEV), and clean electric vehicles (EVs) as other possible ways to reduce carbon emissions in transportation. These vehicles are said to provide solutions to greenhouse gas emissions, provide better use of new energy sources, and benefit from long term energy savings. More importantly, opportunities are beingofferedtoEVs,astheUSgovernmentprovides$2.5 billion in grants and subsidies to various EV related companies,andChinaisshiftingitsfocusondevelopingEV economicandenergypolicies.Thebiggestchallengeisfor clean energy vehicles to be sold to save electricity. Building a good car battery pack for high performance is

important.Chargedlithium ionbatteriesarewellsuitedto HEVs and EVs, but have not yet been widely accepted in the automotive industry due to obstacles such as cost, safety, and low temperature performance associated with the effects of temperature. Thermal battery management (BTM),whichisacriticalissueinthedevelopmentofclean electricvehicles,hasreceivedlittleattentionoverthepast few years due to understanding the thermal properties of lithium ionbatteries.

Huanwei Xu et al. (2021) developed a proposed developmentdesignframeworktominimizethemaximum temperature difference (MTD) of a car lithium battery pack. First, the cooling channels of the two cooling and exhaust systems are analyzed: the serpentine cooling systemandtheU shapedcoolingsystem.Theresultsshow that the serpentine cooling system has a better cooling effect.Second,aflexiblecombinationofacquisitionmodels based on advanced particle development algorithm is proposed to assistin theoptimal design of the serpentine cooling system. The development results show that the proposed framework can solve the problem of explicit development with small samples and find a complete globalsolutionandavoidfallingintothetoplocalsolution. However, this paper only uses a flexible combination of surrogate models to make a significant temperature difference. Considering the multi purpose features of the lithium battery pack, a multi purpose design based on a flexibleacquisitionmodelisafuturestudy.

SeyedMazyarHosseiniMoghaddam(2019)hasdeveloped four battery temperature control solutions using ComputationalFluidDynamic(CFD)simulations.Imitation results show that direct liquid cooling has excellent cooling efficiency as it has a very close contact with cells and high temperature. The downside to direct liquid cooling is the complexity of the design due to its leaking capacity.Thesolubleliquidneededforthistypeofcooling is very expensive. Indirect cooling methods (tube cooling andfloorcooling)havemoderateperformance.Incontrast toaircooling,thedistributionoftemperatureinamodule canbe easilycontrolledasthecoolantisconnectedto the temperature by all cells in the same way. Comparisons

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

between the two indirect methods show that cooling the tube creates a lower cell temperature, however, lower coolinghasasimplerdesign.

Zhiguo Tang et al. (2019) performed a three dimensional (3D) simulation of a multi channel wavy tube in a liquid lithium ion battery cooling module, and numerical adjustments were made by varying the wavy connection angleandwavytubeweightflowrateofmultiplechannels. Theincreaseinwavycontactangleandtheflowrateofthe bulkpositivelyaffecttheefficiencyofheatdissipationand the homogeneity of the temperature field of the battery module. From the output, the maximum temperature and temperaturedifferenceofthebatteryareas inthemodule decreases at the end of the discharge and increases the wavycontactangleandthemaximumflowrate.

Thomas Imre Cyrille Buidin and Florin Mariasiu (2021) conducted research on the type, design and operating principles of BTMSs used in the manufacture of multi structured Li ion batteries, with a focus on cooling technology. The advantages and disadvantages of each component, as well as the proposed BTM solutions, are widely investigated, regarding the compatibility of these systems in different Li ion battery conditions. The integrated information thus provides the necessary and important information and suggests future research guides for those interested in this topic to be used to increase the efficiency of battery temperature control systems.

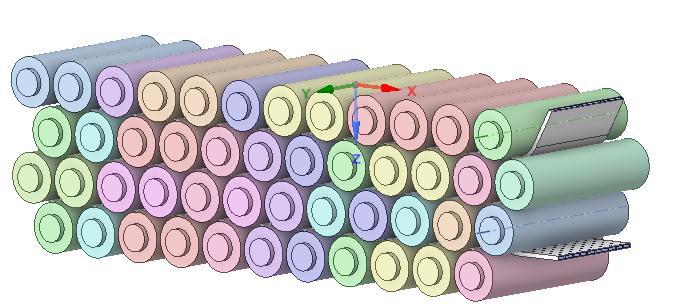

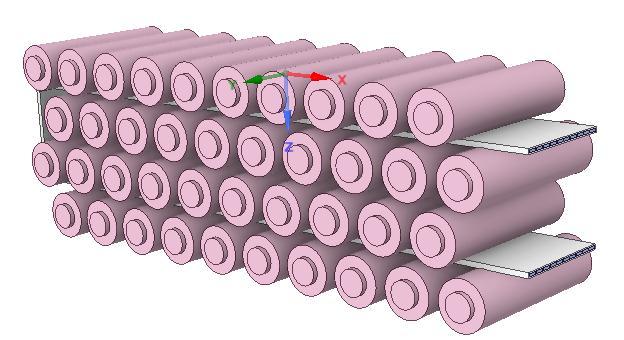

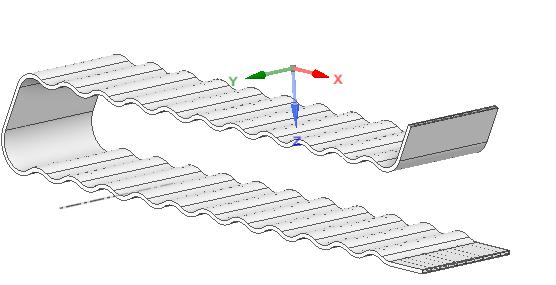

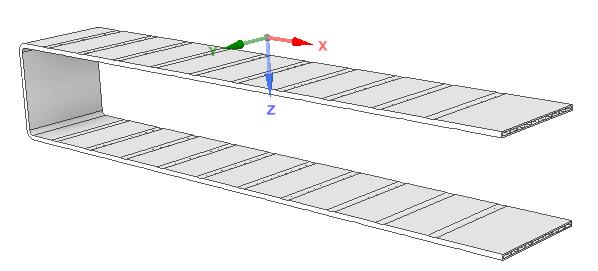

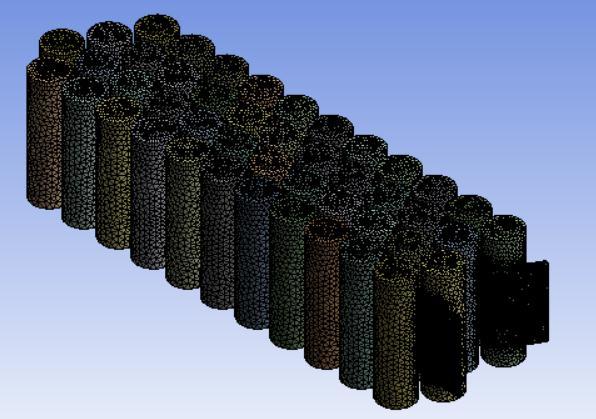

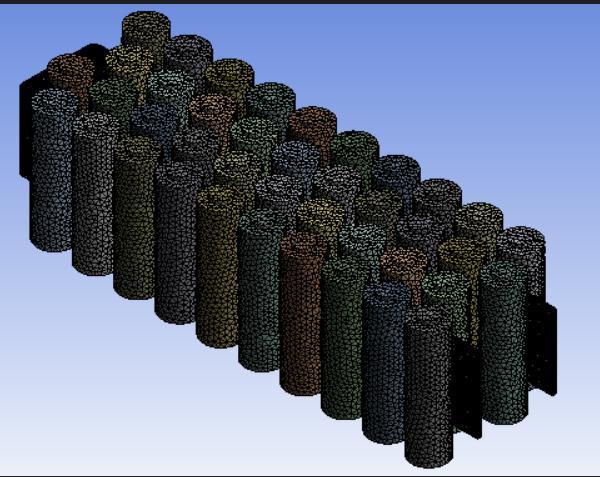

To remove the heat of the lithium battery, two channel coolingstructuresareintroduced.Thefirsttypeofcooling andheatdissipationisawavycoolingsystem.Thesecond type of cooling and exhaust is a U shaped cooling system. Lithium battery used in this analysis cylindrical battery, thebatterymodelis18650diameterandtheheightofone battery is 18 mm and 65 mm respectively. Aluminum cooling plate material. For comparative thermal simulation analysis and simulation, the number of inlets and exits of the two structures are the same. That is, the numberofentryandexitis1,respectively.Inaddition,the size of the cooling plate and the cooling wall of the two designsystemsarekeptthe same,thatis,thethicknessof thecoolingplate is3mm,andthethicknessofthecooling wall is 0.7 mm. The number of batteries in the wavy cooling system is 45 and 40 in the U shaped cooling system. The meshing is made with ANSYS Fluent. Battery packmodelsareseparatedusingtetrahedralmesh.

Material p(Kg/m3 ) C(J/KgK) k(W/(mk)) µ(Kg/(ms))

Water 998.2 4128 0.6 1.003x10 3

Aluminium 2719 891 202.4

Battery 2018 1282 2.7

Table 1.Thermal physical parameters of materials for cooling and heat dissipation system.

Fig.1 3D model of wavy cooling channel battery pack.

Fig.2 3D model of wavy cooling channel

Fig.3 3D model of U shaped cooling channel battery pack

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

volumetric heating generation is 74163 W / m3. In this process, the voltage is a constant value, so the current is also a continuous value, which ensures a continuous voltageandacontinuouscurrentofthetest.

Discharge rate Volumetric heat generation ( W/m3 )

1C 5318

2C 19452

Fig.4 3D model of U shaped cooling channel.

3C 42400 4C 74163

Table 2.Body heat generation rate under different discharge rates of lithium batteries.

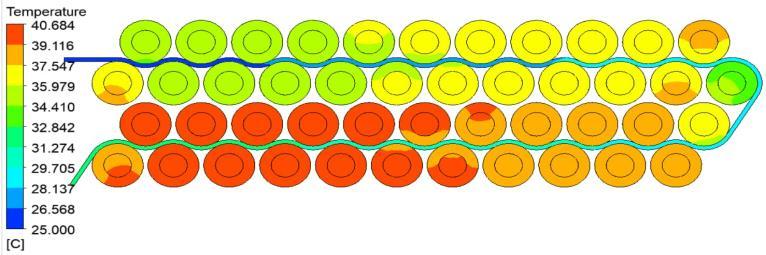

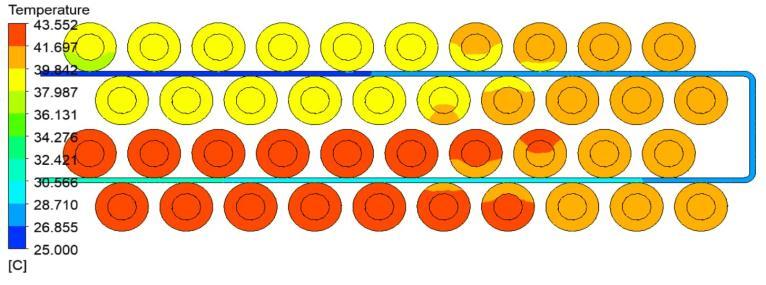

Under conditions of uniform flow rate, cooling temperature,flowratecoolingchannelsaremeasuredand analyzed.Figure7showsthetemperaturedistributionofa lithium battery pack after a hot analysis of the cooling channelsoftwodifferentstructures.

Fig.5 Mesh model of wavy cooling channel battery pack.

It can be seen in Fig. 7 that the maximum temperature of the wavy cooling system is 40.684 ° C. The MTD of the wavy cooling system is 15.321 ° C. The heat released by the lithium battery will be absorbed by the coolant. , and the cooling temperature gradually rises from the point of entrytotheexitpoint.Thehightemperatureofthelithium battery pack comes from source of the battery. It is evident in Fig. 8 that the maximum temperature of the U shapedcoolingsystemis43.552°C,theMTDis18.21°C, and the cooling inlet is also at a low temperature, as well ascoolingtemperature.graduallyrisingfromtheentrance totheexit,theeffectofsimulationisrealandreliable.

Fig.6 Mesh model for U shaped cooling channel battery pack

After the meshing iscompleted, the nextstep isto setthe boundaryconditions.Thecoolingtemperatureattheentry pointissetas25°C,theflowrateofcooling fluidissetat 0.002kg/s. The most important boundary conditionis to set the heat source. Lithium battery pack is considered a source of heat for the same body. In comparison, the discharge rate of lithium battery is set as 4C i.e., the

Fig.7 Temperature distribution result of wavy cooling channel.

Fig.8 Temperature distribution result of U shaped cooling channel

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

• A comparison of the two simulation results shows that the maximum temperature difference (MTD) of the wavy cooling channel is lower than the U shaped cooling channel, which indicates that the cooling channel of the wave can lower the temperature of the lithium battery packaslowaspossible.

• By comparison we can see that the MTD of a wavy coolingpackisalsosmallerthanthatofaU shapedcooling pack

• With the heat transfer information, it is easy to know thatawavycoolingchannelisconnected veryclosetothe lithium battery pack, and excess heat is removed, making the MTD wavy cooling station smaller than the U shaped coolingsystem

• The above results also show that the uniformity of the temperature of the lithium battery pack with the wavy cooling channel is better. Since the design goal of this analysis is to minimize significant temperature differences, the wave cooling channel is adopted as the finalcoolingstructure.

1. A. Mevawalla, S. Panchal, M.K. Tran, et al., Mathematical heat transfer modeling and experimental validation of lithium ion battery considering: tab and surface temperature, separator, electrolyte resistance, anode cathode irreversible and reversible heat [J], Batteries6(4)(2020)61.

2. S. Panchal, M. Mathew, R. Fraser, et al., Electrochemical thermal modeling and experimental measurements of 18650 cylindrical lithium ion battery duringdischargecycleforanEV[J],Appl.Therm.Eng.135 (2018)123 132.

3. R. Jilte, A. Afzal, S. Panchal, A novel battery thermal management system using nano enhanced phase changematerials[J],Energy219(3)(2020)119564.

4. W.Wu,S.Wang,K.Chen,etal.,Acriticalreviewof battery thermal performance and liquid based battery thermal management [J], Energy Convers. Manag. 182 (2019)262 281.

5. H. Zhou, F. Zhou, L. Xu, et al., Thermal performance of cylindrical Lithium ion battery thermal managementsystembasedonairdistributionpipe[J],Int. J.HeatMassTran.131(2019)984 998.

6. A.Z. Maan, D. Ibrahim, M.A. Rosen, A review of novelthermalmanagementsystemsforbatteries[J],Int.J. EnergyRes.42(2)(2018)336 338.

7. P. Nandy, B. Ariantara, R.A. Pamungkas, Experimental investigation on performance of lithium ion battery thermal management system using flat plate loop heatpipeforelectricvehicleapplication[J],Appl.Thermal Eng.(2016)784 789.

8. G. Karimi, X. Li, Thermal management of lithium ion batteries for electric vehicles [J], Int. J. Energy Res. 37 (1)(2013)13 24.

9. S.J. Skerlos, J.J. Winebrake, Targeting plug in hybrid electric vehicle policies to increase social benefits [J],EnergyPol.38(2)(2010)705 708.

10. A.Avadikyan,P.Llerena,Arealoptionsreasoning approach to hybrid vehicle investments [J], Technol. Forecast.Soc.Change77(4)(2010)649 661.

11. M.K. Tran, M. Akinsanya, S. Panchal, et al., Design of a hybrid electric vehicle powertrain for performance optimization considering various powertrain components andconfigurations[J],Vehicles3(1)(2020)20 32.

12. S. Arora, A. Kapoor, W. Shen, A novel thermal management system for improving discharge/charge performance of Li ion battery packs under abuse [J], J. PowerSources378(FEB.28)(2018)759 775.

13. C. Zhao, A.C.M. Sousa, F. Jiang, Minimization of thermalnon uniformityinlithium ionbatterypackcooled by channeled liquid flow [J], Int. J. Heat Mass Tran. 129 (FEB)(2018)660 670.

14. G. Li, S. Li, Physics based CFD simulation of lithium ion battery under the FUDS driving cycle[J], ECSTrans64(33)(2015)1 14.

15. W. Li, A. Garg, M. Xiao, et al., Optimization for liquid cooling cylindrical battery thermal management system based on Gaussian process model[J], J. Therm. Sci. Eng.Appl.13(2)(2020)1 19.

16. Y.Huo,Z.Rao,X.Liu,etal.,Investigationofpower battery thermal management by using mini channel cold plate[J],EnergyConvers.Manag.89(2015)387 395.

17. D.R.Pendegast,E.P.Demauro,M.Fletcher,etal.,A rechargeable lithium ion battery module for underwater use[J],J.PowerSources196(2)(2011)793 800.

18. S.A.Khateeb,M.M.Farid,J.R.Selman,etal.,Design and simulation of a lithium ion battery with a phase change material thermal management system for an electric scooter [J], J. Power Sources 128 (2) (2004) 292 307.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

19. A. Morteza, X.L. Li, Numerical studies of lithium ion battery thermal management systems using phase change materials and metal foams [J], Int. J. Heat Mass Tran.102(11)(2016)1159 1168.

20. W. Li, A. Garg, M. Xiao, et al., Optimization for liquid cooling cylindrical battery thermal management system based on Gaussian process model[J], J. Therm. Sci. Eng.Appl.13(2)(2020)1 19.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal