International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

Dilibban.V.R.R.1, Nandakumar.N2, Sekar.T3 .

1 PG Scholar, Manufacturing Engineering, Government College of Technology, Coimbatore, India, 2,3 Professor, Mechanical Engineering, Government College of Technology, Coimbatore, India ***

Abstract - A Shape Memory alloy can be deform when cold but return to its deform when cold but return to its preformed shape when heated. Shape memory alloy is one of the most preferred suitable materials for manufacturing orthopedic staple, medical devices and tools because of its unique super elasticity properties. The existing materials usedinorthopedic staples would not completely satisfy the biomedical requirement like light weight, anticorrosion propertiesability to not harmful to human tissue etc. Hence this work attempts to develop an orthopedic staple pin made by nickel titanium shape memory alloy for addressing the existing drawback of conventional orthopedic staple pin. The selection nickel titanium shape memory alloy (Nitinol) has elastic modulus properties which are very close to the human close to the human bone than any other materials. It has a superior property is great elasticity and returns back to its original shape. For ensuring the human safety, a static potentio corrosion test was performed on the chosen nitinol. The result revealed that the selected material is suitable for making the orthopedic staple pin.

Key Words: Shape Memory Alloy, Orthopedic staple pin, Nickeltitanium,Corrosiontest.

Shapememoryalloycanbedeformedwhencoldbutreturns toitspredeformedshapewhenitisheated.Itmayalsobe called memory metal, memory alloy, Smart metal, smart alloy or muscle wire. Material that is capable of regaining and with standing large strain tracking inflexible plastic deformationandrememberthelastconfigurationtoretain the principle shape with varying temperature a class of shape alloy or muscle wire. Material that is capable of regaining and with standing large strain lacking inflexible plasticsdeformationandrememberthelastconfigurationto reclaimtheprincipleshapewithvaryingtemperaturearea classofsmartmaterialspecifiedshapememoryalloy.Nickel titaniumhasbeenapprovedasametalbiomaterialusedin medical implants and devices. Shape memory alloy are widespreadissuchapplicationasanorthodonticwirestaple for osteosynthesis stents endodontic and mechanical propertieshighcorrosionresistanceandbiocompatibility.

Orthopedicbonestaplesaresimilarinshapetothestaplein the staple that sits on a disk, bone staples are made of surgical grade stainless steel or titanium and they are thickness,strongerandlarger.Afteraboneissurgicallycut, oneormorestaplesmaybeappliedtothebonetokeepthe bonesegmentinthecorrectedposition.Bonestaplescanalso be used to attract tendons or ligaments to the bone for reconstructionsurgery.AbonestaplecalledtheBlountstaple canbeinsertedsothatitstraddlesagrowthplateplacinga staplessothatitstraddlesonlyonesideofthegrowthplate cancorrectthealignmentofabonecalledguidedgrowthor hemiopia physiodesis placing staples so that theystraddle bothsideofthegrowthplatescanstopabonefromgrowing longercalledgrowthplatefusionorepiphysiodesis.

Nitinol alloys exhibit two closely related and unique properties the shape memory effect super elasticity (also called pseudo elasticity) shape memory is the ability of nitinoltoundergodeformationatonetemperature,stayinits deformedshapewhentheexternalforceisremoved,andits original temperature. Super elasticity is the ability for the metaltoundergolargedeformationandimmediatelyreturn toitsundeformedshapeuponandremoval oftheexternal load. Nitinal can deform 10 30 times as much as ordinary metal and return to its original shape. Whether nitinol behaveswiththeshapememoryeffectorelasticitydepends onwhetheritisabovethetransformationtemperatureofthe specificalloy.Belowthetransformationtemperatureofthe specific alloy. Below the transformation temperature it exhibitstheshapememoryeffectandabovethattemperature itbehavessuperelastically.

InthisformofNitinolbonestaple,theaustenitefinish(Af) transformation temperature is near or less then room temperatureandthestaplemustbeheldopenbysometype ofdevicepriortodeployment.Thistypeofstaplewillattempt tospringclosedatanytemperatureisnearorlessthanroom temperatureassoonastheconstraintisremoved.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

This types of nitinol staple has an Af temperature. Shape recoveryistriggeredbythethermalshapememoryeffectas the staple reaches body temperature. It is important to maintain the temperature during insertion to prevent prematuredeployment.Thiscanbeaccomplishedthrougha combination of external cooling and sufficiently rapid insertion.

This category of Nitinol Staple has an austenite start (As) temperaturenearorslightabovebodytemperaturebutwith an(Af)temperaturenearorslightabovebodytemperature but with an Af temperature near low enough to allow deployment60°Cisgenerallyrecognizedasthetemperature at which tissue damage can occur so the activation temperatureforthestaplemustideallybekeptbelowthis temperature.Thistypeofstaplecanbeactivationinoneof twowaybysimpleapplicationofaheatingelementsuchasa cauterydeviceorbyusingaspeciallydesignedexternalheat source the allows the amount and duration of the applied heattobepreciselycontrolleddependinguponthedegreeof shape recovery desired. The better type of staple will be referred to in subsequent discussion as controlled heat activated.Stapleofallthreetypearecommerciallyavailable. A list of some of the commercially available nitinol bone staple,alongwiththeirtypeofdeploymentmechanism.

With a typical Nitinol bone staple, holes are predrilled, an opennitinolstapleisinsertedintotheholes,andthestaple recoverseithersuperelasticallyorviashapememorytopull thefracturedbonetogetherandapplyacompressiveforceto the fracture surface. Different staple designers and manufacturerhaveexecutedthisbasicapproachinanumber ofdifferentways.

TheBlountstaplesareavailablein1.5mmto5mmdiameter andwidthrangingfrom15mmto25mm,thesestaples are usefulforthetemporaryarrestofgrowthinordertocorrecta deformity or equality of length. The implant combines the technical advantages of the traditionally used rigid Blount staples, which may be a biomechanical advantages in temporary epiphysiodesis and has an easy and guided implantationtechniqueliketheeightplate.Asineightplates supposedlyonlytworigidtacksaresufficientfortemporary epiphysiodesiscomparedtosixBlount staplesintraditional treatment.

TheCoventrystaplesareavailablein5mmto15mmsteps (incrementsof5mm).Theyareutilizedintibiaosteotomies to correct varus or valgus deformities resulting from conditionslikerheumatoidarthritis,traumaorosteoarthritis. CoventryStapleisusedforcorrectingangulardeformityat the knee. Two ormore Coventry Stapleshould be usedon each side of the epiphysis. Our Coventry Staples are made fromthefinestqualitymedicalgradematerialtoensurethe highestquality.

Thethornystaplesareutilizedforfixationofsofttissueto bone like in bony avulsions or tibia fixation in bone reconstruction. They have serrations for the hold of soft tissue.Thethornystapleisusedforfasteningsmallbones, epiphysealmetaphysicalareaofthelongbones,andfixation incollateralligamentsofknee/elbow.

Minimaxfracturefixationwaspopularizedbytheinfluential Bernhard.SMAstapleconstructsareanextrapolationofhis minimax fracture fixation concept. Small problem focused implantsusedtodospecificjobthatarethensupportedbya morerobustfractureneutralizationconstructsuchasplate metrologybasedimplantorexternalfixationframe.

Shape memory alloy staple are most useful in appendicular skeleton fracture pattern that are not reality amenable to conventional interfragmentary compression technique such as leg screw compression plate osteosynthesis or the usage of an articulates tensioning device or some variation there of comparison plate osteosynthesis can be challenging and time consuming to executecorrectlyandisdependentonaperfectplatecontour and on adequate bone stock to generate sufficient friction betweentheplateandbone.

The ratio of titanium to nickel in the Ni Ti alloy has a significant influence on transformation temperature. The change in transformation temperature according to nickel composition.1a0.1%changeinnickelcompositionresultsin a 10° C change in the transformation temperature. In commercialproduction,analysisforchemicalcompositionis oftendoneinsituoronabuttonsample.However,inthecase of Ti Ni alloys, it is difficult to evaluate whether the composition is correct or not by analyzing chemical composition, because melting and casting of Ni Ti alloy is performedundervacuum,andalsobecauseasmallchangein nickel and titanium content causes a large change in transformationtemperature.Forthesereasons,Ti Nialloy

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

composition is commonly evaluated using differential scanning calorimetric (DSC). To measure the nickel and titaniumcontentusingDSC,itisimportantthatthesample hasbeenannealedinavacuumorinactivegas(specifiedby theheattreatmentmethoddefinedbyASTM,JIS,etc.),and hasbeenprotectedfromprocessingdistortionoroxidization. AtypicalDSCcurveforashapememoryalloy.DSCmeasures endothermicandexothermicreactionsatphasechanges.

In order to control the transformation temperature and mechanicalpropertiesofaTi Nialloy,itiscommontoadda thirdelement.Theelementaddedmostcommonlyiscopper, becauseitcanbein asolidsolutionwithTi NialloyataCu contentof30%ormore.Ni Ti Cualloyisusedasanactuator, which utilizes the shape memory characteristic. Other elementssuchasFe,Cr,Co,andPd,canalsobeaddedtoTi Ni alloysandalmostalltheadditionslowerthetransformation temperatureorimproveformability.3However,additional elementsarenotpermittedinTi Nialloysusedformedical devices,underspecificationASTMF2063 05.

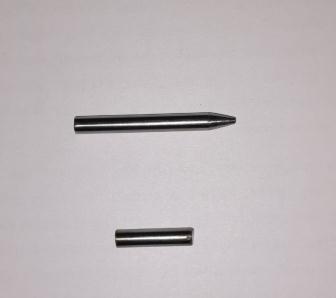

Thecuttingmethodisbasedonsimilarprinciplestothosein thehole drillingmethod.Oncemore,stressisrelaxedbythe removal of material. This time a notch is removed from a specimen, resulting in the creation of a free edge. Nickel titaniumrodof210mmlengthiscutwithhelpofhandcutting machine.Usesafetygloveswhilemachiningtherod.

Abenchgrinderisasimilarorlargerversionofgrinderthat ismountedonapedestal,whichmaybeboltedtotheflooror maysitonrubberfeet.Thesetypesofgrindersarecommonly usedtohandgrindvariouscuttingtoolsandperformother roughgrinding.Aftercuttingofnickeltitaniumrod,therodis grindedwiththehelpbenchgrindingmachine.

While the exact mechanics vary depending on the type of machine press, most machine presses work by pressing a plate or die onto or against a work piece. Using hydraulic pressure,themachinepresspushestheplateordieagainst thesurfaceoftheworkpiece,whichcausestheworkpiece’s shape to deform. After grinding the rod the bend withthe helpofbendingmachinetherodbendedasBlountstaples.

Thefig8istheprototypeofBlounttypeorthopedicstaplepin which can be used for medical implantation and fracture fixationforhumaninjuries.

Corrosion testing refers to the processes conducted by laboratoriesinordertosolve,preventormitigateproblems related to corrosion. These processes can be applied in industrial materials and infrastructure products, and are oftenusedinfailureanalysis.

All corrosion laboratories are composed of expert failure analysts, chemists and engineers that are all certified in corrosiontesting.Suchtestscanprovideusefulinformation inordertomakesounddecisionsregardingtheselectionof materials,processing,andtreatment

Corrosiontestingisa laboratorysimulationofa corrosive saline environment. It is used as an accelerated means of testing the ability of surface coatings to withstand atmosphericcorrosion.Alsoknownassaltfogtesting,it is one of the oldest testing methods used in the HVAC R coatings industry, and for this reason, is often referred to whenselectingHVAC Rcoatings.

First,smallpanels(typically3×5inchesor4×6inches) arepreparedwiththecoatingtobetested.Theedgesandthe backsofthepanelsareprotected,typicallywithtape.Then the front of the panel is “scribed” with a sharp tool to produceascratchthroughthecoatingtothemetalsubstrate. After the panel is prepared, it is placed inside the test cabinet. The cabinet contains racks to hold the panels in positionasspecifiedbyASTMB 117 tiltedback15to30 degreesfromthevertical.

Thecabinetisthenclosed,anda5%saltsolutionis deliveredataconstantrateandtemperatureintothecabinet through an atomizer. Salt fog is sprayed upwards so that dropletswilldescendandsettleonthepanels

After this point, there will be periodic checks of the test panels, as well as monitoring of the salt spray cabinet to ensurethatitfunctionsproperlythroughoutthedurationof the test. During these brief evaluations of the panels, it is determinedwhetherthetestisprogressingasexpectedorif thecoatingonthetestpanelsisfailingprematurely

Althougheachlaboratoryhasaslightlydifferentsetup,the basics of the test are as described above. Weiss Umwelttechnikisfortunatetohaveacabinetwithadigital readoutdisplayingthetotalhoursoftestcabinetoperation, aswell asalarmsthat will 19 notify us abouta variety of importantthings,suchasifthesaltsolutionlevelbecomes low.Thesefeaturesareimportantbecausesomesaltspray tests run for extremely long times. For example, Weiss Umwelttechnik P 413 was tested against ASTM B 117 for 6,000+ hours. That’s 250 straight days (or a little over 8 months)ofcontinuoussaltspray.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Themachinednickel titaniumrodsubjecttocorrosiontest analysis.Theextentofcorrosiononthenickel titaniumrod is below that there is no corrosion formation in nickel titaniumrod.Theintendedpurposeofsubjectingthepanels to corrosion analysis is to check the corrosion resistance property. The nickel titanium rod was analyzed for its corrosion resistance after 24 hrs. There is no sign of corrosionobservationinthesample.

(type iv)

Chambertemperature 35.0°±2.0°c

Saltsolution(concentration/ specificgravitatiy) 5% Nacl method / 1.02 1.04g/cmᶾ

Ph. VALUE / COLLECTION DEVICE 6.5to7.2

Airpressure 0.7to1.4bar

Positionofspecimen 15 to30°Angle

Rateofcollectionofsolution 1to2ml/hr.

Methodofcleaning Tapwater

Methodofhandling Plastictray

Intervalofinspectiontime Oncein24hours

Requirementoftestduration 24hours

Samplereceiptcondition Good Temperature&humidity 30±5°c,<75%RH

11.2. Observation

Fig 11. After corrosion test

11.1 Test report

Table 11.1 corrosion test report for samples

CORROSION TEST REPORT FOR SAMPLE I

Typeoftest Corrosiontest

Typeofsalt/water Nacl(lrgrade)/dmwater (type iv)

Chambertemperature 35.0°±2.0°c Saltsolution(concentration/ specificgravitatiy) 5% Nacl method / 1.02 1.04g/cmᶾ

Ph VALUE / COLLECTION DEVICE 6.5to7.2

Airpressure 0.7to1.4bar

Positionofspecimen 15 to30°Angle

Rateofcollectionofsolution 1to2ml/hr

Methodofcleaning Tapwater

Methodofhandling Plastictray

Intervalofinspectiontime Oncein24hours

Requirementoftestduration 24hours

Samplereceiptcondition Good

Temperature&humidity 30±5°c,<75%RH

CORROSION TEST REPORT FOR SAMPLE II

Typeoftest Corrosiontest

Typeofsalt/water Nacl(lrgrade)/dmwater

Table 11.2. Corrosion observation report for samples

Time Observation I

At0hrs.

Component placed in the chamber.Teststarted

At24hrs. No sign of corrosion observedoverthesample

Time Observation II

At0hrs. Component placed in the chamber.Teststarted

At24hrs. No sign of corrosion observedoverthesample

The result indicates that the nickel titanium rod was excellent, indicated by the observation that it could have corrosion resistance and wear resistance. There is no corrosion formation in the nickel titanium rod after the corrosiontest.Thecorrosiontestconfirmsthecapabilityof thenickel titaniumrodissuitableformakingtheorthopedic staplepin.

Based on the pin on disc wear test results of nickel titaniumrod,itcanbeusedfortheapplicationoforthopedic implantationprocessthatNickeltitaniumrodishavehighly wear resistance. The implantation process increase the hardness shape memory alloy. There is no practical undesirableeffectwasperceivedontheinstrumentsinnickel titaniumrod.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Inadditionthatitisplannedtoconductacytotoxicitytestfor gettingmoreassuranceofhumansafetywithoutcausingany internalinjuries.

[1]. T. HABU Furukawa Techno Material Co. Ltd, Japan, Fabricationofshapememoryalloyparts.FurukawaTechno MaterialCo.Ltd,Japan

[2].SoniKumaria,Dinbandhub,KumarAbhishek.,Studyof machinability aspects of shape memory alloys: A critical review.ELSEVIER

[3]. Mohammad Elahinia a,⁎, Narges Shayesteh Moghaddama Amirhesam Amerinatanzi a, Soheil Saedi b,Guher Pelin Toker b, Haluk Karaca b, Glen S. Bigelowc, Othmane Benafan. Additive manufacturing of NiTiHf high temperatureshapememoryalloy,ELSEVIER.

[4]. Yanqiu Zhang a, Shuyong Jiang a,*, Man Wang b Atomistic investigation on superelasticity of NiTi shape memory alloy with complex microstructures based on moleculardynamicssimulationELSEVIER.

[5]. Z. Lekston, D. Stro´ _z, and M. Je˛drusik Pawłowska PreparationandCharacterizationofNitinolBoneStaplesfor Cranio MaxillofacialSurgery,Springerlink.com

[4].OliverN.Schipper,MDa,*,J.KentEllington,MDbNitinol CompressionStaplesinFootandAnkleSurgery

[5]DANIELATARNIŢĂ1),D.N.TARNIŢĂ2),N.BÎZDOACĂ3), I. MÎNDRILĂ2), MIRELA VASILESCU4) Properties and medical applications of shape memory alloys. Romanian JournalofMorphologyandEmbryology.ELSEVIER

[6]I.Ferrettoa,D.Kimb,N.M.DellaVenturaa,M.Shahverdi a,W.Leeb,C.Leinenbacha,* Laserpowderbedfusionofa Fe Mn SishapememoryalloyELSEVIER

[7] YuWanga FarhadAslaniab AfsanehValizadehaAn investigation into the mechanical behaviour of fibre reinforced geopolymer concrete incorporating NiTi shape memoryalloy,steelandpolypropylenefibers.ELSEVIER

[8] Daniela Tarniţă 1, D N Tarniţă, N Bîzdoacă, Corina Tarniţă,CBerceanu,CBoboreluModularadaptiveboneplate for humerus bone osteosynthesis. National library of medicine

[9] Glen J. D’Silva a, Viorel Goanta b, Constantin Ciocanel. FracturetoughnessevaluationofNi2MnGamagneticshape memoryalloysbyVickersmicroindentation.ELSEVIER

[10]Wan TingChiu*,TakuyaIshigaki1,NaokiNohira,Akira Umise,MasakiTahara,HidekiHosoda.Effectof3dtransition metal additions on the phaseconstituent, mechanical

properties, and shape memory effect of neareeutectoid Tie4Aubiomedicalalloys.ELSEVIER

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |