International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1,2,3,4 Student, Department of Mechanical Engineering, 5AssistantsProfessor, Department of Mechanical Engineering, Mangalore Institute of Technology & Engineering Badaga Mijar, Moodabidri 6CEO, TRIVIDTRANS PVT LTD ***

Abstract - This study offers the relatively new notion of IC engine reconditioning for electric scooters. These internal combustion engines run on fossil fuels, producing very harmful fumes and noise. An electric scooter could be a viable answer to this issue. Existing Internal combustion engine scooters, on the other hand, will face depreciation and disposal issues. As a result, switching these internal combustion engines to electric engines could be a terrific method to solve a lot of difficulties. Automobiles have certain drawbacks in the present day, such as high fuel costs compared to mileage, pollution, and inefficiency. An electric scooter is a type of alternative fuel vehicle that uses electric motors and motor controllers instead.of an.internal combustion.engine.. Power is obtained via battery packs rather than carbon based fuel. This not only saves money, but it also has a less negative influence on the environment. It also has a variety of advantages over typical internal combustion engines, including less local pollution and higher energy efficiency

Key Words: Refurbishment, I.C Engine,Electric Vehicle, Motor, Battery, mileage, pollution, simulation, development.

Indiaistheworld’slargestmarketfortwo wheelerswith roughly360millioninternalcombustionengine2 wheelers onroad.Electricvehicleshavegainedsignificanttractionin India’s 2wheelerand 3wheelerspace[1] .Howeveradding moreEVstotheexistingvehicleloadinthenameofreducing carbonemissionsisnotanidealsolutionasitwillmakethe roads even more congested. To make clean mobility accessible to everyone, India requires a comprehensive scrapping policy that includes provisions for converting internalcombustionenginestoelectricvehicles[2]

The decision about which conversion is better for a particular vehicle depends on the condition of the vehicle body,chassisandtheICengine.Iftheengineisseizedwiththe bodyandthechassisingoodconditionitcanbeconvertedto

acompletelyelectricvehicle[3].Inadditionaconversionkit consistsofapowercontrollertoregulatetheflowofenergy andarechargingsystemtoallowtheflowofelectricitytothe Li ionbatteries.Theconversionprocessalsorequirestweaks tothewiringandotherelectronicfunctions[4]

Severalcalculationsandresearchweredoneonthevehicle chassis to understand the incorporation of the hub motor into the vehicle. The strengthand durabilityofthechassis hadtobetakenintoaccounttodeterminethefactorofsafety andfeasibilityofthevehicle[5]

It was understood that certain changes to the vehicle chassis have to be made in order for the successful incorporation ofthe hub motor intothe vehicle. We found that it makessense to make a 3 dimensional sketch of the chassis and then made changes to it to make the idea possible.Wemadeuseof AutodeskFusion360softwareto do this. The modulation of the chassis using the software made it possible to fabricate the new chassis without any errorsonthefirstattempt[6]

Adweaith Menon[1] , Mithun Naik[2] , Nithesh[3] , Sidharth K S[4] Swaroop G[5], Ramesh k mahadev[6]Fig3showstheinitialconditionofthe vehiclechassis.The chassisusedwasalteredtoincorporatethedesignchanges thatwereneeded.FurtherasshowninFig5fabricationofa battery box and welding of an extra compartment for accommodatingthe controller was done. The battery box wasfixedinsuchawayastonotaffecttheperformanceand electricalcircuitry.Fig4showsthemodificationofvehicle suspensionwhichwasoriginallyasinglesuspensionsystem whichwasnotabletowithstandtheloadwhichwasapplied onthechassisforthesereasonthesesystemwasupgraded todualsuspensionsystemwhichwasabletowithstandthe appliedloadandalsotheyprovidedcomfortandalsosafety forthevehicle.Figshowsthefinalchassisconditionafter modulationofthesuspensionsystemandbatterybox.

Fusion360Simulationisavalidationtoolthatallowsyouto see how a design operates under different scenarios. A highlyskilledspecialistcoulddevoteasignificantamountof time to doing a thoroughAnalysisinordertoacquireexact resultsunderreal worldconditions[7]

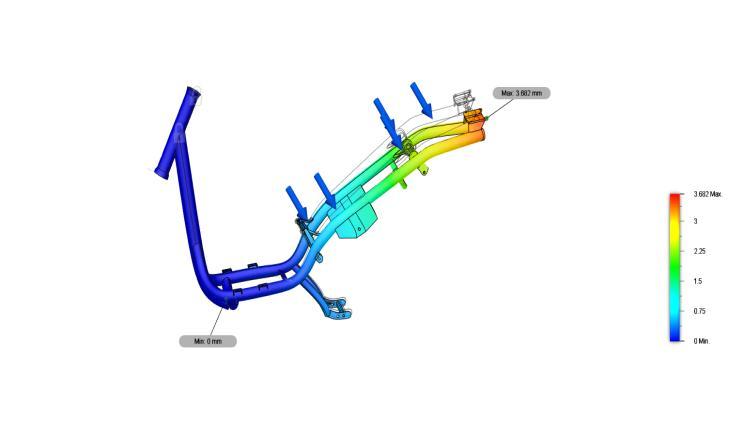

However, the trends and behavioral information obtained from a basic or fundamental study can often be used to predictandimproveadesign.Youmaysignificantlyimprove the whole engineering process by performing this basic analysis early in the design phase.Use the analyses in theSimulationworkspace to determine how loads lead to deformationandfailure,soyoucanunderstandifandhowa part will fail. Or you can determine natural vibration frequencies to avoid resonance. You can identify temperaturedistributionsandthermallyinducedstresses[8] . Fig7:Totaldeformationofchassisusingfusion360software

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

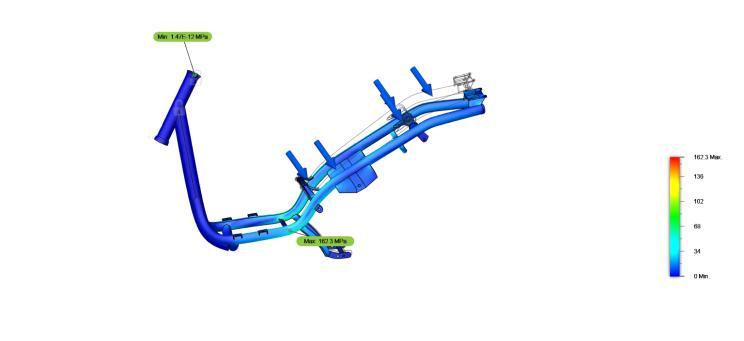

Fig8:Stressanalysisonchassisusingfusion360software

PROPERTY VALUE

Density 7.87g/cc

UltimateTensileStrength 440MPa YieldStrength 370MPa Modulusofelasticity 205GPa

Table1.

TYPE Equivalent (von Mises)Stress

Maximum Principal ElasticStrain

It takes a steady power.supply that is readily availableandcanbereused to operate the motor at full speedandcoverthemaximumrangeattherequiredspeed. To give power, we've chosen lead acid batteries[12] Thevoltagesuppliedshouldbeequaltoorgreaterthanthe motor's inputvoltage, which is 48V DC. To reach the requiredvoltage,weselectedfour12Vbatteriesandlinked theminseries.Thebatteriesaresimpletorechargeanddo notrequireanymaintenance[13]

Selectedbatteriesspecificationsare Current.rating:28.AhVoltage:12.V

Totalnumberofbatteries.:4. Combination Ofbatteries:Series Combined Voltage:48V

Total Deformati on

Minimum 5.5761e 013MPa 9.4996e 004mm/mm 0.mm Maximum 1811. MPa 8.7592e 003mm/mm 143.62 mm

Table2:ResultTable

The frame is the E supporting bike's member and is subjectedtobothstaticanddynamicloads.Italsoacceptsa variety of loads, including vertical, cornering, side.thrust, acceleration,.andbrakingdip..Varioustypesofaccessories and components are strewn throughout the.frame[10]. A frame.should be strong enough to withstand all of the mentionedloads.TheExistingframeoftheI.C.Theengine scooterwaschosenbecauseitmeetsallofthecriteriaand was created by professionals for improved safety and efficiency. To fit the motor, battery, and brakes, some changesaremade[11]

It takes a steady powersupply that is readily availableandcanbereused to operate the motor at full.speed and cover the maximumrange at the requiredspeed. To give power, we've chosen lead acid batteries[12]. The.voltage supplied should.beequal.to or greaterthanthemotor'sinput.voltage,whichis48VDC.To reachtherequiredvoltage,weselectedfour12Vbatteries and linked them in series. The batteries are simple to rechargeanddonotrequireanymaintenance[13] .

A motor with a capacity of up to 250watts is required to drivethevehicleataspeedof35kmphanddeliverarated torqueofroughly6.2N m.WeusedaBrushlessDC.motor, whichcostslessthan8000dollarsandisidealforlow cost applications[14] .

Specifyingthechosenmotor Type:BrushlessD.CMotor Power:2000Watt

Themotorusedthecurrentfromthebatteriestosupplyit in response to the throttle input. The controller gets information from the throttle connector and adjusts the powersupplytothemotor.Wechoseacontrollerthatwas appropriateforourmotorinordertosatisfyourexisting needs.[15]

operatingparametersare: Operatingcurrent:60A OperatingVoltage:48VDC Phaseangle:1200

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

4.1 Load calculation:

Consideringtheweightofthevehicleanditsaccessoriesis usedtocalculatethetotalloadappliedtotheBLDCmotor. Vehicleweight=95kg

Rider=70kg Totalload=165kg.

4.2 Force calculation:

Theforcerequiredtopullthecalculated

Theforcerequiredisgivenbytheformula

F=Crr*M*g Where F=forceinNewton

Crr=coefficientofrollingresistance=0.01 g=accelerationduetogravity=9.81m/s2

M=massofthevehicle(totalload)

F = 0.01* 165 * 9.81 F =16.18N

4.3 Power calculation:

Theformulaisusedtocalculatetheamountofpower requiredtopulltheratedweightatamaximumspeed of30km/hr.

P=F*(V/(3600))

Where., P=Powerinwatts

V=Velocity 30Km/h=30000m/h

P=16.18*(30000/3600)

P=134.83watts

Thebattery'swatt houriscalculatedasfollows: Ah*V=wh

Where, Ah=Amperehour V=Voltage Wh=Watt hour (I)48V 13Abattery =48*13 =624wh

Wemayutilizethisbatterybecauseitproduces480watts, whichisgreaterthantherequiredvoltage[16]

Thedistancethatthisbatterymaytravelisdeterminedby d=wh/F =624/16.18 d=38.56kms

Wecancomputethedistancethatcanbetraveledwitha weightthatisdoublethatoftheactualloadbecausethe roadconditionsmaynotbeuniformalongtheroute. d=wh/F =624/20 =31.2kms

The charging time of a Lithium ion battery varies dependingonthechargerusedtochargeit.Thetimeit takesforaleadacidbatterytochargeisdeterminedby T=Ah/A Where

Ah=Amperehourratingofbattery

A=Currentinamps(charger) T=13/5 =2.6hours

In the future, a rapid charging mechanism could be employed to charge the battery faster [17] For a full charge,you'llneedthefollowingunitsofcurrent.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2745

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

The watt hour is estimated below using a 48v 13ah lithiumionbattery.

48×13=624wh

1amps=1.4kvah

13amps=13/1.4

13amps=9.28kvah

Kw=kvah×Pf

∴(powerfactor)Kw=9.28×0.174

Kw=1.61unitsis.required.

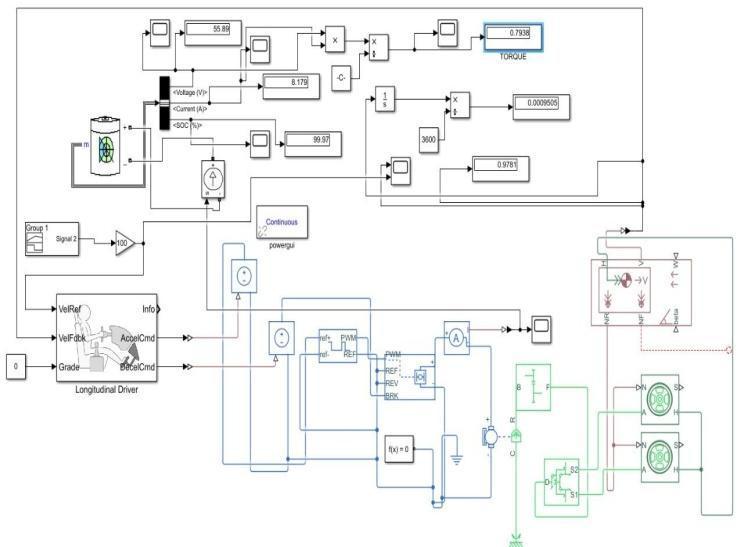

The simulation of a fundamental electric motor drive system utilised in this article to study power flow in both motoring and regeneration. The simulation posits that a powerful magnet a motor controller, a DC motor the desirablequalitiesassociatedwithaPItheelectricbattery, andthecontroller.Usingthisexample,beutilisedtoassess theflowof electric energy efficiencyand drivefora given speedandtorqueloadcircumstances.Severalofthesystem variableswereoutlined,whileotherswereidealisedinthis kind.During the design phase, vehicle driving evaluations andsimulationshavebeencompletedtohelpassistinthe designprocesstoassesswhetherthedesignisappropriate fortheintendeduse.Adrivingcycleisaseriesofvaluesfor thevehicle'sspeedthatarecalculatedonasimulated

During the simulation, a vehicle is to be achieved. the demandthegoalofadrivingcycleistoreducetheamountof expensiveon roadtests,whilesimultaneouslycuttingdown ontestdurationandthetestengineer'sweariness.driving cyclepathleadstothedynamometerortothetestfacility digitalsimulation[18]

The simulation makes the assumption that the values of torqueandspeedareknown.Whenspeedvaluesaretaken intoaccount,torquevaluescanbedeterminedifthewheel dimensionsareknownaswellastheroadloadvaluesthat thevehiclecanhandle.Rollingresistance,airresistance,and gradientresistancesthatareknownorthatcanbecomputed areaddedtogethertoformthetotalroadload.

Beforefabricationandphysicaltestingofthenewvehicle,we shouldhaveanideaabouttheparametersthatwegetforit liketherange,stateofcharge,voltageandcurrent.Forthis purpose,weusetheMathlabsoftware.Basedonthevalues obtained from the calculations on proceeding with the software simulations the torque obtained is 0.7938 N m. Theseconditionsdidnotmatchtherequiredoutputhence based on the requirement of the vehicle and for smooth functionofthevehiclesomemodificationsweremadeinthe parametersobtained[19]

Kerbmassofthevehicle 95kg

Drivermass 70kg Gravity(g) 9.81m/s Gearratio 1:1 Efficiencyoftransmission 0.85 Topspeed 40kmph

Accelerationperformance 0 20kmphin 7.5seconds

Through numerous simulations andphysical testswecametounderstandthefollowingparameters:

Onaflatroad,atopspeedof35km/hwasobtained.

After a full charge, the scooter's range is 35 45 kilometers[20]

For increased range and lower weight, a BMS and lithiumIonbatterycanbeinstalled

Thescooterwassuccessfullytestedforlighteveryday use.

A complete charge of the battery takes about 7 8 hours[21]

Thescooterwillgoataspeedof35km/hforasinglecharge ofthebatteryifthecomponentsmeettheseparameters.It alsocoversa greaterdistance.Ourprototypehasa higher

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

beginning torque due to the usage of a 250W motor. The vehicle'sspeedandrangecanbeextendedbyupgradingthe batterycapacityandmotorparameters.Chargingcanalsobe done on board to extend the vehicle's range of operation[22][23][24]

1. Structuralchangeshadtobemadetothechassis.

2. Analysisofthenewchassishadtobedone.

3. Thestrengthandsustainabilityofthechassisandto bedetermined.

4. Gathering the required components was a challenge.

5. Problemswerefacedduringintegrationofelectrical connectionstothecomponents.

6. Provisions for heat dissipation and battery managementsystem.

7. Difficultyinfaultidentificationsandimplementing safetyprecautions.

Theelectricvehiclehasvariousadvantagesandbenefitsover the internal combustion engine, as demonstrated in this study.Itismoreefficientandcleaner,butithasnegativesas well. We also saw how conversion is superior to buying a newelectricvehicleintermsofqualityandcost.Thebattery is critical to the electric vehicle's future success. If researchers can develop or find the "super battery," the futureofelectricvehiclesisbright.Currently,eachvehicle has a trait that distinguishes it from the others. Only time will tell which vehicle will be the most successful in the future,aswilltechnologicalimprovements.

1. T.W.Ching,SeniorMember,K.U.Chan(2009),“AFull

HybridElectricScooter”,IEEE

2. DesignandfabricationofelectricbikeShwetaMatey March2017

3. Electric vehicle conversion: optimization of parametersinthedesignprocessMirkoGordić,Draga Stamenković, Vladimir Popović, SlavkoMuždeka, AleksandarMićović

4. Design and Analysis of E Scooter Chassis Frame by Prof. Kaveri.SKadam, MrNikhil.S. Sambhar, Ms. Namrata.M. Bora, Mr. Shubham. R. Bhakare, Ms. Swapnali.W.Gaik

5. ConversionofICEngineBikeintoElectricMotorBike byAkashAnilVaidya,Prof.T.S.Sargar,SaketP.Joshi 2019JETIRApril2019,Volume6,Issue4

6. ConversionofICenginevehicletoanelectricvehicle. by Vasanthaseelan, D.S. Dharun, S.Sreerag, R.Gokul ,Volume:06Issue:03|Mar2019

7. Conversion of IC Engine Driven Bike into Electric EngineDrivenBikebyV.Thiyagarajan,V.Sekar

8. A Case Study on the Conversion of an Internal CombustionEngineVehicle intoanElectricVehicle. DelfimPedrosa,VítorMonteiro,HenriqueGonçalves, JúlioS.Martins,JoãoL.AfonsoALGORITMIResearch Centre University of Minho Guimarães, Portugal {delfim.pedrosa|vitor.monteiro|henrique.goncalves |julio.martins

9. ConvertinganInternalCombustionEngineVehicleto an Electric Vehicle. Ali Eydgahi, Eastern Michigan University Mr. Edward Lee Long IV, University of Maryland,EasternShore

10. Electric vehicle conversion: optimization of parameters in the design process by MirkoGordić, Dragan Stamenković, Vladimir Popović, SlavkoMuždeka,AleksandarMićović

11. RetrofittingofExistingScooterinto HybridElectric Scooter by Najmuddin Jamadar,SuhaniJamadar,AbhilashaKumar,

12. FrontandRearwheelIndependentDrivetypeelectric vehicle with compatible driving performance and safetybyNobuyoshiMutoh(2009)

13. Structural and modal analysis of scooter frames by D.MohanKumar,R.Sabarish,Dr.M.PremJeyaKumar

14. Design and Analysis of E-Scooter Chassis Frame by Prof.Kaveri.SKadam 1, Mr. Nikhil.S. Sambhar2, Ms.Namrata.M. Bora3, Mr Shubham. R. Bhakare4, Ms.Swapnali.W.Gaikwad5

15.Keoun B.C, (1995) “Designing an Electric Vehicle Conversion,”ConferenceRecordSouthcon/95,pp.303308,March.

16.DelfimPedrosa, Vítor Monteiro, Henrique Gonçalves, Bruno Exposto, J. G. Pinto, and João L. Afonso, (2012) “Conversion of an Internal Combustion Engine Vehicle intoanElectricVehicle”,SeminárioAnualdeAutomação, EletrónicaIndustrialInstrumentação2012(SAAEI’12).

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

17.Menahem Anderman, Fritz R. Kalhammer, and Donald MacArthur, (2000)“Advanced Batteries for Electric Vehicles: An Assessment of Performance, Cost, and Availability,” Prepared for State of California Air ResourcesBoard.Sacramento,California.

18.Bakar S. A. A., Masuda R., Hashimoto H., Inaba T., Jamaluddin H., Rahman R.A., and Samin P. M, (2012) “Ridecomfortperformanceofelectricvehicleconversion with active suspension system,” Proceedings of SICE AnnualConference(SICE),pp.1980 1985.

19. J. Dixon, (2010) “Energy storage for electric vehicles,” International Conferenceon Industrial Technology,pp. 20 26.8

20.Khaligh,andZ.Li,(2010)“Battery,Ultracapacitor,Fuel Cell , and Hybrid Energy Storage Systems for Electric ,Hybrid Electric , Fuel Cell , and Plug In Hybrid ElectricVehicles:StateoftheArt,”IEEETransactionson VehicularTechnology,vol.59,pp.2806 2814.

21. Keoun B.C, (1995) “Designing an Electric Vehicle Conversion,”ConferenceRecord Southcon/95,pp.303 308,March.

22.Asimakopoulos,B:T.Boumis,C.E.Patsias,A.Safacas,and E. Mitronikas, (2010) “Experience derived from the conversion of a conventional car to a hybrid electric vehicle analysis of the powertrain,” International Symposium on Power Electronics Electrical Drives AutomationandMotion(SPEEDAM),pp.1040 1045.

23. DelfimPedrosa, Vítor Monteiro, Henrique Gonçalves, Bruno Exposto, J. G. Pinto, and João L. Afonso, (2012) “Conversion of an Internal Combustion Engine Vehicle intoanElectricVehicle”,SeminárioAnualdeAutomação, EletrónicaIndustrialeInstrumentação2012(SAAEI’12).

24. Fabrication of Hybrid Scooter by B.Ganapathi Reddy, G.VenkataNagaBhaskarP.B.S.Manikanta,K.Ramakrishna, G.Naveen